Project Title

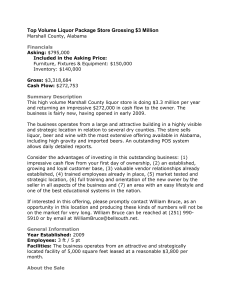

advertisement

Program for North American Mobility in Higher Education Introducing Process Integration for Environmental Control in Engineering Curricula Module 3: Environmental Challenges – Pulp & Paper Industry Caroline Gaudreault Created at: École Polytechnique de Montréal & Texas A&M University, 2003 Purpose of Module 3 What is the purpose of this module? This module is intended to overview the environmental challenges of the pulp & paper industry and, more specifically, the reduction of environmental impacts related with the kraft pulping process. 2 Structure of the Module 3 What is the structure of this module? Module 3 is divided into 3 “tiers”, each with a specific goal: • Tier 1: Basic introduction • Tier 2: Case study applications • Tier 3: Open-ended problem These tiers are intended to be completed in order. Students are quizzed at various points, to measure their degree of understanding, before proceeding. Each tier contains a statement of intent at the beginning, and a quiz at the end. 3 LEGEND Go to the web site Go to next subject More information on the same subject Look for the answer to the question 4 Tier I: Background Information Tier I: Statement of Intent Tier I: Statement of Intent The purpose of this module is to provides a general overview of the concepts related to minimum impact manufacturing in the Kraft process, and an introduction to pertinent PI tools. Tier 1 also includes some selected readings, to help the student acquire a deeper understanding of this subject. 6 Tier I: Content Tier I is broken into three sections: 1.1 Introduction to the kraft pulping process, its related environmental impacts and related regulations 1.2 Introduction to minimum impact manufacturing 1.3 Related PI tools At the end of Tier I, there is a short multipleanswer quiz 7 1.1 Introduction to the kraft pulping process and its related environmental impacts and related regulations General Description of the Kraft Pulping Process The kraft process is a form of chemical pulping. This means that, in order to degrade and dissolve away the lignin and keep most of the cellulose and hemicellulose, the wood chips are cooked with appropriate chemicals in an aqueous solution at elevated temperature and pressure. The main challenge is to form fibers that are practically intact. More specifically, the kraft process involves cooking of the chips using a solution of sodium hydroxide (NaOH) and sodium sulfide (Na2S) One major characteristic of the kraft process is that the cooking chemicals are regenerated in a recovery process that will be discussed later. 9 Advantages and Disadvantages of Kraft Process Advantages: High strength pulp Utilizes proven technology for chemical recovery Handles with a wide variety of wood species Tolerates bark in the pulping process 10 Disadvantages: Unbleached pulp is characterized by a dark brown color It is associated malodorous gases (organic sulfides) Definitions and Nomenclature (1) Pulp White liquor: Liquor containing the active cooking chemicals (NaOH and Na2S) and used to cook chips. Cooking & Washing Black liquor: Residual liquor from cooking containing the reaction products of lignin solubilization. This liquor is concentrated and burnt into a recovery furnace and yields an inorganic smelt of Na2CO3. Green liquor: Liquor obtained by dissolving the latter smelt. The green liquor is reacted with CaO in order to convert the Na2CO3 in NaOH and regenerate the white liquor. Chips BLACK LIQUOR Alkali lignin Hydrolysis salts Sulphonation products Evaporation & Burning WHITE LIQUOR NAOH NA2S GREEN LIQUOR Na2CO3 Na2S The kraft sodium cycle (Source:Smook, 1994) 11 Causticizing Definitions and Nomenclature (2) TERM DEFINITION UNITS Total Alkali Total of all viable sodium alkali compounds i.e. NaOH + Na2S + Na2CO3 + Na2SO4 + Na2S2O3 + Na2SO3 (does not include NaCl) g/L as Na2O Total Titrable Alkali (TTA) Total NaOH + Na2S + Na2CO3 g/L as Na2O Active Alkali (AA) Total NaOH + Na2S g/L as Na2O Effective Alkali (EA) Total NaOH + ½ Na2S g/L as Na2O Activity AA / TTA ratio Causticity NaOH / [NaOH + Na2CO3] ratio % (on a Na2O basis) Sulfidity Na2S / AA (or TTA) ratio % (on a Na2O basis) Causticizing Efficiency (White liquor) Same as causticity. (However, the concentration of NaOH in the green liquor should be subtracted so that the value of NaOH represents only the portion produced by the causticizing reaction.) % (on a Na2O basis) Residual Alkali (Black liquor) Alkali concentration determined by titration Reduction Efficiency (Green liquor) Na2S / (soda sulfur coumpounds) ratio (often simplified as Na2S / [Na2S + Na2SO4 ] ratio) % g/L as Na2O % (on a Na2O basis) (Source:Smook, 1994) 12 Sodium vs. Calcium Cycle 13 (Adapted from European Comission IPPC, 2001) Wood Fibers Pulp fibers are manufactured by chemically dissolving those wood components (mainly lignin) that keep wood cells together to form the original wood structure by minimizing the damages to these components. Chemical Components of Wood Structure of cellulose Wood Lignin 21% Hardwoods 25% Softwoods Carbohydrates 45% Cellulose Glucose 14 2-8% Extractive Terpenes Resin acids (softwood) Fatty acids Phenols Unsaponifiables Hemicellulose 35% Hardwoods 25% Softwoods Glucose Mannose Galactose Xylose Arabinnose Source: Smook, 1994 Overview of the Kraft Process Chips Digester White liquor storage White liquor clarifier Pulp to bleaching Grits Strong black liquor storage 15 Lime Green liquor storage Weak black liquor storage Evaporators Slaker Green liquor clarifier Contaminated condensates Recovering furnace Smelt Dissolving tank Water Lime mud washer Weak Liquor storage Lime mud thickener Causticizers Blow tank Washers Lime mud Lime kiln Water Dregs Dregs Dregs washer Weak liquor storage Source: Smook, 1994 Overview of the Kraft Process Chips Digester Blow tank Washers Weak black liquor storage Evaporators Strong black liquor storage 16 Water Lime The wood is mechanically debarked and cut Lime mud mud White liquor prior White liquor that are screened into chips the chemical washer clarifier storage treatment. Lignin and some carbohydrate materialLime aremud Causticizers dissolved from wood chips during cooking in thickener aqueous solution of alkaline, neutral or acidic componentsGrits at elevated temperature and Lime Lime kiln Slaker Pulp to pressure. bleaching Chips maintain their wood structure during chemical pulping but this latter is so weak that it Green liquor will break down to individual fiber by modest storage Water mechanical action. Green liquor clarifier Contaminated condensates Recovering furnace Smelt Dissolving tank Dregs Weak Liquor storage Dregs Dregs washer Weak liquor storage Source: Smook, 1994 Overview of the Kraft Process Chips Water Lime Spent and Lime dissolved mud mud White liquor inorganic White liquor Washing: washerfrom the clarifier storage organic materials are separated Digester Blow tank Pulp Washers Bleaching Weak black liquor storage Evaporators Strong black liquor storage 17 Contaminated condensates Recovering furnace pulp by multistage counter-current Weak washing system. Spent liquor is sent toLiquor Lime mud Causticizers storage the regeneration system. thickener Screening: Solid impurities contained in Grits washed pulp (mainly Lime incompletely the Lime kiln Slaker delignified wood and knots) are separated by screening. The rejects are Green liquor reprocessed. storage Bleaching: Depending in the intended Water application, pulp can be bleached. Pulp Dregs Green liquor Dregs Dregs made by the kraft process is darker than clarifier washer the original wood. Bleaching is the purification process that modify colored Smelt Weak liquor substance Dissolving so tank they either loose their light storage absorption ability or they dissolve. Source: Smook, 1994 Overview of the Kraft Process Chips White liquor storage Digester White liquor clarifier Pulp Bleaching Grits Strong black liquor storage 18 Lime Green liquor storage Weak black liquor storage Evaporators Slaker In order to be used asGreen a fuel, kraft liquor liquor Dregs Contaminated must be evaporated in aclarifier multistage condensates evaporation system. Recovering furnace Smelt Dissolving tank Water Lime mud washer Weak Liquor storage Lime mud thickener Causticizers Blow tank Washers Lime mud Lime kiln Water Dregs Dregs washer Weak liquor storage Source: Smook, 1994 Overview of the Kraft Process Chips White liquor storage Digester White liquor clarifier