IE-572 Production Planning Systems Design

advertisement

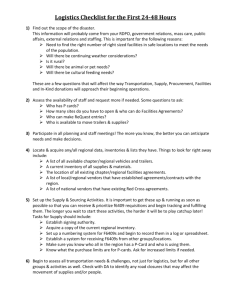

IE-572 Production Planning Systems Design (Term Paper) Lead-Time Reduction in Military Logistics Yunus Emre KARAMANOGLU 20202805 1.Introduction: The word logistics comes from the Greek word ““, meaning skilled in calculation. Further, the dictionary defines logistics as the branch of military science having to do with moving, supplying and quartering troops. Together these definitions imply that logistics involves the care and feeding of combat forces and is supported by significant calculations. In this research, I will try to examine the importance of lead-time, cycle-time, supply chain management from the military point of view. In this research, I will also give some analytical and computational results taken from some of the related papers and will try to explain the model used in the Army and a proposed model for the Army briefly. Logistics and lead-time reduction are very important topics in especially battlefield. There are lots of examples from the history related with this topic. A typical example can be given; In June 1812, the French emperor Napoleon Bonaparte’s invasion force in Russia could not be able to live off the land as in past campaigns. The Russians removed most of the food and crops in advance of Napoleon’s juggernaut. So, the invasion force ultimately depended on a hundreds of miles long supply line of heavy wagons subject to breakdowns and immobilization due to bad weather and poor roads. So, the French Army did reach Moscow but could not hold it. Lessons from this 19th century military logistics debacle still carry weight today. We can say that military logistics is the art and science of equipping and supplying armies. If military logistics is done well, it is a significant combat multiplier. If it is not done well, it can lead to disaster. There is an old say:” For want of the nail a shoe was lost, for want of a shoe the horse was lost…ultimately, the war was lost, all for want of a nail.” Logistics is that important to war fighting. 2. Military Logistics and Commercial Logistics: Military logistics and commercial logistics are parts of the same industry. Both are concerned with focused logistics, precision and velocity, coordinated delivery schedules, fast and flexible distribution, and good infrastructure and equipment at distribution centers. The military supply chain management system looks at the experience and expertise of the private sector, and integrates the business practices used in the commercial sector with the strengths of military readiness and global visibility. Military and commercial readiness (realizing optimal procurement, supply, maintenance and distribution times) can be defined as the optimization of available resources to operate in a possible unforeseen event. In this sense, readiness can be viewed as situational management of an event. Time, cost and quality are still crucial to measuring situational logistics management. A through assessment of supplies, resources and manpower are needed to be matched with the needs of the unforeseen event under surge circumstances. Some of the latest military operations allowed the military to show a new logistics challenge for conducting surge operations. Whether for deployment or other emergency situations such as natural disasters, army has to be equipped with the best readiness resources. To do so requires the achievement of these national goals: a) Standardization of commercial and military logistics metrics and equipment, b) Real-time stockage information, (It is important to have the most current supply status) c) Minimal customer wait time. Achieving optimal procurement, supply, maintenance and distribution times is fundamental to creating an efficient supply chain management system. Just-in-time deliveries and lean manufacturing strategies have become popular with private industry because components can be costly and the value of finished products can drop overnight. High-tech manufacturers have made it possible for companies to operate with little or no inventory. In industry, the safety stock level commonly is set at twice the standard deviation of the demand, given a certain lead-time. With million-dollar component parts and lack of carcasses to replenish the inventory, stocking the inventory at twice the standard deviation may not be realistic goal for the military. The price of military components is so high that forward stocking all the possible parts needed is not be realistic. What may benefit the military is the use of technology to signal when supplies from the authorized stockage lists reach a low point so that the parts can be delivered reliably to forward support activities. In transportation and distribution, private industry operates on scheduled deliveries, because having shipments arriving according to a schedule permits maintenance of lower inventories. For surface deliveries, giving trucking companies more lead-time by forwarding the shipping schedules from the suppliers’ eases their workload. For air cargo deliveries, the military may consider forward stocking heavy. It can be thought that military and commercial strengths could be combined. As the national infrastructure networks and ports become stressed by capacity constraints, logistics companies are relying more on intelligent distribution methods such as the Internet. Virtual service providers allow large corporations to exchange supply information among globally situated retail