Accounting for the Stiffness of Three-Dimensional Features in a TwoDimensional Axisymmetric Rotating Disk Analysis

by

Kurt E. Leach

A Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING

IN MECHANICAL ENGINEERING

Approved:

_________________________________________

Ernesto Gutierrez-Miravete, Project Adviser

Rensselaer Polytechnic Institute

Hartford, Connecticut

April, 2012

1

© Copyright 2012

by

Kurt Leach

All Rights Reserved

2

CONTENTS

Accounting for the Stiffness of Three-Dimensional Features in a Two-Dimensional

Axisymmetric Rotating Disk Analysis ........................................................................ 1

LIST OF TABLES ............................................................................................................. 5

LIST OF FIGURES ........................................................................................................... 6

TABLE OF SYMBOLS .................................................................................................... 8

ACKNOWLEDGMENT ................................................................................................... 9

ABSTRACT .................................................................................................................... 10

1. Introduction................................................................................................................ 11

2. Methodology .............................................................................................................. 12

2.1

Description of Problem .................................................................................... 12

2.2

Test Variables................................................................................................... 12

2.3

Analysis Methodology ..................................................................................... 14

2.3.1

CAD Model Creation ........................................................................... 14

2.3.2

FEA Model Creation ............................................................................ 16

2.3.3

Boundary Conditions ........................................................................... 18

3. Results and Discussion .............................................................................................. 20

3.1

3.2

3.3

Model Validation ............................................................................................. 20

3.1.1

Two-Dimensional Model ..................................................................... 20

3.1.2

Three-Dimensional Model ................................................................... 25

Two Dimensional Interface Load vs. Three Dimensional Interface Load ....... 25

3.2.1

Interface Load Results.......................................................................... 25

3.2.2

General Sensitivities............................................................................. 27

Accounting for Stiffness Difference in Two-Dimensional Axisymmetric

Analysis ............................................................................................................ 29

3.3.1

Plane Strain Elements at Tab ............................................................... 29

3.3.2

Plane Strain Elements at Tab with Altered Material Properties in Outof-Plane Direction ................................................................................ 29

3

3.3.3

Axisymmetric Elements at Tab with Altered Material Properties in Outof-Plane Direction ................................................................................ 29

4. References.................................................................................................................. 30

5. Appendix.................................................................................................................... 32

4

LIST OF TABLES

Table 2.1 – Test Matrix for Parameter Evaluation .......................................................... 13

Table 3.1 – Force Summations for All Cases .................................................................. 22

Table 3.2 – Summary of Contact Results for 25% Material Removed Case .................. 23

Table 3.3 – Summary of Contact Results for 50% Material Removed Case .................. 24

Table 3.4 – Summary of Contact Results for 25% Material Removed Case .................. 24

Table 3.5 – Interface Loads for 25% Material Removed Case........................................ 26

Table 3.6 – Interface Loads for 50% Material Removed Case ........................................ 26

Table 3.7 – Interface Loads for 75% Material Removed Case........................................ 26

Table 3.8 – Interface Load as a Function of Mesh Size .................................................. 27

Table 3.9 – Interface Load as a Function of Planar Element Type ................................. 28

Table 3.10 – Interface Load as a Function of Contact Element Type ............................. 29

5

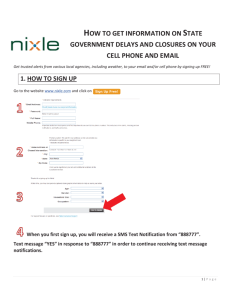

LIST OF FIGURES

Figure 2.1 – Sketch Showing the Tab and Slot of a Typical Interrupted Interface ......... 14

Figure 2.2 – General Dimensions of Generic Rotating Disk used for this Study ............ 15

Figure 2.3 – Schematic showing Sector Angle and Tab Thickness ................................ 16

Figure 2.4 – Finite Element Mesh used for the Two-Dimensional Analysis .................. 17