Causticizers Blow tank Pulp Washers Bleaching Weak black liquor storage Evaporators Strong black liquor storage 19 Contaminated condensates Recovering furnace Lime mud Water Lime mud washer Weak Liquor storage Lime mud thickener The strong black liquor is then burned in a Grits Lime Lime kiln Slaker recovery furnace where inorganic substances are converted into regenerable Green substances. liquor storage Sodium and sulfur salts are converted Water to a smelt of Na2S and Na2CO3 and brought Dregs Green liquor Dregs Dregs to a dissolved tank clarifier washer Smelt Dissolving tank Weak liquor storage Source: Smook, 1994 Overview of the Kraft Process Chips White liquor storage Digester White liquor clarifier Pulp Bleaching Grits Green liquor storage Weak black liquor storage Evaporators Strong black liquor storage 20 Slaker Water Lime mud washer Weak Liquor storage Lime mud thickener Causticizers Blow tank Washers Lime mud Lime Lime kiln Water The smelt is dissolved liquor Dregs washDregs Green liquorin weak clarifier plant. washer the recausticizing Contaminated from condensates Recovering furnace Smelt Dissolving tank Dregs Weak liquor storage Source: Smook, 1994 Overview of the Kraft Process Chips White liquor storage Digester White liquor clarifier Pulp Source: Smook, 1994 21 Strong black liquor storage Slaker Lime liquor The greenGreen liquor is storage clarified. Weak black liquor storage Evaporators Grits Bleaching Green liquor clarifier Contaminated condensates Recovering furnace Smelt Dissolving tank Water Lime mud washer Weak Liquor storage Lime mud thickener Causticizers Blow tank Washers Lime mud Lime kiln Water Dregs Dregs Dregs washer Weak liquor storage Source: Smook, 1994 Overview of the Kraft Process Chips White liquor storage Digester White liquor clarifier Pulp Bleaching Grits Slaker Water Lime mud washer Lime mud thickener Causticizers Blow tank Washers Lime mud Lime Weak Liquor storage Lime kiln Theblack green Weak liquor storage liquor is causticized withGreen reburned lime to form white liquor: liquor storage CaO and water are reacted in a slaker to form CaOH, which in turn Water reacts with Na2CO3 in the green liquor to form NaOH and CaCO3Dregs . Dregs Green liquor Dregs Contaminated Evaporators The CaCO3, which is insoluble, is separated by filtering and is clarifier washer condensates washed free from sodium salts. Smelt Recovering Strong black It is then calcinated in a lime kilnDissolving to CaOtank and reused.Weak liquor furnace storage liquor storage The regenared white liquor is reused in cooking. 22 Source: Smook, 1994 Pollutants in the P&P Industry What is a pollutant? A pollutant is “a substance that can alter the natural environment” (Springer and al., 2000). US EPA classification of pollutants 23 Oxygen-demanding substances Disease-causing agents Synthetic organic compounds Plant nutrients Inorganic chemical and mineral substances Sediments Radioactive substances Thermal discharges Environmental Impacts of the Kraft Process Wood preparation Chips To learn about major environmental impacts of the kraft process: Click on the yellow then pink boxes! White liquor clarifier White liquor storage Digester Pulp Bleaching Grits Source: Smook, 1994 24 Strong black liquor storage Lime Green liquor storage Weak black liquor storage Evaporators Slaker Green liquor clarifier Contaminated condensates Recovering furnace Smelt Dissolving tank Water Lime mud washer Lime mud thickener Causticizers Blow tank Washers Lime mud Weak Liquor storage Lime kiln Water Dregs Dregs washer Weak liquor storage Dregs Wood Preparation Air Pollution: Transportation of logs, production, screening, transportation and storage of chips as well as debarking activities can result in the emission of particulate matters. That are extremely difficult to measure. Water Pollution: Water is used for 3 purposes: log conveyance?, log washing and wet debarking. For more information Another type of fugitive emission associated with wood preparation activities is gaseous such as volatile organic compounds (VOC). 25 Return to the flowsheet Pulp Production Air Pollution: Water Pollution: The cooking process results in formation and releases of VOC’s and reduced components (TRS) that are odorous. Wood chips are cooked in aqueous solution. These compounds can exit the digester either in gaseous or liquid form. The gas are sent to condensers to remove water and other condensable compounds. For more information The non-condensable gas are incinerated in order to eliminate the odorous ones. The remainder are condensed and used to pre-heat the chips. 26 Return to the flowsheet Pulp Washing, Screening and Deknotting 27 Air Pollution: Water Pollution: The pulp washing, screening and deknotting do not result in new pollutant but volatile compounds contained in the pulp can escape during those operations. Pulp is washed to remove pulping chemicals and soluble wood components and diluted with water. For more information Return to the flowsheet Bleaching: Oxygen Delignification (OD) – Air Pollution In OD, steam, caustic (as oxidized white liquor), and oxygen are added to the pulp in order to reduce the lignin content before further bleaching. VOC’s are present in the incoming pulp, white liquor and washer shower water and can be released. CO2 and CO are formed in the reactor during the delignification. 28 Bleaching – Air Pollution Bleaching occurs in a multistep process involving the use of chemicals that will oxidize and dissolve the lignin. Following this process, the cellulose and the hemicellulose will be separated from the undesirable material. This process also involves chemical utilization. Traditionally, chlorine was used in the first stage of bleaching but it was replaced by ClO2 because of the possible formation of unwanted chlorine compounds. Use of sodium hypochlorite in the third stage has also mostly been discontinued because of concerns related with chloroform and AOX formation. Exhausts gases from bleaching will contain VOC’s, unreacted bleaching chemical, and inadvertently formed compounds. Most VOC’s are returned to the unbleached pulp slurry. It is also possible that ClO2 and Cl are present in small amounts in the bleach plant gases. CO is mostly formed in the first stage of bleaching. 29 Bleaching – Water Pollution Different chemicals are used in a multi-stage process to bleach the pulp. Aqueous washing is performed between stages to remove bleaching chemicals and any dissolved wood components extracted during bleaching. Water is also used to prepare bleaching chemical solutions and in air emission control scrubbers. Because waste water from bleaching usually has a high content in content in chlorine, it is incompatible with chemical recovery process and it is sent directly to the wastewater treatment. For more information 30 Return to the flowsheet Chemical Recovery: Evaporation Air Pollution: Water Pollution: Following the cooking, the spent cooking liquor referred to as weak black liquor. This liquor is composed of around 85% water and 15% solids that are a complex mixture of sulfur and sodium containing organic and inorganic compounds. Water from weak black liquor is evaporated and the condensates from the evaporators comprise the excess water from liquor concentration. These condensates can be reused in other processes but excess condensates are discharged to the wastewater treatment. During the evaporation of water, gaseous volatile compounds can be formed. Also, because of the presence of sodium sulfide in Kraft cooking liquor, TRS compounds can be released during the evaporation. To avoid bad odors, these gas are sent to combustion in order to oxidize the TRS. 31 Return to the flowsheet The condensates can contain high level of TRS, methanol and acetone. For more information Chemical Recovery: Recovery Furnace – Air Pollution When the liquor has a minimum of 60% solids, it is sent in the recovery furnace where the organic compounds are burnt and the inorganic compounds transformed in a molten smelt. The recovery furnace is the recovery furnace is the predominant source of TRS emissions. Particulates such as sodium sulfate and sodium carbonate are also emitted by the recovery furnace. Potassium compounds and other metals can be present in smaller quantities. Recovery furnaces also emit SO2, NOx, CO, volatile organic compounds and other products from incomplete combustion. There is also a potential for SO3, H2SO4, HCL and NH3 emissions. There are possibilities for other chlorinated compounds emissions but in very small quantities. 