Discretized constitutive equation White Metzner

advertisement

• Žitný BC project for Glasgow

students 2015 (frozen since

September 2015)

RZ10

Metzner White

convergent/divergent

Gauss planar channel flow

GAČR = kolagen

Motto: It is a big mistake for teachers that they do not

ask students about their dreams and ideas before

creative genes of pure-minded students came under

the tutelage of tutors. And an even bigger mistake is

when the students afraid to talk about their crazy

ideas.

1

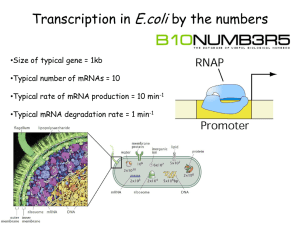

History of project

The idea, how to determine the relaxation time of viscoelastic fluid by comparing the

pressure drop at elongation and compression flows in a converging/diverging slot, think

about everyone after reading the first book about rheology. The problem is in a technical

realization of viscoelastic stresses measurement along a channel with a variable cross

section: Possible solution was to use the concept of groove strain-gauge sensors for

measuring the axial pressure profile in the annular gap of existing extrusion rheometer

(the development of these sensors was implemented from the beginning of the

seventies). The first practical experiments (convergent/divergent gap between the

cylindrical tube with attached sensors and internal double-cone pin) were up in the early

nineties. Relevant results were summarized in Pavlovec thesis (theoretical solution

assuming the analytic velocity profiles corresponding to a power fluid flow and numerical

solutions of viscoelastic fluid type Metzner White) and in thesis by Zeleny (experiment

with collagen and a double-cone pin - certain differences in pressure losses in the

convergent/divergent slit were recorded). Mr. Pavlovec was an excellent student, but its

thesis has not been completed (Fortran programs did not converged and the result was

reduced to extremely simplified 1D analysis). The problem is simply too complicated for

single student without sufficient background.

And that is the true goal of this presentation: to prepare a groundwork for english

speaking students from Glasgow.

2

History of project

Previous presentation RZ8 was almost duplicated thesis of Pavlovec, programmed in MATLAB with certain

exemptions in differencing (but basic simplification consisting in using the power law velocity profile, was

preserved). Although solutions converge, the results raise some doubts, especially the occurrence of strange

peaks of calculated pressures in the axis of the channel and also the unexpected effect of elasticity: Pressure

loss in the convergent section was lower than in the divergent section (see following sheet No. 13). Independent

solutions and programming performed by student (Mr. Frouz) reportedly received identical results (presented at

the Students Conference). Still, I'd be very happy if he could express his findings in the form of diagrams on a

slide 13, so that a consensus was evident.

The following diagram is a visualization of what's happening with a loaded fiber. According to this concept

the normal stress on the wall should be lower than during the stretching of the fiber during its compression.

But it is at odds with the results of the model (see sheet 7).

Stretched fiber

Compressed fiber

Equilibrium fiber

This visualization is perhaps misleading (it say that the normal stress in the zone of elongation is less than in the

compression zone), because the de-facto ignores the influence of time. I will be grateful to anyone who offers a

better interpretation of what was really going on polymer fibers.

3

History of project

discussion of simplifying assumptions (assumed velocity profile not affected by elastic forces)

RZ8 model assuming linear cross-sectional profile of convergent/divergent slots along with the assumption of a

power law velocity profile actually result to a discontinuity of elongation rate (positive constant rate of elongation in

the convergent zone while a constant negative rate in the divergent zone). The discontinuity and weak singularity at

the transition may cause unrealistic peak pressures and inaccuracies axial profile of normal stresses.

These fundamental shortcomings could be eliminated using the model described in this presentation. The axial

cross-sectional profile channel (and therefore the rate of elongation) is a smooth function (Gaussian curve), and the

velocity field is calculated (based on the concept of the current function and vorticity). Technically speaking, the

manufacture of the walls with the Gaussian profile should be no problem (using rapid prototyping - the geometry of

the channel varies exchanging inserts, which must anyway be of non-conductive plastic which is then glued strips

electrodes). The disadvantage is the computational complexity of relationships and the possibility of an error

(because in this presentation are reported in respect of each field checked Kontroloval:

....

xxxxx ..).

Solution flow of viscoelastic fluid in a convergent / divergent slot can also be simulated by existing commercial

software (Polyflow ANSYS) and OpenFOAM. These project can be alternatively solved by other Glasgow

students. The ideal would be a comparison of approaches - it is a matter of debate.

4

Literature

Crochet M.J., Davies A.R., Walters K.: Numerical simulation of non-Newtonian flow.

Elsevier 1984

Pavlovec J.: Výtlačný reometr pro viskoelastické kapaliny. Dipl.práce, ČVUT FS, 1991

Anderson J.D.: Computational Fluid Dynamics. McGraw Hill, Inc., N.Y., 1995

Owens R.G., Phillips T.N.: Computational Rheology. Imperial College Press, London

2002

Additional papers

Davidson et al. Velocity and stress fields of polymeric liquids flowing in a periodically constricted channel. J. Non-Newtonian Fluid

Mech. 49 (1993)

Baird D.G. First normal stress difference measurements…., J. Non-Newtonian Fluid Mech. 148 (2008)

Baaijens F. Mixed FEM for viscoelastic flow analysis, a review. J. Non-Newtonian Fluid Mech. 79 (1998)

James D.F., Chandler G.M.,Armour S.J. : A converging channel rheometer for the measurement of extensional viscosity. Elsevier

1998 (mam jen papirovou kopii bez bibl.udaju)

James D.F., Chandler G.M., Armour S.J. : Measurement of the extensional viscosity of M1 in a converging channel rheometer. J.

Non-Newtonian Fluid Mech. 35 (1990)

Han Chang Dae: Measurement of the rheological properties of polymer melts with slit rheometer I.Homopolymer systems. J.Applied

Polymer Science, 15 (1971)

Davies J.M. et al: Theory for normal stresses in slits and capillaries. J. Phys. D. : Appl.Phys, Vol.6 (1973), 2259-2266

Cogswell F.N. Converging flow of polymer melts in extrusion dies. Polymer Engngr. and Sci. (1972)

Cogswell F.N. Converging flow and stretching flow a compilation. J. Non-Newtonian Fluid Mech. Vol.4 (1978), 23-38

Binding D.M. An approximate analysis for contraction and converging flows. J. Non-Newtonian Fluid Mech. Vol.27 (1988), 173-189

5

Diploma work J.Pavlovec: Výtlačný reometr pro viskoelastické kapaliny. 1991

Only INFO old presentation RZ8 (skip)

Adviser R.Žitný, oponent M.Houška

Convergent section with

positive elongation

Divergent section

compression of fibers

Constitutive model UCM (upper convective Maxwell) modification White-Metzner

𝜇 𝐼𝐼

𝜏𝑖𝑗 +

𝐺

𝜕𝜏𝑖𝑗 𝜕𝑢𝑖

𝜕𝑢𝑗

𝑢𝑘

−

𝜏 −

𝜏

= 𝜇 𝐼𝐼

𝜕𝑥𝑘 𝜕𝑥𝑘 𝑘𝑗 𝜕𝑥𝑘 𝑖𝑘

Relaxation

time

𝜕𝑢𝑖 𝜕𝑢𝑗

+

𝜕𝑥𝑗 𝜕𝑥𝑖

Viscosity

6

Vague idea of Maxwellian model (maxwell.xlsx)

Vague because it does not specify the nature of the stress (imagine that it

is for example an elongation stress in the direction of flow). The model

considers a linear change in velocity u and strain rate along a channel.

𝜏 + 𝜆 𝑢0 + Δ𝑢 ∙ 𝑥

u0

du

g0

dg

sig0

lam

dx

mju

1

0.1

1

0.2

10

0.005

0.01

10

𝑑𝜏

= 𝜇 𝛾0 + Δ𝛾 ∙ 𝑥

𝑑𝑥

𝜆=

𝜇

𝐺

Only INFO old presentation RZ8 (skip)

relaxation time [s]

Particular solution

𝜇

𝜏𝑃 =

𝛾 + 𝜆 𝛾0 Δ𝑢 − 𝑢0 Δ𝛾 + Δ𝛾𝑥

1 + 𝜆∆𝑢 0

General solution

𝜇

1

𝑢0

𝜏=

𝛾 + 𝜆 𝛾0 Δ𝑢 − 𝑢0 Δ𝛾 + Δ𝛾𝑥 + 𝑐 ∙ 𝑒𝑥𝑝 −

ln(𝑥 + )

1 + 𝜆∆𝑢 0

𝜆∆𝑢

∆𝑢

5

Effect of relaxation time increase to axial stress

profile (, 2, 5)

Weissenberg number (elasticity number) 𝑊 =

= relaxation time * rate of deformation

7

𝑢

=

𝐺ℎ

Pavlovec : dimensionless parameters

Transformation into an orthogonal coordinate system

Kontroloval:FROUZ

Frouz

Kontroloval

Only INFO old presentation RZ8 (skip)

H

H

LI

L

L

LI

L

L

x

𝑥 − 𝑥0

=

∆𝐿

𝑦

𝑦

𝑦

𝜂=

=

=

𝑥−𝑥

ℎ(𝑥) 𝐻0 1 + 𝛽

𝐻0 1 + 𝛽 ∆𝐿 0

Inlet section

𝑥0 = 0, ∆𝐿 = 𝐿𝐼

𝛽 = 0, 𝐻0 = 𝐻

Convergent section

𝑥0 = 𝐿𝐼 , ∆𝐿 = 𝐿

∆𝐻

𝛽=−

,𝐻 = 𝐻

𝐻0 0

Transformation of derivatives

𝜕𝐹 𝜕𝐹 𝜕 𝜕𝐹 𝜕

1 𝜕𝐹

𝜕𝐹

=

+

=

−

𝜕𝑥 𝜕 𝜕𝑥 𝜕 𝜕𝑥 𝐿 𝜕

1 + 𝜕

Divergent section

𝑥0 = 𝐿 + 𝐿𝐼 , ∆𝐿 = 𝐿

∆𝐻

𝛽=

, 𝐻 = 𝐻 − ∆𝐻

𝐻0 0

𝜕𝐹 𝜕𝐹 𝜕 𝜕𝐹 𝜕

1

𝜕𝐹

1

𝜕𝐹

=

+

=

=

𝜕𝑦 𝜕 𝜕𝑦 𝜕 𝜕𝑦 𝐻0 1 + 𝜕 𝐿 1 + 𝜕

8

Power law approximation of velocities

Kontroloval FROUZ

Only INFO old presentation RZ8 (skip)

Axial velocity

𝑢𝑚

𝑢𝑥 =

(1 − 1 − 2𝜂

1 + 𝛽𝜉

𝑢𝑚

𝑢𝑥 =

1 − 2𝜂 − 1

1 + 𝛽𝜉

𝑢𝑚 =

𝑛+1

𝑛 ), 0.5

𝑛+1

𝑛

, > 0.5

𝑉 2𝑛 + 1

𝐻0 𝑛 + 1

Transversal component (satisfying continuity equation

𝜀𝛽𝑢𝑚

𝑢𝑦 =

𝜂(1 − 1 − 2𝜂

1 + 𝛽𝜉

𝜀𝛽𝑢𝑚

𝑢𝑦 =

𝜂(1 − 2𝜂 − 1

1 + 𝛽𝜉

𝜀=

𝜕𝑢𝑥 𝜕𝑢𝑦

+

= 0)

𝜕𝑥

𝜕𝑦

𝑛+1

𝑛 ), 0.5

𝑛+1

𝑛 ),

> 0.5

𝐻0

∆𝐿

9

Power law approximation of viscosity

Kontroloval FROUZ

Only INFO old presentation RZ8 (skip)

Viscosity as a power function of the second invariant

𝜇 𝐼𝐼 = 𝐾

𝜕𝑢𝑥

2

𝜕𝑥

2

𝜕𝑢𝑦

+2

𝜕𝑦

2

𝜕𝑢𝑥 𝜕𝑢𝑦

+

+

𝜕𝑦

𝜕𝑥

2

𝑛−1

Rate of deformation in the dimensionless coordinates (0,1), (0,1)

𝜕𝑢𝑥

1 𝜕𝑢𝑥

𝜕𝑢𝑥

=

−

𝜕𝑥

𝐿 𝜕

1 + 𝜕

𝜕𝑢𝑥

1

𝜕𝑢𝑥

=

𝜕𝑦

𝐿 1 + 𝜕

𝜕𝑢𝑦

1 𝜕𝑢𝑦

𝜕𝑢𝑦

=

−

𝜕𝑥

𝐿 𝜕

1 + 𝜕

𝜕𝑢𝑦

𝜕𝑢𝑦

1

=

𝜕𝑦

𝐿 1 + 𝜕

10

Constitutive equation White Metzner

𝑥𝑥 = −𝑝 + 𝑥𝑥

𝑦𝑦 = −𝑝 + 𝑦𝑦

𝑥𝑦 = 𝑥𝑦

𝜏𝑥𝑥 +

𝜇 𝐼𝐼

𝐺

𝜇 𝐼𝐼

𝜏𝑦𝑦 +

𝐺

𝜏𝑥𝑦 +

𝜇 𝐼𝐼

𝐺

𝑢𝑥

Kontroloval FROUZ

Only INFO old presentation RZ8 (skip)

An important conclusion: the lower flat plate is yy = 0, which

means that the pressure sensor measures the isotropic pressure p

𝜕𝜏𝑥𝑥

𝜕𝜏𝑥𝑥

𝜕𝑢𝑥

𝜕𝑢𝑥

𝜕𝑢𝑥

+ 𝑢𝑦

−2

𝜏𝑥𝑥 − 2

𝜏𝑥𝑦 = 2𝜇 𝐼𝐼

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝜏𝑦𝑦

𝜕𝜏𝑦𝑦

𝜕𝑢𝑦

𝜕𝑢𝑦

𝜕𝑢𝑦

𝑢𝑥

+ 𝑢𝑦

−2

𝜏 −2

𝜏

= 2𝜇 𝐼𝐼

𝜕𝑥

𝜕𝑦

𝜕𝑥 𝑥𝑦

𝜕𝑦 𝑦𝑦

𝜕𝑦

𝑢𝑥

𝜕𝜏𝑥𝑦

𝜕𝜏𝑥𝑦 𝜕𝑢𝑦

𝜕𝑢𝑥

+ 𝑢𝑦

−

𝜏𝑥𝑥 −

𝜏

= 𝜇 𝐼𝐼

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑦 𝑦𝑦

𝜕𝑢𝑥 𝜕𝑢𝑦

+

𝜕𝑦

𝜕𝑥

11

Pressure distribution by integration Cauchy equations from left. Results

7

0

G=150

x 10

diff=-0.16817 Vdot=0.000375

white-metzner

figure(1)

