CHO - Moodle

advertisement

MANUFACTURING ISSUES OF TWO « BIOLOGICALS » AND REGULATION Youssou NDAO Anne-Félice PELLET, Laure TIQUET, Florent ZOONEKYND, Khadra BUBAKER 1 ACTUAL SITUATION Top 10 Selling Biologics in 2011 Drug Type Revenue Cell line Humira Monoclonal antibody 8,24 b$ CHO Enbrel Fusion protein 7,89 b$ CHO Remicade Monoclonal antibody 7,19 b$ SP2/0 Rituxan Monoclonal antibody 6,79 b$ CHO Avastin Monoclonal antibody 5,98 b$ CHO Herceptin Monoclonal antibody 5,94 b$ CHO Insulin 5,45 b$ Esch. coli Neulasta Cytokine 3,95 b$ Esch. coli Lucentis Monoclonal antibody 3,77 b$ Esch. coli Epogen Erythropoiesis stimulating protein 3,73 b$ CHO Lantus Summary of product characteristics (www.ema.europa.eu/ & EvaluatePharma, June 2012 3 7 Mammalian Cells 2 PROTEIN PRODUCTION PIPELINE Target Selection SALVAGE APPROACHES Target Optimization Gene Cloning Selection of Expression Vector Selection of Expression Host Expression Analysis Scaling up Fermentation Purification Purification Optimization Characterization Concentration & Storage http://www.sciencedirect.com/science/article/pii/S1046202311001605 3 GENE CLONING Donor DNA Recombinant Vector with insert 1 or 2 Restriction frangments Transformation Replication, Amplification & cell division Clone of donor fragment 1 4 4 BUILDING THE MASTER CELL BANK Collection of cells of uniform composition derived from selected cell clone containing the expression construct MCB is cryopreserved in aliquots stored in the liquid nitrogen • Working Cell Bank derived from one or more vials of cells from the MCB • Cells from the MCB expanded by serial subculture up to a passage number selected by the manufacturer and approved by regulator 5 ICH Q5D: Derivation and characterization of cell substrates used for production of Biotechnological/Biological CHARACTERIZATION OF MCB • Manufacturers should perform Quality control tests for all cell banks include: Identity: expression construct Sterility: Test for the presence of contaminating cell lines, viruses, mycoplasma, and bacteria Stability: coding region (for recombinant cell banks) must be determined during cultivation and storage 6 ICH Q5D: Derivation and characterization of cell substrates used for production of Biotechnological/Biological CELL PREPARATION FOR FREEZING Refeed cells to ensure log phase of growth Label cryotubes with cell line, cells/vial, date, MCB Use trypan blue for viability Count cells Select a freezing media Select a cryoprotective agent (DMSO or glycerol) => Place cryovials gradualy in freezer -40°C/-80°C, and in liquid nitrogen (-196°C) 7 Cell preparation for freezing: Dana M. Hopkins Wm. Davies, Jr. Career & Technical HS, Rochester, NY THAWING CELL BANK Cells are damaged to a certain degree DMSO may be toxic to cells after thawing Cells should be thawed rapidly (37°C) and then diluted slowly into warm growth medium Removal of DMSO by changing media quickly (dilution) 8 www.corning.com/lifesciences CELL CULTURE MEDIA Over extended periods by serial passage is a high-risk approach • Genotypic and phenotypic variation • Risk of laboratory accidents • contamination with microorganisms • cross-contamination with other cells Monitored • Critical operating parameters • Cell growth, viability Appropriate procedures in place • To detect contamination/decontaminate the equipment 9 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2958569/#R53 PROCESS CHARACTERIZATION AND VALIDATION Identification of : Critical operational parameters Key performance indicators Use qualified analytical methods and raw materials