32 Return to the flowsheet Chemical Recovery: Dissolving and Clarification – Air Pollution Molten smelt drains from the furnace to a tank and the smelt is broken up with steam. The smelt particles fall into an agitated solution of weak wash. The mixture is called green liquor that is pumped to the clarifier where suspended solids are removed. Most of the emissions from the dissolving tank are TRS and particulate matter that are similar to the ones from the recovery furnace. VOC and NH3 can also be released. 33 Return to the flowsheet Chemical Recovery: Lime Kiln Air Pollution: Water Pollution Lime mud is calcinated to form CaO and CO2 in the lime kiln. Water is used to wash the solid precipitates formed in the recovery cycle. Washing recovers sodium and sulfur containing from green liquor dregs and lime mud. This weak wash is reused to dissolve recovery furnace and the excess is sent to the wastewater treatment. Most of the emissions from the lime kiln are TRS and particulate matter. SO2 emissions are low because of the alkaline atmosphere in the lime kiln. Lime kiln can also emit NOx, CO and VOC from incomplete combustion. 34 For more information Return to the flowsheet Chemical Recovery: Slaker – Air Pollution CaO from the kiln and green liquor from the dissolving tank are mixed together to give NaOH, CaCO3. A large amount of steam that must be ventiled is formed. The steam contains a lot a particulate matter that are mostly calcium and sodium carbonates and sulfates. NH3 can also be formed. 35 Return to the flowsheet Chemical Recovery Other Causticizing Area Equipment Air Pollution: Other equipment associated with the processing of green liquor (clarifiers, storage, surge tanks and dregs washers), white liquor (causticizers tanks, clarifiers, pressure filters and storage tanks), and lime mud (mix tanks, dilution tanks, storage tanks, pressure filters and pumps) can vent to the atmosphere. However, gas flow rates such as VOC and NH3 from this equipment are usually very small and concentrations low. 36 Return to the flowsheet Representative Bleached Kraft Mill Water Loads The highest volume of discharges comes from the paper mill. The largest BOD loads occur at the bleach plant. The paper mill process the highest amount of TSS. Return to Lime Killn Return to Evaporation Return to Pulp Production 37 Return to Bleaching Return to Pulp Washing Return to Wood Preparation (Source: Springer and al., 1997) Most Impacting Environmental Regulations Legislation is one of the drivers for implementing environmental changes and it is also recognized as a important factor to conserve an advantage over competitors. Also, there is a consensus that legislations will be more and more stringent over the next 25 years. For this reason, the regulations that have the most significant impact on the pulp and paper industry will be described in the following slides. The importance of legislation as well as of other drivers for environmental change will be described in tier II. 38 US EPA Clean Water Act The Clean Water Act launched in 1977 established the basic structure for regulating discharges of pollutants into the waters of the United States. By this, the USEPA has the authority to implement pollution control programs (e.g. setting wastewater standards for industry). It aims at reducing direct pollutant discharges into waterways, finance municipal wastewater treatment facilities, and manage polluted runoff using regulatory and non-regulatory tools. 39 US EPA Cluster Rule The US EPA Cluster Rule integrates air and water regulations. It was first published in 1998 and was applying to bleached paper grade kraft, soda and paper grade sulfite mills. Key features of the Cluster Rule are: 40 Implementation within 3 years; Bleach plant eflluent limitations for dioxin, chlorinated phenolics, and chloroform; AOX limitations; Establishment of best management practices (BMP) for control of spills of spent pulping liquor, turpentine and soap; Encouragement of project XL; No Change on BOD and TSS limits; No limits on color, methylene chloride, or methy ethyl ketone; No current COD limitations, but it changes in the future. US EPA Project XL Project XL stands for "eXcellence and Leadership” and is a US pilot program that allows state and local governments, businesses and federal facilities to develop with EPA innovative strategies to test better or more cost-effective ways of achieving environmental and public health protection. Project XL has 8 selection criteria: 1. Produce superior environmental results beyond those that would have been achieved under current and reasonably anticipated future regulations or policies; 2. Produce benefits such as cost savings, paperwork reduction, regulatory flexibility or other types of flexibility that serve as an incentive to both project sponsors and regulators; 3. Supported by stakeholders; 4. Achieve innovation/pollution prevention; 5. Produce lessons or data that are transferable to other facilities; 6. Demonstrate feasibility; 7. Establish accountability through agreed upon methods of monitoring, reporting, and evaluations; and 8. Avoid shifting the risk burden, i.e., do not create worker safety or environmental justice problems as a result of the experiment. 41 In addition, projects must present economic opportunities and incorporate community planning. Industrial Depollution Attestations (Quebec) Program for Industrial Waste Reduction: The Program for waste reduction was launched in 1988. Quebec Ministry of Environment has developed an intervention strategy integrating all receiving medias. The target industrials sectors were those whom contaminant rejects, more specifically releases of toxic substances had the largest impacts on local environments. Industrial Depollution Attestations: The Industrial Depollution Attestation is the legal tool that allows the ministry to operationalyze the Program for Waste Reduction. 42 Industrial Depollution Attestations (Quebec) The Industrial Depollution Attestation is a permit, renewable every 5 years, that establishes the environmental conditions under which the industry must operate. The Industrial Depollution Attestation main components are: Reject standards to respect; Requirements related to rejects follow-up; Other operation conditions as determined by the ministry; Studies to perform; Due dates and additional requirements. Targeted Sectors: 43 Pulp and Paper (is the only one to have completely implemented the program to date); Mines and Metallurgy; Organic and Inorganic Chemistry; Agri-food industry, wood transformation and textiles. Integrated Pollution Prevention and Control (IPPC) - Europe What is the IPPC: The IPPC is a European set of common rules on permitting for industrial installations. The aims of the IPPC Directive is to minimize pollution from various point sources throughout the European Union. Permits, based on the concept of Best Available Techniques (or BAT), are necessary to certain industry to be able to operate. 44 Kyoto Protocol and GHG Mitigations Climate change is a problem which affects all countries. Many human activities emit greenhouse gases (GHGs) to the atmosphere ( heating and cooling buildings, using energy,transportation, industrial processes, etc.). When in contact with the sun radiations, the GHGs act like a greenhouse's glass to block this heat from escaping back to space increasing the earth temperature. In1997, more than 160 countries met in Kyoto (Japan), and agreed to targets to reduce GHG emissions. This agreement is called the Kyoto Protocol. Canada's target is to reduce its GHG emissions to 6 percent below 1990 levels by the period between 2008 and 2012. The Protocol will only become legally binding when it is ratified by at least 55 countries, covering at least 55 per cent of the emissions addressed by the Protocol. Neither USA or Mexico have ratified the protocol. At this time (May 2004) the implementation is pending ratification by either USA or Russia. 45 GHG Mitigations & Pulp and Paper In 2003, the Forest Products Association of Canada has sign an agreement with the Canadian government concerning the GHG emissions which includes a commitment by the industry to reduce its greenhouse gas (GHG) emissions intensity by an average of 15 percent by 2008 to 2012, the first Kyoto commitment period. 46 References ENVIRONNEMENT QUÉBEC. 2003. Le Programme de réduction des rejets http://www.menv.gouv.qc.ca/programmes/prri/index.htm (page consulted in 2004) EUROPEAN COMISSION. Integrated Pollution Prevention and Control (IPPC) – 47 industriels et l’attestation d’assainissement. Reference Document on Best Available Techniques in the Pulp and Paper Industry. 2001, 475 p. Gullichsen, J. Fogelholm, C-J. (eds). Papermaking Science and Technology, Chemical Pulping, Book 6A. Tappi Press, Helsinki, Finland, 2000, 693 p. SMOOK, G.A. Handbook for pulp & paper technologists. 2nd ed. Angus Wilde Publications, Vancouver, Canada, 1992, 419 p. SPRINGER, Allan M. (ed.) Industrial Environmental Control – Pulp and Paper Industry. 3rd ed. Tappi Press, Atlanta, USA, 2000, 711 p. USEPA. 2003. Project XL. http://www.epa.gov/ProjectXL/ (page consulted in 2004) USEPA. 2003. Industrial Water Pollution Controls. http://www.epa.gov/OST/pulppaper/cluster.html (page consulted in 2004). 1.2 Introduction to minimum impact manufacturing (MIM) Content A. MIM concepts B. Progressive water system closure and build-up of NPE’s C. Zero discharge concepts D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 49 Content A. MIM concepts B. Zero discharge concepts C. Progressive water system closure and build-up of NPE’s D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 50 Weyerhaeuser’s Vision of MIM Minimum impact manufacturing (MIM) concept has first been introduced by Weyerhaeuser: “Using a Minimum Impact Manufacturing strategy, Weyerhaeuser directs its efforts to manufacturing quality products with minimal environmental impact and maximum return to shareholders. The strategy works to prevent pollution by continuously reducing process byproducts and finding ways to capture, reuse or recycle them.” (Weyerhaeuser website, 2004) 51 Weyerhaeuser’s Vision of MIM For a production facility MIM includes Weyerhaeuser's commitment to strive to close the loop by further: Optimizing raw materials used at the mill level Reducing water usage Minimizing fossil fuel for energy in manufacturing Reducing/eliminating hazardous waste Generating less solid waste Reducing emissions to all media Eliminating spills Reusing and recycling from our mills the materials and residuals that previously went to landfills Collecting and recycling used waste paper for use as a raw material (Weyerhaeuser website, 2004) 52 Goals of MIM Minimum Impact Manufacturing aims to: Eliminate process issues before they become environmental problems. Address multiple environmental areas, including air and water quality, solid and hazardous waste minimization and more. Use science and economics to focus on pollution prevention at the source rather than end-of-pipe remedies. (Weyerhaeuser website, 2004) 53 Environmental Hiearchy of Needs Completion of the Forest products cycle Energy, odor, color, biodiversity, etc. Resource depletion acute toxicity, raw effluent, etc. 54 Minimum Impact Subtle, Complex, Aesthetic Chronic toxicity, bioaccumulation, etc. Chronic and/or Long-Term Effects Acute Impacts on the environment Source: Erickson, Zacher and Decrease, 1996 Key Environmental Parameter Related to MIM 55 Water Air Water Usage Bleach Plant Effluent Volume Final Effluent Volume BOD COD TSS Effluent AOX Dioxin Color Chronic Toxicity Nutrients Particulate TRS Methanol Chloroform Chlorine Chlorine Dioxide CO/CO2 NOx SO2 VOCs Opacity HAPS Solid Waste Solid Waste Generated Solid Waste Disposition: - Landfill - Recycled - Energy Reduction Plans/Achievements Hazardous Waste Elimination Other Accidental Releases Non-Compliant Events SARA 313 Releases Energy Use/Energy Exports Aesthetics: - Site Appearance - Odor - Noise Improvement Projects Chemical Management Key Environmental Accomplishments Content A. MIM concepts B. Zero discharge concepts C. Progressive water system closure and build-up of NPE’s D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 56 Goal of Process Closure The goal of process closure with respect to effluent discharges is to minimize the amount of waste generated. This can be accomplished by: Using more efficient processes; Using processes that do not require water; Recovering the waste materials. (Source, NCASI, 2003) 57 Rapson-Reeve Process In 1967 Rapson proposed a bleached kraft pulp manufacturing process that had the potential to greatly reduce, if not eliminate, effluent discharges. The idea was based on a collection of technologies, including incresed use of chlorine dioxide for bleaching and a process for generating this chemical that could be fully integrated with the chemical requirements of the kraft pulping and bleaching processes. The driver for this process was a cost effective alternative to the biological effluent treatment. The process was implemented by the Great Lakes Paper mill in Thunder Bay, but abandoned. 58 Rapson-Reeve Process The original effluent-free mill concept was based on the following ideas: 59 Replace 70-80% of the chlorine in the chlorination stage with an equivalent amount of chlorine dioxide. Use a new chlorine dioxide generating process. Use countercurrent washing in bleach plant, using wastewater from the wet end of the pulp dryer or paper machine to minimize de volume of filtrate to be recovered. Use a portion of the bleaching filtrate to wash the unbleached filtrate, allowing the dissolved from bleaching to be recovered via evaporation and burning. Use the remainder of the bleaching filtrate to wash the lime mud and green liquor dregs and to dissolve the smelt from the recovery furnace. Rapson Reeve Process Effluent-free concept (Cont’d): 60 Treat the evaporator condensates with a small amount of chlorine dioxide to oxidize the foul-smelling compounds and use the oxidized condensates in place of fresh water on the wet end of the pulp dryer or paper machine. Remove the sodium chloride from the liquor cycle by extracting it from the recovery furnace flue gas in the electrostatic precipitator. A portion of the extract would be used to generate chlorine dioxide for the bleach plant and the remainder would be discarded. Establish closed water systems for wood debarking, pulp screening, and cleaning. Main Problems in Making a Mill EffluentFree Non-process elements can accumulate. Pulp quality can be affected. About one quarter of the water pollution in bleached pulp mills comes from spills and wash-up and are not well controlled. Calcium trap: when there is any acid stage in the bleaching sequence (ozone), calcium carbonate will travel with the pulp in neutral or alkaline stages, but dissolve in acid stages. If countercurrent washing is used, the calcium will be precipitated into the pulp in any previous alkaline stage and carried forward to be redissolved in acid stage. In order to obtain the appropriated displacement ratio and purge for each stage, the flow of filtrate in and out must be precisely balanced. In order to minimize the consumption of oxidizing agent in subsequent stages throught incomplete washing, the concentration of organic matter in each filtrate must be carefully controlled. 61 Process Closure Technologies Definition: Process closure technologies can be defined as those which effect or enable the reduction of waterborne wastes from pulp manufacturing facilities. They serve to divert wood components and other raw materials from liquid waste streams by prevention, reuse, or recovery. These technologies were largely driven by the desire to limit the discharge of chlorinated organic compounds. 