Figure 2.5 – Finite Element Mesh used for the Three-Dimensional Analysis (shown is

the 50% mat’l removed, 16 tab case)............................................................................... 18

Figure 2.6 – Boundary Conditions to be applied to the Models ...................................... 19

Figure 3.1 – Free body diagram for the 1st Disk (2D Model – 25% material removed

case) ................................................................................................................................. 21

Figure 3.2 – Free body diagram for the 2nd Disk (2D Model – 25% material removed

case) ................................................................................................................................. 22

Figure 3.3 – Plot of Nodal Reaction Forces for All Three Cases .................................... 25

Figure 3.4 – Radial Deflections for Different Mesh Sizes .............................................. 28

6

7

TABLE OF SYMBOLS

TPS = Thickness applied to Plane Stress with Thickness Element (in)

N = Total Number of Tabs

T = Width of One Tab in Circumferential Direction (in)

R = Net section radius (in)

% = Percent Material Removed to create the Tab

Fcentrif = Centrifugal Load (lbf)

m = mass of disk (lbf-s2/in)

r = radial center of mass (in)

ω = Angular Velocity (rad/s)

Fhoop = Radial Constraining Load due to Circumferential Strains (lbf)

σH = Circumferential Stress (psi)

A = Cross-sectional Area of the Fully Circumferential Section (in2)

Finterface = Force transmitted Between 1st Disk and 2nd Disk due to Contact (lbf)

Fconstraint = Reaction force at Radial Constraint (lbf)

8

ACKNOWLEDGMENT

Type the text of your acknowledgment here.

9

ABSTRACT

Type the text of your abstract here.

10

1. Introduction

In the gas turbine industry, both aviation and power generation, the performance and

durability of the engine’s components are of the utmost importance. In aviation gas

turbines, such as commercial turbofan engines, this attention to component durability is

magnified since public safety is in the balance. Therefore, it is essential for any aircraft

engine producer to ensure that safety and component durability are at held in high

regard.

Along with that notion, weight and cost are the biggest drivers toward

competitiveness. One of the biggest weight and cost contributors to a turbofan engine

are the compressor and turbine rotors. The rotors also pose the highest safety in the case

that they fail. With today’s modern advances in finite element analysis, a rotor system

for either a turbine or compressor can be modeled to understand the state of stress in

each rotating component. With today’s capability, it is impractical to create a full threedimensional model of a rotor system; therefore, axi-symmetry is taken advantage of for

modeling these rotors. However, most rotors have non-axisymmetric features such as

holes, tabs, slots, splines, etc. These features are necessary to rotor and engine

functionality; however it can be challenging to model these features in a twodimensional axi-symmetric model. This project will examine the ways that some of the

error caused by non-axisymmetric features, specifically tabs, can be reduced.

11

2. Methodology

2.1 Description of Problem

In two-dimensional rotating disk analyses, three-dimensional out-of-plane features need

to be accounted for since almost all rotors are not perfectly axisymmetric. A popular

way to account for the out-of-plane features is to use plane stress with thickness element

and then apply the appropriate thickness amount to account for the mass of the feature.

In the case of tabs, the thickness that is applied is shown by Equation 2.1.

Equation 2.1

Where:

TPS = Thickness applied to Plane Stress with Thickness Element (in)

N = Total Number of Tabs

T = Width of One Tab in Circumferential Direction (in)

Assuming the same material properties are applied to the plane stress with thickness

elements as the axisymmetric elements, then the mass will be accurately captured;

however, there will be significant differences in stiffness. For the same metal-to-air ratio

in the tab, the same thickness value will be applied regardless of the number of features.

In other words, the thickness value applied in the model will be the same whether there

are 2 large tabs of 100” thickness with or 100 small tabs of 2” thickness. In each of

these instances the stiffness will be different and therefore should be treated differently

in the two-dimensional axisymmetric model. Understanding the difference between the

plane stress with thickness stiffness and the true stiffness (measured with a threedimensional cyclic symmetric model) will be an aid to help determine what corrective

action to take to account of this stiffness difference in the two-dimensional axisymmetric

model.