for consistency and accuracy Product quality specifications are approved as part of BLA Three and five consecutive full-scale runs are normally required for BLA (US & EU) 10 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2958569/#R53 PROCESS TECHNOLOGY TRANSFER A “gap analysis” should be conducted Limitations and potential risks Facility and equipment modifications and qualification activities should be completed prior to full-scale production runs Pre- and post-change product not identical, but: . Biological activity highly comparable, . Changes have no impact upon the safety or efficacy of the product 11 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2958569/#R53 12 http://www.sciencedirect.com CHARACTERIZATION OF PRODUCT Peptide Mapping • Evidence for the identity to confirm desired product structure for lot release purposes Carbohydrate structure • For glycoproteins, the carbohydrate content (neutral sugars, amino sugars, and sialic acids) • Glycosylation site(s) of the polypeptide chain is analyzed 13 ICH Q6B: Test procedures and acceptance criteria for Biotechnological/Biological products STORAGE FACILITIES Auditing process to ensure that maintenance and documentation are kept up to date Process changes and degradation products during storage Heterogeneity patterns in the material used during preclinical and clinical development Stability profile to proof that changes will be detected 14 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2958569/#R53 PROBLEMATIC OF POSTTRANSCRIPTIONAL MODIFICATION 95082 82391 100000 Putative PTMs by Category 19478 Frequency 10000 5756 5058 4448 2642 2237 2204 1888 1490 1219 1176 1032 846 1000 100 10 1 Post-Translational Modification 15 Proteome-wide post-translational modification statistics: frequency analysis and curation of the swiss-prot Database. George A. Khoury, Richard C. Baliban & Christodoulos A. Floudas. PROBLEMATIC OF POSTTRANSCRIPTIONAL MODIFICATION 95082 82391 100000 Putative PTMs by Category 19478 Frequency 10000 5756 5058 4448 2642 2237 2204 1888 1490 1219 1176 1032 846 1000 100 10 1 N-glycosylation Post-Translational Modification 16 Proteome-wide post-translational modification statistics: frequency analysis and curation of the swiss-prot Database. George A. Khoury, Richard C. Baliban & Christodoulos A. Floudas. N-GLYCOSYLATION IN HUMAN KINETICS Oligosaccharyl transferase NIH Public Access, Metabolism, Cell Surface Organization, and Disease James W. Dennis, Ivan R. Nabi, and Michael Demetriou 17 N-GLYCOSYLATION IN HUMAN Glycosylation = Dynamic Tri-antennary complex Leu Asn Gly Ser … Arg Ile Cys Thr Asn Glu Ser 18 NIH Public Access, Metabolism, Cell Surface Organization, and Disease James W. Dennis, Ivan R. Nabi, and Michael Demetriou N-GLYCOSYLATION IN HUMAN Glycosylation = Dynamic Tri-antennary complex Leu Asn Gly Ser … Arg Ile Cys Thr Asn Glu High-Mannose type Ser No glycan NIH Public Access, Metabolism, Cell Surface Organization, and Disease James W. Dennis, Ivan R. Nabi, and Michael Demetriou 19 N-GLYCOSYLATION IN HUMAN Example of human IgG 20 High Throughput Isolation and Glycosylation Analysis of IgG–Variability and Heritability of the IgG Glycome in Three Isolated Human Populations, The American Society for Biochemistry and Molecular Biology, Inc. 2011 EXAMPLE OF N-GLYCOSYLATION PROBLEMATIC IN CHO Ex : IgG - Increase serum clearance - Reduced ADCC 21 Optimal and consistent protein glycosylation in mammalian cell culture, P Hossler, SF Khattak, ZJ Li - Glycobiology, 2009 - Soc Glycobiology EXAMPLE OF N-GLYCOSYLATION