ITM 361 project

advertisement

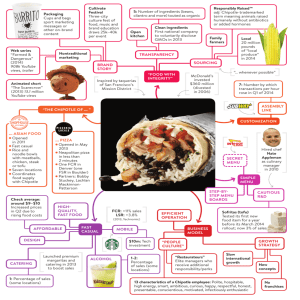

Introduction The business which Team C has targeted for the study was Chipotle Mexican Grille located at 533 South Howard Avenue. Chipotle provides a food service that is as quick as a fast-food restaurant but provides the quality of a sit-down restaurant. Its menu is limited as it consists of burritos, burrito bowls, quesadillas, tacos and salads. The team decided to observe Chipotle because it is a well-known and respected service restaurant that has become very efficient in providing a fast service with quality food. [The factor of Chipotle having good taste food to enjoy during observation breaks had little to do with our decision]. Our goal upon finishing the analysis is to be able to recognize and understand why management has implemented the tactics that they do in order to operate an efficient service. By being able to pinpoint and understand particular tactics this will help the individual team members later on in their future endeavors. Body Chipotle Mexican Grille provides a food service to its customers. The ordering process that the restaurant runs by is a single system multiple phase process following a line flow process. Even though in a typical line process the products are highly standardized, Chipotle is able to implement this strategy because of the continuous linear movement of the resources. Even though there are five menu items combined with various ingredients there is a limited selection still classifying as standardized. The line process was determined by the process structure and layout of the ordering procedure of the customer and food materials moving linearly from one operation to the next. A single system multiple phase process is applicable in this situation because of the high customer involvement (face-to-face) and a mix of specialization of the resources. Finally, Chipotle’s service is a hybrid-office process because it has high customer contact and a highly customized service, but at the same time the line flow routine is performed the same for all customers. Single Channel Multiple Phase Process: A line of customers form at the far left end of the counter in single file. The first phase begins with an employee asking the customer what they will be having today. The customer orders a burrito, quesadilla, taco, burrito bowl, or a salad, which will determine which foundation the employee will use. The employee will heat a large tortilla for the burrito or quesadilla, three smaller tortillas for the tacos, or grab an aluminum bowl for the salad and burrito bowl. We will use an example of making a burrito for the rest of the example. While the tortilla is heating the employee asks the next customer in line what they will have to keep the process moving. The fourth step is asking the first customer what rice, beans, and meat they would like on the burrito. The choices of beans are refried, pinto, and black. The choices of rice are brown, yellow, and white. And the choices of meat are beef (carnitas or barbocao), chicken, or pork. The employee scoops the selected beans, rice, and meat onto the burrito and slides it to the next phase. The sixth step, but the first in phase two, is carried out by a second employee who asks the customer what vegetables they would like on the burrito. The choices range from three sauces (mild, medium, hot), olives, onions, cheese (white and yellow), sour cream, guacamole, lettuce, and peppers. The employee provides the ingredients requested and then wraps the burrito. The vegetable stage is the only phase is channel two. The employee slides the burrito to employee number three (phase three) which will finish the process. The staff member asks the customer if they would like chips and drink or anything else today. If the customer answers yes, they get the selected drink and chips. The final step in the entire process is completing the payment transaction. Flowchart of Chipotle Service Process Phase 1 Phase 2 Phase 3 Chipotle Employee Greets Customer, “Good Afternoon” Chipotle Employee2 receives burrito from Stage 1 Chipotle