62 Zero Discharge Concept For a majority of pulp mills zero-effluent discharge is impracticable. Currently, zero effluent operation appears to be restricted to plants producing bleached chemical thermal mechanical pulp and non-chlorine bleaching agents. Since the bleach plant is the major source of contaminated effluent in a kraft pulp mill, the closure of these circuits is an essential prerequisite for producing a zero-effluent kraft mill. This requires the simultaneous resolution of a number of problems: 63 water balance, chemicals balance, corrosion, precipitation of salts and removal of non-product substances. Low Effluent Kraft Mill Examples Newest Mills of America The 3 newest mills of America were designed to be highly economical and environmentally performing using high capacity, single line facilities, and employing modern technology for pulp production and effluent treatment. None of these mills practices recovery of bleaching wastewaters but their effluent quality is among the best in the world. These mills are: 64 Bahia Sul, Brazil; Alabama Pine Pulp, USA; Alberta-Pacific, Canada. Low Effluent Kraft Mill Examples Mill Practicing Recovery of Bleaching Filtrates Linerboard mills: 65 AssiDomän Frövi, Swenden; Kappa Kraftliner (formerly AssiDomän) Piteå, Sweden; SCA Munksund, Sweden. Low Effluent Kraft Mill Examples Mill Practicing Recovery of Bleaching Filtrates Bleached papergrade kraft mills: 66 Blue Ridge Paper Products – Canton, North Carolina, U.S.A. International Paper Company – Franklin, Virginia, U.S.A. Aspa Bruk – Smurfit Munksjö, Sweden M-Real Sverige AB – Husum, Sweden SCA Pulp AB – Östrand, Sweden Södra Cell – Mörrum, Sweden Södra Cell – Värö Bruk, Sweden Stora Enso – Skoghall, Sweden Metsä-Botnia – Rauma, Finland UPM-Kymmene Wisaforest – Pietarsaari, Finland Content A. MIM concepts B. Zero discharge concepts C. Progressive water system closure and build-up of NPE’s D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 67 Progressive Water System Closure Conventional methods to achieve water closure are simple and include: Using counter-current washing in pulping and bleaching operations; Closing brownstock screen room; Using dry debarking; Using evaporator condensate for brownstock washing; Recycling excess whitewater from paper machine to bleach plant; Reusing stripped condensates from steam stripping of foul condensates; Using equipment and process that require less water; Using cooling towers for vacuum pump seal water an non-contact cooling water; Using first bleach stage washer/filtrate to dilute brown high-density stock; Recycle/reuse secondary and/or tertiary treated effluent; Applicating changes to pulping and bleaching practices will further strive to the closure. 68 Non Process Elements (NPEs) NPEs are materials such as potassium (K), phosphorus (P), manganese (Mn), magnesium (Mg), iron (Fe), aluminium (Al), silicon (Si), calcium (Ca), barium (Ba), and chlorine (Cl) that enter the chemical pulping process with the wood, water and chemicals. When we decrease fresh water consumption, there is a potential for increasing the concentration of some troublesome substances and more specifically NPEs. 69 NPEs Consequences NPEs accumulate in the sodium and calcium cycle in kraft process potentially causing the following consequences: 70 Corrosion of the recovery boiler and other equipment; Deposits on the boiler tubes that reduce heat transfer; Scale in the digester, evaporators, and heat exchangers; Blinding of white liquor and lime mud filters; Reduced reburned lime reactivity; Ring formation in the lime kiln; Increased dust formation in the lime kiln; Increased chemical consumption in bleaching; Reduced effectiveness of ozone and peroxide bleaching. NPEs Classification There are to catogories of NPEs: 1. NPEs that form insoluble metal hydroxides or carbonates and are removed from the sodium cycle with the dregs and grits: mostly Ca, Mg, Mn and Si. 2. NPEs that form soluble compounds in alkaline solution: mostly Al, Cl, and K. 71 Build-up of NPEs In an « open » mill the presence of NPEs is not importance since they are purged outside the system. When progressively closing mill, many outlets are not available anymore. The consequence of this is the build-up of NPEs. NPEs have a tendency to accumulate in eighter the sodium or calcium cycle in the following way: Sodium Cycle: K > Cl > Al > Fe > Si > Mn > Mg > Ca Calcium Cycle: Mg > Al > Fe > Mn > Si > Na > K > S > Cl The most troublesome NPEs are K, Cl and Na. Na is the most tricky because it is a process and nonprocess element at the same time. 72 Content A. MIM concepts B. Progressive water system closure and build-up of NPE’s C. Zero discharge concepts D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 73 Tracking Models for Water, NPE’s, and Targeted Species Path diagram equation: It is a mass integration tool whose objective is to track targeted species (e.g., NPEs and water) as they propagate throughout the process and provides the right level of details to be incorporated into a mass integration analysis. A typical form of the path equations is to describe outlet flows and compositions from each critical unit as a function of inlet flow, inlet compositions, and appropriate design and operating parameters. Steps for analysis will be described in the following slides. 74 Main Characteristic of the Path Diagram Equation In order to optimize water allocation in a pulping process, two important activities can be used together: mass integration and process simulation. Mass integration techniques handle process objectives, data, requirements and constraints. It will allow to fix performance targets, solution strategies, and proposed changes to the process. P roc es s Because of these changes, the performance must be reassessed using process analysis or simulation. The use of process simulation enables the update of flowrates and compositions throughout the process 75 (Source: Lovelady, 2001) O b jec tiv es , D a ta , a n d C o ns traints P roc es s m o d ific ations , s truc tu ra l c ha ng es , P ro ce ss In teg ra tion P ro ce ss S im ula tion In p u t-o u tpu t re la tion s,n e w p ro ce ss p e rfo rm a nc e P e rfo rm an ce ta rg e ts, S olu tio ns, S tra te gies , a n d Ins igh ts , Learn more about simulation Learn more about Mass integration 1. Degrees of Freedom NV = NS x NC F= NV - NE = NC (NS - 1) F: degrees of freedom NV: number of variables NE: number of equations NC: number of targeted species NS: number of outlet streams Assumptions: All inlets to a unit are known and it is desired to determine the outputs of the unit. F must provided as additional modeling equations, assumptions, measurements, or data in order to have an appropriately specified (determined) set of equations that is solvable. Outlet streams Nstreams out Inlet stream (Fresh inputs or outlets from other units) Unit U 76 2. Mixer-Splitter Model The mixer-splitter model is a modeling technique which relies on nominal data . The nominal data are those for the plant prior to any changes and can be obtained via simulation, fundamental modeling, direct measurements, or literature data. There are various of the mixer splitter model: Fixed split model; Flow ratio model ; Species ratio model. Based on the knowledge of the process, choices can be made for the selected model and streams/species. Path equations can be developed for water and targeted NPEs throughout the process. 77 Fixed Split Models The fixed split model adopts a certain split for the flows of the various streams leaving the unit. This model is useful in predicting flows out of many units, particularly separators. αF F 78 Fixed Split Model (1-α)F Flow Ratio Model The ratio model, relates certain streams or components via fixed ratios. The flow ratio model assumes that inlet and outlet flows of certain streams maintain a certain ratio. F Flow Ratio Model G2 = G1 x F2 F1 79 G Species Ratio Model The species ratio model is another form of the ratio model. It assumes relationship between certain species within the same stream via fixed ratios. This is particularly useful when one component can be accurately tracked while another one cannot. F Flow Ratio Model B2 = A2 x (β/α ) 80 Specy A = α Specy B = β Content A. MIM concepts B. Progressive water system closure and build-up of NPE’s C. Zero discharge concepts D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 81 Energy in Kraft Mill Kraft mills are usually partly energy sufficient: 82 They generate power using sources such as wood wastes and spent pulping liquor. This is very important since CO2 emissions from renewable sources are not included in the greenhouse gases inventory considered under the Kyoto protocol. The emergence of new technologies will allow the kraft mill to be essentially energysufficient in the future. Kraft Mill Energy Efficiency To maximize operating profit a mill requires the following technologies: 83 Since black liquor is the largest source of energy in a kraft mill, it is important to use it in an efficient way. A higher solids content will result in more steam produced and less heat going to recovery stack as water vapor. Pulping yield must be increased using new cooking technologies with reduced energy consumption. Washing and screening must be runned at higher consistencies and their performance must be increased in order to reduce the water necessary to wash the pulp. For improved steam economies and evaporation to high solids levels with scaling, modern evaporators with heat treatment can be used. Kraft Mill Energy Efficiency To maximize operating profit a mill requires the following technologies: New kiln technology with large precoat filters, flash dryers, product coolers and better insulating brick will reduce lost of heat. Screening and conditioning of chips will reduce fines generation and improve digester yield. Others: 84 Economies of scale are important in terms of energy consumption; Using less water will generally reduce heating requirements; Efficient mill layout will reduce friction loss associated with long piping; Etc. Content A. MIM concepts B. Progressive water system closure and build-up of NPE’s C. Zero discharge concepts D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 85 Effect of Water Closure on Energy Effect of reducing water usage on energy flows are strong and complex. This leads to complex process designs and an increasing need for systematic and system-oriented analysis of energy and water use in the mills. On of the challenge is to deal with excess heat that increases the temperature of process streams and effluent. Process integration can be an useful tool to understand this can of problems. 