Power Plant Efficiency: Supercritical Technology & Cost Analysis

advertisement

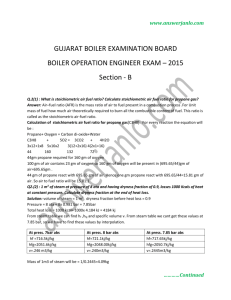

DETAILS OF CALCULATIONS: POWER OUTPUT = 660 MW TOTAL ENERGY DELIVERED @ 660 MW FOR A PERIOD OF ONE HOUR = 660MWH Taking Efficiency = 37.96 % and 90 % PLF Input = 660* 103 x 0.9 x 860 kcal / 0.3796 = 1345732.35 Kcal (1 KWH = 860kcal) Design calorific value of coal = 3300 Kcal/ kg Coal requirement per hour = 1345732.35 / 3300 = 408 T At efficiency 38.96 % coal requirement per hour = 397 T Yearly saving of coal by increasing efficiency of 1 % = 11 x 24 x 365 days = 96,360 MT Total value of the coal saved @ Rs 650 / MT = Rs 626 lakhs If the efficiency increases by 2.5 % = Rs 626 x 2.5 = 1565 Lakhs Considering the life time as 30 Years, the savings in Fuel cost will be Rs 46950 Lakhs ~ 470 Crores For three units = 470 x 3 = 1410 Crores INDIRECT SAVINGS Assuming Auxiliary Power consumption as 8 % Estimated reduction in auxiliary power consumption = 0.3 % For 660 MW units savings of auxiliary power = 8 % x 660 x 0.003 = 0.158MW Yearly savings in MW = 0.158 x 365 x 24 x 0.9 = 1248 .825 = 1248825 units Taking the unit cost as Rs 2.50 per unit Savings = 32.00 Lakhs Total for three units = 32 x 3 = 96.00 Lakhs ~ 1.0 Crores For life time = 30. Crores TOTAL = 1410 + 30 = 1440 CRORES ASSUMING THE LIFE AS 30 YEARS, THE APPROXIMATE SAVINGS WILL BE RS 48 CRORES PER YEAR FOR ALL THREE UNITS TOGETHER. INCREASE IN PLANT EFFICIENCY by SUPER CRITICAL PARAMETERS Efficiency Increase 1.5 6 5 4 0.6 0.9 3.2 3 . 2 1 167 bar 250 bar 250 bar 250bar 250 bar 538/538’c 538/538 540/560’c 566/566 ‘c 580/600’c Comparison of BHEL V/s Doosan Units Doosan Units BHEL Units • Total Weight- 27960 MT • Total MT – – – – – Structure – 6924 MT Pr. Parts – 7080 MT P C Piping – 3032 MT P F System – 3823 MT Draft System – 5004 MT – Refractory/Insulation C&I/Misc – 2097 MT – – – – – – Weight- 28585 Structure – 10801 MT Pr. Parts – 5800 MT P C Piping – 1445 MT P F System – 2342 MT Draft System – 5680 MT Refractory/Insulation C&I/Misc – 2517 MT COMPARISION OF 660 MW Vs 500 MW BOILER Description unit 660 T/HR 2225 1625 KG/CM2 256 179 0C 540 540 T/HR 1742 1397.4 0C 303.7 338.5 RH STEAM TEMP OUTLET 0C 568 540 RH STEAM PRESS INLET KG/CM2 51.17 46.1 FEED WATER TEMP 0C 291.4 255.2 S/H STEAM FLOW SH STEAM PR SH STEAM TEMP RH STEAM FLOW RH STEAM TEMP INLET 500 Tonnage Comparison Description 660 MW 500 MW Structural Steel Erection 7383 9200 Boiler Proper & Accessories (Pre. Parts) 7080 5300 Refractory, Insulation & Cladding 1410 2000 Power Cycle Piping 3032 2200 54 76 Coal Firing System 3573 2000 Draft System 5275 5200 62 200 Miscellaneous System 130 280 Electrical & Instrumentation 282 380 28281 26836 Soot Blowing System Fuel oil system TOTAL Material Comparison Description 660 MW 500 MW Structural Steel Alloy Steel Carbon Steel Water wall T22 Carbon Steel SH Coil T23, T91 T11, T22 RH Coil T91,Super 304 H T22, T91,T11 LTSH T12 T11 Economizer SA106-C Carbon Steel Welding Joints (Pressure Parts) 42,000 Nos 24,000 Nos Structural Comparison Slno 660 MW 1 STRUCTURALS 500 MW a b. Remarks Entire structural is bolting typeentire structure is bolted. Holes are drilled on the columns and gusset plates, and supplied with matching plates. Structural is assembled at site with welding Advantages (660MW) of Bolting