2.2 Test Variables

The first step in finding a way to correct the stiffness in the two-dimensional axisymmetric analysis is to understand the variables that contribute to the stiffness

difference. A three-dimensional model will be run in order to understand what the true

12

stiffness of the slotted flange should be.

Then it will be compared to the two-

dimensional representation to evaluate the difference in load transferred through the

contact. Here, two variables will be evaluated, the number of tabs and the percent

material removed by the slots.

Number of Tabs

Table 2.1 – Test Matrix for Parameter Evaluation

% Material Removed

25%

50%

75%

4

4

4

8

8

8

16

16

16

32

32

32

64

64

64

The equation for percent material removed by the slot is shown in Equation 2.2.

Equation 2.2

Where: N = Number of Tabs

T = Thickness of One Tab (in)

R = Net section radius (in)

% = Percent Material Removed to create the Tab

The sketch in Figure 2.1 shows the tab thickness defined as well as the slot width for a

sector cut of a typical high pressure turbine rotating disk.

13

Figure 2.1 – Sketch Showing the Tab and Slot of a Typical Interrupted Interface

2.3 Analysis Methodology

2.3.1

CAD Model Creation

First, three-dimensional and two-dimensional solid models must be created in a

Computer Aided Design (CAD) software. For this project, NX 6 was be used to create

the solid models. To make the model creation easier, the CAD model was built using

parametric modeling. By creating a parametric model, the tab thickness and the number

of tabs can be defined at a variable, and when the variable changes, the updates

propagate through the rest of the model. A sketch of the generic model along with some

dimensions is shown in Figure 2.2.

14

Figure 2.2 – General Dimensions of Generic Rotating Disk used for this Study

For the three-dimensional model, the two-dimensional section was swept in order

to create a sector. The sector angle was defined as 360˚ divided by number of tabs

modeled. Equation 2.2 can be rearranged in order to come up with an appropriate tab

thickness for a given the number of tabs and percent of material removed by the tab.

Figure 2.3 shows an example of one of the three-dimensional models that was created

along with the sector angle and tab thickness definition.

15

Figure 2.3 – Schematic showing Sector Angle and Tab Thickness

Using this methodology, all the CAD models necessary to complete the test matrix

will be built.

2.3.2

FEA Model Creation

After the two-dimensional sheet bodies and the three-dimensional solid bodies are

created the models will be imported in to finite element analysis software. For this

project ANSYS will be used as the analysis software. The two-dimensional ANSYS

models will be built first.

2.3.2.1 Two-Dimensional Model

The two-dimensional models will be analyzed using PLANE42 elements. The

axisymmetric option will be used for the axisymmetric regions of the part, and the plane

stress with thickness option will be used to model the tab. The thickness value applied

to the plane stress with thickness region will be equal to the number of tabs multiplied

16

by the tab thickness. For the contacts, CONTAC12 node-to-node contact elements will

be used. An initial contact stiffness of 1E+10 will be used, and the penetrations and

relative sliding will be checked in order to ensure the proper contact behavior.

CONTAC12 elements have a significant advantage over 2D surface-to-surface in terms

of solution time and convergence probability. A mesh size study will be performed in

order to make sure that the loads and deflections are converged as a function of mesh

size.

The two-dimensional mesh size will then be carried over into the three-

dimensional model. Figure 2.4 shows the finite element mesh that will be used for the

two-dimensional analysis.

Figure 2.4 – Finite Element Mesh used for the Two-Dimensional Analysis

2.3.2.2 Three-Dimensional Model

The three-dimensional models will be analyzed using SOLID45 elements. The

axisymmetric portion of the two disks will be sweep meshed such that each of the

symmetry boundaries has a matching mesh. This facilitates the application of cyclic

symmetric boundary conditions.

The cyclic symmetric boundary condition can be

achieved by coupling the nodes on one symmetry boundary with the corresponding

nodes on the opposite symmetry boundary in all degrees-of-freedom (radial, axial and

17

circumferential).

