NMR Report Template - Energize Connecticut

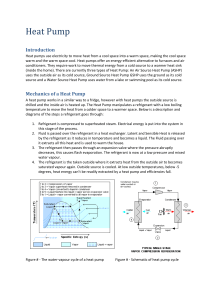

advertisement