Only%main

INFO

old presentation

RZ8 (skip)

clear

all;

plot(x(1:ig2),pp(1:ig2))

% white metzner - velocities

% rychlosti ux(1:nx,1:ny),uy(1:nx,1:ny),

% derivace duxdksi(1:nx,1:ny), duxdeta(1:nx,1:ny), duydksi(1:nx,1:ny),

duydeta(1:nx,1:ny)

% duxdx(1:nx,1:ny), duxdy(1:nx,1:ny), duydy(1:nx,1:ny), duydx(1:nx,1:ny)

% viskozity mju(1:nx,1:ny)

% beta, dl, h0, n, vdot, K G koeficient konzistence a modul G

-0.5

-1

p [Pa]

-1.5

-2

-2.5

-3

-3.5

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

x [m]

PRESSURE

160

140

120

x

100

80

60

40

20

Peek pressure on the axis of the channel is about an

approximation error

5

10

15

20

y

25

30

K=100;

n=0.5;

nx=59;

ny=37;

dl=0.2;

h=0.005;

h0=h;

dh=0.004;

um=0.1;

vdot=um*h0*(n+1)/(2*n+1)

G=5000

beta=0;

uxy;

for i=1:nx

pp(i)=pav(i);

x(i)=(i-1)*dl/(nx-1);

end

beta=-dh/h0;

uxy;

ig=nx;

ig0=ig;

for i=2:nx

ig=ig+1;

pp(ig)=pav(i);

x(ig)=(ig-1)*dl/(nx-1);

end

ig1=ig;

h0=h-dh;

beta=dh/h0;

uxy;

for i=2:nx

ig=ig+1;

pp(ig)=pav(i);

x(ig)=(ig-1)*dl/(nx-1);

end

ig2=ig;

hold on

plot(x(ig0),pp(ig0),'ro')

plot(x(ig1),pp(ig1),'ro')

plot(x(ig2),pp(ig2),'ro')

d1=pp(ig0)-pp(ig1);

d2=pp(ig1)-pp(ig2);

drel=(d1-d2)/max(abs(d1),abs(d2));

disp(sprintf('dp conv=%0.5g dp div=%0.5g

dif=%0.5g',d1,d2,drel));

title(sprintf('G=%0.5g diff=%0.5g Vdot=%0.3g',G,drel,vdot))

xlabel('x [m]')

ylabel('p [Pa]')

12

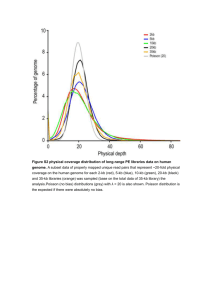

Axial pressure profiles p(x)

7

0

G=110

x 10

7

diff=-0.246 Vdot=0.000375

0

-0.5

𝑊=

(n=0.5, K=100, V=0.000375 m2/s)

G=150

x 10

7

diff=-0.16817 Vdot=0.000375

0

-0.5

-0.5

G=200

x 10

𝐾𝑢 2000

=

𝐺ℎ

𝐺

diff=-0.11166 Vdot=0.000375

Commented presentation RZ8

The graphs show what happens when you grow modulus G (resp. While reducing the relaxation time). Small values

-1

-1

-1

G represent great influence elasticity (pressure gradient in the convergent gap is then smaller than the divergent)

-1.5

-1.5

-2

p [Pa]

p [Pa]

p [Pa]

-1.5

-2

-2

W=10

W=18

-2.5

-2.5

-2.5

-3

-3

-3

-3.5

0

0.1

0.2

0.3

0.4

0.5

0.6

-3.5

0.7

0

0.1

0.2

0.3

x [m]

7

0.5

0.6

7

diff=0.00025101 Vdot=0.000375

0

W=4

-1

G=1000

x 10

0

W=2

-2

-2.5

-2.5

-3

-3

0.3

0.4

x [m]

0.3

0.5

0.6

0.7

0.4

G=5000

x 10

0.5

0.6

0.7

diff=0.071136 Vdot=0.000375

W=0.4

-1

-1.5

p [Pa]

p [Pa]

-2

0.2

0.2

-0.5

-1.5

0.1

0.1

7

diff=0.03977 Vdot=0.000375

-1

-1.5

0

0

x [m]

-0.5

-0.5

-3.5

-3.5

0.7

p [Pa]

0

G=500

x 10

0.4

x [m]

-3.5

-2

G-2.5= 5000 negligible elasticity, different

pressures

are error of approximation

-3

-3.5

0

0.1

0.2

0.3

0.4

x [m]

0.5

0.6

0.7

0

0.1

0.2

0.3

0.4

x [m]

0.5

13

0.6

0.7

Stream function, vorticity, elastic stresses

𝑢=

𝜕

𝜕𝑦

𝜕

𝑣=−

𝜕𝑥

=

𝜕𝑣 𝜕𝑢

−

𝜕𝑥 𝜕𝑦

s

𝜏𝑥𝑥

𝜕𝑢

= 𝑠𝑥𝑥 + 2𝜇

𝜕𝑥

14

Stream function, vorticity, elastic stresses

Geometry

Approximate profiles u,v, , for power law fluid

iteration

Elastic stresses sxx, syy, sxy (hyperbolic MW)

Poisson equation for

Nodal velocities and viscosity. BC for

Poisson equation for

This is rather complicated project

probably too difficult for batchelor or

even diploma work.

However it can be significantly

simplified by skiping the solution of

flow , (assuming only velocity

approximation) and neglecting

viscosity variation.

Poisson equation for pressure p

15

Gaussian axial profile of gap

The reason for choosing the smooth profile of the upper walls: the exclusion of the weak singularity at a

sharp edge between converging and diverging axial channel crossection

-3

6

x 10

5

y

Physical domain

4

3

2

1

0

x

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

Transformation of coordinates (x,y) (x,y)

and metric coefficients

0.4

𝜕 𝜕 𝜕 𝜕 2 𝜕 2

𝜕𝑥 𝜕𝑥 𝜕𝑦 𝜕𝑥𝜕𝑦 𝜕𝑥2

necessary for transformation of first and

second order derivatives

i,j+1

i,j

i,j-1

Computational domain

16

Gaussian axial profile of gap

Metric coefficients of first derivatives

Dimensionless geometric parameters

𝐿

𝐿

ℎ

𝐸 = exp(−2 1 − 2 )

= 𝐻𝑘

= 𝑘

=𝐻

-3

6

x 10

5

4

H

3

y

𝜕

>0

𝜕𝑥

2

1

0

0

0.05

0.1

𝜕

<0

𝜕𝑥

=1

h

x

Lk

𝜕𝜉

1

=

𝜕𝑥

𝐿𝑘

Kontroloval Zitny

0.15

=0

0.2

0.25

0.3

0.35

0.4

Ld

𝜕 2𝐸2 (1 − )(1 − 𝜅)

=

𝜕𝑥

(1 − (1 − )𝐸) 𝐿𝑘

Transformation from computational domain (0,2) (0,1)

to physical domain x(0,Lk+Ld), y(0,H)

𝑥 = 𝐿𝑘

𝑦 = 𝐻(1 − (1 − )𝐸)

𝜕

1

=

𝜕𝑦

1 − (1 − )𝐸 𝐻

17

Gaussian axial profile of gap

Kontroloval: zitny

Metric coefficients of second derivatives

Because depends upon x only linearly the second derivatives of are zero

𝜕2𝜉

=0

𝜕𝑥 2

𝜕2𝜉

=0

𝜕𝑦 2

𝜕2𝜉

=0

𝜕𝑥𝜕𝑦

Only two derivatives of transversal coordinate are nonzero

𝜕2𝜂

=0

𝜕𝑦 2

𝜕2

2𝐸𝜆2 1 − 𝜅

= 2

(2𝜆2 1 − 𝜉

2

𝜕𝑥

𝐿𝑘 1 − 1 − 𝜅 𝐸

𝜕2

2𝐸2 (1 − )(1 − 𝜅)

=

𝜕𝑥𝜕𝑦

1 − 1 − 𝐸 2 𝐻𝐿𝑘

2

1+ 1−𝜅 𝐸

− 1)

1− 1−𝜅 𝐸

Ověřeno numerickými diferencemi

18

INIT calculation of metric coefficients

geometry

INIT

Approximate profiles u,v, ,

for power law fluid

Geometrie h, H, Lk, Ld, , Nx, Ny

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

ksi=linspace(0,2,nx);

eta=linspace(0,1,ny);

Poisson equation for

Velocities, µ , BC for

Poisson equation for

i=1,2..Nx

J=1,2..Ny

𝑦𝑖, 𝑗 = 𝐻(1 − (1 − )𝐸)

𝜕

2𝐸2 (1 − )(1 − 𝜅)

|𝑖 , 𝑗 =

𝜕𝑥

(1 − (1 − )𝐸) 𝐿𝑘

𝜕2

| =

𝜕𝑥 2 𝑖 , 𝑗

2𝐸𝜆2 1 − 𝜅

𝐿2𝑘 1 − 1 − 𝜅 𝐸

(2𝜆2

Poisson equation for pressure p

𝑥𝑖 = 𝐿𝑘

𝜕

1

|𝑖 , 𝑗 =

𝜕𝑦

1 − (1 − )𝐸 𝐻

21+ 1−𝜅 𝐸

1−𝜉

− 1)

1− 1−𝜅 𝐸

𝜕2

2𝐸2 (1 − )(1 − 𝜅)

|𝑖 , 𝑗 =

𝜕𝑥𝜕𝑦

1 − 1 − 𝐸 2 𝐿𝑘 𝐻

19

INIT.m calculation of coefficients (MATLAB)

clearvars

Matrices defined at INIT

um=0.1;n=0.5;K=100;

x(nx), y(nx,ny) kartézské souřadnice

H=0.005;h=0.001;Lk=0.2;Ls=0.2;delta=0.1;

ksi(nx),eta(ny) výpočtová doména

lambda=Lk/delta;

dksidx(nx,ny),detadx(nx,ny),detady(nx,ny)

/x, /x,

kappa=h/H;

detadxdy(nx,ny),detadxdx(nx,ny)

2/xy, 2/x2,

nx=201;

gxx(nx,ny),…gx(nx,ny)

ny=41;

ksi=linspace(0,2,nx);

Matrices defined later

eta=linspace(0,1,ny);

psi(nx,ny), omega(nx,ny)

x=Lk*ksi;

u(nx,ny),v(nx,ny),dudx(nx,ny),dudy(nx,ny),dvdx(nx,ny),dvdy(nx,by)

for j=1:ny

mju(nx,ny),dmjudx(nx,ny), dmjudy(nx,ny), dmjudxdy(nx,ny), , /x, /y,

for i=1:nx

Approximation for power law fluid

E=exp(-(Lk/delta)^2*(ksi(i)-1)^2);

y(i,j)=eta(j)*H*(1-(1-kappa)*E);

psin(nx,ny), omegan(nx,ny)

end

un(nx,ny),vn(nx,ny),dudxn(nx,ny),dudyn(nx,ny),dvdxn(nx,ny),dvdyn(nx,by)

end

mjun(nx,ny),dmjudxn(nx,ny), dmjudyn(nx,ny), dmjudxdyn(nx,ny),

%derivace transformaci

Stresses

for i=1:nx

sxx(nx,ny), syy(nx,ny), sxy(nx,ny),

E=exp(-(lambda*(ksi(i)-1))^2);

for j=1:ny

k1=1-(1-kappa)*E;

dksidx(i,j)=1/Lk;

detadx(i,j)=eta(j)*(1-kappa)*E*2*lambda^2*(1-ksi(i))/(k1*Lk);

detady(i,j)=1/(k1*H);

detadxdy(i,j)=(1-kappa)*2*lambda^2*(1-ksi(i))*E/(H*Lk*k1^2);

detadxdx(i,j)=2*lambda^2*eta(j)*(1-kappa)*E/(Lk^2*k1)*(2*lambda^2*(1-ksi(i))^2*(1+(1-kappa)*E)/k1-1);

gxx(i,j)=dksidx(i,j)^2; gyy(i,j)=detadx(i,j)^2+detady(i,j)^2; gxy(i,j)=2*detadx(i,j)*dksidx(i,j); gx(i,j)=detadxdx(i,j);

end

end

%figure(2)

%surf(eta,ksi,detadx)

%title('deta/dx')

geometry

Approximate profiles u,v, ,

for power law fluid

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

Poisson equation for

Velocities, µ , BC for

Poisson equation for

Poisson equation for pressure p

Transformation of derivatives of quantity F (e.g. , , sxx, syy, sxy)

Kontroloval: zitny

Transformation of first derivative

𝜕𝐹 𝜕𝐹 𝜕𝜉 𝜕𝐹 𝜕𝜂

=

+

𝜕𝑥 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝐹 𝜕𝐹 𝜕𝜂

=

𝜕𝑦 𝜕𝜂 𝜕𝑦

Transformation of second derivatives (derivation is a bit lengthy)

𝜕 2 𝐹 𝜕𝐹 𝜕 2 𝜂 𝜕 2 𝐹 𝜕𝜉 2 𝜕 2 𝐹 𝜕𝜂 2

𝜕 2 𝐹 𝜕𝜂 𝜕𝜉

=

+

( ) + 2 ( ) +2

𝜕𝑥 2 𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

𝜕𝜂 𝜕𝑥

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

𝜕 2 𝐹 𝜕 2 𝐹 𝜕𝜂 2

=

( )

𝜕𝑦 2 𝜕𝜂2 𝜕𝑦

𝜕2𝐹

𝜕 2 𝐹 𝜕𝜂 𝜕𝜂 𝜕𝐹 𝜕 2

𝜕 2 𝐹 𝜕𝜂 𝜕𝜉

=

+

+

𝜕𝑥𝜕𝑦 𝜕𝜂2 𝜕𝑦 𝜕𝑥 𝜕𝜂 𝜕𝑥𝜕𝑦 𝜕𝜉𝜕𝜂 𝜕𝑦 𝜕𝑥

𝜕2𝐹

𝜕 𝜕𝐹 𝜕𝜂

𝜕 2 𝐹 𝜕𝜂 𝜕𝐹 𝜕 2

𝜕 2 𝐹 𝜕𝜉 𝜕 2 𝐹 𝜕 𝜕𝜂 𝜕𝐹 𝜕 2

=

=

+

=(

+ 2 ) +

𝜕𝑥𝜕𝑦 𝜕𝑥 𝜕𝜂 𝜕𝑦 𝜕𝑥𝜕 𝜕𝑦 𝜕𝜂 𝜕𝑥𝜕𝑦

𝜕𝜕 𝜕𝑥

𝜕 𝜕𝑥 𝜕𝑦 𝜕𝜂 𝜕𝑥𝜕𝑦

... it would be possible to express the transformation of derivatives also in the reverse direction, but usually we

do not need this

21

Cauchy equations with consideration of inertia forces

(𝑢

Kontroloval: zitny

𝜕𝑢

𝜕𝑢

𝜕𝑝 𝜕𝜏𝑥𝑥 𝜕𝜏𝑥𝑦

+𝑣 )=−

+

+

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑥

𝜕𝑦

𝜕𝑣

𝜕𝑣

𝜕𝑝 𝜕𝜏𝑥𝑦 𝜕𝜏𝑦𝑦

(𝑢

+𝑣 )= −

+

+

𝜕𝑥

𝜕𝑦

𝜕𝑦

𝜕𝑥

𝜕𝑦

Elimination of pressure by introducing the vorticity =

𝜕𝑣 𝜕𝑢

−

𝜕𝑥 𝜕𝑦

and using the continuity equation

The result is the transport equation of vorticity (right side resultant stress). At zero Re (creeping flow, 0) the

left side is zero and vorticity disappears from this equation.