The contact will be modeled with CONTA174 surface-to-surface

contact elements with a contact stiffness of 1E+10. Again, the penetration amounts will

be checked in order to ensure that this is an appropriate value. Figure 2.5 shows the

finite element mesh that will be used for the 50% percent material removed, 16 tab case.

Figure 2.5 – Finite Element Mesh used for the Three-Dimensional Analysis (shown is the 50% mat’l

removed, 16 tab case)

2.3.3

Boundary Conditions

The boundary conditions will be iterated in the two-dimensional axisymmetric

model in order to generate a contact load on the order of 100,000 lbs for the full

circumference. The 1st Disk will be fixed at the inner diameter in the axial direction and

the 2nd Disk will be fixed at the inner diameter in the radial and axial directions. The

rotation speed will be iterated in order to come up with a value that meets the load

criteria.

18

Figure 2.6 – Boundary Conditions to be applied to the Models

After some iteration, a value of 12,000 RPM was chosen for the rotational speed. This is

on the order of magnitude of the operation of a commercial jet engine high turbine rotor.

Also, it provides on the order of 100,000 lbs of interface load which it typical of an HPT

rotor interface load.

19

3. Results and Discussion

3.1 Model Validation

3.1.1

Two-Dimensional Model

3.1.1.1 Free-Body Diagram

In order to validate the model behavior, a free-body diagram was created of both the

components. The main loads acting on the two disk are the centrifugal load due to the

angular rotation (Fcentrif), the radial constraint due to the circumferential strains (Fhoop),

the contact load (Finterface) and the radial constraint (Fconstraint). The centrifugal load due to

the angular rotation was approximated by Equation 3.1.

Equation 3.1

Where:

Fcentrif = Centrifugal Load (lbf)

m = mass of disk (lbf-s2/in)

r = radial center of mass (in)

ω = Angular Velocity (rad/s)

The radial constraint due to the circumferential strain is approximated by Equation 3.2.

Equation 3.2

Where:

Fhoop = Radial Constraining Load due to Circumferential Strains (lbf)

σH = Circumferential Stress (psi)

A = Cross-sectional Area of the Fully Circumferential Section (in2)

The interface load and the reaction at the radial constraint were extracted directly from

the analysis results. Figure 3.1 shows the free-body diagram of the 1st disk with all the

loads for the 25% material removed case.

20

The 1st disk shows a residual radial force of 4,000 lbs. This difference can be due to the

approximation of Fcentrif and Fhoop for this system. However, this is only 0.1% of the

highest load on the disk and about 2.5% of the interface load.

Figure 3.1 – Free body diagram for the 1st Disk (2D Model – 25% material removed case)

Figure 3.2 shows the 2nd disk free body diagram.

21

Figure 3.2 – Free body diagram for the 2nd Disk (2D Model – 25% material removed case)

The 2nd disk shows a residual force for 500 lbs. Again, this difference can be attributed

to the approximation of the centrifugal load and the hoop constraint. Table 3.1 shows

the force summations for all three cases.

Table 3.1 – Force Summations for All Cases

Overall, based on these force summations, the two-dimensional axisymmetric model is

behaving as expected and all the forces are accounted for within some tolerance.

22

3.1.1.2 Global Deflections

3.1.1.3 Contact Checks

The contact behavior in the two-dimensional model needs to be validated in order to

ensure that the contact elements are behaving as expected.

Some of the checks

performed include: checking contact load distribution, contact penetration, relative

motion between contact node pairs, and element status. Table 3.2 shows a summary of

the aforementioned results for the 25% material removed case.

Table 3.2 – Summary of Contact Results for 25% Material Removed Case

Here it is shown by looking at the contact element status that only the last two elements

along the surface are in contact, and the remaining elements are out of contact. This

result is verified by the fact that the last two elements are transmitting a load and the

other contact elements are not. Also, the elements that are not in contact show a gap

between the node pairs, whereas the elements in contact show some amount of

penetration. This penetration is necessary in order to gain model convergence, however

to large of penetration can lead to incorrect model results. A typically accepted value for

contact penetration is ~0.1 mils, and here 0.01 mils of penetration is shown. Therefore,

the contact stiffness chosen (1E+10) is sufficient enough for this particular application.