locations. Since economy of scale is the driving force in commercial industries, the larger the conglomerate, the better the business. When businesses are located all over the globe and information acts as another mode of transportation in logistics, technology becomes increasingly important for daily operations. Some logistics providers have become information management firms, with the adoption of the Internet for electronic commerce, customers have come to expect ready access to real-time inventory procurement, ordering and tracking. The information revolution is leading the charges in supply chain distribution and fulfillment patterns. E-commerce, e-procurement, e-retailing and virtual warehousing concepts are changing the relationships between suppliers and distributors, altering the implications for freight movement patterns, and- since the internet offers accessibility from any location- redefining the relative location of the workplace. Real-time access to business data on potential customers and suppliers provides managers with dynamic inventory control and immediate vehicle dispatching capabilities for freight delivery systems. In my opinion, each military installation can be conceived of as a decentralized retail center that can be connected to a centralized hub or a major distribution center that can distribute supplies. If end items are in need of repair parts, the technology is available to signal low stockage at any location for that particular repair part so it can be reordered instead of waiting for carcasses. Transportation delivery systems are fairly reliable and are not the major bottlenecks to getting the necessary parts to the soldiers in the field. In private sector logistics, direct coordination of retailers, suppliers and transporters using technology such as the internet has enabled retailers to fill empty shelves more quickly because such a system helps the respective parties predict each other’s needs. For the military, an internet-based system connecting installations would require that all of the installations share information with military procurement, supply and transportation offices. The usefulness of the technology such as the internet during wartime is debated among military logisticians. Lack of spare parts is not necessarily the major hindrance to efficient military logistics. Having the spare part where it is needed is the key area for logistics improvement. This is another topic for the military logisticians. For example during operation Desert Storm, $ 2.7 billion worth of spare parts went unused, according to a 1992 General Accounting Office report. It is estimated that, if the Army had had an effective cargo-tracking method, it could be saved about $ 2 billion. As a result of the Gulf War experience, automatic identification technology and intransit visibility systems have been established as mechanisms that will save the military money in the long term. Also, in Turkish Army this technology is being used in some pilot units. For military surface distribution, the idea of having coordinated, scheduled truck deliveries at installations is not very different from the type of coordination that occurs between the retailers and the supply chain management system. 3.Literature Review: Although the scientific developments are related with the armies and wars, (most of the scientific developments have emerged from the results of wars and the needs of the armies), there is no enough paper related directly to the military affairs. In most of the papers that I read so far, I noticed that the authors use a comparison between military affairs and commercial affairs that are related to my research topic. I think the reason of this is that they try to make a path between these two different areas. They try to use the improvements in commercial affairs to obtain improvements and use them in the military affairs. In this brief literature review, I tried to give the papers related to not only lead-time reduction in military logistics but also in the different areas of military affairs such as cycle-time reduction, multi-echelon inventory system used in air forces, etc. In 1960, Clark and Scarf considered optimal policies for a multi-echelon inventory problem. After that, Sherbrooke (1967), gave METRIC (Multi-echelon Technique for Recoverable Item Control). Metric is a mathematical model of a base-depot supply system in which item demand is compound poison with a mean value estimated by a Bayesian procedure. Coleman and Abrams (1961), considered a mathematical model for operational readiness. They developed an operational-readiness model in terms of military-type equipment, which includes uncertain test results and failures caused by testing. Denicoff et al. (1967) considered the problem of ranking items according to their worth, where each item has associated with it a vector of attributes. A ranking system is developed and tested for aviation repair parts. Gross and Soriano (1969) considered the effect of reducing lead–time on inventory levels and used a simulation analysis for this problem. Levin and Friedman (1982) addressed the problem of how to deploy military support units to achieve maximum “effectiveness” which is similar to a multi-period warehouse location model, for which they proposed a branch and bound technique to reduce the state space for a dynamic program. Lee (1987) presented a two-echelon model with one-for-one replenishment in which he allows for lateral transshipments between local warehouses. Pyke (1990) presented a simulation study for a two-echelon system for repairable parts for electronic equipment on military aircrafts. Moinzadeh and Schmidt (1991) investigated the use of emergency replenishments for a singleechelon model with deterministic lead-times. Schrady and Wadsworth (1991), considered the level and seriousness of the interactions between logistics and tactical decisions. Tagaras and Cohen (1992) considered the analysis of two-location periodic review inventory systems with non-negligible replenishment lead-times. They used in their system emergency transshipments as a resource action to reduce the occurrence of shortages. Betaque (1995) assessed the feasibility of pure sea-based logistics for forces of different sizes. Kang and Gue (1997) described a simulation model for offloading supplies for maritime prepositioned ships. Their model estimated the time required for offload given an allocation of transportation and material handling assets. McAllister (1998) used the tactical logistics and distribution system (TloaDS) (Hamber 1998) to estimate times required to land different forces from a sea-base. He considered the movement of supply classes 1 (food and water), 3 (fuel), and 4 (ammunition), in addition to some maintenance and medical requirements. Related works from center for naval analyses include Nance et al. (1998) and Ivancovich et al. (1991). Kang et al. (1998) described two simulation models for repair processes of aircraft in the navy, and suggested ways to reduce cycle time and improve readiness. In 1998 in a study-conducted by RAND Arroyo Center, a new concept “Velocity Management” (VM) initiative entered to the military terminology. Through the VM, the Army has been working to adopt best business practices to make its logistics processes faster, better and cheaper. Alfredson and Verrijdt (1999) considered a two-echelon inventory system for service parts. To obtain high service levels at a low cost, they allowed not only for normal supply of parts but also for emergency supply options in terms of lateral transshipments and direct deliveries. Gue (2003) developed a multi-period facility location and material flow model and showed how to configure the land-based distribution system over time to support a given battle plan with minimum inventory. 4.Analytical-Computational Results and Implications: Improving military logistics and military supply chain begin with the history of war. Year by year, lots of improvements have been made by different armies. They used different ways to have a more efficient logistics support system. After each war, they learned various lessons and used these to improve their logistics systems. By the help of technological developments, the scientists developed lots of different approaches, but the most important developments have begun with the end of World War 2. Generally, related literature about this topic is based on commercial logistics. The papers related with lead-time reduction in military logistics use the lead-time reduction concept in commercial logistics as a reference. Coleman and Abrams (1961), considered a mathematical model for operational readiness. They developed an operational-readiness model in terms of military-type equipment, which includes uncertain test results and failures caused by testing. They suggested that to ensure a high degree of operational readiness of a complicated device or system either continuous monitoring or periodic testing of the components that are subject to failure must be undertaken. Operational readiness is defined as the probability that a given system would be available when demanded, where the time of demand may be some unpredictable period of emergency (Reliability has different meanings in different systems. An aircraft requires reliability to support its use on a recurring basis. A missile system, on the other hand, must be capable of responding immediately to surprise threat, where the objective exists to keep system readiness at acceptable levels). They assumed that P(t) represents the probability that the system is “up” at given time t and F(t) represents the emergency time distribution function. If the emergency might appear at any time in the interval [0,T] with equal probability, then 0 t0 FT(t)= t/T 0tT 1 Tt the efficiency of the system is given by; T T EffT = P (t )dFT (t ) (1/ T ) P (t )dt 0 0 Operational readiness could be considered as the limiting efficiency when T T T Pup=limT (1/T) P(t )dt 0 Pup=total time up / total time in use They compared perfect periodic checkout, imperfect periodic checkout and then continuous monitoring. As a result they obtained followings: a) Optimization of operational readiness depends on consideration of mission objectives, environment constraints, costs, etc. b) The factor of costs should be reflected in order to find operational modes that will optimize cost and effectiveness. Because of the mounting cost of ground support, handling and test equipment and facilities, a cost-effectiveness analysis is very important, for example; reallocation of some of the maintenance money into more units might provide a greater number of systems used for the same amount of money spent. c) The set-up and teardown times required during checkout should be introduced. The effect of considering checkout after repair as separate from the direct repair function should be explored. Since the emergency period within which a system might be used will last a finite time, the probability of availability as well as the changing