Syllabus

advertisement

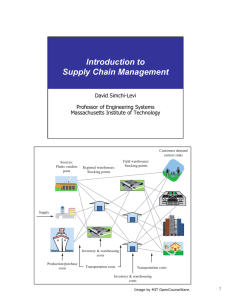

IE 572 - Production Planning Systems Design Spring 2003 Instructor Alper Sen, office: EA-321B, phone: 290-1539, e-mail: alpersen@bilkent.edu.tr Course Schedule Monday 10:40-12:30, Wednesday 9:40-10:30 (EA-322) Office Hours By appointment only Course summary This is a graduate level course in production and distribution systems planning. Major emphasis will be given to the design and management of the supply chain. The topics that are covered in this course include logistics network configuration, risk pooling and multiechelon inventory systems, value of information in supply chains, coordination of the supply chain using contracts and other mechanisms, distribution strategies for the supply chain and product design for supply chain efficiency. The topics will be covered in two steps. First, the concepts, issues and solution approaches will be introduced using material which is mostly qualitative. This first step is aiming to get the student familiar with the main issues in designing and managing the supply chain and practical innovations attempting to solve them. Lectures will include real life examples or cases when possible. The second step will focus on recent academic research in supply chain management. The emphasis will be on analytical modeling of the supply chain. The analytical models either evaluate the performance of a particular supply chain configuration or prescribe solutions or solution approaches. This part of the lecture will be covered using recent papers that appeared in scholarly journals. Course Textbook Simchi-Levi, D., Kaminsky, P., and Simchi-Levi, E., Designing and Managing the Supply Chain: Concepts, Strategies, and Cases, McGraw-Hill, 1999 ISBN: 0-07-235756-8. Supplemental Texts Chopra, S., and Meindl P., Supply Chain Management: Strategy, Planning and Operation, Prentice Hall, 2001 ISBN 0-013-026465-2. Tayur, S, Ganeshan R., and Magazine M. (eds), Quantitative Models for Supply Chain Management, Kluwer Academic Publishers, 1999 ISBN 0-7923-8344-3 Student Responsibilities and Grading Attendance is mandatory and students who will miss a class should inform the instructor in advance. Class participation is required and students may need to prepare before the class. The main responsibility of the student is reading and understanding each academic paper (see the list of papers that are not underlined below) and presenting one in class. The students are expected to understand the analytical modeling and derivations without much help from the instructor, however a short introduction to inventory theory will be provided in the first 2 weeks of the class. Paper summary (25%) Each student need to read each paper that will be discussed in the class and submit a one page summary prior to the class. The summary should include a description of the problem/phenomena studied in the paper, specific features that distinguish the paper from earlier work, a verbal description of the analytical model, main analytical and computational results and practical insights gained from the study. Paper presentation (20%) Each student need to present one paper (see the list of papers that are under required sections below) in class. The presentation should be about 20-25 minutes which will be followed by a class discussion. Research proposal (30%) Each student is required to study a specific topic of their choice (in supply chain management, topics related to their thesis is fine as long as the linkages with SCM can be established) in depth and submit a proposal for researching a specific problem. The proposal should include a qualitative discussion of why the problem is important, a detailed literature survey and proposed methodology and modeling tools to be used in the research. Suggested research could be analytical modeling as well as an empirical study. Main deliverable is a report describing the proposal; however a presentation may also be necessary depending on the schedule. Final (25%) A written close books and notes exam covering the concepts and research covered in the class. Course Outline Introduction Required Simchi-Levi, Chapter 1 G. J. van Ryzin, “Analyzing inventory cost and service in supply chains”, Columbia Business School Teaching Note Supplemental Chopra-Meindl, Chapter 1-3 H. E. Scarf, “Inventory theory”, Operations Research, 50, 186-191 (2002) Inventory Management and Risk Pooling Required Simchi-Levi, Chapter 3 G. P. Eppen, “Effects of centralization on expected costs in a multi-location