Laboratory Experiment to Determine Batch Ethanol Production by S

advertisement

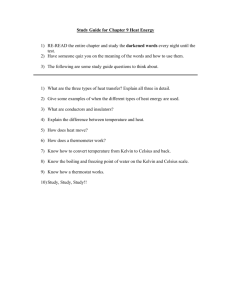

Laboratory Experiment to Determine Batch Ethanol Production by S. cerevisiae Benjamin Reves May 11, 2005 Outline Background Theory Procedure Results Conclusions Recommendations Impact Questions Background Need for Ethanol Ethanol used as raw material and solvent in the chemical, food, and pharmaceutical industries Four million tons of ethanol are produced each year Eighty percent by fermentation Energy Information Administration has predicted annual consumption growth in U.S. of 3.2% each year Saccharomyces cerevisiae Common type of yeast Eucaryotic Reproduces by budding Can grow aerobically or anaerobically Current Methods Batch Reactor Fed-batch Reactor Continuous Reactor Packed Bed Reactor Theory Glycolysis Breakdown of 6-C glucose into two molecules of 3-C pyruvate Fate of pyruvate – – Aerobic Conditions- TCA cycle Anaerobic Conditions- Converted to ethanol via acetaldehyde Cell Growth Substrates + cells extracellular products + more cells Batch Growth Lag Phase Exponential Growth Phase Deceleration Phase Stationary Phase Death Phase Yield Coefficients Help to quantify growth kinetics YX/S=-X/S YP/S= -P/S YP/X= P/X Product Formation Growth-associated products qp 1 dP YP / X g X dt Non-growth-associated products qp Mixed-growth-associated products qp g Temperature Effects Optimal temperatures Product formation affected Diffusion limitations Objectives Objectives Study ethanol production and glucose utilization by Saccharomyces cerevisiae Study effect of temperature on fermentation Construct growth curves Methods Stages of Experimentation Autoclaving Inoculation Growth of Culture Analyzing Samples Autoclaving Sterility is a must! Saturated steam at 121oC used to kill all spores Autoclave Preparing Inoculum Inoculum is typically 5-10% of total working volume Yeast obtained from microbiology department on plates Inoculating needle used to take yeast from plate into 800 mL of YEB Placed on shaker at 30oC Importance of inoculum condition Inoculum Preparation Yeast Extract Broth Undefined vs. Defined Media 1 L YEB contains: – – 20 grams of glucose 10 grams of yeast extract broth Glucose is carbon/energy source Yeast extract provides cofactors and ions Fermentor 7.5 L BioFlo 110 Modular Benchtop Fermentor Controller and PCU Temperature Control Fermentor PCU Headplate Taking Samples Fermentor equipped with sample port Sample tubes had been autoclaved Optical density of sample measured Centrifuged for 5 minutes at 2000 rpm Liquid decanted and stored at 4oC Centrifuge Centrifuged Samples Estimating Cell Concentration Spectrophotometer used to measured absorbance at 650 nm Sterile YEB used as blank Beer’s Law: A=bc Linear correlation between absorbance and concentration of cells Calibration curve constructed Spectrophotometer Construction of Calibration Curve Optical density measured Washed with 10 mM phosphate buffer Dried in oven at 35 Celsius OD Calibration Curve OD Calibration 0.5 0.45 0.4 X = 1.1435*Abs. + 0.0358 R2 = 0.9966 X (mg/ml) 0.35 0.3 0.25 0.2 0.15 0.1 0.05 0 0 0.05 0.1 0.15 0.2 Absorbance 0.25 0.3 0.35 0.4 Glucose Determination Glucose assay kit ordered from Sigma Based on UV absorbance of NADH at 340 nm Glucose + ATP NAD+ Hexokinase Glucose-6-Phosphate + ADP G6PDH G6P + Samples Diluted 6-Phosphogluconate + NADH Ethanol Determination Ethanol assay kit ordered from R-Biopharm Based on absorbance of NADH at 340 nm Sample diluted ADH NAD+ acetaldehyde + NADH + H+ Ethanol + Acetaldehyde + NAD+ + H2O Al-DH acetic acid + NADH + H+ Results Growth Curve for 30 Celsius X (mg cells/ ml) Growth Curve for 30 Celsius 1.800 1.600 1.400 1.200 1.000 0.800 0.600 0.400 0.200 0.000 X 0 5 10 15 20 Time (h) 25 30 35 Growth Curve for All Runs X (mg cells/ mL) Growth Curve 1.8 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 30 Celsius 37 Celsius 25 Celsius 0 10 20 30 Time (h) 40 50 Concentration Plot for 30 Celsius Glucose and Ethanol Concentrations vs. Time for 30 Celsius 45 40 Cocentration (mg/ml) 35 30 25 Glucose 20 Ethanol 15 10 5 0 0 5 10 15 20 Time (h) 25 30 35 Glucose Concentration Glucose Concentration (mg/ml) Glucose Concentration vs. Time 60 50 40 30 Celsius 30 37 Celsius 20 25 Celsius 10 0 0 10 20 30 Time (h) 40 50 Ethanol Production Ethanol Production Ethanol Concentration (mg/ml) 12 10 8 30 Celsius 6 37 Celsius 4 25 Celsius 2 0 0 10 20 30 Time (h) 40 50 Yield Coefficients YP/S (mg P/mg S) 25oC 30oC 37oC 0.229 0.282 0.247 YX/s (mg cells / mg S) 0.027 0.0378 0.0293 YP/X (mg P/ mg cells) 8.44 7.45 8.44 Conclusions Yeast grew the fastest at 30 Celsius Lag times were longer at 25 and 37 Celsius Glucose was fully used in each run Amount of ethanol produced was almost the same for each run Runs should be allowed to proceed longer Recommendations Determine growth and productivity effects due to other factors such as pH Determine optimal inoculum size and age Investigate better methods of analyzing samples Operate fermentor in other manners: continuous, continuous with recycle, fedbatch HPLC Impact Typically carried out at graduate level CBU has ability to perform at undergraduate level Hope to collaborate with School of Sciences in the future Questions?