PROBLEMATIC IN CHO T1/2 Low temperature Overexpression of CMP-SAT Glycerol 22 Optimal and consistent protein glycosylation in mammalian cell culture, P Hossler, SF Khattak, ZJ Li - Glycobiology, 2009 - Soc Glycobiology EXAMPLE OF N-GLYCOSYLATION PROBLEMATIC IN CHO Example of recombinant EPO CLINICAL TRIALS Activity 1 Activity 2 Activity 3 Activity 4 Half-life 1 Half-life 2 Half-life 3 Half-life 4 … = Product efficacy 23 http://www.ncbi.nlm.nih.gov/pmc/articles/PMC3449730/pdf/10616_2004_Article_267657.pdf DEGRADATION PRODUCTS • Desired product: – Protein which has the expected structure – Protein expected from the DNA sequence – Anticipated post-translational modification (glycoforms), Degradation products may be either: • Product-related substance • Degradation products 24 II – ETUDES DE CAS Perjeta Pertuzumab® Fabrazyme® & Replagal® 25 PERJETA® - Pertuzumab 26 ® PERJETA - Pertuzumab Recombinant humanized IgG1 Indication : Her2-positive metastatic breast cancer Combination with Trastuzumab and Docetaxel Aggressive tumor and a poor prognosis Clinical pharmacology and biopharmaceutics review of perjeta http://www.ncbi.nlm.nih.gov.doc-distant.univ-lille2.fr/pmc/articles/PMC3462608/ 27 MECHANISM OF ACTION Her 2 binding Inhibition of Her2 dimerisation Inhibition of key intracellular pathways which are critical to cell proliferation and survival 28 Clinical pharmacology and biopharmaceutics review of perjeta MECHANISM OF ACTION Pertuzumab • Subdomain II of HER2 Pertuzumab Trastuzumab • Subdomain IV of HER2 HER2 Trastuzumab http://clincancerres.aacrjournals.org/content/17/15.cover-expansion 29 ADCC : Antibody-dependent cellmediated cytotoxicity Macrophages NK Cells Neutrophils FcγR Tumor cell Lysis of the target cell 30 Comment améliorer les propriétés effectrices des anticorps monoclonaux thérapeutiques ? Christophe Carnoy CLINICAL TRIALS / « CLEOPATRA » 12.4 months with Placebo VS 18.4 months with Pertuzumab => 6.1 months of improvement (p < 0.001) Baselga J, Cortés J, Kim SB, et al. Pertuzumab plus trastuzumab plus docetaxel for metastatic breast cancer. N Engl J Med. 2012;366:109-119. 31 COST OF TREATMENT Perjeta® $5,900 per month Herceptin® $71,000 per year $4,500 per month $54,000 per year $125,000 for 1 year Pharmaceutical Approval Update Marvin M. Goldenberg, PhD, RPh, MS / Vol. 37 No. 9 • September 2012 • P&T 32 MANUFACTURING Recombinant DNA technology in CHO FDA pre-approval inspection Failure rate for the Working Cell Bank thaw during the 2012 manufacturing campaign 33 CENTER FOR DRUG EVALUATION AND RESEARCH APPLICATION NUMBER:125409Orig1s000 CHEMISTRY REVIEW(S) « We discovered that the Sponsor was experiencing serious issues with the thaw and subsequent propagation of cells from WCB » 34 35 http://www.bionique.com/mycoplasma-resources/technical-articles/certified-working-cell-bank.html December 2011 Genentech filed applications for approval in US and EU HISTORY February 2012 FDA grants pertuzumab “Priority Review” June 8, 2012 FDA’s Approval (Product launch about 2 weeks post-approval) 2011 December 7, 2011 Improvement PFS by 6.1 months (NEJM) 2012 May 2012 Submission in Japan March 2012 FDA Pre-license drug inspection August 2012 Approval in Switzerland Failure rate for WCB growth PDL Biopharma Corporate Overview July 2012 Dec 13, 2012 Positive opinion from the CHMP 36 TO RECAP 37 RESTRICTIONS ON APPROVAL Restriction from FDA : Only campaign 2010 approved Potential shortage MANUFACTURING ISSUES Could have ramifications for the development and approval of biosimilars Genentech’s Perjeta Clears FDA