newsboy Problem”, Management Science, 25, 498-501 (1979) L. B. Schwarz, ‘A model for assessing the value of warehouse risk-pooling: risk pooling over outside-supplier lead times”, Management Science, 35, 828-842 (1989) A. J. Clark and H. Scarf, "Optimal policies for the multi-echelon inventory problem", Management Science, 6, 475-490 (1960) C. G. Sherbrooke, “Metric: a multi-echelon technique for recoverable item control”, Operations Research, 16, 122-141 (1968) Supplemental Chopra-Meindl, Chapter 7-8 Logistics Network Configuration Required Simchi-Levi, Chapter 2 S. J. Erlebacher and R. D. Meller, “The interaction of location and inventory in designing distribution systems”, IIE Transactions, 32, 155-166 (2001) M. S. Daskin and C. R. Coullard, “An inventory-location model: formulation, solution algorithm and computational results”, Annals of Operations Research, 110, 83-106 (2002) Supplemental Chopra-Meindl, Chapter 10-11 C. P. Teo, J. Ou and M. Goh, “Impact on inventory costs with the consolidation of distribution centers”, IIE Transactions, 33, 99-110 (2000) The Value of Information Required Simchi-Levi, Chapter 4 H. Lee, P. Padmanabhan, S. Whang, “Information distortion in a supply chain: the bullwhip effect”, Management Science, 43, 546-558 (1997) F. Chen, Z. Drezner, J. K. Ryan and D. Simchi-Levi, “Quantifying the bullwhip effect in a simple supply chain: the impact of forecasting, lead times and information”, Management Science, 46, 436-443 (2000) H. Lee, K. C. So and C. S. Tang, “The value of information sharing in a two-level supply chain”, Management Science, 46, 626-643 (2000) G. P. Cachon and M. Fisher, ‘Supply chain inventory management and the value of shared information”, Management Science, 46, 1032-1048 (2000) Supplemental Chopra-Meindl, Chapter 12-13 C. J. Corbett and X. de Groote, “A supplier’s optimal quantity discount policy under asymmetric information”, Management Science, 46, 444-450 (2000) Distribution Strategies Required Simchi-Levi, Chapter 5 M. L. Spearman, “Customer service in pull production systems”, Operations Research, 40, 948-958 (1992) S. Rajagopalan, “Make to order or make to stock: model and application”, Management Science, 48, 241-256 (2002) K. L. Cheung and H. L. Lee, “The inventory benefit of shipment coordination and stock rebalancing in a supply chain”, Management Science, 48, 300-306 (2002) Supplemental S. Cetinkaya and L. Chung-Yee, “Stock replenishment and shipment scheduling for vendor-managed inventory systems”, Management Science, 46, 217-232 (2000) J. Deleersnyder, T. J. Hodgson, H. Muller, P. J. O’Grady, “Kanban controlled pull systems: an analytical approach”, Management Science, 35, 1079-1091 (1989) Strategic Alliances Required Simchi-Levi, Chapter 6 B. A. Pasternack, “Optimal pricing and return policies for perishable commodities”, Marketing Science, 4, 166-176 (1985) G. D. Eppen and A. V. Iyer, “Backup agreements in fashion buying: value of upstream flexibility”, Management Science, 43, 1469-1484 (1997) Z. K. Weng, “Channel coordination and quantity discounts”, Management Science, 41, 1509-1522 (1995) H. L. Lee and S. J. Whang “Decentralized multi-echelon supply chains: incentives and information”, Management Science, 45, 633-640 (1999) V. Iyer and M. E. Bergen, “Quick response in manufacturing-retailer channels”, Management Science, 43, 559-570 (1997) Y. Bassok and R. Anupindi, “Analysis of supply contracts with total minimum commitment”, IIE Transactions, 29, 373-381 (1997) Supplemental Chopra-Meindl, Chapter 13 K. Moinzadeh and S. Nahmias, “Adjustment strategies for a fixed delivery contract”, Operations Research, 48, 408-423 (2000) J. P. Monahan, “A Quantity Discount Pricing Model to Increase Vendor Profits”, Management Science, 30, 720-726 (1984) K. L. Donohue, “Efficient supply contracts for fashion goods with forecast updating and two production modes”, Management Science, 46, 1397-1411 (2000) P. Jeuland and S. M. Shugan, “Managing Channel Profits”, Marketing Science, 2, 239-272 (1983) Coordinated Product and Supply Chain Design Required Simchi-Levi, Chapter 8 H. L. Lee “Effective Inventory and Service Management through Product and Process Redesign”, Operations Resarch, 44, 151-159 (1996). H. L. Lee and C. Tang, “Modeling the costs and benefits of delayed product differentiation”, Management Science, 43, 40-53 (1997) Supplemental Y. Aviv and A. Federgruen, “Design for postponement: a comprehensive characterization of its benefits under unknown demand distributions”, Operations Research, 49, 578-598 (2001)