86 Content A. MIM concepts B. Progressive water system closure and build-up of NPE’s C. Zero discharge concepts D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 87 BAT Concept (Source: European IPPC) BAT: Best Available Technology economically achievable Key characteristics of BATs: There is no single reference of best available techniques in pulp and paper industry. In contrast, the list of techniques to consider in the determination of BAT provides a lot of different options of an overall BAT for given mills, which may be combined in different ways. The BAT-concept is process-related because the environmental impact is caused on this level i.e. by different manufacturing processes as for instance cooking, bleaching, de-inking, coating etc. The single processes, the raw materials used and the product properties to be achieved determine the emission of a mill. That means when approaching the pulp and paper industry different types of raw materials used and processes involved have to be distinguished. 88 BAT Concept (Source: European IPPC) Key characteristics of BATs (Cont’d): As pulp and paper products are highly diverse and utilized processes even for one and the same product may vary greatly, many factors of production technology must be taken into account to guarantee a high level of environmental protection. For the pulp and paper industry the best available techniques cannot be defined solely by describing unit processes. Instead, the whole installations must be examined and dealt with as entities. BAT in pulp and paper industry is linked to the environmental performance of mills. There are different options for suitable combinations of processes depending - besides other things - on the product properties to be achieved. As a consequence, the process-oriented approach has to be extended by a product-oriented concept i.e. the BAT approach must be linked to the environmental performance of specific types of mills where specific products are manufactured. Thus, in this document best available techniques are presented for major mill classes separately. 89 BAT - Remark The following programs are based on BAT: USEPA Cluster Rules; European IPPC. 90 Content A. MIM concepts B. Progressive water system closure and build-up of NPE’s C. Zero discharge concepts D. Tracking models for water, NPE’s, and targeted species E. Kraft mill energy efficiency F. Relation between minimum energy and minimum effluent G. BAT concepts H. Example of application of MIM concept 91 Application of MIM Concepts: The Flint River Case Study Description of the mill Flint River is a Kraft pulp mill located in Georgia, USA. It is producing 320 000 tons per year of fluff pulp. Flint River Operations' environmental performance has been recognized as superior within the bleached Kraft pulping industry. Flint River was the first bleached Kraft pulp mill to employ commercially viable advanced technologies that minimize adverse impacts to the environment such as oxygen delignification, 100% chlorine dioxide substitution and bleaching and extensive water conservation practices. 92 Application of MIM Concepts: The Flint River Case Study Weyerhaeuser Project XL: Weyerhaeuser Company's pulp manufacturing facility in Oglethorpe, Georgia, is striving to minimize the environmental impact of its manufacturing processes on the Flint River and surrounding environment by pursuing a long-term vision of a Minimum (environmental) Impact Mill. Weyerhaeuser Company is taking immediate steps by decreasing water use and meeting or exceeding all regulatory targets. EPA and the State of Georgia have agreed to propose changes in the rules to support minimum impact manufacturing. The Final Project Agreement was signed on January 17, 1997. 93 Application of MIM Concepts: The Flint River Case Study MIM phases at Flint River MIM Phase I (1979-1980) Original Facility Design Oxygen Delignification Extensive Water Recycle / Reuse Chlorine/Chlorine Dioxide Bleaching Air Emissions / Low Odor / BACT/ NSPS Extensive Wastewater Treatment MIM Phase II (1981-1985) 94 River & Lake Environmental Studies Holding Pond Addition / Delta Color Management Process Reliability I (Rate/Surge) Spill Containment & Liquor Best Management Practices Application of MIM Concepts: The Flint River Case Study MIM phases at Flint River MIM Phase III (1986-1995) Process Reliability II (Statistical Process Control) Elimination Of Molecular Chlorine Bleach Plant & Chemical Generator Collection Emergency Response Team (Fire/Hazmat/EMT/Confined Space) ISO 9000 Certification MIM Phase IV (1996-1997) 95 Isothermal Cooking Odor Control System Upgrade Energy Steam Reductions ISO 14001 Environmental Management System (EMS) Application of MIM Concepts: The Flint River Case Study MIM phases at Flint River MIM Phase V Bleach Plant Effluent Reductions Solid Waste Reductions Timberland Resource Strategies Water Use Reduction Energy Conservation Hazardous Air Pollutant (HAP) Emission Reductions MIM Phase VI: 96 Life Cycle Inventory References EUROPEAN COMISSION. Integrated Pollution Prevention and Control (IPPC) – Reference Document on Best Available Techniques in the Pulp and Paper Industry. 2001, 475 p. LOVELADY, EVA M. An Integrated Approach to the Optimization of Water Usage and Discharge in Pulp and Paper Plants. Auburn University, USA, 2002, 185 p. 97 Minimum Impact Manufacturing. 1996 International Environmental Conference & Exhibits. 1996, p.623-628. NCASI. Pulp Mill Process Closure: A Review of Global Technology Developments and Mill Experiences in the 1990s. Technical Bulletin No. 860, May 2003, 108 p. PAPRICAN. Energy cost reduction in the pulp and paper industry. Pointe Claire, QC, Canada : Pulp and Paper Research Institute of Canada, 1999. USEPA. Project XL – Weyerhaeuser Company. http://www.epa.gov/projectxl/weyer/index.htm (page consulted in 2004). WEYERHAEUSER. 2001. Minimum Impact Manufacturing. http://www.weyerhaeuser.com/environment/reducingpollution/minimumimpact mfg.asp (page consulted in 2004) 1.3 Related PI Tools Content Process Simulation Process Integration Mass Integration Energy Integration LCA Integrating these tools to address MIM 99 Content Process Simulation Mass Integration Energy Integration LCA Integrating these tools to address MIM 100 What is a Model? A Simulation? A model is an abstraction of a process operation used to build, change, improve or control that process. Models are useful for: Equipment design, sizing, selection Comparison of possible configurations Evaluation of process performance against limits (e.g. concentrations, effluent discharge rates, …) Debottlenecking and optimization Control strategy development and evaluation Simulation involves performing a series of experiments with a process model. 101 Return to Path Diagram Equation Benefits of Simulation Better understanding of the process Consistent set of typical mill data Objective comparative evaluation of options for ROI etc. Identification of bottlenecks, instabilities etc. Perform many experiments cheaply once model built Avoid implementing ineffective solutions 102 Return to Path Diagram Equation Models Are Only an Approximation of the Reality There is many type of models: 103 Physical (e.g. mimic panel) vs. mathematical Quantitative vs. qualitative First principles vs. empirical Steady state vs. dynamic Type and level of precision of a model will depend on many factors such as: Phenomena represented Level of detail and granularity Assumptions Kind of input required Functions performed (constraint satisfaction? optimization? …) Nature of output generated Return to Path Diagram Equation Content Process Simulation Process Integration Mass Integration Energy Integration LCA Integrating these tools to address MIM 104 Process Integration Definitions: “Process integration is a holistic approach to process design, retrofitting, and operation which emphasizes the unity of the process.” (El-Halwagi, 1997) “The holistic analysis of processes involving the following elements: 105 Process data; Systems and tools; Process engineering principles and in dept process sector knowledge.”