despite Unresolved Manufacturing Issues Elsevier Business Intelligence: 'The Pink Sheet' - June 18, 2012 38 RECOMMENDATIONS ON APPROVABILITY Three concurrent plans to resolve the cell growth issues Manufacturing from the Master Cell Bank Manufacturing using a modified process from Working Cell Bank Developing a new WCB and manufacturing from this new WCB 39 Center for drug evaluation an d research – 125409Orig1s000 Chemistry Review0 APPROVAL’S CONDITIONS Letter from Division of Monoclonal Antibodies (DMA) 13 Perjeta Commitments 40 1- Stability study of the drug substance manufactured from specific thaws 2012 pertuzumab campaign Real time Confirm the use-by-date Stressed stability testing Evaluate the intrinsic stability of the active molecule Identify degradation products Choose analytical methods Predict the stability of a drug formulation Shortened shelf life Risk of lack of biological effects 41 http://www.hc-sc.gc.ca/dhp-mps/prodpharma/applic-demande/guide-ld/chem/stabt_stabe-fra.php#1.3 42 Stability studies : EMA’s guideline “…proteins and/or polypeptides, maintenance of molecular conformation and, hence of biological activity, is dependent on noncovalent as well as covalent forces. The products are particularly sensitive to environmental factors such as temperature changes, oxidation, light, ionic content, and shear. In order to ensure maintenance of biological activity and to avoid degradation, stringent conditions for their storage are usually necessary.” 43 Guideline Quality of Biotechnological Products: Stability Testing of Biotechnological/BiologicalProducts 2- Stability studies of the Master Cell Bank at more frequent intervals than the currently proposed 10 years Check the stability of the MCB every 4 years 44 3- Reassess release and stability specifications for pertuzumab drug substance and drug product through June 30, 2014 45 Process validation study to support manufacture of pertuzumab from 4- Master Cell Bank 5- Working Cell Banks by a modified process 6- A new Working Cell Bank 46 Process validation study Objective : check that all manufacturing steps lead to a product in compliance with standard of stability and reproducibility. Drug substance manufacturing campaigns are able to deliver consistent product with comparable strength, quality, purity and potency to that used in the phase 3 clinical trial Reproducibility : glycosylation profile, ADCC activity, and purity 47 48 Process validation studies : EMA’s guideline “The evaluation/validation data provide essential information on the reproducibility and robustness of the process steps and are an important element to guarantee consistency in the quality of the product.” 49 “Effective process validation contributes significantly to assuring drug quality … • Quality, safety, and efficacy are designed or built into the product. • Quality cannot be adequately assured merely by in-process and finished-product inspection or testing. • Each step of a manufacturing process is controlled to assure that the finished product meets all quality attributes including specifications.” 