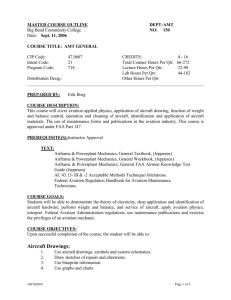

optimization of aviation maintenance technician training

advertisement