value of the system role throughout this period should be considered. Sherbrooke (1967), gave METRIC (Multi-echelon Technique for Recoverable Item Control). Metric is a mathematical model of a base-depot supply system in which item demand is compound poison with a mean value estimated by a Bayesian procedure. When a unit fails at base level there is a probability r that it can be repaired at the base according to an arbitrary probability distribution of repair time, and a probability 1-r that it must be returned to depot for repair according to some arbitrary distribution. Metric is being used in Turkish Air Force and Vari-Metric is going to be in use in near future. Denicoff et al. (1967) considered the problem of ranking items according to their worth, where each item has associated with it a vector of attributes. A ranking system is developed and tested for aviation repair parts. The objective of the study is to determine whether some items are more important than others for the accomplishment of aircraft missions. If items differ in essentially, it is important to take such differences into account in providing logistics support . The essentiality ranking is made by generating a vector of attributes for each repair part on the basis of human judgments. These judgments are obtained using a questionnaire that explicitly establishes the ground rules for making attribute assignments. Judgmental priority rules are then applied to vectors to rank the items. The ranking procedure, although designed for military aircraft, has other applications, including commercial ones. Such applications are appropriate whenever budgetary or other considerations require a priority system for allocating resources, e.g. in the procurement and distribution of material stocks including repair parts. Gross and Soriano (1969) considered the effect of reducing lead–time on inventory levels and used a simulation analysis for this problem. In many resupply situations; it is possible to accomplish reductions in order replenishment time by increasing replenishment costs, as, for example, for air resupply rather than sea or ground resupply, or special delivery etc. Since faster resupply generally means added resupply expense, it is necessary to estimate the potential savings due to faster resupply. When mean leadtime is reduced, potential savings are achievable in two types of inventories: Average on-order inventory (pipeline inventory) and average on-shelf inventory resulting from allowable reductions in safety stock levels without adversely affecting system performance. They used the percent of unit requests filled immediately from on-shelf inventory, which they referred to as availability. Reduction in pipeline inventory is straightforward to compute, namely the product of the mean demand and the amount of reduction in mean lead-time. Although this usually represents the larger saving, it is necessary to evaluate achievable reductions in on-shelf inventory, for in many situations, this represents the only saving since often pipeline inventory costs are outside the system. The total savings, then, in inventory carrying cost whether it is pipeline and on-shelf or just on shelf, must be larger than the increase in replenishment cost if the faster resupply is to be economical. They deal with estimating achievable on-shelf inventory savings for military overseas resupply system when resupply is performed by air rather than sea. These results, together with the study of pipeline inventory savings (in this situation, pipeline savings are within the system) and transportation costs, indicated the line items, which should be airlifted overseas on economic grounds. An outgrowth of these studies is forecasts of the cargo capacities of each mode of transportation needed in order to insure an economic system operation. For greater flexibility and reality, they decided upon a simulation approach. The simulation model is developed for a periodic review s,S inventory policy. The model is governed in the following manner: Once every period r, to be referred to as the view period, the program calls for a review of the inventory position, i.e. on-hand inventory plus on-order inventory level. If the inventory position is below a level s, an order for amount, which will bring the inventory position back to a level S, is placed. This is the type of procedure most commonly in used in military supply systems. The simulation model operates on a basic time period. The user can decide whether to set this basic at one day, week, month, etc. and also what value to make r (r being expressed in terms of basic time periods). They used the following notations for simulation: A : Average availability (percent) I : Average on-shelf inventory level (units) P0 : Average percent of units not filled from on-shelf inventory = 1-A s : Lower inventory control point (units) S : Upper inventory control point (units) x : Mean demand per period (units per period) t : Mean lead-time (periods) I0 : Operating inventory level = S-s (units) Ip : Average on-order inventory level (pipeline inventory) = xt (units) Is : Safety level (units) This study is concerned with the military supply system during an era in which most supplies have been sea lifted. The mean lead-time, including transportation, delays and processing times, is estimated to be 13 weeks. Furthermore, it is estimated that shipping by air will reduce the mean lead-time to about 2 weeks. The inventory control policies, governing the studied supply system, set