50 7- Study to establish a drug substance release specification to control for antibody-dependant cellular cytotoxicity (ADCC) activity of pertuzumab ADCC boosted according to the glycoforms Verify the expected activity 51 8- Study to assess the ability of a CE-SDS assay to detect and quantitate pertuzumab fragmentation Check that the product is stable once it is made (no fragmentation) Different / too low glycosylation Not protected enough in the culture media Fragmentation Lack of efficacy 52 9- Tests for in vivo adventitious viruses and genetic inconsistency using end of production cells Importance of ensuring the finished products well kept free of « adventitious » agents. Importance of genetic homogeneity of all last cells used for the production 53 10- Re-qualify the bioburden test for the bulk drug substance and inprocess bioburden samples Control microbial contamination of the drug and on the samples recovered during manufacture 54 11- Revalidate the hold time for nonsterile cell culture media Check the time during which a culture medium is sterile 55 12- Comprehensive risk assessment regarding the microbial control of the cell culture process and action plan based on the assessment Find the critical points to prevent or eliminate the risk of microbial contamination in cell culture 56 13- Plan for responding to potential pertuzumab shortages Draft Plan Submission : 07/2012 Final Plan Submission : 09/2012 Communications to healthcare providers and patients Mechanism for ensuring that patients who are already receiving pertuzumab can continue to be treated according to the product label 57 TO CONCLUDE Issues • Stability • Thaw • Cell growth • Contamination Risk by FDA • Shortage • Stock management New clinical study? 58 REPLAGAL® & FABRAZYME® 59 INDICATION Indication : Fabry disease = lysosomal storage disorder Orphan disease => incidence of 1 per 60,000 to 1 per 35,000 live births (HAS) = 5,000 patients worldwide, France ≈ 300, US ≈ 700 Deficiency of the enzyme α-galactosidase A Accumulation of Gb3 Renal cells Cardiac cells http://www.has-sante.fr/portail/upload/docs/application/pdf/2010-12/ald_17_pnds_fabry_vd.pdf CNS cells Endothelial cells 60 60 HUMAN α GALACTOSIDASE A Active site 61 http://www.replagal.co.uk/hcp/about-replagal/ SYNTHESIS OF α GALACTOSIDASE A IN PHYSIOLOGICAL STATE Glycosylation 62 http://www.ncbi.nlm.nih.gov/books/NBK11598/?report=printable SITE OF ACTION OF α GALACTOSIDASE A Lysosome 63 http://www.lysosomalstorageresearch.ca/Fabry_eClinic/n-algasidase-alfa.html FABRY DISEASE Absence of enzyme Enzyme’s activity decreased 64 http://www.ncbi.nlm.nih.gov/books/NBK11598/?report=printable FABRY DISEASE No GLA 65 http://www.lysosomalstorageresearch.ca/Fabry_eClinic/n-algasidase-alfa.html EFFECT OF GLYCOSYLATION ON ACTIVITY OF α GALACTOSIDASE A Stability => T1/2 Enzymatic transport Modification of the biodistribution and bioactivity 3D configuration N192 et N215 sites of glycosylation (domain 1) mutate frequently => no binding to the M6P receptor => no adressing to the lysosome 66 http://www.ncbi.nlm.nih.gov/books/NBK11598/?report=printable TWO TYPES OF FABRY DISEASE Causes Morbidity Classical Atypical variants Absence of enzyme Enzyme’s activity decreased • Renal failure • Cardiomyopathy • Cerebrovascular incident • Renal • Cardiac One of them only occur. All these features occur together or at least two. GL-3 accumulation in the kidney vascular endothelium http://www.ncbi.nlm.nih.gov/books/NBK11572/#A1092 http://wiki.medpedia.com/Fabry%27s_Disease 67 MORBIDITY RATE 80 70 60 50 40 30 20 10 0 Males Females 68 http://www.ncbi.nlm.nih.gov/books/NBK11572/table/A1079/?report=objectonly MECHANISMS OF FABRY DISEASE http://flipper.diff.org/app/items/info/2968 69 ENZYME REPLACEMENT THERAPY Recombinant human αgalactosidase A, produced in a human cell line by gene activation Recombinant human αgalactosidase A, produced in CHO cells by recombinant techniques 70 ERT MECHANISM 71 http://www.ncbi.nlm.nih.gov/books/NBK11598/?report=printable CHEMICAL & PHARMACOLOGICAL CHARACTERISTICS REPLAGAL® FABRAZYME® Manufacturing Human cells CHO cells Frequence of occurrence of IgG 55% 80% IgE No Yes Reaction at the injection site 10% 50% Duration of infusion 40 minutes 2-4 hours Plasma half-life 42 to 117 min 15 to 45 min Dosage 0,2 mg/Kg per 14 days 1 mg/Kg per 14 days 72 BIOCHEMINAL CHARACTERISATION Replagal® Oligomannose / oligosaccharide ratio Fabrazyme® • Fucose : 3.0 • Fucose : 1.8 • Galactose : 12.2 • Galactose : 8.0 • N-acetyl glucosamine : • N-acetyl glucosamine : 22.5 18.4 Sialic Acid / Galactose 0.56 0.88 Mannose-6-phosphate on oligomannose side chain 1.8 3.1 Glycolisation sites (Asparagine residues) 108 / 161 / 184 73 http://glycob.oxfordjournals.org/content/13/4/305.full#T2 - Table III GLYCOSYLATION SITES Replagal ® % total glycoforms Fabrazyme ® % total glycoforms 15% 44% 25% 39% Biphosphorylated oligomannose 7 / 36% Phosphorylated oligomannose 6 28 / Major oligosaccharides species in each binding sites Asparagine 108 Trianttennary fucosylated trisialylated (more complex different sialilation) Asparagine 161 Phosphorylated oligomannose 7 Asparagine 184 74 http://glycob.oxfordjournals.org/content/13/4/305.full#T2 - Table IV FABRAZYME ® CLINICAL TRIALS Protoccol No. Study design FB9702-01 Phase1/2 study Open label nonrandomized dose finding Primary endpoint Duration (n) Doses • • • 10 weeks 10 weeks 10 weeks 10 days 10 days (15) Clinical pharmacodynamics pharmacokinetic safety parameters • • • • • 0.3mg /kg/eow 1.0mgg/kg/eow 3.0mg/kg/eow 1.0mg/kg/q48h 3.0mg/kg/q48h AGAL-1-002-98 Phase 3 double blind placebo control Morphological assessment of GL-3 inclusions of the kidney • 1.0mg/kg/14q 20 weeks (29) AGAl-006-99 Phase ½ extension Ongoing safety and efficacy parameters of phase ½ open label • 1.0mg/kg/14q Until marketing approval AGAl-005-99 Phase 3 extension Ongoing safety and efficacy parameters of phase 3 • 1.0mg/kg/q14 Approx. 5 years (58) AGAl-007-99 Morphological assessment of GL-3 inclusions of the endothelium kidney • 1.0mg/kg/q14d 20 weeks (13) AGAl-008-00 Time of clinically significant progression of the renal, cardiac, cerebral vascular, & death among Fabry with advanced case. EMA & brief document • • Primary end point Fabrazyme / Placebo criteria 35 months 1.0mg/kg/14q 75 REPLAGAL® CLINICAL TRIALS Protoccol No. Study design TKT 001 Open label , dose escalation safety Phase 1 Primary endpoint Doses Duration (n) Worsening pain value. Area Under the curve. Single dose (10) 0.2mg/kg/ 6 months (26) TKT 003 Randomized double blind placebo controlled Phase 2 Chronic neuropathic pain, renal function, kidney pathology, plasma, urine sediment, kidney GL-3 content, cardiac structure & function TKT 006 Open label maintenance study for pts completing TKT003 / 0.2mg/kg 1 year (25) TKT 011 Open label maintenance study for pts completing TKT 006 / / 1 year interim analysis (24) TKT 005 Randomized, double blind, placebo controlled phase 2 CardiacGL-3 levels, (2ary cardiac mass, renal function, GL-3 plasma urine) 0.2mg/kg/eow 6 months Open label (15) TKT 014 Open label safety and efficacy trial in females Safety on females 0.2mg/kg/eow 3-12 weeks (15) EMA & brief document Primary end point criteria 76 USA APPROVAL Accelerated approval Special Conditions 601.40 Scope Biological products effectiven ess and safety for treating 601.41 Scope 601.43 Scope Approval based on a surrogate endpoint Withdrawal procedures 77 EUROPEAN APPROVAL REPLAGAL® BLA under "Exceptional Circumstances" FABRAZYME® August 2001 August 2001 Simultaneous approval Commercialization in Europe February 2002 February 2002 End of "Exceptional Circumstances" in Europe No February 2008 Orphan designation for the 2 drugs 78 TREATMENT COST REPLAGAL® FABRAZYME® Bottle price 1910 € 3900 € Unit dose 3.5 mg 35 mg Dosage 0.2 mg/kg 1 mg/kg Injection price 109.1 €/kg 111.4 €/kg Annual cost of treatment 183 360 € ~ 191 968 € 79 FABRAZYME MANUFACTURING AND VIRAL CONTAMINATION Production sites Viral contamination Consequences Acquisition by SANOFI 80 PRODUCTION SITES 2004 Fabrazyme : 1 x 2KL Cerezyme: 3 x 2KL 2011 / 2012 Fabrazyme : 1 x 2KL Cerezyme: 3 x 2KL 81 THE VIRAL CONTAMINATION (June 2009) Which Virus? The vesivirus 2117 Contagiousness of the virus? Not for human, but for used to product drugs (CHO only) Where? In the production site of Allston Landing, MA, US How does it work? It affects the quality and not the quantity of enzymes producted by those cells 82 EMA, Questions/réponses sur les difficultés d’approvisionnement de Cerezyme et de Fabrazyme, 14 août 2009 HOW THE VIRUS WAS DETECTED ? 83 CONSEQUENCES • Regulatory consequences • Financial consequences • Supplying consequences 84 REGULATORY CONSEQUENCES Regulatory inspection EMEA/ ANVISA /PMDA/ FDA Plant Decontamination June –October 2009 October 2008 February 2009 June 2009 End 2012 March 2010 Q2 2010 Regulatory inspection FDA 483Form FDA Warning Letter Sign Consent Decree Viral FDA contamination Enforcement Action End Consent Decree 85 FINANCIAL CONSEQUENCES -1.8% 1800 1600 1400 29% 0.64 % -13% 29% 1.3% 1200 1000 Preview 800 Published 600 400 200 0 2005 2006 2007 2008 2009 2010 86 http://www.zonebourse.com/GENZYME-CORPORATION-4875/agenda/ ACQUISITION BY SANOFI Plavix Taxotere Appoved Nov. 1997 FDA 6.6 Billion 2009 Approved July 1998 by EMEA Approved on 1996 FDA Approved on Noc 1995 by EMEA • SANOFI decide to buy GENZYME with an offer of more than 20 Billion $ on Feb 2011 6.9% sales growth • Better idea to buy Genzyme on the 1St Q 2011. 87 CONSEQUENCES ON SUPPLYING 88 Source: company press releases and SEC filings CONSEQUENCES ON THE U.S. MARKET 89 REPLAGAL® – BIOEQUIVALENCE PROBLEMS AFTER A SWITCH OF PROCESS 90 REPLAGAL® MANUFACTURING 91 http://www.replagal.co.uk/hcp/about-replagal/ REPLAGAL® BLA 2001 : BLA accepted by the EMA in Europe 2003 : BLA denied by the FDA in the US 92 92 6 YEARS AFTER REPLAGAL REJECTION OF BLA IN THE U.S. … Fabrazyme® shortage in the US (June 2009) 93 93 38 SUMMER 2009 : THE FDA MADE AVAILABLE THE REPLAGAL® UNDER A TREAMENT IND Treatment IND = Investigational New Drugs Clinical study of 140 patients (20% of US fabry’s patients) Oct 2009 to June 2012 Opportunity for Shire to collect data FDA - For Consumers 94 GENZYME‘S CRISIS WAS SHIRE'S OPPORTUNITY March 2010 2nd submission for BLA => denied Summer 2009 US : Substitution by Replagal June 2009 27th March 2012 FDA Advisory Committee FABRAZYME SHORTAGE December 2009 1st submission for BLA => denied March 2012 November 2011 3rd submission for BLA BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 95 BUT IN MARCH 2012 … « Surprise » withdrawal of Replagal BLA 96 96 « SURPRISE » WITHDRAWAL OF REPLAGAL® BLA - EXPLANATIONS Fabrazyme reappearance Contents of the briefing documents Sent anonymously to 97 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 CONTENTS OF THE BRIEFING DOCUMENTS FDA require additional clinical data for safety and efficacity Lack of data / clinical studies Equivalence old/new product ? Data from 46 countries + IND studies 98 98 Biocentury, Behind Shire's decision to abandon Replagal for Fabry's in U.S, June 25, 2012 THE NEW MANUFACTURING