𝜕

𝜕

2

2

2

(𝑢

+𝑣 )=

(𝜏 − 𝜏𝑥𝑥 ) + ( 2 − 2 ) 𝜏𝑥𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥𝑦 𝑦𝑦

𝜕𝑥

𝜕𝑦

Fulfill the continuity equation by introducing the current function

𝜕

𝑢=

𝜕𝑦

𝜕

𝑣=−

𝜕𝑥

2 2

− = 2 + 2

𝜕𝑥

𝜕𝑦

22

Initial conditions - stream function (for a power law fluid)

geometry

Stream function (,)

x 10

Approximate profiles u,v, ,

for power law fluid

-4

4

iteration

3

Elastic stress sxx, syy, sxy

(hyperbolic MW)

2

Poisson equation for

1

0

2

1.5

Velocities, µ , BC for

1

0.8

1

0.6

0.4

0.5

0

Poisson equation for

0.2

0

Velocity components u,v (,)

Poisson equation for pressure p

v [m/s]

x 10

-3

0.5

6

0.4

4

0.3

0.2

2

0.1

0

0

2

-2

1.5

1

0.8

1

0.6

-4

1

0.4

0.5

0

0.2

0

-6

2

0.5

1.5

1

0.5

0

0

Velocities calculated in this way satisfy continuity equation and correspond to the steady creeping flow of

power law fluid (without elastic effects). It is assumed that these initial conditions can be applied also as

boundary conditions at inlet and outlet (far from the disturbance of throat).

23

Initial conditions - stream function (for a power law fluid)

Section corresponding to the distance from the

entrance =x/Lk

Kontroloval: zitny

𝐻 = 𝐻 1 − 1 − 𝑒 −

2

1−

2

= 𝐻(1 − 1 − 𝐸)

𝜕𝐻

𝐸

2

= 2𝐻 (1 − )( − 1)

𝜕𝑥

𝐿𝑘

Stream function (um is maximum velocity for the gap thickness H). It holds umH=umH .

𝐻 2𝑦

𝑛

2𝑦

2𝑦 2𝑛+1

𝑥, 𝑦 = 𝑢𝑚 ( −

(1 − 𝑠𝑖𝑔𝑛(1 − )|1 −

| 𝑛 ))

2 𝐻 2𝑛 + 1

𝐻

𝐻

Corresponding velocity components

2𝑛+1

𝐻

𝑛

= 𝑢𝑚 (2 −

(1 − 𝑠𝑖𝑔𝑛(1 − 2)|1 − 2| 𝑛 ))

2

2𝑛 + 1

𝜕 𝑢𝑚 𝐻

2𝑦 𝑛+1

𝑢 𝑥, 𝑦 =

=

(1 − |1 −

| 𝑛 )

𝜕𝑦

𝐻

𝐻

𝜕

𝐻

𝑣 𝑥, 𝑦 = −

= −2𝑢𝑚

𝜕𝑥

𝐻

2

𝐻 𝑦

2𝑦 𝑛+1

(1 − ) (1 − )(1 − |1 −

| 𝑛 )

𝐻 𝐿𝑘

𝐻

24

Initial conditions – vorticity (for a power law fluid)

Vorticity

𝜕𝑣 𝜕𝑢

=

−

𝜕𝑥 𝜕𝑦

Auxilliary variables

corresponds to the direction

anti-clockwise

𝑍 =1−

𝐻 𝐻

𝐹=

( − 1)(1 − 𝑍

𝐻 𝐻

𝐻 = 𝐻 1 − 1 − 𝑒 −

2

1−

2

= 𝐻(1 − 1 − 𝐸)

𝜕𝐻

𝐸

2

= 2𝐻 (1 − )( − 1)

𝜕𝑥

𝐿𝑘

2𝑦

𝐻

𝑛+1

𝑛 )

Kontroloval: zitny

𝜕𝐹

𝐻

𝐻

= 2 ((1 − 2 )(1 − 𝑍

𝜕𝐻 𝐻

𝐻

𝑛+1

𝑛 )

dudy-num

𝐻

𝑛+1

− 𝑠𝑖𝑔𝑛 𝑍 ( − 1)

𝑍

𝐻

𝑛

1

𝑛

1−𝑍 )

OMEGA

3000

4000

2000

1000

2000

0

1

𝜕𝑢 𝜕 2 2𝑢𝑚 𝐻 𝑛 + 1

=

=

(

)𝑠𝑖𝑔𝑛(𝑍)|𝑍|𝑛

𝜕𝑦 𝜕𝑦 2

𝐻 2

𝑛

-1000

0

-2000

-2000

-3000

2

dvdx-num

1.5

1

0.8

1

0.6

0.4

0.5

0

0.8

-4000

2

1.5

0.2

0

1

0.8

1

0.6

0.4

0.5

𝜕𝑣

𝜕2

2𝑢𝑚 2 𝑦 𝜕𝐹 𝜕𝐻

𝐾

=− 2 =−

(

1− − )

𝜕𝑥

𝜕𝑥

𝐿𝑘

𝜕𝐻 𝜕𝑥

𝐿𝑘

0.6

0

0.2

0

Verified by three methods: analytically, direct

numerical difference and differential

transformed derivatives (it took me few days to

match the threee procedures

0.4

0.2

0

-0.2

2

1.5

1

0.8

1

0.6

0.4

0.5

0

0.2

0

25

Initial conditions – viscosity (for a power law fluid)

Auxilliary variables

𝑍 =1−

𝜕𝑢

𝜕2

𝐻

=

= −2𝑢𝑚

𝜕𝑥 𝜕𝑥𝜕𝑦

𝐻

2

𝜕𝑣

𝜕2

𝐻

=−

= −2𝑢𝑚

𝜕𝑦

𝜕𝑥𝜕𝑦

𝐻

2

𝜕𝑢

𝜕𝑥

2

𝜇 𝐼𝐼 = 𝐾

2

2𝑦

𝐻

Kontroloval: zitny

𝐻 = 𝐻 1 − 1 − 𝑒 −

2

−1

(1 − )𝐸

(1 − 𝑍

𝐿𝑘

𝑛+1

𝑛

𝑛+1

+

𝑠𝑖𝑔𝑛 𝑍 𝑍

𝑛

1

𝑛

1−

2

= 𝐻(1 − 1 − 𝐸)

1−𝑍 )

Verified numerically

𝐻 1 −

(1 − )

(1 − 𝑍

𝐻

𝐿𝑘

+2

𝜕𝑣

𝜕𝑦

2

+

𝜕𝑢 𝜕𝑣

+

𝜕𝑦 𝜕𝑥

𝑛+1

𝑛

2

Analytical expressions for first derivatives are too

complicated and will be approximated numerically

𝑛+1

+

𝑠𝑖𝑔𝑛 𝑍 𝑍

𝑛

1

𝑛

1−𝑍 )

𝑛−1

Dangerous peeks correspond to regions

with smal velocity gradients (this is

disadvantage of power law model)

𝜕µ 𝜕µ 𝜕 𝜕µ 𝜕 µ𝐸 − µ𝑊 𝜕 µ𝑁 − µ𝑆 𝜕

=

+

+

𝜕𝑥 𝜕 𝜕𝑥 𝜕 𝜕𝑥

2ℎ𝑥 𝜕𝑥

2ℎ𝑦 𝜕𝑥

𝜕µ 𝜕µ 𝜕 µ𝑁 − µ𝑆 𝜕

=

𝜕𝑦 𝜕 𝜕𝑦

2ℎ𝑦 𝜕𝑦

26

Initial conditions – POWER.m (MATLAB code 1/2)

geometry

Velocities, stream function, vorticity, viscosity for power law fluids

Approximate profiles u,v, ,

for power law fluid

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

for i=1:nx

Ek=exp(-lambda^2*(1-ksi(i))^2);

Hk=H*(1-(1-kappa)*Ek);

for j=1:ny

Z=1-2*y(i,j)/Hk;

HK=H/Hk;

psi(i,j)=um*H/2*(1-Z-n/(2*n+1)*(1-sign(Z)*abs(Z)^((2*n+1)/n)));

u(i,j)=um*H/Hk*(1-abs(Z)^((n+1)/n));

v(i,j)=-2*um*(lambda*H/Hk)^2*(1-Hk/H)*(1-ksi(i))*y(i,j)/Lk*(1-abs(Z)^((n+1)/n));

dudy(i,j)=2*um*H/Hk^2*(n+1)/n*sign(Z)*abs(Z)^(1/n);

F=(HK^2-HK)*(1-abs(Z)^((n+1)/n));

dHkdx=2*H*lambda^2*(1-kappa)*(ksi(i)-1)*Ek/Lk;

dFdHk=H/Hk^2*((-2*HK+1)*(1-abs(Z)^((n+1)/n))-sign(Z)*(HK-1)*(n+1)/n*abs(Z)^(1/n)*(1-Z));

dvdx(i,j)=-2*um*lambda^2*y(i,j)/Lk*(dFdHk*dHkdx*(1-ksi(i))-F/Lk);

omega(i,j)=dvdx(i,j)-dudy(i,j);

dudx(i,j)=-2*um*(HK*lambda)^2*(1-kappa)*(ksi(i)-1)*Ek/Lk*(1-abs(Z)^((n+1)/n)+sign(Z)*(n+1)/n*abs(Z)^(1/n)*(1-Z));

dvdy(i,j)=-2*um*(HK*lambda)^2*(1-1/HK)*(1-ksi(i))/Lk*(1-abs(Z)^((n+1)/n)+sign(Z)*(n+1)/n*abs(Z)^(1/n)*(1-Z));

mju(i,j)=K*(2*dudx(i,j)^2+2*dvdy(i,j)^2+(dudy(i,j)+dvdx(i,j))^2)^((n-1)/2);

end

end

Poisson equation for

Velocities, µ , BC for

Poisson equation for

Poisson equation for pressure p

27

Initial conditions – POWER.m (MATLAB code 2/2)

geometry

Approximation of viscosity derivatives

Approximate profiles u,v, ,

for power law fluid

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

dmjudx(1:nx,1:ny)=0; dmjudy(1:nx,1:ny)=0;

for i=2:nx-1

for j=2:ny-1

dmjudx(i,j)=(mju(i+1,j)-mju(i-1,j))/(2*hx)*dksidx(i,j)+(mju(i,j+1)-mju(i,j-1))/(2*hy)*detadx(i,j);

dmjudy(i,j)=(mju(i,j+1)-mju(i,j-1))/(2*hy)*detady(i,j);

end

end

for i=1:nx

dmjudx(i,1)=dmjudx(i,2);

dmjudx(i,ny)=dmjudx(i,ny-1);

end

for j=1:ny

dmjudx(1,j)=dmjudx(2,j);

dmjudx(nx,j)=dmjudx(nx-1,j);

end

Poisson equation for

Velocities, µ , BC for

Poisson equation for

Poisson equation for pressure p

% copy matrices

psin=psi; omegan=omega; un=u; vn=v;

dudxn=dudx; dudyn=dudy; dvdxn=dvdx; dvdyn=dvdy;

mjun=mju; dmjudxn=dmjudx(nx,ny); dmjudyn=dmjudy;

28

PSI Transformation of stream function into computational domain

Kontroloval: zitny

2 2

+

= −

𝜕𝑥 2 𝜕𝑦 2

Poisson equation for stream function

can be transformed into computational

domain using previously calculated metric

coefficients

𝜕 2 𝜓 𝜕 2 𝜕 2 𝜓

( ) + 2

𝜕𝜉 2 𝜕𝑥

𝜕

𝜕

𝜕𝑥

2

𝜕

+

𝜕𝑦

2

𝜕 2 𝜓 𝜕 𝜕 𝜕 𝜕 2

+2

+

= −

𝜕 𝜕𝑥 𝜕𝑥 𝜕 𝜕𝑥 2

𝜕2𝜓

𝜕2𝜓

𝜕2𝜓

𝜕

𝑔 + 2 𝑔𝑦𝑦 +

𝑔 +

𝑔 = −

𝜕𝜉 2 𝑥𝑥

𝜕

𝜕 𝑥𝑦 𝜕 𝑥

𝑔𝑥𝑥

𝜕

= ( )2

𝜕𝑥

𝜕

𝑔𝑦𝑦 =

𝜕𝑥

2

𝜕

+

𝜕𝑦

2

𝜕 𝜕

𝑔𝑥𝑦 = 2

𝜕𝑥 𝜕𝑥

𝜕2

𝑔𝑥 = 2

𝜕𝑥

29

PSI Discretization of stream function

Kontroloval: xxxxxx

=1

i,j+1

i,j

i,j-1

=0

=1

=0

hy

=2

hx

𝜕2𝜓

𝜕2𝜓

𝜕2𝜓

𝜕

𝑔 + 2 𝑔𝑦𝑦 +

𝑔 +

𝑔 = −

𝜕𝜉 2 𝑥𝑥

𝜕

𝜕 𝑥𝑦 𝜕 𝑥

𝑔𝑦𝑦

𝑔𝑥𝑥

−

2

+

+

𝑖−1,𝑗

𝑖,𝑗

𝑖+1,𝑗

2

2 𝑖,𝑗−1 − 2𝑖,𝑗 + 𝑖,𝑗+1

ℎ𝑥

ℎ𝑦

𝑔𝑥𝑦

𝑔𝑥

+

+ 𝑖−1,𝑗−1 − 𝑖−1,𝑗+1 − 𝑖+1,𝑗−1 +

− 𝑖,𝑗−1 = −𝑖𝑗

4ℎ𝑥 ℎ𝑦 𝑖+1,𝑗+1

2ℎ𝑦 𝑖,𝑗+1

30

PSI by alternation direction implicit method (ADI) Time evolution approximation

geometry

Approximate profiles u,v, ,

for power law fluid

PSI

iter=1,2,…

i=2..Nx-1

Sweep of tridiagonal system for in

horizontal direction (only smoothing)

This horizontal sweep

doesn’t work correctly.