structure: oFast in erection. oClean environment oNo Welding network required oSafety at site oPainting finish is good o( No Weld surface) No Welding work involved in assembly/ Erection , except Walkway rail post welding Assembly is carried out with Welding Can be dismantled if required ( For Maintenance purpose) Material supply is tier wise including staircases, railing, gratings etc. Material is supplied as per the erection sequence. Erection completion tier wise, including gratings, platforms , staircases etc. c COST COMPARISON 1 Cost of SG Package 1970.73 Cr 1020.54 Cr with ESP 2 Cost of ESP 183.54Cr 3 Total cost of Boiler + ESP 2154.27 Cr 1020.54 Cr 4 Cost of Boiler per MW with ESP 1.09 Cr 1.02 Cr 5 Cost of TG for entire stage 1204.72 Cr 634.31 Cr 6 TG cost per MW 0.6Cr 0.63 Cr BOILER SPECIFICATION Description unit S/H STEAM FLOW T/HR 2225 KG/CM2 256 0C 540 T/HR 1742 0C 303.7 RH STEAM TEMP OUTLET 0C 568 RH STEAM PRESS INLET KG/CM2 51.17 FEED WATER TEMP 0C 291.4 SH STEAM PR SH STEAM TEMP RH STEAM FLOW RH STEAM TEMP INLET = Boiler Efficiency Quoted Turbine Heat Rate 100% TMCR 86.27% 100% Load 1904 Kcal / KWH 80% TMCR 86.60% 80% Load 1924 Kcal / KWH 60% TMCR 86.68% 60% Load 1973 Kcal / KWH 50% TMCR 86.91% 50% Load 2065 Kcal / KWH Net Plant Heat Rate = NTRH = 2207 KCal / KWHR ( at 100% TMCR) 80% TMCR 60% TMCR 50% TMCR = 2222 Kcal / KWHR = 2276 Kcal / KWHR = 2376 Kcal / KWHR Plant Efficiency at 100% TMCR = 38.96% 80% TMCR = 38.7 % 60% TMCR = 37.78% 50% TMCR = 36.19% SUPERCRITICALTHERMAL CYCLE ADVANTAGES • • • • (1) Improvements in plant efficiency . Decrease in Coal Consumption Reduction in Green House gases. Overall reduction in Auxiliary Power consumption. • Reduction in requirement of Ash dyke Land & Consumptive water. SUPERCRITICAL – ADVANTAGES (2) • Sliding pressure operation because of Once through system . • Even distribution of heat due to spiral wall arrangement leading to less Boiler tube failure, thereby improving system continuity and availability of the station. • Low thermal stress in Turbine . • The startup time is less for boiler. SUPERCRITICAL – DISADVANTAGES • Higher power consumption of BFP • Higher feed water quality required. • More complex supporting and framing in Boiler due to Spiral Wall tubes. • Slight higher capital cost. • Increased dependency For Spares and services. IMPORTANCE OF EFFICIENCY • The cost of operating the Plant of 3 x 660 MW, one percentage point below the design point, will incur additional fuel cost of Rs. 16 Crores in a year. • The indirect costs for Maintenance, APC, Ash Dyke land etc. will give additional burden of Rs. 1Crores in a year. • The environment will benefit on account of reduction in GHGs like Co2, NOX & SOX. • The life time savings of Rs.550- 600 Crores can be achieved by increasing efficiency by one percentage . • At Sipat, we gain an efficiency of 2.5 percentage by adopting super critical technology in 1980 MW station, thus saving Rs. 1440 Crores in its life time. REDUCTION IN CO2 EMMISSION • CONSIDERING AVG COAL CONSUMPTION OF AT FULL LOAD OPERATION : 400T/HR • IMPROVEMENT IN EFFICIENCY FOR SUPER CRITICAL TECHM COMPARED TO 500 MW BOILER : 1.5% • REDUCTION IN COAL FLOW : 6 T/HR • REDUCTION IN CO2 EMMISSION (FIXED CARBON CONTENT IN COAL 30%) : 6 T/HR • REDUCTION IN CO2 EMMISSION PER YEAR : 52560 TONS