IAE II ANSWER KEY EEFA 1. A production function can be

advertisement

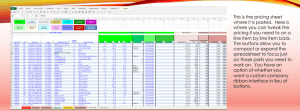

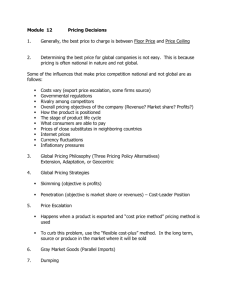

IAE II ANSWER KEY EEFA 1. A production function can be expressed in a functional form as the right side of where is the quantity of output and capital, labour, land or raw materials). are the quantities of factor inputs (such as 2. In she short run, every firm is constrained by some fixed input that (1)leads to diminishing returns to variable inputs and (2)limits its capacity to produce. As a firm approaches that capacity, it becomes increasingly costly to produce successively higher levels of output. Marginal costs ultimately increase with output in the short run. 3. Negative Demand Unwholesome demand No demands Latent Demand Declining demand Irregular demand Full demand Overfull demands 4. Accounting method Statistical or econometric method Survivorship Method Engineering method 5. In the short run, there are both fixed and variable costs. In the long run, there are no fixed costs. 6. Survival Profit Sales Status Quo 7. 1. Survival: 2. Return on Investment: 3. Market Stabilisation: 4. Maintenance and Improvement of Market Position: 5. Meeting or Following Competition: 6. Pricing to Reflect Product Differentiation: 7. Preventing New Entry: 8. Production Function A production function can be expressed in a functional form as the right side of where is the quantity of output and quantities of factor inputs (such as capital, labour, land or raw materials). are the If is not a matrix (i.e., a scalar, a vector, or even a diagonal matrix), then this form does not encompass joint production, which is a production process that has multiple co-products. On the other hand, if maps from then it is a joint production function expressing the determination of different types of output based on the joint usage of the specified quantities of the inputs. One formulation, unlikely to be relevant in practice, is as a linear function: where function: are parameters that are determined empirically. Another is as a Cobb-Douglas production The Leontief production function applies to situations in which inputs must be used in fixed proportions; starting from those proportions, if usage of one input is increased without another being increased, output will not change. This production function is given by Other forms include the constant elasticity of substitution production function (CES), which is a generalized form of the Cobb-Douglas function, and the quadratic production function. The best form of the equation to use and the values of the parameters ( ) vary from company to company and industry to industry. In a short run production function at least one of the 's (inputs) is fixed. In the long run all factor inputs are variable at the discretion of management. 9. Estimation of cost i. Time Period: We must choose an appropriate time period for the analysis of cost. The choice of such a time period involves the following important considerations: a. Normality: The time period of study should be normal. A period during which the changes in technology, plant size, efficiency, other dynamic events are non-existent or are at their minimum. b. Variety: the length of period should be such that it includes sufficiently wide variation in output, so that enough observation is available for getting a reliable cost function. c. Recent period: since the results of the cost function are to be used as a guide for future planning, the period chosen should be recent enough to include data which will be relevant for the future. 10. RETURN TO SCALE The law of returns to scale describes the relationship between outputs and the scale of inputs in the long-run when all the inputs are increased in the same proportions. To meet a long-run change in demand the firm increases its scale of production by using more space, more machines and laborers in the factory. i. All factors (inputs are variable but enterprises is fixed. ii. A worker works with given tools and implements. iii. Technological changes are absent iv. There is perfect competition. v. The product is measured in quantities. This is explained with the help of a diagram 11. COST FUNCTIONS 1. Accounting method: this method is used by the cost accountants. Essentially, in this method the data is classified into various cost categories. Observations of cast are then taken at the extreme and the various intermediate levels of output. By plotting the output levels and the corresponding costs on a graph and joining them by a line the cost functions are estimated. The cost functions, thus found, may be linear or non-linear. It must be noted that while finding cost functions from basic data in this wat, no attention is generally paid to build up a hypothesis or to find out the changes in conditions which influence cost. 2. Statistical or econometric method: this method uses statistical techniques on economic data to find the nature of cost-output relationship. The economic data may relate to past records of the firm or to the different firms in the same business at a point of time. If we use the series data we generally get a short-run cost function, while if we take resources to the cross section data we derive a long-run cost function. 3. Survivorship Method: this method is based on the rationale that overtime competition tends to eliminate firms of inefficient size and that only the firms with efficient size will survive as these will have lower average cost. The size-group whose share in the industry grows the most during the specified time period is considered the most efficient size-group. For example, if the share of small firms in the industry increases at the cost of the share of large firms, it implies that the optimum size of a firm in the present case is the small one. 4. Engineering method: In the engineering approach, the cost functions are estimated with the help of physical relationships, such as weight of supplies and materials used in a process, rated capacity of equipment, etc. emphasis is placed primarily on the physical relationship of production and these are then converted into money terms to arrive at an estimate of costs. This method may be useful if good historical data is difficult to obtain. But this method requires a sound understanding of engineering and a detailed sampling of the different process under controlled conditions, which may not always be possible. 12. A. Cost-oriented Method: 1. Cost plus pricing: 2. Mark-up pricing: 3. Break-even pricing: 4. Target return pricing: 5. Early cash recovery pricing: B. Market-oriented Methods: 1. Perceived value pricing: 2. Going-rate pricing: a. Competitors ‘parity method: b. Premium pricing: c. Discount pricing: 3. Sealed-bid pricing: 4. Differentiated pricing: a. Customer segment pricing: b. Time pricing: c. Area pricing: d. Product form pricing 13. 1. Survival: 2. Return on Investment: 3. Market Stabilisation: 4. Maintenance and Improvement of Market Position: 5. Meeting or Following Competition: 6. Pricing to Reflect Product Differentiation: 7. Preventing New Entry: