DOLOMITE BRICKS

advertisement

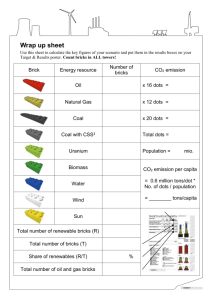

DOLOMITE BRICKS Dolomite is a magnesium limestone (CaMgCO3). It occurs in nature. Calcined dolomite brick particles are united with the help of silicate binders and water. Mixture is then molded to bricks which are air dried and burnt to temperature ranging between 1200 to 1560oC for about one day which gives stabilized dolomite bricks. Such bricks are quite stable towards basic slag. Properties Dolomite bricks are more porous, more shrinkage softness and less stronger than magnesia bricks. They can be used up to 2300oC without load and up to 1650oC with load. Uses Dolomite is generally used as a repairing material rather than as a direct refractory because of its defects like porosity, shrinkage and softness. However stabilized dolomites are used in electric furnaces, Bessemer converters, open hearth furnaces etc, cheap substitute for magnesia bricks. 1 NEUTRAL REFRACTORIES CARBON REFRACTORIES Carbon refractories are again divided into two types depending on the nature of raw material. a) Carbon Refractories From Coke Carbon bricks are made from blast furnace coke by crushing and grinding in edge runner mill mixed with tar (as binding material) then the mixture is passed through pug mill, heated with a steam jacket for few hours. After this, the mixture is molded into the bricks which are first dried in cool room and then fired in kilns from 11oo to 1300oC. b)Graphite Bricks Graphite is the refractory material while fireclay is the binding material. Pure graphite is crushed, finely powdered and mixed with fireclay. It is then processed for the manufacturing of the bricks as the fireclay bricks. Properties They are light grey in color. They possess high crushing strength. 2 If not exposed to air, they can withstand high temperature. However, if heated in presence of air, they burn. They are not attacked by either acid or basic slags. They can only be used under neutral conditions. They are practically infusible, insensitive to spalling. They are close textured and can withstand under fluctuation of temperature. They are also not attacked by corrosive slags etc. Uses Carbon and graphite bricks are widely used as material of construction of electrodes, linings of highly chemical resistant equipments, reactors, electric furnaces, copper, aluminum and lead smelting furnaces. SILICON CARBIDE BRICKS Silicon carbide is made in an electric furnace at temperature of 1500oC from sand and coke with the addition of some sawdust and a little amount of a salt. When sawdust is burnt, the gases are produced which increases the porosity of the charge. 3 Salt reacts with iron and similar impurities present in raw material forming volatile chlorides. This increases the purity of the final product. The silicon carbide is removed from the furnace then the product is mixed with bonding agent like clay or silicon nitride then shaped by molding and dried at approximately 1400 to 2000oC in electric furnace. Recently, self bond type silicon carbide bricks have been prepared; in this silicon carbide particles are mixed with a temporary binding agent such as glue then pressed and fired at 2000oC, at this temperature the inter-crystalline bond of silicon carbide develops. Properties I. Silicon Carbide Bricks are dark grey and blue black in color. II. They have high thermal conductivity and very low co-efficient of expansion. III. Clay bonded bricks can be used up to 1750oC. IV. Nitride bonded bricks have a high strength and superior thermal shock resistance than clay bonded bricks. 4 V. Self bonded products have high refractoriness, superior strength, high density, high abrasion resistance and high chemical resistance. VI. However silicon carbide bricks tend to oxidize to silica when heated in air at temp of 900 to 1000O C, but this drawback is overcome by coating them with thin layer of zirconium. Uses They are used for partition walls of chamber kilns, Coke ovens and muffle furnaces due to their hardness, great strength and toughness. They are also used as heating elements in furnaces in the form of rocks and bars. ZIRCONIA BRICKS Zirconia bricks are obtained by heating zirconite mineral (ZrO2) using colloidal zirconia (prepared by drying zirconium nitrate solution and taking residue into solution and again drying) or alumina or binding material at 1700oC. Since mineral zirconite under goes volume change on heating and cooling, so it is stabilized by adding MgO2 or CaO. 5 Properties I. They can be used up to 2000oC but specially prepared bricks can be used up to 2600oC. II. Their refractoriness is about 1900oC under load. III. They are quiet resistant to thermal shock. Uses Zirconia bricks are very costly and hence are used only where high temperature is maintained e.g. high frequency electric furnace. CHROMITE BRICKS These are made by firing at 1500 to 1700oC crushed chromite (FeO.Cr2O3) mixed with a little clay as binding material. Properties I. Chromite bricks are neutral in character. II. They posses high density, resistance to acidic and basic slags and moderate resistance to spalling. III. They can be used up to 1800oC without load and 1430oC with load. IV. They posses high crushing strength. 6 V. They have moderate thermal conductivity. Uses Their most important use is in separating acid and basic refractory linings so as to prevent their interaction even at high temperature, for example between acid roofs of basic open hearth furnaces and the basic bricks of side walls. Their application is in bottom of soaking pits, Sodium Carbonate recovery furnaces etc. 7