(Stuart, 2002) Content Process Simulation Process Integration Mass Integration Energy Integration LCA Integrating these tools to address MIM 106 Mass Integration Definition: “Systematic methodology that provides a fundamental understanding of global flows of mass within the process and employs this holistic understanding in identifying performance targets and optimizing the generation and routing of species throughout the process” (El-Halwagi, 1997) Pollution prevention is one of the most important objectives of mass integration! 107 Return to Path Diagram Equation Principles of Mass Integration Mass integration is based on chemical engineering principles combined with system analysis. Mass flow must be represented from a species viewpoint: For each targeted species, there are sources (streams that carry the substances) and sinks (reactors, heaters/coolers, etc.). Streams living the sinks become sources. The sinks can be generator of targeted species. Each sink/generator can be manipulated through design or their operations can be changed in order to affect the flow rate and composition of what each sink/generator accepts as discharges. Sources are generally prepared for sinks through segregation and separation via waste interception network. Effective pollution prevention can be reached by combination of stream segragation, mixing, interception, recycle from sources to sinks and sink/generator manipulations. 108 Return to Path Diagram Equation Segregation, Recycle, Interception and Sink/Generator Manipulation Segregation: Avoiding the mixing of the streams. Recycle: Utilization of pollutantladen stream (a source) in a process unit (a sink). Interception: Utilization of separation unit operation to adjust the composition of the pollution-laden streams to make them acceptable for sinks. Sink/Generator manipulation: Design or operation of changes that alter the flowrate or composition of pollutant-laden streams entering or leaving the process units. 109 Sources Return to Path Diagram Equation Mass and Energy-Separating Segregated Sinks/ Agents In Sources Generators Sources (back to process) 1 2 Waste Interception Network Nsink Mass and Energy-Separating Agents Out (To Regeneration and Recycle) Source: El-Halwagi, 1997 Content Process Simulation Process Integration Mass Integration Energy Integration LCA Integrating these tools to address MIM 110 Energy Integration Definition: “Systematic methodology that provides a fundamental understanding of energy utilization within the process and employs this understanding in identifying energy targets and optimizing heat-recovery and energy-utility systems” (El-Halwagi, 1997) Energy integration tool: Thermal-pinch techniques are based on thermodynamic principles and are used, among others, to identify minimum heating and cooling utility requirements. 111 Principles of Thermal Pinch Reduction of Utilities Hot Utility Cold Utility Utility costs decrease $ Internal Exchanges Trade-off PROCESS Costs related to exchange area increase Trade-off From 100% utilies… … toward 100% internal exchanges 112 Composite Curves Definition: Composite Curves consist of temperature-enthalpy (T-H) profiles of heat availability in the process (the “hot composite curve”) and heat demands in the process (the “cold composite curve”) together in a graphical representation. 113 Grand Composite Curve The grand composite curve is the tool that is used for setting multiple utility targets. T Qh Heat transfer intra process Pinch Point Qc 114 H Grand Composite Curve Example of Application T HP LP Reduction of high pressure steam (HP) by using a source of energy of lower quality (LP) H 115 Heat Exchanger Network Design Key Steps Heat and Mass Balances 1. Data Extraction 2. Analysis Targeting Process Modifications Utility Selection PINCH ANALYSIS 3. 4. 116 Design Process Simulation Total Site Analysis Selection of Alternatives 5. Project Detailling Source: Linnhoff March,1998 Content Process Simulation Process Integration Mass Integration Energy Integration LCA Integrating these tools to address MIM 117 What is LCA Definitions: A systematic set of procedures for compiling and examining the inputs and outputs of materials and energy and the associated environmental impacts directly attributable to the functioning of a product or service system throughout its life cycle.” (Source: ISO 14040: Life cycle assessment – principles and framework, 1998) "Life Cycle Assessment is a process to evaluate the environmental burdens associated with a product, process, or activity by identifying and quantifying energy and materials used and wastes released to the environment; to assess the impact of those energy and materials used and releases to the environment; and to identify and evaluate opportunities to affect environmental improvements. The assessment includes the entire life cycle of the product, process or activity, encompassing, extracting and processing raw materials; manufacturing, transportation and distribution; use, reuse, maintenance; recycling, and final disposal". (Source: Guidelines 118 for Life-Cycle Assessment: A 'Code of Practice', SETAC, Brussels, 1993 ) Example Life Cycle of Newspaper Wood Allocated out of the System Aspen Waste paper Management Forestry Spruce Steam Generation Hog fuel Sawmill Lumber Allocated out of the system Waste paper Chips TMP Electricity Production Municipal Landfill Fuel Production Air emissions DIP Chemical Production Wastewater Papermaking Water Newsprint Writing Newspaper Use phase 119 Solid wastes Effluent Treatment Sludge Treatment Landfill Industrial Transportation LCA Methodology Applications: Goal and Scope Definition Interpretation Invetory Analysis Impact Assessment For more information on each LCA methodology steps, click on the corresponding box. 120 Development and improvement of products Strategic planning Public policy development Marketing Others Other tools: Technical Economic Market Social etc Limitations Goal and Scope Definition The goal of an LCA study shall unambiguously state the intended application, the reasons for carrying out the study and the intended audience, i.e. to whom the results of the study are intended to be communicated. 121 Goal and Scope Definition The scope of the LCA consists in: the functions of the product system, or, in the case of comparative studies, the systems ; the functional unit ; the product system to be studied ; the product system boundaries ; allocation procedures ; data requirements ; assumptions ; types of impact and methodology of impact assessment, and subsequent interpretation to be used ; limitations ; initial data quality requirements ; type of critical review, if any ; type and format of the report required for the study. Goal and Scope Definition Interpretation Invetory Analysis 122 Impact Assessment Function Definition: Service supplied by a system of product or a process unit. Examples: System Possible functions 123 Paper Recycling Cogeneration Waste paper valorisation Electricity generation Deinked pulp production Steam production Etc. Etc. Return to the scope Functional Unit Definition: « Quantified performance of a product system for use as a reference unit in a life cycle assessment study » Examples: System 124 Paper Recycling Cogeneration Possible functions Waste paper valorisation Deinked pulp production Etc. Electricity generation Steam production Etc. Related functional unit Recuperation of 1000 kg of waste paper Production of 1 ton of deinked pulp Etc. Generation of 1MW of electricity Production of 300000 of steam by hour at 125oC and 0.3 MPa Etc. Return to the scope Product System Environment Elementary flow Unit process A Elementary flow Intermediate flow Elementary flow Definition: « Collection of materially and energetically connected unit processes which performs one or more defined functions » 125 