Employee3 receives wrapped burrito from Stage 2 Employee asks, What would you like today?” Employee asks, “What vegetables would you like?” Employee asks, “Would you like chips and a drink?” Burrito Bowl Burrito Taco Salad Employee selects large tortilla and heats it Sauces Greens Hot Peppers Employee asks, “what rice, beans, and meat would you like?” Rice Cheeses White Extras Gaucamole Wrap it Up Beans Meat End of Phase 2; Employee passes burrito to Phase 3 Yw Br Wt Re Bl Pnt Bf Chx Yes Get drink No Get Chips Employee tells customer the total amount due Employee collects payment and transaction is complete Prk End of Phase 3: EAT!!! End of Phase 1; Employee passes burrito to phase 3 Legend Phases: Start & End Choices Employee Steps Selection of Choice Time Management and Work Measurements: In regards to collecting, measuring, and analyzing data the team decided to use the time study method. This approach is comprised of (1) selecting each work element, which can be seen in the flowchart above, (2) timing the elements, (2) determining a sample size, and (3) setting the final standard. The working elements were sectioned into 12 components which are illustrated by the light purple squares in the flowchart. The timing of the individual elements was done with the stopwatch feature on the iPhone. The team observed Chipotle on three different occasions during lunch (12:00pm- 1:00pm) and three separate occasions during dinner for an hour each. In total we have six hours of observations, three hours of lunch and three hours of dinner. The 12 components are: (1) Greeting and asking the customer what they wanted, (2) heating the tortilla, (3) scooping the beans, (4) rice, and (5) meat, (6) passing the burrito to phase two and the second “hello”, (7) asking what sauce, greens, cheese, and extras the customer wanted, (8) wrapping the burrito, (9) passing the burrito to phase three and asking the customer if they wanted chips and a drink, (10) getting the chips and (11) drink, and (12) taking payment. The “Time Study Method Table” below reveals four different values for the time study method. First, is the amount of time it took for each individual element to be completed for all three observations separated into lunch and dinner. These values have the white background. Next is the average of that independent variable for the three observations for both lunch and dinner. These averages are highlighted light purple. The third value is located at the bottom of the table which illustrates the total time of the guest interaction from the initial greeting to the payment transaction per individual observation. These values are highlighted light orange. The final calculated value is the average of the total processing time for the three observations divided into lunch and dinner. These averages are highlighted bright yellow. Time Study Method Average Recorded Lunch Time (Seconds) Obs 1 Obs 2 Obs 3 Total Ave 12.6 13.1 12.3 12.7 22.2 21.8 22 22.0 9.6 8.8 8.2 8.9 8.1 8.6 8.9 8.5 10.2 10.4 10.8 10.5 4.5 4.4 4.4 4.4 Average Recorded Dinner Time (Seconds) Obs 1 Obs 2 Obs 3 Total Ave 14.2 15.6 16.1 15.3 24.2 24.7 24.2 24.4 10 10.8 11.2 10.7 9.2 9.3 10.8 9.8 11.4 12.6 11.8 11.9 6.2 6.3 6.1 6.2 Asking what sauce, green, cheese and extras 26.3 26.2 27.2 26.6 30.4 31.8 31.6 31.3 Wrap it Up Pass to Phase 3 Get Chips Get Drink Payment Transaction 13.6 3.4 5.2 4.7 19.9 14.3 3.6 5.8 5.6 20.3 13.9 3.3 5.1 5.3 21.2 13.9 3.4 5.4 5.2 20.5 16.3 4.2 6.2 6.1 18.2 17.3 4.1 6.8 5.4 16.8 18.9 4.5 6.6 4.7 19.2 17.5 4.3 6.5 5.4 18.1 Total (min/sec) 2.34 2.38 2.38 2 min 37 sec 2.61 2.69 2.76 3 min 9 sec Elements Initial Greeting Heating of Tortilla Applying Beans Applying Rice Applying Meat Pass to Phase 2 Utilization, a way to measure efficiency, is the degree to which a resource is currently being used. The equation is: 𝑈𝑡𝑖𝑙𝑖𝑧𝑎𝑡𝑖𝑜𝑛 = 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑂𝑢𝑡𝑝𝑢𝑡 𝑅𝑎𝑡𝑒 𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 × 100% . Our output rate is going to be scaled over one hour. Since it is possible to service between two to three customers at a time, the average output