MEG381.LABS.PreswsureCalib

advertisement

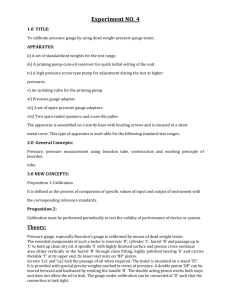

UNIVERSITY OF BAHRAIN COLLEGE OF ENGINEERING DEPARTMENT OF MECHANICAL ENGINEERING MEG 381 Instrumentation Calibration of a pressure gauge (dead weight test) Introduction: DEAD WEIGHT TESTERS The operation of dead weight testers is based on the principle of balancing known weights against the force produced by an unknown pressure action on a hydraulic piston of a known area. When these forces reach equilibrium, the unknown pressure equals the dead weight and piston. Dead weight testers incorporate a built-in pump for generating pressure and can be used for checking spring gauges, calibrating bourdon gauges, recorders, transmitters or other instruments, pressure testing small vessels, and measuring gas pressure with high accuracy. Brass weights (optional stainless steel weights) Measuring units psi, bar, kPa or kg/cm2 Supplied with metal carrying case(s) Portable version with an accuracy of +/- 0.1 % of rated pressure: Pressure ranges from 500 psi up to and including 15,000 psi. Laboratory version with an accuracy of +/- 0.05 % (optional +/- 0.03 %) of rated pressure: Pressure ranges from 500 psi up to and including 20,000 psi, electric motor drive 220 V (optional 110 V). High pressure laboratory dead weight tester with an accuracy of +/- 0.1 % for very high pressures: 25,000 psi, 35,000 psi and 40,000 psi Objective: Getting to know the concept of calibration by calibrating a Burdon tube pressure gauge using Deal weights. Apparatus: As shown in the figure below. The ory: The applie d pressu re on the piston p Wher e, F= force. = mg A= area. m= mass. g= acceleration due to gravity ( g=9.81 m/s2 ). It is given that the piston has a diameter of 20mm. Therefore the area, F A A 4 20 10 3 2 314.16 10 6 m 2 For a mass of 1kg: F 1Kg 9.81m / s 2 9.81N P 9.81 314.16 106 0.0312 10 6 N / m 2 0.31 105 N / m 2 = 0.31 bar Sensitivity: 0.3 bar per 1kg. Procedure: 1) Placed the pressure gauge unit on a table and see that it is properly installed according to the manufacturer’s manual. 2) Pressure Gauge Nullification: At atmospheric conditions you will find that the pointer below zero. An adjustment is necessary to eliminate the reading due to piston’s weight. On adjust the knob on the backside of the gauge until the pointer reaches zero. 3) Placed the given dead weights one by one. Read the pointer of the gauge precalculation: place the weights gently on the piston . The pressure creating piston is not entirely free from friction to its motion in the cylinder. Under static conditions the friction is of considerable amount. In order to eliminate the error due to friction. The piston together with the weights should be in rotational motion. Then static friction change to sliding friction which is considerably less. Make sure that the piston is rotated in the same direction. Result: Piston Mass (kg) Area of piston (m2) Pressure in cylinder Pc(KN/m2) Gauge (1) Reading Pg ( KN/m2) Gauge (2) Reading Pg ( KN/m2) Average PR ( KN/m2) Absolute Gauge Error PC-PR %Error (PCPR)/PC *100 0 0 5 2.5 -2.5 ___ 1 31.2 20 30 25 6.23 19.93884 2 62.5 45 60 52.5 9.95 15.93578 93.7 75 90 82.5 11.2 11.93272 125 105 125 115 9.9 7.929664 156 135 155 145 11.1 7.129052 6 187 165 185 175 12.4 6.595311 7 219 195 195 195 23.6 10.78899 3 4 5 314.16*10^-6 m2 0 By using mat lab program, we can get precision error and bise error.