Ex 2 Due - Confluence

advertisement

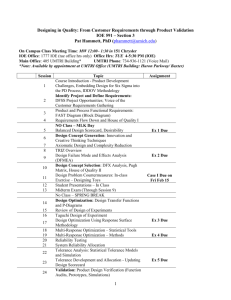

MFG 599-3: Designing in Quality: From Customer Requirements through Product Validation Pat Hammett, PhD (phammett@umich.edu) On Campus Class Meeting Time: MW 12:00– 1:30 in 165 Chrysler Center IOE Office: 1777 IOE (tue office hrs only) Office Hrs: TUE 4-5:30 PM (IOE) Main Office: 405 UMTRI Building* UMTRI Phone: 734-936-1121 (Voice Mail) *Note: Available by appointment at UMTRI Office (UMTRI Building: Huron Parkway/ Baxter) Session 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 Topic Course Introduction – New Product Development and its Challenges, Embedded DFSS Identify DFSS Project Opportunities IDDOV Methodology Define Customer Requirements: Voice of the Customer Requirements Gathering NO CLASS MLK Break Survey Analysis Methods Product and Process Functional Requirements: FAST Diagram (Block Diagram) Requirements Flow Down and House of Quality I Design Concept Generation: Innovation and Creative Thinking Techniques TRIZ Overview Design Concept Selection: Pugh Matrix, House of Quality II Design Failure Mode and Effects Analysis (DFMEA) Design Issue Countermeasures, DFX Analysis, Axiomatic Design Principles: In-class Exercise – Designing Toys Assignment Student Presentations – In Class Case I Due Feb 19 No Class – SPRING BREAK Design Optimization: Design Transfer Functions and P-Diagrams Midterm Exam (in class) Conventional Design of Experiments Taguchi Robustness Concepts Taguchi Design of Experiment Design Optimization Using Response Surface Methodology Design Optimization Using Transfer Functions and Simulation Multi-Response Optimization and Desirability Reliability Testing System Reliability Allocation Tolerance Analysis: Statistical Tolerance Models and Simulation Tolerance Development and Allocation Validation: Product Design Verification (Prototypes, Simulations) / Updating Scorecard Manufacturing Process Validation 1 Ex 1 Due Ex 2 Due Ex 3 Due Ex 4 Due Ex 5 Due 27 Course Summary FINAL Exam – TBD Course Web Page: Case 2 Due Final Exam ctools.umich.edu Lecture Notes: All lecture notes, homework sets, solutions, and tutorials are available through the course web page. Course Text Book: The course lecture notes have been developed from a variety of sources. TEXTBOOK REFERENCE: Design for Six Sigma: A Roadmap for Product Development by Kai Yang, Basem S. EI-Haik -- IBSN: 0-071-412085 Others Reference Books Used in the Course: Taguchi’s Quality Engineering Handbook G. Taguchi, S. Chowdhury, and Y. Wu, Wiley-Interscience, ISBN: 0471413348 Axiomatic Quality: Integrating Axiomatic Design with Six Sigma, Reliability, and Quality Engineering B. El-Haik, Wiley-Interscience, IBSN: 047168273X Engineering of Creativity: Introduction to TRIZ Methodology of Inventive Problem Solving S. Savransky, CRC Press, ISBN: 0849322553 Response Surface Methodology: Process and Product Optimization Using Designed Experiments R. Myers and D. Montgomery; Wiley-Interscience, IBSN: 0471581003 Software: Minitab 14 Software or equivalent and QETools Templates Provided Useful Web Sites: Product Development: www.npd-solutions.com/bok.html Six Sigma: www.isixsigma.com Instructor: qetools.com Statistics Material: http://davidmlane.com/hyperstat/index.html Other DFSS Books: - Design for Six Sigma in Technology and Product Development by C. Creveling, J. Slutsky, D. Antis - Design for Six Sigma: Launching New Products and Services without Failure by Geoff Tennant 2 Course Grading Assignment Multiple Choice Exercises (5) Case Study Reports (2) Class Participation/Discussion Board Exam I Final Exam Total Points 50 90 40 100 120 400 Homework: (all homework must be submitted electronically – see instructions on web page). Case Study Assignments: Assignments must be emailed using a single report file. Acceptable file submittal formats: (Adobe PDF or MS Word) – For additional format issues on page lengths and headings: See “Case Study Report Requirements”. Case # #1 #2 Topic IDD – Design Concept Selection Design Robustness and Optimization Points 40 50 Case Study and Exercise Submittal Policies: Case Study Assignments should be completed in teams of ~3. All assignments submitted electronically must be posted by 11:59 PM of the assigned due date. For on-line multiple choice exercises, no late homework submittals will be accepted. For case study reports, students may turn in one case study four calendar days after it is due. If you turn in an assignment after the late date or have more than one late assignment, the maximum score possible for that assignment will be 20 points. Case studies are considered a critical component of this course and students are expected to complete all case study reports. Failure to complete a case study will result in an additional loss of 20 points (beyond a 0 for the assignment) AND a lowering of your final grade. Discussion Board/Participation Score (all student discussion posts must be completed by last day of class): Throughout the course, I will post various discussion questions within ctools – See ‘Discussion Tab’. For off campus students, I will expect you to respond to at least 4 of these (responses should be 1-2 paragraphs in length). Students may create 1 blog/discussion thread of their own at part of their 4 discussion posts (Blog on a Topic of personal interest). I will evaluate your participation score based on the quality of your discussion postings (Note: you are also welcome to add to in-class discussions). For on campus students, I will evaluate your participation score based on a combination of attendance, participation in classroom discussions, and response to at least 2 instructor discussion posts. Students may create 1 blog/discussion thread of their own at part of their 4 posts (Blog on a Topic of personal interest). 3 Course Description: As organizations improve their operational quality, they recognize the need to apply more systematic analytical techniques to design quality into their products and services. This course provides methods and analysis tools for preventing quality and warranty concerns. This course focuses on the Design for Six Sigma Quality methodology: IDDOV. Using the IDDOV framework, this course examines tools and methods for identifying customer requirements, evaluating design concepts, and optimizing processes to meet quality objectives. The course integrates several tools from Voice of the Customer Analysis, Transfer Functions, Failure Mode Effects Analysis, TRIZ, DFX Analysis, Experimental Design, Taguchi Methods, Response Surface Methodology, Design for Reliability, and Tolerance Simulation and Analysis. Course Objectives and Outcomes: Links shown in brackets are to departmental educational objectives: COURSE OBJECTIVES 1 Know how to apply basic statistical procedures to solve engineering problems. 2 Build a base of skills in drawing conclusions from data using modern statistical software 3 Learn how to gather design requirements and build quality into a product or service. 4 Integrate statistical analysis tools with quality problem solving methodologies. Links shown in brackets are to course objectives: COURSE OUTCOMES 1 Appreciate the challenges with gathering customer requirements and developing new products and services. 2. Learn innovation and design analysis techniques to create products that better meet customer requirements. 3. Know graphical and numerical techniques for summarizing and presenting data. 4. Know methods for drawing valid conclusions (inference) for different situations such as tests of hypothesis. 4