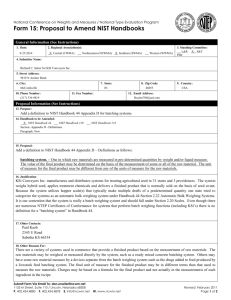

L&R Committee Agenda Items

advertisement