Maybe because is almost

independent on

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

Poisson equation for

Velocities, µ , BC for

Poisson equation for

Poisson equation for pressure p

i=2..Nx-1

Sweep of tridiagonal system for

in vertical direction (sections i)

Norm of difference new-old and

repetition the PSI loop

31

PSI Discretization of stream function (time marching)

gxx … coefficients were calculated during INIT.m

1 −

2 1 2

=+

+

𝑡1

𝜕𝑥 2 𝜕𝑦 2

𝑔𝑥𝑥

𝜕 2

𝜕

= ( ) 𝑔𝑦𝑦 =

𝜕𝑥

𝜕𝑥

Kontroloval: xxxxxx

2

𝜕

+

𝜕𝑦

2

𝜕 𝜕

𝑔𝑥𝑦 = 2

𝜕𝑥 𝜕𝑥

𝜕2

𝑔𝑥 = 2

𝜕𝑥

2 − 1

2 1 2 2

=+

+

𝑡2

𝜕𝑥 2

𝜕𝑦 2

-implicit (horizontal lines) This part (-implicit step) does not work at tests

1𝑖𝑗

𝑡1

It was substituted by a simple filter, see the source code

𝑖𝑗 𝑔𝑦𝑦

𝑔𝑥𝑥

𝑔𝑥𝑥 1

𝑔𝑥𝑥

1

+

2

−

=

+ 2 𝑖,𝑗−1 − 2𝑖,𝑗 + 𝑖,𝑗+1

𝑖,𝑗

𝑖+1,𝑗

2

2

2

𝑡

ℎ𝑥

ℎ𝑥

ℎ𝑥

ℎ𝑦

1

𝑔𝑥

𝑖+1,𝑗+1 + 𝑖−1,𝑗−1 − 𝑖−1,𝑗+1 − 𝑖+1,𝑗−1 +

− 𝑖,𝑗−1 + 𝑖𝑗

2ℎ𝑦 𝑖,𝑗+1

− 1𝑖−1,𝑗

𝑔𝑥𝑦

+

4ℎ𝑥 ℎ𝑦

-implicit (vertical lines)

2𝑖𝑗

𝑔𝑦𝑦

𝑔𝑦𝑦 2

𝑔𝑦𝑦

𝑔𝑥

𝑔𝑥

2

− 𝑖,𝑗−1

−

+ 2 2 𝑖,𝑗 −

+

2𝑖,𝑗+1

2

2

𝑡2

2ℎ𝑦

2ℎ𝑦

ℎ𝑦

ℎ𝑦

ℎ𝑦

1𝑖𝑗 𝑔𝑥𝑥

𝑔𝑥𝑦

1

1

1

=

+ 2 𝑖−1,𝑗 − 2 𝑖,𝑗 + 𝑖+1,𝑗 +

1𝑖+1,𝑗+1 + 𝑖−1,𝑗−1 − 𝑖−1,𝑗+1 − 𝑖+1,𝑗−1 + 𝑖𝑗

𝑡2 ℎ𝑥

4ℎ𝑥 ℎ𝑦

32

PSI Discretization of stream function PSIE.m (MATLAB)

Kontroloval: xxxxxx

Estimated

dt2=(H/ny)^2*1e3; dt1=(Lk/nx)^2*1e3;

psiold=psi;

time step

for iter=1:20

% horizontal lines (only smoothing)

for j=2:ny-1

aa(1)=0;bb(1)=1;cc(1)=0;dd(1)=psi(1,j); aa(nx)=0;bb(nx)=1;cc(nx)=0;dd(nx)=psi(nx,j);

for i=2:nx-1

aa(i)=-gxx(i,j)/hx^2;

bb(i)=1/dt1+2*gxx(i,j)/hx^2;

cc(i)=-gxx(i,j)/hx^2;

dd(i)=psi(i,j)/dt1;

end

Soution of

psi(1:nx,j)=tridag(aa,bb,cc,dd,nx);

end

tridiagonal system

% vertical lines

by factorization

for i=2:nx-1

aa(1)=0;bb(1)=1;cc(1)=0;dd(1)=psi(i,1); aa(ny)=0;bb(ny)=1;cc(ny)=0;dd(ny)=psi(i,ny);

for j=2:ny-1

aa(j)=-gyy(i,j)/hy^2+gx(i,j)/(2*hy);

bb(j)=1/dt2+2*gyy(i,j)/hy^2;

cc(j)=-gyy(i,j)/hy^2-gx(i,j)/(2*hy);

ddxx=gxx(i,j)/hx^2*(psi(i-1,j)-2*psi(i,j)+psi(i+1,j));

ddxy=gxy(i,j)/(4*hx*hy)*(psi(i+1,j+1)+psi(i-1,j-1)-psi(i-1,j+1)-psi(i+1,j-1));

dd(j)=psi(i,j)/dt2+ddxx+ddxy+ddomega;

end

psi(i,:)=tridag(aa,bb,cc,dd,ny);

end

% norm of differences

sum=0;

for i=1:nx

for j=1:ny

sum=sum+abs(psi(i,j)-psiold(i,j));

end

end

sdev=sum/(nx*ny)/psiw;

disp(sprintf(' iter=%d relsum=%.5g',iter,sdev))

if sdev<0.00001

break

end

end

function u = tridag(a,b,c,r,n)

bet=b(1);

u(1)=r(1)/bet;

for j=2:n

gam(j)=c(j-1)/bet;

bet=b(j)-a(j)*gam(j);

u(j)=(r(j)-a(j)*u(j-1))/bet;

end

for j=n-1:-1:1

u(j)=u(j)-gam(j+1)*u(j+1);

end

ddomega=omega(i,j);

33

Post processing (velocities, viscosities, BC for vorticity) UVMBC.m

for i=2:nx-1

geometry

for j=2:ny-1

Approximate profiles u,v, ,

v(i,j)=-(psi(i+1,j)-psi(i-1,j))/(2*hx)*dksidx(i,j)-(psi(i,j+1)-psi(i,j-1))/(2*hy)*detadx(i,j);

for power law fluid

u(i,j)=(psi(i,j+1)-psi(i,j-1))/(2*hy)*detady(i,j);

end

iteration

end

Elastic stress sxx, syy, sxy

for i=2:nx-1

(hyperbolic MW)

for j=2:ny-1

Poisson equation for

dudx(i,j)=(u(i+1,j)-u(i-1,j))/(2*hx)*dksidx(i,j)+(u(i,j+1)-u(i,j-1))/(2*hy)*detadx(i,j);

dudy(i,j)=(u(i,j+1)-u(i,j-1))/(2*hy)*detady(i,j);

dvdx(i,j)=(v(i+1,j)-v(i-1,j))/(2*hx)*dksidx(i,j)+(v(i,j+1)-v(i,j-1))/(2*hy)*detadx(i,j);

dvdy(i,j)=(v(i,j+1)-v(i,j-1))/(2*hy)*detady(i,j);

Velocities, µ , BC for

end

end

Poisson equation for

for i=2:nx-1

for j=2:ny-1

mju(i,j)=K*(2*dudx(i,j)^2+2*dvdy(i,j)^2+(dudy(i,j)+dvdx(i,j))^2)^((n-1)/2);

end

Poisson equation for pressure p

end

for i=2:nx-1

for j=2:ny-1

dmjudx(i,j)=(mju(i+1,j)-mju(i-1,j))/(2*hx)*dksidx(i,j)+(mju(i,j+1)-mju(i,j-1))/(2*hy)*detadx(i,j);

dmjudy(i,j)=(mju(i,j+1)-mju(i,j-1))/(2*hy)*detady(i,j);

end

end

for i=1:nx

dmjudx(i,1)=dmjudx(i,2); dmjudx(i,ny)=dmjudx(i,ny-1);

end

for j=1:ny

dmjudx(1,j)=dmjudx(2,j); dmjudx(nx,j)=dmjudx(nx-1,j);

end

rlx=0.5;

for i=1:nx

omega(i,1)=omega(i,1)*(1-rlx)+rlx*2*psi(i,2)/hy^2*detady(i,1)^2;

omega(i,ny)=omega(i,ny)*(1-rlx)+rlx*2*(psi(i,ny-1)-psiw)/hy^2*(detadx(i,ny)^2+detady(i,ny)^2;

end

34

Decomposition extrastress on the elastic and viscous component

Kontroloval: zitny

Decomposition viscous stress tensor for purely viscous component (described by model GNF - Generalised

Newtonian Fluid) and the elastic component sij is apparently purposeless, but has the advantage that it leads

to an equation in which the vorticity dominates even at zero Re.

𝜕𝑢

𝜏𝑥𝑥 = 𝑠𝑥𝑥 + 2𝜇

𝜕𝑥

𝜕𝑣

𝜕𝑢

𝜏𝑦𝑦 = 𝑠𝑦𝑦 + 2𝜇

= 𝑠𝑦𝑦 − 2𝜇

𝜕𝑦

𝜕𝑥

𝜏𝑥𝑦

𝜕𝑢 𝜕𝑣

= 𝑠𝑥𝑦 + 𝜇( + )

𝜕𝑦 𝜕𝑥

It is only an approximation

of the corresponding

constant viscosity

Transport equations for vorticity (right side of the resultant elastic strain). From a purely hyperbolic transport

equation is zero Re turned out nice for elliptic equations (LAD - LAplacian Driven)

𝜕

𝜕

2 𝜔 2 𝜔

2

2

2

𝑢

+𝑣

−µ

+

=

𝑠 − 𝑠𝑥𝑥 +

−

𝑠

𝜕𝑥

𝜕𝑦

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑥𝑦 𝑦𝑦

𝜕𝑥 2 𝜕𝑦 2 𝑥𝑦

For comparison

𝜕

𝜕

𝑢

+𝑣

𝜕𝑥

𝜕𝑦

2

2

2

=

(𝜏 − 𝜏𝑥𝑥 ) + ( 2 − 2 ) 𝜏𝑥𝑦

𝜕𝑥𝑦 𝑦𝑦

𝜕𝑥

𝜕𝑦

35

Kontroloval:

Decomposition extrastress on the elastic and viscous component (variable

µ9zitny

The variable viscosity (non-zero first and second derivatives of viscosity). In addition Laplacian vorticity there

appears a number of terms (partial derivatives of velocity)

2

2

2

𝜏 − 𝜏𝑥𝑥 +

−

𝜏

𝜕𝑥𝑦 𝑦𝑦

𝜕𝑥 2 𝜕𝑦 2 𝑥𝑦

2

2

2

2 2

=

𝑠 − 𝑠𝑥𝑥 +

−

𝑠 +

+

𝜕𝑥𝑦 𝑦𝑦

𝜕𝑥 2 𝜕𝑦 2 𝑥𝑦

𝜕𝑥 2 𝜕𝑦 2

𝜕 𝜕

𝜕 𝜕

2 𝜕𝑣

2 2

+2

+2

+4

+

−

𝜕𝑥 𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑥𝑦 𝜕𝑦

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑣 𝜕𝑢

+

𝜕𝑥 𝜕𝑦

Neglecting second derivatives of viscosity (even the first derivatives are highly discontinuous and could be

causing problems during solution)

𝜕 𝜕

𝜕 𝜕

2 𝜔 2 𝜔

2

2

2

(𝑢 − 2 )

+ (𝑣 − 2 )

−µ

+

=

𝑠 − 𝑠𝑥𝑥 +

−

𝑠

𝜕𝑥 𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑥𝑦 𝑦𝑦

𝜕𝑥 2 𝜕𝑦 2 𝑥𝑦

36

Transformation vorticity into computational domain

Kontroloval: zitny

Transport equation for vorticity (variable viscosity)

𝜕 2 𝜕

−µ

𝜕𝜉 2 𝜕𝑥

2

𝜕2

+ 2

𝜕

𝜕

𝜕𝑥

2

𝜕

+

𝜕𝑦

2

𝜕 2 𝜕 𝜕

+2

+

𝜕 𝜕𝑥 𝜕𝑥

𝜕

𝜕µ 𝜕 𝜕

𝜕2

𝜕µ 𝜕

𝜕µ 𝜕

+

(𝑢 − 2 )

+

−µ 2 + (𝑣 − 2 )

+ (𝑢 − 2 )

𝜕

𝜕𝑥 𝜕𝑥 𝜕

𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑥 𝜕𝑥

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝜕 𝜕 𝜕𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝜕 2 𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝜕 𝜕 𝜕𝑠𝑥𝑦 𝜕 2

=

+

+

+

𝜕2

𝜕𝑦 𝜕𝑥

𝜕

𝜕𝑥𝑦

𝜕

𝜕𝑦 𝜕𝑥

𝜕 𝜕𝑥 2

𝜕 2 𝑠𝑥𝑦 𝜕 2 𝜕 2 𝑠𝑥𝑦 𝜕 2

𝜕 2 𝑠𝑥𝑦 𝜕 𝜕 𝜕 2 𝑠𝑥𝑦 𝜕 2

+

( ) +

( ) +2

−

( )

𝜕2 𝜕𝑥

𝜕2 𝜕𝑥

𝜕 𝜕𝑥 𝜕𝑥

𝜕2 𝜕𝑦

𝜕µ 𝜕

𝑣𝑥 = (𝑢 − 2 )

𝜕𝑥 𝜕𝑥

𝐷

𝐷𝑡 material derivative of

streamline

𝜕2

𝜕µ 𝜕

𝜕µ 𝜕

𝜕2

𝐷

𝜕µ 𝜕 𝜕µ 𝜕

𝑣𝑦 = −µ 2 + 𝑣 − 2

+ 𝑢 − 2

= −µ 2 +

− 2(

+

)

𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑥 𝜕𝑥

𝜕𝑥

𝐷𝑡

𝜕𝑥 𝜕𝑥 𝜕𝑦 𝜕𝑦

𝜕2

𝜕2

𝜕2

𝜕

𝜕

µ

𝑔 +

𝑔 +

𝑔

+

𝑣 +

𝑣

𝜕𝜉 2 𝑥𝑥 𝜕2 𝑦𝑦 𝜕 𝑥𝑦

𝜕 𝑥 𝜕 𝑦

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

=

𝑞1 +

𝑞2 +

𝑞3 +

𝑞 +

𝑞 +

𝑞 +

𝑞 −

𝑞

𝜕2

𝜕

𝜕

𝜕 4

𝜕2 5

𝜕2 6 𝜕 7

𝜕2 8

37

Discretized vorticity – central differences

Kontroloval: xxxxxx

𝜕2

𝜕2

𝜕2

𝜕

𝜕

−µ

𝑔 +

𝑔 +

𝑔

+

𝑣 +

𝑣

𝜕𝜉 2 𝑥𝑥 𝜕2 𝑦𝑦 𝜕 𝑥𝑦

𝜕 𝑥 𝜕 𝑦

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

=

𝑞1 +

𝑞2 +

𝑞3 +

𝑞 +

𝑞 +

𝑞 +

𝑞 −

𝑞

𝜕2

𝜕

𝜕

𝜕 4

𝜕2 5

𝜕2 6 𝜕 7

𝜕2 8

𝑔𝑦𝑦

𝑔𝑥𝑦

𝑔𝑥𝑥

µ

𝑖−1,𝑗 − 2𝑖,𝑗 + 𝑖+1,𝑗 + 2 𝑖,𝑗−1 − 2𝑖,𝑗 + 𝑖,𝑗+1 +

+ 𝑖−1,𝑗−1 − 𝑖−1,𝑗+1 − 𝑖+1,𝑗−1

4ℎ𝑥 ℎ𝑦 𝑖+1,𝑗+1

ℎ𝑥2

ℎ𝑦

𝑣𝑦

𝑣𝑥

+

(𝑖+1,𝑗 − 𝑖−1,𝑗 ) +

(

− 𝑖,𝑗−1 ) = 𝐺𝑖𝑗

2ℎ𝑥

2ℎ𝑦 𝑖,𝑗+1

Right hand size Gij is nonzero only for nozero stresses

𝐺𝑖𝑗

𝑞1

𝑞2

= 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖,𝑗+1 − 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖,𝑗 + 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖,𝑗−1 +

𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖,𝑗+1 − 𝑠𝑦𝑦 − 𝑠𝑥𝑥

2ℎ𝑦

ℎ𝑦

𝑞3

+

𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖+1,𝑗+1 + 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖−1,𝑗−1 − 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖+1,𝑗−1 − 𝑠𝑦𝑦 − 𝑠𝑥𝑥 𝑖−1,𝑗+1

4ℎ𝑥 ℎ𝑦

𝑞4

𝑞5

𝑞6 − 𝑞8

+

𝑠𝑥𝑦𝑖,𝑗+1 − 𝑠𝑥𝑦𝑖,𝑗−1 + 2 𝑠𝑥𝑦𝑖+1,𝑗 − 2𝑠𝑥𝑦𝑖,𝑗 + 𝑠𝑥𝑦𝑖−1,𝑗 +

𝑠𝑥𝑦𝑖,𝑗+1 − 2𝑠𝑥𝑦𝑖,𝑗 + 𝑠𝑥𝑦𝑖,𝑗−1

2ℎ𝑦

ℎ𝑥

ℎ𝑦2

𝑞7

+

𝑠

+ 𝑠𝑥𝑦𝑖−1,𝑗−1 − 𝑠𝑥𝑦𝑖−1,𝑗+1 − 𝑠𝑥𝑦𝑖+1,𝑗−1

4ℎ𝑥 ℎ𝑦 𝑥𝑦𝑖+1,𝑗+1

𝑖,𝑗−1

38

Discretised vorticity – upwind dif. at dominated convective transport

Kontroloval: xxxxxx

𝜕2

𝜕2

𝜕2

𝜕

𝜕

µ

𝑔 +

𝑔 +

𝑔

+

𝑣 +

𝑣

𝜕𝜉 2 𝑥𝑥 𝜕2 𝑦𝑦 𝜕 𝑥𝑦

𝜕 𝑥 𝜕 𝑦

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝜕𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑠𝑥𝑦

=

𝑞1 +

𝑞2 +

𝑞3 +

𝑞 +

𝑞 +

𝑞 +

𝑞 −

𝑞

𝜕2

𝜕

𝜕

𝜕 4

𝜕2 5

𝜕2 6 𝜕 7

𝜕2 8

Interpretation of these velocity components is not immediately apparent (may be negative)

𝜕µ 𝜕

𝑣𝑥 = (𝑢 − 2 )

𝜕𝑥 𝜕𝑥

𝜕2

𝜕µ 𝜕

𝜕µ 𝜕

𝑣𝑦 = µ 2 + (𝑣 − 2 )

+ (𝑢 − 2 )

𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑥 𝜕𝑥

𝑔𝑦𝑦

𝑔𝑥𝑦

𝑔𝑥𝑥

−

2

+

+

−

2

+

+

𝑖+1,𝑗+1 + 𝑖−1,𝑗−1 − 𝑖−1,𝑗+1 − 𝑖+1,𝑗−1

𝑖−1,𝑗

𝑖,𝑗

𝑖+1,𝑗

𝑖,𝑗−1

𝑖,𝑗

𝑖,𝑗+1

2

2

4ℎ

ℎ

ℎ𝑥

ℎ𝑦

𝑥 𝑦

µ

+

𝑣𝑦 + 𝑣𝑦

𝑣𝑦 − 𝑣𝑦

𝑣𝑥 + 𝑣𝑥

𝑣𝑥 − 𝑣𝑥

(𝑖,𝑗 − 𝑖−1,𝑗 ) +

(𝑖+1,𝑗 − 𝑖,𝑗 ) +

(𝑖,𝑗 − 𝑖,𝑗−1 ) +

(𝑖,𝑗+1 − 𝑖,𝑗 ) = 𝐺𝑖𝑗

2ℎ𝑥

2ℎ𝑥

2ℎ𝑦

2ℎ𝑦

Comparing the size of the convective and diffusive member

𝜕 2 𝜕 2

𝜕 𝜕 2

𝜕

(

)

+

⋯

+

µ

+

𝑢

+⋯

𝜕𝜉 2 𝜕𝑥

𝜕

𝜕𝑥 2

𝜕𝑥

39

Boundary conditions – vorticity

Kontroloval: xxxxxx

The boundary conditions for vorticity resulting from the requirement of zero velocity on the wall u = v = 0 =0, 1

𝜕 𝜕

𝜕 𝜕 1 𝜕 2𝐸2 (1 − )(1 − 𝜅)

𝑢=𝑣=0

=

=0

=

+

=0

𝜕𝑥 𝜕𝑦

𝜕𝑥 𝜕 𝐿𝑘 𝜕 (1 − (1 − )𝐸) 𝐿𝑘

𝜕 𝜕

1

=

=0

𝜕𝑦 𝜕 (1 − (1 − )𝐸) 𝐻

It follows from these equations that the first partial derivative must be zero in physical and computational plane. In the

computational plane complete quadratic polynomial will replace the stream function around a node on the wall

2 + 𝑎 2 + 𝑎

=

𝑎

+

𝑎

+

𝑎

+

𝑎

0

1

2

3

4

5

i,j=Ny

=1

Six polynomial coefficients should ensure 4 values in

hy

nodes and two conditions of zero derivatives at point

i,Ny-1

i,Ny. Coefficients of coordinates are zero.

=0

i,j=1

=0

=2

𝑖,𝑁𝑦−1 − 𝑤

() = 𝑤 +

(1 − )2

=1 Gaussian wall

2

ℎ𝑦

𝑖,2 2

()

=

=0 plain wall

2

ℎ𝑦

40

Boundary conditions – vorticity

Kontroloval: xxxxxx

Substituting the definition of a polynomial we get a strong vorticity boundary condition at Gaussian wall

geometry

𝜕2𝜓

𝑤 = − 2

𝜕

𝜕

𝜕𝑥

2

2

𝜕

+

𝜕𝑦

𝑖,𝑁𝑦−1 − 𝑤 2𝐸2 1 − 1 − 𝜅

=2

(

1 − 1 − 𝐸 𝐿𝑘

ℎ𝑦2

2

+

1

Approximate profiles u,v, ,

for power law fluid

2)

1− 1− 𝐸 𝐻

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

Strong boundary condition at the bottom wall

𝜕2𝜓

𝑤 = − 2

𝜕

𝜕

𝜕𝑥

2

2

𝜕

+

𝜕𝑦

𝑖,2

=2 2

ℎ𝑦

Poisson equation for

Velocities, µ , BC for

1

1− 1− 𝐸 𝐻

Poisson equation for

2

Boundary conditions for , at input and output expect stabilized velocity profile

Poisson equation for pressure p

-3

6

x 10

𝐻 ∗ = 𝐻(1 − 1 − 𝑒 − )

2

5

4

3

5

=1

y

2

1

0

0

0.05

0.1

x

0.15

0.2

x 10

)

-3

4.5

=0

0.25

0.3

0.35

0.4

where um is the maximum velocity in the flow channel

axis (width H) corresponding to a power law fluid flow

index n

4

3.5

3

y [m]

H

Velocity profile at inlet (for y<H*/2)

2𝑦

𝑢 𝑦 = 𝑢𝑚 (1 − 1 − ∗

𝐻

𝑛+1

𝑛

2.5

2

1.5

1

0.5

0

0

0.02

0.04

0.06

u

41

0.08

0.1

Boundary conditions – stream function and vorticity

𝐻 ∗ = 𝐻(1 − 1 − 𝑒 − )

2

Boundary conditions for , at inlet and outlet with gap thickness

𝐻 2𝑦

𝑛

2𝑦

2𝑦 2𝑛+1

𝑦 = 𝑢𝑚 ( ∗ −

(1 − 𝑠𝑖𝑔𝑛(1 − ∗ )|1 − ∗ | 𝑛 ))

2 𝐻

2𝑛 + 1

𝐻

𝐻

Stream function at inlet

Overall flowrate

𝑛+1

𝑤 =

𝑢 𝐻

2𝑛 + 1 𝑚

-3

5

4.5

4.5

4

4

3.5

3.5

3

3

y [m]

y [m]

x 10

is the boundary condition for at upper wall (w=0 at bottom wall)

1

𝜕𝑢

𝑛 + 1 2𝑢𝑚 2𝑦

𝑛

=−

=−

( − 1)

𝜕𝑦

𝑛 𝐻∗ 𝐻∗

Vorticity at inlet and outlet

5

2.5

2

1.5

1.5

1

1

0.5

0.5

0

1

2

3

psi

4

5

6

x 10

-4

x 10

Approximation valid only

for fully developed

velocity profile

-3

2.5

2

0

Kontroloval: xxxxxx

0

-140

-120

-100

-80

-60

omega

-40

-20

0

42

Iterative solution of OMG.m

geometry

Approximate profiles u,v, ,

for power law fluid

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

OMG

Poisson equation for

Velocities, µ , BC for

Nodal velocities and boundary

conditions for ()

i=2..Nx-1

Poisson equation for

Poisson equation for pressure p

Solution of tridiagonal systém

for in vertical direction i.

(upwind)

43

Iterative solution of (OMG.m)

Previously derived transport by pseudovelocities and implementation of upwind

𝜕µ 𝜕

𝜕2

𝜕µ 𝜕

𝜕µ 𝜕

𝑣𝑥 = (𝑢 − 2 )

𝑣𝑦 = µ 2 + (𝑣 − 2 )

+ (𝑢 − 2 )

𝜕𝑥 𝜕𝑥

𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑥 𝜕𝑥

𝑣𝑥 + 𝑣𝑥

𝑣𝑥 − 𝑣𝑥

𝑣𝑦 + 𝑣𝑦

𝑣𝑦 − 𝑣𝑦

𝑉𝑥𝑝 =

𝑉𝑥𝑚 =

𝑉𝑦𝑝 =

𝑉𝑦𝑚 =

2µℎ𝑥

2µℎ𝑥

2µℎ𝑦

2µℎ𝑦

In a similar way like solution of stream function we separate discretized algebraic equations for vorticity to the

time marching solution consisting in horizontal sweep (time step dt1) and vertical sweep (time step dt2).

2𝑖,𝑗

1𝑖𝑗 𝑔𝑥𝑥

𝑔𝑦𝑦

𝑔

𝑔

1

𝑦𝑦

𝑦𝑦

+ 2 2 − 𝑉𝑦𝑝 + 𝑉𝑦𝑚 − 2𝑖,𝑗−1

− 𝑉𝑦𝑝 − 2𝑖,𝑗+1

+ 𝑉𝑦𝑚 =

+

𝑖−1,𝑗 − 2𝑖,𝑗 + 𝑖+1,𝑗

2

𝑡2

𝑡2 ℎ𝑥2

ℎ𝑦

ℎ𝑦

ℎ𝑦2

𝑔𝑥𝑦

𝐺𝑖𝑗

+𝑉𝑥𝑝 𝑖,𝑗 − 𝑖−1,𝑗 + 𝑉𝑥𝑚 𝑖+1,𝑗 − 𝑖,𝑗 +

+ 𝑖−1,𝑗−1 − 𝑖−1,𝑗+1 − 𝑖+1,𝑗−1 −

4ℎ𝑥 ℎ𝑦 𝑖+1,𝑗+1

𝜕 𝜕

𝑞1 =

𝜕𝑦 𝜕𝑥

𝜕2

𝑞2 =

𝜕𝑥𝑦

𝜕 𝜕

𝑞3 =

𝜕𝑦 𝜕𝑥

𝜕2

𝑞4 = 2

𝜕𝑥

𝑞5 = (

𝜕 2

)

𝜕𝑥

𝑞6 = (

𝜕 2

)