Unit process B Elementary flow Intermediate flow Elementary flow Unit process C Elementary flow Product flow Environment Return to the scope System Boundaries Environment System boundaries Elementary flow Unit process A Elementary flow Intermediate flow Elementary flow Definition: « Interface between a product system and the environment or other product systems » Unit process B Elementary flow Intermediate flow Elementary flow Unit process C Elementary flow Product flow 126 Environment Return to the scope Allocation 127 Most industrial processes comprise more that one output product, and raw material inputs include intermediate products. These processes are multifunctional. In LCA terms, this means that the product system under system provides more functions than the one related to the functional unit. A decision will have to be taken in order to decide how to split flows and environmental intervention between these functions. This is allocation: “partitioning the input or output flows of a unit process to the product system under study” The allocation procedures must respect the mass conservation rules. The production of by-products as well as the open loop recycling are two common situations implicating allocation. By-Products Definition: A by-product can be defined as an output which is neither the primary product neither a waste. Example: Suppose you have a system with primary function to produce paper. In this system, you have a unit process which is wood sawing and which results in two products, chips and lumber. Only chips will be used in the wood manufacturing, lumber will be sent out of the system and use in another one. So, in the system which has as main funtion to produce paper, lumber is a by-product. 128 Open vs. Close-Loop Recycling Close-loop recycling: Raw Material The product is reused in the same product system to produce the same product. Production Recycling Use No allocation required! Disposal Close-loop recycling: Recycling of one product from on system to another. 129 Allocation of environmental impacts and credits of recycling will have to be allocated between both system. Return to the scope Raw Material (product 1) Raw Material (product 2) Production (product 1) Production (product 2) Recycling Use (produit 1) Use (produit 2) Disposal (product 1) Disposal (product 2) Inventory Analysis Definition: “Phase of life cycle assessment involving the compilation and quantification of inputs and outputs, for a given product system throughout its life cycle” Goal and Scope Definition Interpretation 130 (Source: ISO 14041) Invetory Analysis Impact Assessment Life Cycle Impact Assessment Definition: “Phase of life cycle assessment aimed at understanding and evaluating the magnitude and significance of the potential environmental impacts of a product system” (Source: ISO 14042) 131 From Inventory to Impact Assessment Impact Inventory Production Processes Energy Production Waste Disposal & Management Transport Emissions: CFC Pb Cd HAP COV DDT CO2 SO2 NOX P Dust Etc. Resource Depletion Resource Depletion Global Warming Ozone Depletion Ecotoxicology Human Health Smog Acidification Eutrophication Etc… Mortality and Diceases Agregated Indicator Resource Depletion Ecosystem Depletion Aesthical Value Solid Wastes Solid Wastes Problem Approach “Midpoint” Damage Approach “Endpoint” Solid wastes 132 PRECISION Goal and Scope Definition Interpretation Invetory Analysis Impact Assessment Interpretation Definition: “Phase of life cycle assessment in which the findings of either the inventory analysis or the impact assessment, or both, are combined consistent with the defined goal and scope in order to reach conclusions and recommendations” LCA FRAMEWORK INTERPRÉTATION GOAL & SCOPE LCI LCIA 1. Significant points identification 2. Verification by: - Completeness check - Sensibility check - Coherence check - Others Conclusions Recommendations Reports Goal and Scope Definition Interpretation Invetory Analysis 133 (Source: ISO 14043) Applications Impact Assessment LCA Main Limitations Site-specific impact are not well considered Steady-state approach Linear modeling Based on a number of technical assumptions and value choices for instance: Impact categories Characterization models System boundaries Weighting of impacts Availability and reliability of data and models 134 Content Process Simulation Process Integration Mass Integration Energy Integration LCA Integrating these tools to address MIM 135 In Summary Minimum Impact Manufacturing aims at minimizing: Resource consumption Energy consumption Environmental impact (soil, air and water emissions) Simulation are useful to better understand the process Mass integration is a tool to reduce resource consumption and reject in the environment Energy integration is a tool that allows for a better utilization of the energy LCA allows for a holistic evaluation of environmental impacts over the product chain 136 Integration of Tools to Address MIM MIM is a multi-objective problem involving the best trade-offs between: Minimum resource consumption; Minimum energy consumption; Minimum air emissions; Minimum water emissions; Minimum solid wastes. This is also submitted to a lot of complicated constraints: 137 Process constraints ; Technology constraints; Life cycle interactions; Costs. For these reasons, integration of PI tools to address MIM is not obvious. References El-Halwagi, Mahmoud M. Pollution Prevention through Process Integration, Academic Press, San Diego, USA, 1997, 318 p. ISO 1997. Management environnemental – Analyse du cycle de vie Principes et cadres. CAN/CSA-ISO 14040:1997 ISO 1998. Management environnemental – Analyse du cycle de vie – Définition de l’objectif et du champ de l’étude et analyse de l’inventaire. CAN/CSA-ISO 14041:1998 ISO 2000. Management environnemental – Analyse du cycle de vie – Analyse de l’impact du cycle de vie. CAN/CSA-ISO 14042:2000 ISO 2000. Management environnemental – Analyse du cycle de vie – Interprétation du cycle de vie. CAN/CSA-ISO 14043:2000 Linnhoff March. 1998. Introduction to Pinch Technology. http://www.linnhoffmarch.com/pdfs/PinchIntro.pdf (page consulted in 2004) 138 QUIZ Question 1 What is one of the main characteristics of kraft processes? a) b) c) d) 140 The mechanical pulp The necessity to bleach the pulp The chemical recovery system Its low water consumption Question 2 Which of the following unit processes generates the most sulfur compound emissions? a) b) c) d) 141 Oxygen delignification Bleaching Pulping (digester) Recovery furnace Question 3 Toward which of the following elements is MIM oriented? a) b) c) d) e) 142 Reducing air emissions Reducing solid wastes Maximising shareholder value a and b a, b and c Question 4 Which of these technical problem can be associated to process closure? a) Accumulation of undesirable elements in the recovery system b) Higher cost of utility c) Higher energy consumption d) Need of more pulping chemicals 143 Question 5 Which of these tracking model will you use if one component can be accurately tracked while another one cannot a) b) c) d) 144 Fixed split model Flow ratio model Species ratio model Degree of freedom equation Question 6 Which of these is not a characteristic of BAT? a) b) c) d) 145 They must be economically achievable They must be process unit oriented They must be process oriented They must be product oriented Question 7 Which of the following will not decrease Kraft mill energy consumption a) b) c) d) 146 Water consumption reduction Chips screening Less piping Changing ECF bleaching for TCF bleaching Question 8 Which of the following trade-offs is the most communly associated with energy integration? a) Reducing energy while increasing water consumption b) Capital vs. operating costs c) Energy vs. chemical costs d) Time horizon vs. energy savings 147 Question 9 Which of the following correspond to segregation in mass integration? a) Avoiding the mixing of the streams. b) Utilization of pollutant-laden stream (a source) in a process unit (a sink). c) Utilization of separation unit operation to adjust the composition of the pollution-laden streams to make them acceptable for sinks. d) Design or operation of changes that alter the flowrate or composition of pollutant-laden streams entering or leaving the process units. 148 Question 10 Which of the following can be described as a functional unit? a) The production of kraft pulp b) The production of kraft pulp during 10 hours c) The production of 1 admt kraft pulp d) b and c 149