rate during lunch hour is going to be 63 customers. We calculated with the following set of equations: 60 𝑚𝑖𝑛 𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑂𝑢𝑡𝑝𝑢𝑡 𝑅𝑎𝑡𝑒 = 2.37 𝑚𝑖𝑛 × 2.5 = 63.3 We divided 2.37 (2 minutes 37 seconds) into 60 minutes to see how many customers could go through the line in one hour which was 25. We then multiplied 63, which represents one customer going through the line one at a time, by 2.5. We used 2.5 because this represents two to three customers going through the line at once. Maximum output 76, which is the 25 customers multiplied by 3, which is the most amount of customers that can go through 63 the line at a time. Therefore, utilization is 𝑈 = 76 × 100% = 83%. This is a good percentage over the busy lunch period. For dinner we followed the same process of equations and substituted 3.09 for the time per customer which came out to 19. The average amount of customers going through the line over an hour 49 was 49 and the maximum number was 59. We calculated utilization to be 𝑈 = 58 × 100% = 84%. 84% is another high utilization percentage. The capacity requirement is the capacity needed for a future time period to meet the demand of the firm’s customers. To calculate the capacity requirement the team followed the equation: 𝑝𝑎𝑐𝑖𝑡𝑦 𝑅𝑒𝑞𝑢𝑖𝑟𝑒𝑚𝑒𝑛𝑡 = 𝑀= 𝐷𝑝 𝑁[1−( 𝐶 ) 100 𝑃𝑟𝑜𝑐𝑒𝑠𝑠𝑖𝑛𝑔 ℎ𝑜𝑢𝑟𝑠 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑑 𝑓𝑜𝑟 𝑦𝑒𝑎𝑟 ′𝑠 𝑑𝑒𝑚𝑎𝑛𝑑 𝐻𝑜𝑢𝑟𝑠 𝑎𝑣𝑎𝑖𝑎𝑙𝑏𝑙𝑒 𝑓𝑟𝑜𝑚 𝑎 𝑠𝑖𝑛𝑔𝑙𝑒 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝑢𝑛𝑖𝑡 𝑝𝑒𝑟 𝑦𝑒𝑎𝑟 (𝑎𝑓𝑡𝑒𝑟 𝑑𝑒𝑑𝑢𝑐𝑡𝑖𝑛𝑔 𝑑𝑒𝑠𝑖𝑟𝑒𝑑 𝑐𝑢𝑠ℎ𝑖𝑜𝑛) ; when; D= demand forecast for the year (number of customers serviced) p= processing time (in hours per customer served) N= total number of hours per year during which the process operates C= desired capacity cushion 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝐶𝑢𝑠ℎ𝑖𝑜𝑛 = 100% − 𝑈𝑡𝑖𝑙𝑖𝑧𝑎𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑒 % Setup time (s) the time require to change a process or an operation from making one service or product to another. S will be one for our calculations because there is no setup time required between customers due to the consistent flow and multiple employees handling multiple customers. 𝐶𝑎𝑝𝑎𝑐𝑖𝑡𝑦 𝑅𝑒𝑞𝑢𝑖𝑟𝑒𝑚𝑒𝑛𝑡 = 94,320 𝑥 .042 3960(1− 17 ) 100 = 2.8, therefore there needs to be 3 employees on the line to meet future demand. D: We calculated demand by taking the two busiest hours of the day that we observed which was 112. We then estimated the next nine hours at 150 customers based off of conversation the team had with employees about their busy hours. This brought the total to 262 per day and we multiplied that by 360 days, since there are holidays Chipotle does not open on. This gave us a demand of 94,320 customers for the year. p: We calculated processing time in hours per customer served by taking the total number of hours opened over the year (11 hours/day x 360 days) which was 3,960 hours. Then we divided that by the demand of customers for the year which came out to .042 N: The total number of hours operated was 11 hours a day multiplied by 360 days which was 3,960 hours. C: The desired capacity cushion as previously stated is 100% - utilization rate which was 83%, therefore, it is 17. The Service System As previously demonstrated Chipotle implements a single channel, multiple phase service. The first employee-customer interaction begins when “Employee 1” greets the customer, takes their order and provides the rice, beans, and meat to the item selected. Phase two begins when “Employee 2” gets the burrito which currently consists of rice, beans and meat. During this phase the employee applies the sauces, vegetables, extras, and then wraps the burrito. Phase three, the last phase, is done by “Employee 3” who asks the customer if they want chips and a drink. The phase is completed with the payment transaction. This service system is illustrated in Figure 1. Figure 1: Single Channel, Multiple Phase Customer Line Phase 1: Greeting, menu item selection, rice, beans meat Phase 2: Sauces, greens, extra, and wrapping it up Phase 3: Chips and a drink and payment transaction The waiting line model is