Also, the relative axial motion between the contacts was evaluated. The amount of

relative motion between the node pairs is around 0.010” for all of the contact pairs. The

global element size in this analysis is 0.050” and therefore, the relative axial motion of

the contact node pairs only consumes about 20% of the element length and therefore, the

23

uses of a node-to-node contact type is sufficient for this analysis.

For further

verification, see section 3.2.2.3 where a sensitivity to contact element type is performed.

Summaries of the contact results for the 50% and 75% percent material removed case

are shown in Table 3.6 and Table 3.7 respectively.

Table 3.3 – Summary of Contact Results for 50% Material Removed Case

Table 3.4 – Summary of Contact Results for 25% Material Removed Case

For these two cases, appropriate contact behavior is validated in the same manner that

the 25% material removed case was. The elements in contact show a radial force

transmitted and a small amount of penetration, and the elements out of contact show a

gap between node pairs and no transmission of load. The contact penetration amounts

are appropriate for this application and the relative axial motion levels are acceptable.

One difference between the cases is that as the percent material removed increases, the

24

radial load becomes more distributed along the contacting surface. This is validated also

by looking at nodal reaction plots of the contact surface as seen in Figure 3.3.

Figure 3.3 – Plot of Nodal Reaction Forces for All Three Cases

The nodal force plot validates the contact behavior with respect to the load distribution

along the contacting surface. Overall, the contact elements are behaving correctly and

the contact element type and contact stiffness chosen are appropriate for this application.

3.1.2

Three-Dimensional Model

3.1.2.1 Comparison of Three-Dimensional Results to Two-Dimensional Results

3.2 Two Dimensional Interface Load vs. Three Dimensional Interface

Load

After running the model at the aforementioned boundary conditions, the results were

post-processed in order to understand the differences in interface load between the twodimensional axisymmetric model and the three-dimensional cyclic symmetry model.

3.2.1

Interface Load Results

Table 3.5, Table 3.6 and Table 3.7 show the differences between the two-dimensional

axisymmetric model and the three-dimensional cyclic symmetric model for the 25%,

50% and 75% material removed for the tab cases respectively.

25

Table 3.5 – Interface Loads for 25% Material Removed Case

Table 3.6 – Interface Loads for 50% Material Removed Case

Table 3.7 – Interface Loads for 75% Material Removed Case

Here it is evident that the difference between the two-dimensional axisymmetric

model and the three-dimensional cyclic symmetric model increases as the number of

tabs decrease. This difference was shown to be as high 34.3% for the 75% material

removed – 4 tab case. It is clear that the method of using plane stress with thickness

elements to model the tab in the two-dimensional axisymmetric model is not sufficient in

cases where there is a small quantity of tabs with a large thickness. As the number of

tabs increase and therefore the tab width decreases, the interface load for the three26

dimensional cyclic symmetric model begins to converge on the two-dimensional

axisymmetric model interface load. This is because the tabs decrease in width and the

tabs region becomes a plane stress application. For plane stress theory to be completely

applicable, the thickness must be one-tenth of the smallest in-plane dimension. For this

case, that would mean that the tab width would need to be 0.040”. However, for the

purposes of only capturing the overall stiffness of the tab (and not the stresses in the

two-dimensional axisymmetric model), the limits may need to expanded.

3.2.2

General Sensitivities

In order to ensure that the solid element type, mesh size and contact element type used

were appropriate, a number of sensitivity studies were performed, including mesh size,

axisymmetric element type, and contact element type.

3.2.2.1 Mesh Size

The mesh in the two-dimensional axisymmetric model was iterated from a global

element size of 0.050” down to 0.010”. The following table shows the interface load for

a given case as a function of mesh size.

Table 3.8 – Interface Load as a Function of Mesh Size

The data shows that the maximum difference between a mesh size of 0.010” and

0.050” is about 0.2%. Therefore a mesh size of 0.050” is sufficient for this analysis.

27

Figure 3.4 shows the radial deflections for different mesh sizes. The differences in the

global radial deflections between the different mesh size cases are indecipherable.

Figure 3.4 – Radial Deflections for Different Mesh Sizes

The 0.050” element mesh size will continue to be used for this analysis. This allows for

accurate results, meanwhile providing sufficient computational efficiency. This mesh

size will also be used for the three-dimensional analysis, using this study as a basis.

3.2.2.2 Solid Element Type

There are two different four node planar element types available for use in ANSYS, the

PLANE42 and the PLANE182 (both have axisymmetric and plane stress with thickness

options). Here a general sensitivity was performed in order to be sure that these element

types yield consistent results. Table 3.9 shows that there is essentially no difference in

interface load between the two different element types.

Table 3.9 – Interface Load as a Function of Planar Element Type

28

3.2.2.3 Contact Element Type

In the two-dimensional model, there are a number of different options for contact

elements. Here, node-to-node contact (CONTAC12) and two-dimensional surface-tosurface contact (CONTA172) were evaluated. Table 3.10 shows the interface load

results for the two contact element types.

Table 3.10 – Interface Load as a Function of Contact Element Type

The node-to-node contact element is not suited well for analysis where large deflections

and large rotations come in to play, however, they are far more robust and

computationally efficient than the surface-to-surface contact elements. Here it is shown

that the load does not change significantly between the contact element types, and

therefore the node-to-node contact elements will continue to be used for this study.

3.3 Accounting for Stiffness Difference in Two-Dimensional

Axisymmetric Analysis

3.3.1

Plane Strain Elements at Tab

3.3.2

Plane Strain Elements at Tab with Altered Material Properties in Out-ofPlane Direction

3.3.3

Axisymmetric Elements at Tab with Altered Material Properties in Out-ofPlane Direction

29

4. References

[1]

ANSYS 11.0 Theory Reference, ANSYS Corporation, 2007

[2]

Budynas, Richard Gordon, Joseph Edward Shigley, and J. Keith Nisbett.

Shigley’s Mechanical Engineering Design. 8th ed. New York, NY: McGraw-Hill

Science/Engineering/Math, 2008.

[3]

Davis, Erica. “A Study of a Combined 2D Axisymmetric and 3D Cyclically

Symmetric Finite Element Model of a Turbine Disk” RPI Master's Project

http://www.ewp.rpi.edu/hartford/~ernesto/SPR/Davis-FinalReport.pdf

[4]

Hassan, Mohammed. “Vibratory Analysis of Turbomachinery Blades” RPI

Master's Project http://www.ewp.rpi.edu/hartford/~ernesto/SPR/Hassan-FinalReport.pdf

[5]

Cook, Robert D. Concepts and Applications of Finite Element Analysis. 4th Ed.

John Wiley and Sons, 2002

[6]

Meguid, S.A., P.S. Kanth, and A. Czekanski. "Finite element analysis of fir-tree

region in turbine discs." Finite elements in analysis and design. 35.4 (2000): 305-317.

Web. 1 Feb. 2012.

[7]

Sun, W. “Bolted joint analysis using ANSYS superelements and gap elements”.

4th Int ANSYS Conf Exhib 1989 Part 2, p 6.66-6.75, 1989. Publ by ANSYS

[8]

Jettappa, Richard Rodrigues. “Pseudo-density approach to the solution of a thin

rotating turbine engine disk”. Proceedings of the ASME Turbo Expo, v 6, PARTS A

AND B, p 1087-1095, 2010, ASME Turbo Expo 2010: Power for Land, Sea, and Air, GT

2010. Publ by ASME

30

[9]

Beisheim, J. R. “Three-dimensional finite element analysis of dovetail

attachments with and without crowning”. Journal of Turbomachinery, v 130, n 2, April

2008. Publ by ASME

31

5. Appendix

32