𝜕𝑥

𝑞7 = 2

𝜕 𝜕

𝜕𝑥 𝜕𝑥

𝑞8 = (

𝐺𝑖𝑗

𝑞1

𝑞2

= 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

− 2 𝑠𝑦𝑦 − 𝑠𝑥𝑥

+ 𝑠𝑦𝑦 − 𝑠𝑥𝑥

+

𝑠𝑦𝑦 − 𝑠𝑥𝑥

− 𝑠𝑦𝑦 − 𝑠𝑥𝑥

𝑖,𝑗+1

𝑖,𝑗

𝑖,𝑗−1

𝑖,𝑗+1

𝑖,𝑗−1

2ℎ𝑦

ℎ𝑦

𝑞3

𝑞4

+

𝑠𝑦𝑦 − 𝑠𝑥𝑥

+ 𝑠𝑦𝑦 − 𝑠𝑥𝑥

− 𝑠𝑦𝑦 − 𝑠𝑥𝑥

− 𝑠𝑦𝑦 − 𝑠𝑥𝑥

+

𝑠

− 𝑠𝑥𝑦𝑖,𝑗−1

𝑖+1,𝑗+1

𝑖−1,𝑗−1

𝑖+1,𝑗−1

𝑖−1,𝑗+1

4ℎ𝑥 ℎ𝑦

2ℎ𝑦 𝑥𝑦𝑖,𝑗+1

𝑞5

𝑞6 − 𝑞8

𝑞7

+ 2 𝑠𝑥𝑦𝑖+1,𝑗 − 2𝑠𝑥𝑦𝑖,𝑗 + 𝑠𝑥𝑦𝑖−1,𝑗 +

𝑠

−

2𝑠

+

𝑠

+

𝑠

+ 𝑠𝑥𝑦𝑖−1,𝑗−1 − 𝑠𝑥𝑦𝑖−1,𝑗+1 − 𝑠𝑥𝑦𝑖+1,𝑗−1

𝑥𝑦𝑖,𝑗+1

𝑥𝑦𝑖,𝑗

𝑥𝑦𝑖,𝑗−1

4ℎ𝑥 ℎ𝑦 𝑥𝑦𝑖+1,𝑗+1

ℎ𝑥

ℎ𝑦2

44

𝜕 2

)

𝜕𝑦

Iterative solution of OMG.m

%vorticity

omegaold=omega;

for iter=1:20

%vertical sweep

for i=2:nx-1

aa(1)=0;bb(1)=1;cc(1)=0;dd(1)=omega(i,1); aa(ny)=0;bb(ny)=1;cc(ny)=0;dd(ny)=omega(i,ny);

for j=2:ny-1

vx=(rho*u(i,j)-2*dmjudx(i,j))*dksidx(i,j);

vy=(rho*v(i,j)-2*dmjudy(i,j))*detady(i,j)+mju(i,j)*detadxdx(i,j);

Vxp=(vx+abs(vx))/(2*mju(i,j)*hx);

Vxn=(vx-abs(vx))/(2*mju(i,j)*hx);

Vyp=(vy+abs(vy))/(2*mju(i,j)*hy);

Vym=(vy-abs(vy))/(2*mju(i,j)*hy);

G1=q1(i,j)/hy^2*(syy(i,j+1)-sxx(i,j+1)-2*(syy(i,j)-sxx(i,j))+syy(i,j-1)-sxx(i,j-1));

G2=q2(i,j)/(2*hy)*(syy(i,j+1)-sxx(i,j+1)-syy(i,j-1)+sxx(i,j-1));

G3=q3(i,j)/(4*hx*hy)*(syy(i+1,j+1)-sxx(i+1,j+1)+syy(i-1,j-1)-sxx(i-1,j-1)-syy(i+1,j-1)+sxx(i+1,j-1)-syy(i-1,j+1)+syy(i-1,j+1));

G4=q4(i,j)/(2*hy)*(sxy(i,j+1)-sxy(i,j-1));

G5=q5(i,j)/hx^2*(sxy(i+1,j)-2*sxy(i,j)+sxy(i-1,j));

G6=(q6(i,j)-q8(i,j))/hy^2*(sxy(i,j+1)-sxy(i,j)+sxy(i,j-1));

G7=q7(i,j)/(4*hx*hy)*(sxy(i+1,j+1)+sxy(i-1,j-1)-sxy(i-1,j+1)-sxy(i+1,jk-1));

Gij=G1+G2+G3+G4+G5+G6+G7;

aa(j)=-gyy(i,j)/hy^2+Vyp;

cc(j)=-gyy(i,j)/hy^2-Vym;

bb(j)=1/dt2+2*gyy(i,j)/hy^2-Vyp+Vym;

dd1=omega(i,j)/dt2+gxx(i,j)/hx^2*(omega(i-1,j)-2*omega(i,j)+omega(i+1,j));

dd2=Vxp*(omega(i,j)-omega(i-2,j))+Vxm*(omega(i+1,j)-omega(i,j));

dd3=gxy(i,j)/(4*hx*hy)*(omega(i+1,j+1)+omega(i-1,j-1)-omega(i+1,j-1)-omega(i-1,j+1));

dd(j)=dd1+dd2+dd3-Gij/mju(i,j);

end

omega(i,:)=tridag(aa,bb,cc,dd,ny);

end

sum=0;

for i=1:nx

for j=1:ny

sum=sum+abs(omega(i,j)-omegaold(i,j));

end

end

sdev=sum/(nx*ny)/psiw; disp(sprintf(' iter=%d relsum=%.5g',iter,sdev))

if sdev<0.00001

break

end

end

45

Constitutive equations White Metzner.

Geometry

Approximate profiles u,v, , for power law fluid

iteration

Elastic stress sxx, syy, sxy (hyperbolické MW)

When you skip these three

sections (iterative refinement of

the stream function and vorticity)

will result Pavlovec approximation

of the solution, but for a smooth

Gaussian gap profile.

Poisson equation for

Nodal velocities and viscosity. BC for

Poisson equation for

Poisson equation for pressure p

46

Constitutive equation White Metzner.

Kontroloval: xxxxxx

2

𝑠𝑥𝑥

2𝜇 𝜕𝑢

𝜇

𝜕𝑠𝑥𝑥

𝜕𝑠𝑥𝑥

2𝜇 𝜕𝑢

2𝜇2 𝜕 2 𝑢

𝜕2𝑣

𝜕𝑢

1−

+

𝑢

+𝑣

=

𝑠𝑥𝑦 −

(𝑢 2 − 𝑣 2 − 2

𝐺 𝜕𝑥

𝐺

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝑦

𝐺

𝜕𝑥

𝜕𝑦

𝜕𝑥

2

𝑠𝑦𝑦

𝜕𝑠𝑦𝑦

𝜕𝑠𝑦𝑦

2𝜇 𝜕𝑢

𝜇

2𝜇 𝜕𝑣

2𝜇2 𝜕 2 𝑢

𝜕2𝑣

𝜕𝑣

1+

+

𝑢

+𝑣

=

𝑠𝑥𝑦 +

(𝑢 2 − 𝑣 2 + 2

𝐺 𝜕𝑥

𝐺

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝑥

𝐺

𝜕𝑥

𝜕𝑦

𝜕𝑦

𝜕𝑢

−

𝜕𝑦

2

𝜕𝑣

+

𝜕𝑥

2

−

𝜕𝑢 𝜕𝑣

)

𝜕𝑦 𝜕𝑥

+

𝜕𝑢 𝜕𝑣

)

𝜕𝑦 𝜕𝑥

𝜕𝑠𝑥𝑦

𝜕𝑠𝑥𝑦

𝜇

𝜇 𝜕𝑣

𝜕𝑢

𝜇2

𝜕2𝑣 𝜕2𝑣

𝜕2𝑢 𝜕2𝑢

𝜕𝑢 𝜕𝑣

𝜕𝑢 𝜕𝑣

𝑠𝑥𝑦 +

𝑢

+𝑣

=

𝑠 +

𝑠

− (𝑢

−

+𝑣

−

−2

−2

)

𝐺

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝑥 𝑥𝑥 𝜕𝑦 𝑦𝑦

𝐺

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑦 2 𝜕𝑥 2

𝜕𝑥 𝜕𝑥

𝜕𝑦 𝜕𝑦

𝜕𝑣 𝜕𝑣 𝜕𝑢

= −2 ( − )

𝜕𝑦 𝜕𝑥 𝜕𝑦

47

Kontroloval: xxxxxx

Constitutive equation White Metzner. Boundary conditions (BC) at wall.

For upper curved wall

𝑠𝑥𝑥

𝑠𝑦𝑦

𝑠𝑥𝑦

2𝜇 𝜕𝑢

2𝜇 𝜕𝑢

2𝜇2

𝜕𝑢

1−

=

𝑠𝑥𝑦 +

(2

𝐺 𝜕𝑥

𝐺 𝜕𝑦

𝐺

𝜕𝑥

2

2𝜇 𝜕𝑢

2𝜇 𝜕𝑣

2𝜇2

𝜕𝑣

1+

=

𝑠 +

(2

𝐺 𝜕𝑥

𝐺 𝜕𝑥 𝑥𝑦

𝐺

𝜕𝑦

2

𝜕𝑢

+

𝜕𝑦

2

𝜕𝑣

+

𝜕𝑥

2

+

𝜕𝑢 𝜕𝑣

)

𝜕𝑦 𝜕𝑥

System of 3 linear algebraic

equations for 3 unknowns

𝜕𝑢 𝜕𝑣

+

)

𝜕𝑦 𝜕𝑥

2𝜇2 𝜕𝑢

𝜇 𝜕𝑣

𝜕𝑢

𝜕𝑣 𝜕𝑢

=

𝑠𝑥𝑥 +

𝑠𝑦𝑦 +

( − )

𝐺 𝜕𝑥

𝜕𝑦

𝐺 𝜕𝑥 𝜕𝑥 𝜕𝑦

2𝜇 𝜕𝑢

1−

𝐺 𝜕𝑥

0

−

𝜇 𝜕𝑣

𝐺 𝜕𝑥

0

2𝜇 𝜕𝑢

1+

𝐺 𝜕𝑥

𝜇 𝜕𝑢

−

𝐺 𝜕𝑦

2𝜇 𝜕𝑢

−

𝐺 𝜕𝑦

2𝜇 𝜕𝑣

−

𝐺 𝜕𝑥

1

𝑠𝑥𝑥

𝑠𝑦𝑦 =

𝑠𝑥𝑦

2𝜇 2

𝜕𝑢

(2

𝐺

𝜕𝑥

2

2

𝜕𝑢

+

𝜕𝑦

2

+

𝜕𝑢 𝜕𝑣

)

𝜕𝑦 𝜕𝑥

2

2𝜇 2

𝜕𝑣

𝜕𝑣

𝜕𝑢 𝜕𝑣

(2

+

+

)

𝐺

𝜕𝑦

𝜕𝑥

𝜕𝑦 𝜕𝑥

2𝜇 2 𝜕𝑢 𝜕𝑣 𝜕𝑢

( − )

𝐺 𝜕𝑥 𝜕𝑥 𝜕𝑦

For bottom (planar) wall

𝑠𝑥𝑥

2𝜇2 𝜕𝑢

=

𝐺 𝜕𝑦

𝑠𝑦𝑦 = 0

2

At wall with transducers is

syy=0 and yy =0.

It offers the possibility to integrate WM

hyperbolic equations from left to right and

bottom to top

𝑠𝑥𝑦 = 0

48

Transformation of constitutive equations White Metzner.

𝑠𝑥𝑥 1 −

Kontroloval: xxxxxx

2𝜇 𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

𝜇

𝜕𝑠𝑥𝑥 𝜕𝜉 𝜕𝑠𝑥𝑥 𝜕𝜂

𝜕𝑠𝑥𝑥 𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

(

+

) +

𝑢(

+

) +𝑣

=

𝑠

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝐺

𝜕𝜉 𝜕𝑥

𝜕𝜂 𝜕𝑥

𝜕 𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦

2

2

2𝜇2

𝜕𝑢 𝜕 2 𝜂 𝜕 2 𝑢 𝜕𝜉

𝜕 2 𝑢 𝜕𝜂

𝜕 2 𝑢 𝜕𝜂 𝜕𝜉

𝜕 2 𝑣 𝜕𝜂

−

(𝑢(

+

+ 2

+2

)−𝑣 2

𝐺

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

𝜕𝜂 𝜕𝑥

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

𝜕𝜂 𝜕𝑦

2

2

𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

𝜕𝑢 𝜕𝜂

𝜕𝑢 𝜕𝜂 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

−2

+

−

−

(

+

))

𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝜂 𝜕𝑦

𝜕𝜂 𝜕𝑦 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝑠𝑦𝑦 1 +

2

𝜕𝑠𝑦𝑦 𝜕𝜉 𝜕𝑠𝑦𝑦 𝜕𝜂

𝜕𝑠𝑦𝑦 𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

𝜇

2𝜇 𝜕𝑢 𝜕𝜂

(

+

) +

𝑢(

+

) +𝑣

=

𝑠

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝐺

𝜕𝜉 𝜕𝑥

𝜕𝜂 𝜕𝑥

𝜕 𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦

2

2

2𝜇2

𝜕𝑢 𝜕 2 𝜂 𝜕 2 𝑢 𝜕𝜉

𝜕 2 𝑢 𝜕𝜂

𝜕 2 𝑢 𝜕𝜂 𝜕𝜉

𝜕 2 𝑣 𝜕𝜂

+

(𝑢(

+

+ 2

+2

)−𝑣 2

𝐺

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

𝜕𝜂 𝜕𝑥

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

𝜕𝜂 𝜕𝑦

2

2

𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

𝜕𝑢 𝜕𝜂 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

+2

+

+

+

+

(

+

))

𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝜂 𝜕𝑦 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

2

𝜕𝑠𝑥𝑦 𝜕𝜉 𝜕𝑠𝑥𝑦 𝜕

𝜇

𝜕𝑠𝑥𝑦 𝜕𝜂

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

𝜕𝑢 𝜕𝜂

𝑠𝑥𝑦 +

𝑢(

+

)+𝑣

=

(

+

)𝑠 +

𝑠

𝐺

𝜕 𝜕𝑥

𝜕 𝜕𝑥

𝜕𝜂 𝜕𝑦

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝑥𝑥 𝜕𝜂 𝜕𝑦 𝑦𝑦

𝜇2

𝜕𝑣 𝜕 2 𝜂 𝜕 2 𝑣 𝜕𝜉

− (𝑢

+

𝐺

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

𝜕 2 𝑢 𝜕𝜂 2 𝜕𝑢 𝜕 2 𝜂 𝜕 2 𝑢 𝜕𝜉

+𝑣

( ) −

−

𝜕𝜂2 𝜕𝑦

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

2

2

𝜕 2 𝑣 𝜕𝜂

+ 2

𝜕𝜂 𝜕𝑥

𝜕 2 𝑢 𝜕𝜂

− 2

𝜕𝜂 𝜕𝑥

2

2

𝜕 2 𝑣 𝜕𝜂 𝜕𝜉 𝜕 2 𝑣 𝜕𝜂

+2

−

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥 𝜕𝜂2 𝜕𝑦

2

𝜕 2 𝑢 𝜕𝜂 𝜕𝜉

𝜕𝑣 𝜕𝜂 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂 𝜕𝑢 𝜕𝜂

−2

−2

(

+

−

))

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

𝜕𝜂 𝜕𝑦 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝜕𝜂 𝜕𝑦

49

Transformation of constitutive equations White Metzner (auxilliary variables)