used to balance the gains that might be made by increasing efficiency of the service system against the cost of doing it. The operating characteristics of the system are: (1) Line Length; Short lines mean either good customer service or too much capacity. Given that there are only three Chipotle employees at the line this indicates good customer service because the line never reached more than five deep during peak hours. (2) Number of Customers in System; The low number of customers in line and being served resembles the efficiency of the service process. (3) Waiting Time in Line; The waiting time in line also reflects efficiency of the service provided. At any given time during our observations, the longest time any customer waited, even if they were fourth or fifth in line, was 53 seconds. This is extremely low considering the volume that Chipotle does during these hours. (4) Total Time in System; The total elapsed time (the longest out of all arrivals) from entering the back of the line to the payment transaction was three minutes and thirty-eight seconds. The single channel, multiple phase service is comprised of a single-server model since the customer population is infinite and all customers are patient, the mean service rate exceeds the mean arrival rate, customers are served on first-come first-served basis and the length of waiting is unlimited. The customers go from one server to the other given the phase that they are in. Constraint Management The main issue within constraints is the dealing with bottlenecks. A bottleneck is a capacity constraint that limits the firm’s ability to meet the product volume or demand. Referring back to the “Time Study Method” table which shows the time required to complete each task, we can look at the average time per segment to see if there are any bottlenecks. To identify a bottleneck the occurring event will take less time to complete than the preceding event. For example, asking the customer what sauce, greens, and extras they want it takes on average 26.6 seconds. This is a bottleneck for the previous step of passing the burrito on to Phase Two because that only takes 4.4 seconds. Therefore, since it only takes 4 seconds to pass on the burrito and 27 seconds to satisfy the customer’s needs there is a 23 second overlap where nothing can be done till the preceding event is finished. There are only two bottlenecks throughout the burrito making process: Bottleneck number one, heating the tortilla and bottleneck number two, asking the customer what condiments they would like. The next step after identifying the bottleneck is to exploit the bottleneck, however, due to the importance of each of these steps that is not possible. For the first bottleneck, the tortilla has to be heated to meet the customer’s expectations so Chipotle cannot create a shortcut for this step. The second bottleneck is not fixable either as the employee has to fill the burrito with up to six or seven condiments. The only possible solution would be to have an employee for every two condiments but that is not practical or efficient. Luckily these bottlenecks do not hinge the process that dramatically. Chipotle has implemented the Five S Practice to conduce visual control and lean production out of its service system. The first element of the practice is sorting. Chipotle has sorted the entire service station into a practical and efficient manner. The tortillas are found at the beginning of the line next to the heated press and tray baskets. The order continues with the three different kinds of rice, to the three different kinds of beans, to the five different kinds of meat. The final station has the sauces, cheeses, vegetables, and extras all grouped together. This also relates to the second S of straighten, where everything has a place. The line is always kept clean which satisfies the third S of shine. Chipotle has made this a standardized method for all its stores and it is sustainable satisfying the final two S’s. The team did not notice any specific LEAN methods to minimize waste other than the Five S Practice strategy. INTERVIEW / CONCLUSION