PROCESS FOR REPLAGAL® 99 1st CHANGE IN THE PROCESS 2007 Transition to a new manufacturing system April 2009 Bovine serum and animalderived protein No animal-derived components in culture medium Roller bottles Bioreactor AIM : Eliminate animal components able to lead to contamination and increase the yields BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 100 1st CHANGE IN THE PROCESS 2007 Transition to a new manufacturing system EMA Approved in April 2009 => Alewife manufacturing plant in Cambridge, MA TGA (Australia) Approved in May 2010 => on the condition Shire conduct a study assessing the new version April 2009 CADTH (Canada) Approved in 2010 => on the condition Shire conduct a study assessing the new version 101 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 2nd CHANGE IN THE PROCESS Sept 2010 Purification of Replagal at the new facility in Lexington June 2011 Aim : Increase manufacturing capacity Approved by EMA, June 2011 102 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 3 TYPES OF ® REPLAGAL PRODUCTS 1. Original product : roller bottles process Clinical trial NO SAMPLES 2. Animal-free product, bioreactor process 3. Animal free product, bioreactor process + purification in Lexington Non clinical tests/ lack of human data 103 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 2 CHARACTERISTICS CRITICAL TO THE EFFICACY OF ERT (non clinical TGA data) M6P Animal free product Ac. Sialique Animal free product + purification in Lexington M6P Ac. Sialique TGA concluded : "small differences" in the two formulations "do not lead to any biologically significant differences in either pharmacodynamic or pharmacokinetic properties" BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 104 FDA POINT OF VIEW Changes of chemical characteristics Changes of pharmacological characteristics Batches produced after changes are different from the original one 105 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 SHIRE DECISION Additional studies would cause a significant delay Approval possible in a distant future Withdrawal of Replagal BLA 106 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 CURRENT SITUATION IN THE U.S. Patients dependent on a single supplier for a life-sustaining drug An access to Replagal would protect against future supply disruptions 107 BioCentury on BioBusiness “Behind Shire's decision to abandon Replagal for Fabry's in U.S” By Steve Usdin, Monday, June 25, 2012 THE LACK OF A MEDICINE JOINS THE LACK OF THERAPEUTIC EVALUATION 108 NO COMPARISON STUDY BETWEEN THE 2 ERT BUT … Canadian trial (2007 – 2017) 370 fabry’s patients - 3 arms Fabrazyme shortage , 29 patients switched to Replagal => no significant differences Tsuboi study 11 patients, data collected for 3 years after a switch Fabrazyme/Replagal => no significant differences 109 CONCLUSION Replagal and Fabrazyme are a significant therapeutic advance as first ERT for Fabry disease The long-term effectiveness needs to be evaluate The comparison between the 2 ERT needs to be done 110 BIOLOGICALS PRODUCTION One Company Reference « Master Cell Bank » Thaw New plant Viral Contamination Controlled Manufacturing process Caracterized Biological product 111 THE BIOSIMILAR One Company Reference « Master Cell Bank » Reproductibility 10y experience Thaw New plant Viral Contamination Controlled Manufacturing process « Similar product » 112 THANKS FOR YOUR ATTENTION 113

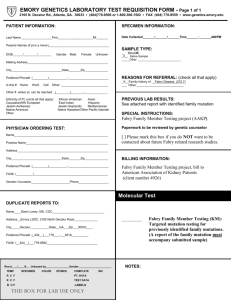

![[Date] - Fabrazyme](http://s3.studylib.net/store/data/007856986_2-92736280fd31154fb73068d0df9b074f-300x300.png)