𝑠𝑥𝑥

𝑠𝑦𝑦

Kontroloval: xxxxxx

2𝜇 𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

𝐴=

(

+

)

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜇 𝜕𝑠𝑥𝑥 𝜕𝜉 𝜕𝑠𝑥𝑥 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1−𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠 − 𝑄𝑥𝑥

𝐺 𝜕𝜉 𝜕𝑥

𝜕𝜂

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦

Interpretation as

material derivative

𝜇 𝜕𝑠𝑦𝑦 𝜕𝜉 𝜕𝑠𝑦𝑦 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1+𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠 + 𝑄𝑦𝑦

𝐺 𝜕𝜉 𝜕𝑥

𝜕𝜂

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦

𝐷

𝜕𝜂

𝜕𝜂

=𝑢

+𝑣

𝐷𝑡

𝜕𝑥

𝜕𝑦

(corresponding to motion of fluid

particle along =konst)

𝜇 𝜕𝑠𝑥𝑦 𝜕𝜉 𝜕𝑠𝑥𝑦 𝜕

𝜕𝜂

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

𝜕𝑢 𝜕𝜂

𝑠𝑥𝑦 +

𝑢

+

(𝑢

+𝑣 ) =

(

+

)𝑠𝑥𝑥 +

𝑠

− 𝑄𝑥𝑦

𝐺 𝜕 𝜕𝑥

𝜕

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝜂 𝜕𝑦 𝑦𝑦

2𝜇2

𝜕𝑢 𝜕 2 𝜂 𝜕 2 𝑢 𝜕𝜉

=

(𝑢(

+

𝐺

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

2

2𝜇2

𝜕𝑢 𝜕 2 𝜂 𝜕 2 𝑢 𝜕𝜉

𝑄𝑦𝑦 =

(𝑢(

+

𝐺

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

2

𝜇2

𝜕𝑣 𝜕 2 𝜂 𝜕 2 𝑣 𝜕𝜉

𝑄𝑥𝑦 = (𝑢

+

𝐺

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

2

𝑄𝑥𝑥

𝜕 2 𝑢 𝜕𝜂

+ 2

𝜕𝜂 𝜕𝑥

2

𝜕 2 𝑢 𝜕𝜂

+ 2

𝜕𝜂 𝜕𝑥

2

𝜕 2 𝑣 𝜕𝜂

+ 2

𝜕𝜂 𝜕𝑥

2

𝜕 2 𝑢 𝜕𝜂 𝜕𝜉

𝜕 2 𝑣 𝜕𝜂

+2

)−𝑣 2

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

𝜕𝜂 𝜕𝑦

2

𝜕 2 𝑢 𝜕𝜂 𝜕𝜉

𝜕 2 𝑣 𝜕𝜂

+2

)−𝑣 2

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

𝜕𝜂 𝜕𝑦

2

2

𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

−2

+

𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

2

𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

+2

+

𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

2

𝜕 2 𝑣 𝜕𝜂 𝜕𝜉 𝜕 2 𝑣 𝜕𝜂

𝜕 2 𝑢 𝜕𝜂

+2

−

+𝑣

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥 𝜕𝜂2 𝜕𝑦

𝜕𝜂2 𝜕𝑦

𝜕𝑣 𝜕𝜂 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂 𝜕𝑢 𝜕𝜂

−2

(

+

−

))

𝜕𝜂 𝜕𝑦 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝜕𝜂 𝜕𝑦

2

𝜕𝑢 𝜕𝜂

−

𝜕𝜂 𝜕𝑦

2

−

𝜕𝑢 𝜕𝜂 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

(

+

))

𝜕𝜂 𝜕𝑦 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝑢 𝜕𝜉 𝜕𝑢 𝜕𝜂

+

+

𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕𝑢 𝜕 2 𝜂 𝜕 2 𝑢 𝜕𝜉

−

−

𝜕𝜂 𝜕𝑥 2 𝜕𝜉 2 𝜕𝑥

2

2

+

𝜕𝑢 𝜕𝜂 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

(

+

))

𝜕𝜂 𝜕𝑦 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝜕 2 𝑢 𝜕𝜂

− 2

𝜕𝜂 𝜕𝑥

2

𝜕 2 𝑢 𝜕𝜂 𝜕𝜉

−2

𝜕𝜉𝜕𝜂 𝜕𝑥 𝜕𝑥

50

Discretized constitutive equation White Metzner (UP direction)

geometry

=1

=0

Kontroloval: xxxxxx

i-1,j

i,j

𝑠𝑥𝑥 𝑖,1 =

hy

i,j-1

=0

i,j=1

=2

2𝜇

𝐺

2

𝜕𝑢

𝜕𝑦

2

Approximate profiles u,v, ,

for power law fluid

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

𝑠𝑦𝑦 𝑖,1 = 0

Poisson equation for

Velocities, µ , BC for

𝑠𝑥𝑦 𝑖,1 = 0

Poisson equation for

Poisson equation for pressure p

𝑠𝑥𝑥 𝑖,𝑗

𝜇 𝑠𝑥𝑥 𝑖,𝑗 − 𝑠𝑥𝑥 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑥 𝑖,𝑗 − 𝑠𝑥𝑥 𝑖,𝑗−1 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1−𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠

− 𝑄𝑥𝑥

𝐺

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝑠𝑦𝑦 𝑖, 𝑗

𝜇 𝑠𝑦𝑦 𝑖,𝑗 − 𝑠𝑦𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑦𝑦 𝑖,𝑗 − 𝑠𝑦𝑦 𝑖,𝑗−1 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1+𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠

+ 𝑄𝑦𝑦

𝐺

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝜇 𝑠𝑥𝑦 𝑖,𝑗 − 𝑠𝑥𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑦 𝑖,𝑗 − 𝑠𝑥𝑦 𝑖,𝑗−1 𝜕

𝜕𝜂

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

𝜕𝑢 𝜕𝜂

𝑠𝑥𝑦 𝑖,𝑗 +

𝑢

+

(𝑢

+𝑣 ) =

(

+

)𝑠

+

𝑠

− 𝑄𝑥𝑦

𝐺

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝑥𝑥 𝑖,𝑗 𝜕𝜂 𝜕𝑦 𝑦𝑦 𝑖,𝑗

51

Discretized constitutive equation White Metzner (UP direction).

Kontroloval: xxxxxx

Resulting system of algebraic equations for three stresses at point i,j evaluated from

stresses at left and from bottom

𝜇 𝑢 𝜕 𝑢 𝜕 𝑣 𝜕

1−𝐴+ (

+

+

)

𝐺 ℎ𝑥 𝜕𝑥 ℎ𝑦 𝜕𝑥 ℎ𝑦 𝜕𝑦

0

=

𝜇

𝐺

𝜇

𝐺

𝜇

𝐺

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

− (

+

)

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝑠𝑥𝑥 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑥 𝑖,𝑗−1 𝜕𝜂

𝑢

+

(𝑢

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝑠𝑦𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑦𝑦 𝑖,𝑗−1 𝜕𝜂

𝑢

+

(𝑢

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝑠𝑥𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑦 𝑖,𝑗−1 𝜕𝜂

𝑢

+

(𝑢

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

2𝜇 𝜕𝑢 𝜕𝜂

0

−

𝐺 𝜕𝜂 𝜕𝑦

𝜇 𝑢 𝜕 𝑢 𝜕 𝑣 𝜕

2𝜇 𝜕𝑢 𝜕𝜂

1+𝐴+ (

+

+

)

−

𝐺 ℎ𝑥 𝜕𝑥 ℎ𝑦 𝜕𝑥 ℎ𝑦 𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦

𝜇 𝜕𝑢 𝜕𝜂

𝜇 𝑢 𝜕 𝑢 𝜕 𝑣 𝜕

−

1+ (

+

+

)

𝐺 𝜕𝜂 𝜕𝑦

𝐺 ℎ𝑥 𝜕𝑥 ℎ𝑦 𝜕𝑥 ℎ𝑦 𝜕𝑦

𝜕𝜂

+ 𝑣 ) − 𝑄𝑥𝑥

𝜕𝑦

𝜕𝜂

+ 𝑣 ) − 𝑄𝑦𝑦

𝜕𝑦

𝜕𝜂

+ 𝑣 ) − 𝑄𝑥𝑦

𝜕𝑦

𝑠𝑥𝑥 , 𝑖𝑗

𝑠𝑦𝑦 , 𝑖𝑗

𝑠𝑥𝑦 , 𝑖𝑗

52

Discretized constitutive equation White Metzner (DOWN direction)

geometry

=1

i-1,j

=0

Kontroloval: xxxxxx

=0

i,j+1

i,j

i,j=1

𝑠𝑥𝑥 𝑖,1 =

hy

=2

2𝜇

𝐺

2

𝜕𝑢

𝜕𝑦

2

Approximate profiles u,v, ,

for power law fluid

iteration

Elastic stress sxx, syy, sxy

(hyperbolic MW)

𝑠𝑦𝑦 𝑖,1 = 0

Poisson equation for

Velocities, µ , BC for

𝑠𝑥𝑦 𝑖,1 = 0

Poisson equation for

Poisson equation for pressure p

𝑠𝑥𝑥 𝑖,𝑗

𝜇 𝑠𝑥𝑥 𝑖,𝑗 − 𝑠𝑥𝑥 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑥 𝑖,𝑗+1 − 𝑠𝑥𝑥 𝑖,𝑗 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1−𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠

− 𝑄𝑥𝑥

𝐺

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝑠𝑦𝑦 𝑖, 𝑗

𝜇 𝑠𝑦𝑦 𝑖,𝑗 − 𝑠𝑦𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑦𝑦 𝑖,𝑗+1 − 𝑠𝑦𝑦 𝑖,𝑗 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1+𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠

+ 𝑄𝑦𝑦

𝐺

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝜇 𝑠𝑥𝑦 𝑖,𝑗 − 𝑠𝑥𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑦 𝑖,𝑗+1 − 𝑠𝑥𝑦 𝑖,𝑗 𝜕

𝜕𝜂

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

𝜕𝑢 𝜕𝜂

𝑠𝑥𝑦 𝑖,𝑗 +

𝑢

+

(𝑢

+𝑣 ) =

(

+

)𝑠

+

𝑠

− 𝑄𝑥𝑦

𝐺

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝑥𝑥 𝑖,𝑗 𝜕𝜂 𝜕𝑦 𝑦𝑦 𝑖,𝑗

53

Discretized constitutive equation White Metzner (DOWN direction).

Kontroloval: xxxxxx

Resulting system of algebraic equations for three stresses at point i,j evaluated from

stresses at left and top

1−𝐴+

𝜇 𝑢 𝜕 𝑢 𝜕 𝑣 𝜕

(

−

−

)

𝐺 ℎ𝑥 𝜕𝑥 ℎ𝑦 𝜕𝑥 ℎ𝑦 𝜕𝑦

0

=

𝜇

𝐺

𝜇

𝐺

𝜇

𝐺

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

− (

+

)

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥

𝑠𝑥𝑥 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑥 𝑖,𝑗+1 𝜕𝜂

𝑢

−

(𝑢

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝑠𝑦𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑦𝑦 𝑖,𝑗+1 𝜕𝜂

𝑢

−

(𝑢

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

𝑠𝑥𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑦 𝑖,𝑗+1 𝜕𝜂

𝑢

−

(𝑢

ℎ𝑥

𝜕𝑥

ℎ𝑦

𝜕𝑥

2𝜇 𝜕𝑢 𝜕𝜂

𝐺 𝜕𝜂 𝜕𝑦

𝜇 𝑢 𝜕 𝑢 𝜕 𝑣 𝜕

2𝜇 𝜕𝑢 𝜕𝜂

1+𝐴+ (

−

−

)

−

𝐺 ℎ𝑥 𝜕𝑥 ℎ𝑦 𝜕𝑥 ℎ𝑦 𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦

𝜇 𝜕𝑢 𝜕𝜂

𝜇 𝑢 𝜕 𝑢 𝜕 𝑣 𝜕

−

1+ (

−

−

)

𝐺 𝜕𝜂 𝜕𝑦

𝐺 ℎ𝑥 𝜕𝑥 ℎ𝑦 𝜕𝑥 ℎ𝑦 𝜕𝑦

𝜕𝜂

+ 𝑣 ) − 𝑄𝑥𝑥

𝜕𝑦

𝜕𝜂

+ 𝑣 ) − 𝑄𝑦𝑦

𝜕𝑦

𝜕𝜂

+ 𝑣 ) − 𝑄𝑥𝑦

𝜕𝑦

0

−

𝑠𝑥𝑥 , 𝑖𝑗

𝑠𝑦𝑦 , 𝑖𝑗

𝑠𝑥𝑦 , 𝑖𝑗

54

Kontroloval: xxxxxx

Discretized constitutive equation White Metzner (iterative threediagonal)

2𝜇 𝜕𝑢

1−

𝐺 𝜕𝑥

0

=1

i-1,j

=0

=0

𝑠𝑥𝑥 𝑖,𝑗 1 − 𝐴 +

𝑠𝑦𝑦 𝑖, 𝑗

i,j+1

i,j

i,j-1

i,j=1

hy

−

𝜇 𝜕𝑣

𝐺 𝜕𝑥

0

2𝜇 𝜕𝑢

1+

𝐺 𝜕𝑥

𝜇 𝜕𝑢

−

𝐺 𝜕𝑦

=2

𝑠𝑥𝑥 𝑖,1

2𝜇 𝜕𝑢

−

𝐺 𝜕𝑦

2𝜇 𝜕𝑣

−

𝐺 𝜕𝑥

𝑠𝑥𝑥𝑖,𝑛𝑦

𝑠𝑦𝑦 𝑖, 𝑛𝑦 =

𝑠𝑥𝑦𝑖,𝑛𝑦

1

2𝜇2 𝜕𝑢

=

𝐺 𝜕𝑦

2𝜇 2

𝜕𝑢

(2

𝐺

𝜕𝑥

2

2

𝜕𝑢

+

𝜕𝑦

2

+

𝜕𝑢 𝜕𝑣

)

𝜕𝑦 𝜕𝑥

2

2𝜇 2

𝜕𝑣

𝜕𝑣

𝜕𝑢 𝜕𝑣

(2

+

+

)

𝐺

𝜕𝑦

𝜕𝑥

𝜕𝑦 𝜕𝑥

2𝜇 2 𝜕𝑢 𝜕𝑣 𝜕𝑢

( − )

𝐺 𝜕𝑥 𝜕𝑥 𝜕𝑦

2

𝑠𝑦𝑦 𝑖,1 = 0

𝑠𝑥𝑦 𝑖,1 = 0

𝜇 𝑠𝑥𝑥 𝑖,𝑗 − 𝑠𝑥𝑥 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑥 𝑖,𝑗+1 − 𝑠𝑥𝑥 𝑖,𝑗−1 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

𝑢

+

(𝑢

+𝑣 ) =

𝑠

− 𝑄𝑥𝑥

𝐺

ℎ𝑥

𝜕𝑥

2ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝜇 𝑠𝑦𝑦 𝑖,𝑗 − 𝑠𝑦𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑦𝑦 𝑖,𝑗+1 − 𝑠𝑦𝑦 𝑖,𝑗−1 𝜕𝜂

𝜕𝜂

2𝜇 𝜕𝑢 𝜕𝜂

1+𝐴 +

𝑢

+

(𝑢

+𝑣 ) =

𝑠

+ 𝑄𝑦𝑦

𝐺

ℎ𝑥

𝜕𝑥

2ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝜇 𝑠𝑥𝑦 𝑖,𝑗 − 𝑠𝑥𝑦 𝑖−1,𝑗 𝜕𝜉 𝑠𝑥𝑦 𝑖,𝑗+1 − 𝑠𝑥𝑦 𝑖,𝑗−1 𝜕

𝜕𝜂

𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

𝜕𝑢 𝜕𝜂

𝑠𝑥𝑦 𝑖,𝑗 +

𝑢

+

(𝑢

+𝑣 ) =

(

+

)𝑠

+

𝑠

− 𝑄𝑥𝑦

𝐺

ℎ𝑥

𝜕𝑥

2ℎ𝑦

𝜕𝑥

𝜕𝑦

𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝑥𝑥 𝑖,𝑗 𝜕𝜂 𝜕𝑦 𝑦𝑦 𝑖,𝑗

55

Kontroloval: xxxxxx

Discretized constitutive equation White Metzner (iterative threediagonal)

Diagonal (vector bb)

WM

BC for sxx, syy, sxy

i=2,3,…,nx

Low diagonal (vector aa)

Upper diagonal (vector cc)

𝜇 𝑢 𝜕𝜉

𝜇

𝜕𝜂

𝜕𝜂

𝜇

𝜕𝜂

𝜕𝜂

− 𝑠𝑥𝑥 𝑖,𝑗−1

𝑢

+𝑣

+ 𝑠𝑥𝑥 𝑖,𝑗+1

𝑢

+𝑣

𝐺 ℎ𝑥 𝜕𝑥

2𝐺ℎ𝑦

𝜕𝑥

𝜕𝑦

2𝐺ℎ𝑦

𝜕𝑥

𝜕𝑦

𝜇

𝜕𝜉 2𝜇 𝜕𝑢 𝜕𝜂

=

𝑠𝑥𝑥 𝑖−1,𝑗 𝑢

+

𝑠

− 𝑄𝑥𝑥

𝐺ℎ𝑥

𝜕𝑥 𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝑠𝑥𝑥 𝑖,𝑗 1 − 𝐴 +

iteration

stress sxx (3diagonal solver)

stress syy (3diagonal solver)

stress sxy (3diagonal solver)

𝜇 𝑢 𝜕𝜉

𝜇

𝜕𝜂

𝜕𝜂

𝜇

𝜕𝜂

𝜕𝜂

− 𝑠𝑦𝑦 𝑖,𝑗−1

𝑢

+𝑣

+ 𝑠𝑦𝑦 𝑖,𝑗+1

𝑢

+𝑣

𝐺 ℎ𝑥 𝜕𝑥

2𝐺ℎ𝑦

𝜕𝑥

𝜕𝑦

2𝐺ℎ𝑦

𝜕𝑥

𝜕𝑦

𝜇

𝜕𝜉 2𝜇 𝜕𝑢 𝜕𝜂

=

𝑠

𝑢

+

𝑠

− 𝑄𝑦𝑦

𝐺ℎ𝑥 𝑦𝑦 𝑖−1,𝑗 𝜕𝑥 𝐺 𝜕𝜂 𝜕𝑦 𝑥𝑦 𝑖,𝑗

𝑠𝑦𝑦 𝑖,𝑗 1 + 𝐴 +

I section

𝜇 𝑢 𝜕𝜉

𝜇

𝜕𝜂

𝜕𝜂

𝜇

𝜕𝜂

𝜕𝜂

𝑠𝑥𝑦 𝑖,𝑗 1 +

− 𝑠𝑥𝑦 𝑖,𝑗−1

𝑢

+𝑣

+ 𝑠𝑥𝑦 𝑖,𝑗+1

𝑢

+𝑣

𝐺 ℎ𝑥 𝜕𝑥

2𝐺ℎ𝑦

𝜕𝑥

𝜕𝑦

2𝐺ℎ𝑦

𝜕𝑥

𝜕𝑦

𝜇

𝜕𝜉 𝜇 𝜕𝑣 𝜕𝜉 𝜕𝑣 𝜕𝜂

𝜕𝑢 𝜕𝜂

=

𝑠

𝑢

+

(

+

)𝑠

+

𝑠

− 𝑄𝑥𝑦

𝐺ℎ𝑥 𝑥𝑦 𝑖−1,𝑗 𝜕𝑥 𝐺 𝜕𝜉 𝜕𝑥 𝜕𝜂 𝜕𝑥 𝑥𝑥 𝑖,𝑗 𝜕𝜂 𝜕𝑦 𝑦𝑦 𝑖,𝑗

56

Discretized constitutive equation White Metzner MW.m (Matlab)

Kontroloval: xxxxxx

Resulting system of algebraic equations for three stresses at point i,j evaluated from stresses at left and from bottom

57

Poisson equation for pressure

(𝑢

𝜕𝑢

𝜕𝑢

𝜕𝑝 𝜕𝜏𝑥𝑥 𝜕𝜏𝑥𝑦

+𝑣 )=−

+

+

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑥

𝜕𝑦

Kontroloval: xxxxxx

geometry

Approximate profiles u,v, ,

for power law fluid

iteration

𝜕𝑣

𝜕𝑣

𝜕𝑝 𝜕𝜏𝑥𝑦 𝜕𝜏𝑦𝑦

(𝑢

+𝑣 )= −

+

+

𝜕𝑥

𝜕𝑦

𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕2𝑝 𝜕2𝑝

𝜕𝑢 𝜕𝑢

𝜕2𝑢

𝜕2𝑣

𝜕𝑣 𝜕𝑢

𝜕2𝑢

𝜕 2 𝑣 𝜕𝑣 𝜕𝑣

+

+

+𝑢 2+𝑣 2+2

+𝑣

+𝑢

+

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑥 𝜕𝑥

𝜕𝑥

𝜕𝑦

𝜕𝑥 𝜕𝑦

𝜕𝑥𝑦

𝜕𝑥𝑦 𝜕𝑦 𝜕𝑦

𝜕 2 𝑥𝑦

𝜕2𝑝 𝜕2𝑝

𝜕𝑣 𝜕𝑢 𝜕𝑣 𝜕𝑢

𝜕 2 𝑥𝑥 𝜕 2 𝑦𝑦

= 2 + 2 + 2

−

=

+

+2

𝜕𝑥

𝜕𝑦

𝜕𝑥 𝜕𝑦 𝜕𝑦 𝜕𝑥

𝜕𝑥 2

𝜕𝑦 2

𝜕𝑥𝜕𝑦

Elastic stress sxx, syy, sxy

(hyperbolic MW)

Poisson equation for

Velocities, µ , BC for

Poisson equation for

Poisson equation for pressure p

Decomposition to elastic and viscous components

𝜕 2 𝑥𝑥 𝜕 2 𝑠𝑥𝑥

𝜕3𝑢

𝜕µ 𝜕 2 𝑢

𝜕 2 µ 𝜕𝑢

=

+ 2µ 3 + 4

+2 2

𝜕𝑥 2

𝜕𝑥 2

𝜕𝑥

𝜕𝑥 𝜕𝑥 2

𝜕𝑥 𝜕𝑥

𝜕 2 𝑦𝑦 𝜕 2 𝑠𝑦𝑦

𝜕3𝑣

𝜕µ 𝜕 2 𝑣

𝜕 2 µ 𝜕𝑣

=

+ 2µ 3 + 4

+2 2

𝜕𝑦 2

𝜕𝑦 2

𝜕𝑦

𝜕𝑦 𝜕𝑦 2

𝜕𝑦 𝜕𝑦

𝜕 2 𝑥𝑦 𝜕 2 𝑠𝑥𝑦

𝜕3𝑢

𝜕3𝑣

𝜕µ 𝜕 2 𝑢 𝜕 2 𝑣

𝜕µ 𝜕 2 𝑣

𝜕2𝑢

𝜕 2 µ 𝜕𝑢 𝜕𝑣

=

+µ

+

+

+

+

+

+

+

𝜕𝑥𝜕𝑦

𝜕𝑥𝜕𝑦

𝜕𝑥𝜕𝑦 2 𝜕𝑦𝜕𝑥 2

𝜕𝑦 𝜕𝑥𝜕𝑦 𝜕𝑥 2

𝜕𝑥 𝜕𝑥𝜕𝑦 𝜕𝑦 2

𝜕𝑥𝜕𝑦 𝜕𝑦 𝜕𝑥

58

Poisson equation for pressure

Kontroloval: xxxxxx

For constant viscosity

𝜕 2 𝑥𝑦 𝜕 2 𝑠𝑥𝑥 𝜕 2 𝑠𝑦𝑦

𝜕 2 𝑠𝑥𝑦

𝜕 2 𝑥𝑥 𝜕 2 𝑦𝑦

𝜕3𝑢

𝜕3𝑣

𝜕3𝑢

𝜕3𝑣

+

+2

=

+

+2

+ µ(2 3 + 2 3 + 2

+2

)

𝜕𝑥 2

𝜕𝑦 2

𝜕𝑥𝜕𝑦

𝜕𝑥 2

𝜕𝑦 2

𝜕𝑥𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥𝜕𝑦 2

𝜕𝑦𝜕𝑥 2

A sum of all the members in the viscosity coefficient is

zero, therefore, the viscosity does not directly affect the

relationship between the pressure and the elastic tension

𝜕3𝑢

𝜕3𝑣

𝜕3𝑢

𝜕3𝑣

2 3+2 3+2

+2

=0

𝜕𝑥

𝜕𝑦

𝜕𝑥𝜕𝑦 2

𝜕𝑦𝜕𝑥 2

𝜕 2 𝑠𝑥𝑦

𝜕2𝑝 𝜕2𝑝

𝜕𝑣 𝜕𝑢 𝜕𝑣 𝜕𝑢

𝜕 2 𝑠𝑥𝑥 𝜕 2 𝑠𝑦𝑦

+

+ 2

−

=

+

+2

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑥 𝜕𝑦 𝜕𝑦 𝜕𝑥

𝜕𝑥 2

𝜕𝑦 2

𝜕𝑥𝜕𝑦

For variable viscosity the relationship between the pressure and the elastic tension appear

𝜕 2 𝑠𝑥𝑦

𝜕2𝑝 𝜕2𝑝

𝜕𝑣 𝜕𝑢 𝜕𝑣 𝜕𝑢

𝜕 2 𝑠𝑥𝑥 𝜕 2 𝑠𝑦𝑦

+

+ 2

−

=

+

+2

+

𝜕𝑥 2 𝜕𝑦 2

𝜕𝑥 𝜕𝑦 𝜕𝑦 𝜕𝑥

𝜕𝑥 2

𝜕𝑦 2

𝜕𝑥𝜕𝑦

𝜕 𝜕 𝜕 𝜕

𝜕 2 µ 𝜕𝑢 𝜕𝑣

𝜕 2 µ 𝜕𝑢 𝜕 2 µ 𝜕𝑣

2(

−

+

+

+ 2

+

)

𝜕𝑥 𝜕𝑦 𝜕𝑦 𝜕𝑥 𝜕𝑥𝜕𝑦 𝜕𝑦 𝜕𝑥

𝜕𝑥 𝜕𝑥 𝜕𝑦 2 𝜕𝑦

59

Poisson equation for pressure. Boundary conditions

Kontroloval: xxxxxx

The equation for pressure distribution is elliptic equation of second order, and in each point of the border is

necessary to prescribe exactly one boundary condition: Either directly pressure (at least in one point, because

the pressure field in an incompressible liquid is defined up to an arbitrary constant) or the normal derivative of

the pressure (Neuman boundary condition of the second kind). At the inlet, where we assume the absence of

elastic effects can be fixed e.g. zero pressure over the cross section (p = 0). The solid wall (u = v = 0) is

required to enter a pressure gradient, starting from the Cauchy equilibrium equations

𝜕𝑝 𝜕𝜏𝑥𝑥 𝜕𝜏𝑥𝑦 𝜕𝑠𝑥𝑥 𝜕𝑠𝑥𝑦

𝜕2𝑢 𝜕2𝑢

𝜕2𝑣

𝜕 𝜕𝑢 𝜕 𝜕𝑢 𝜕𝑣

=

+

=

+

+ (2 2 + 2 +

)+2

+

( + )

𝜕𝑥

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥𝜕𝑦

𝜕𝑥 𝜕𝑥 𝜕𝑦 𝜕𝑦 𝜕𝑥

𝜕𝑝

=

𝜕𝑥

𝜕𝑠𝑥𝑥 𝜕𝑠𝑥𝑦

𝜕

𝜕 𝜕𝑢 𝜕 𝜕𝑢 𝜕𝑣

+

−

+2

+

( + )

𝜕𝑥

𝜕𝑦

𝜕𝑦

𝜕𝑥 𝜕𝑥 𝜕𝑦 𝜕𝑦 𝜕𝑥

𝜕𝑝 𝜕𝜏𝑦𝑦 𝜕𝜏𝑥𝑦 𝜕𝑠𝑦𝑦 𝜕𝑠𝑥𝑦

𝜕2𝑣 𝜕2𝑣

𝜕2𝑢

𝜕 𝜕𝑣 𝜕 𝜕𝑢 𝜕𝑣

=

+

=

+

+ 2 2 + 2+

+2

+

( + )

𝜕𝑦

𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑦

𝜕𝑥

𝜕𝑥𝜕𝑦

𝜕𝑦 𝜕𝑦 𝜕𝑥 𝜕𝑦 𝜕𝑥

𝜕𝑝

=

𝜕𝑦

𝜕𝑠𝑦𝑦 𝜕𝑠𝑥𝑦

𝜕

𝜕 𝜕𝑣 𝜕 𝜕𝑢 𝜕𝑣

+

−

+2

+

( + )

𝜕𝑦

𝜕𝑥

𝜕𝑥

𝜕𝑦 𝜕𝑦 𝜕𝑥 𝜕𝑦 𝜕𝑥

60