both Is and I0 at one month of supply, thus they have, (1) Is = I0 = 4.3x where, x is mean weekly demand. Then the policy called for is, (2) s = Is + Ip S = Is + Ip + I0 where Is and I0 are given by equation (1), for a t = 13. Inventory is reviewed weekly, thus r=1.There is some particular A and I associated with this procedure. They are interested in obtaining for, a t = 2, I0 given by equation (1) and r = 1, what the new Is can be, still maintaining the same A. They are also interested in the resulting reduction I. In addition, the A associated with current procedure can also be estimated. From available data and knowledge of supply personnel, the A is expected to be about 0.95 or slightly better. This knowledge concerning A incidents whether their assumptions of demand and leadtime distribution shapes and variances are realistic, since under the input settings representing normal procedure, the resulting A’s should be in the neighborhood of 0.95. They studied a total of twenty-two different cases. Fifteen of the twenty-two cases run are for r = 1 and I0 / x=4.3 corresponding to current military practice at the time of the study. The fifteen cases differed in the demand and lead-time distributions. The generalizations of results are the followings: 1) Service level effect on achievable inventory reduction: The simulation results showed that the higher the service requirement (availability) the greater the reduction possible when mean lead-time is reduced. Most systems operate at high A levels (usually 0.90), reducing x can effect some significant savings in I. 2) Sensitivity of inventory systems to demand and lead-time distribution characteristics: The mean lead-time has a strong effect. They observed the effect of mean demand, demand and mean leadtime distribution shapes and variances. The sensitivity of the system to changes in demand variation appeared a great deal weaker than the sensitivity to lead-time variations. The same is true concerning sensitivity to lead-time and demand distribution shapes. Since all inventory quantities are measured in terms of x, that is, in weeks of supply, the absolute value of x should have no effect. x, t, vx and vt are examined separately, it is intuitively appealing that the greatest impact on the inventory system would be caused by total “system variation”. That is the variation of demand over a lead-time. Since they observed that x is only a scaling factor, they compute /x, where ρ is the standard deviation of demand over the lead-time. /x = tvx2 + tvt2 from this equation it can be seen that t and vt generally play a more important role than vx in determining /x. When t is reduced, the resulting decrease in /x is greater for situations in which the initial value of /x is large. 3) Sensitivity of inventory systems to order quantity: As I0 increases, less safety stock is required since fewer orders are placed causing the system to be in a vulnerable position less often. However the larger orders more than offset this inventory savings so that I increases. Since I0 causes fewer orders to be placed which results in being in a vulnerable position less often and increases the system availability. This is paid for by an increase in I. Changing the lead-time has no effect on the number of orders placed: only the average demand affects this. 4) System sensitivity to review period: Given two review periods, one being a multiple of the other (for example, six and twelve), the one with the smaller review period is better, especially as the demand variation increases. If the demand variations are large enough, the frequency of review might become more important than when review takes place with respect to average time between orders. Finally, we can say that: a) For the operating purpose of the military resupply systems studied, reducing the mean lead-time from 13 weeks (sea lifted) to 2 weeks (air lifted) would allow a reduction of approximately 3 weeks of supply in safety stock levels with a corresponding reduction in average on-shelf inventory approximately 3 weeks supply. b) The higher the availability specification for system performance, the larger the allowable reduction in safety stock, when mean lead-time is reduced, which in turn produces higher potential savings resulting from lower mean on-shelf inventory. c) Changing the time between inventory reviews has an effect on system performance. d) Keeping all other conditions fixed, increasing I0 increases the availability level but also increases average on-shelf inventory. e) Changes in system performance seem to be most sensitive to mean lead-time and variation in lead-time and less sensitive to variation in demand and distribution shape. f) Goodrich and Ward (1982), considered the developments in ships and shipping. The main topic of their paper is the technology by which ships and their operation are improved and the need to take account of the operational environment. The implication of a range of the major requirements and influences on the final product are considered. Levin and Friedman (1982) addressed the problem of how to deploy military support units to achieve maximum “effectiveness” which is similar to a multi-period warehouse location model, for which they proposed a branch and bound technique to reduce the state space for a dynamic program. Pyke (1990) presented a simulation study for a two-echelon system for repairable parts for electronic equipment on military aircrafts. His main goal is to investigate the use of priority rules for the central repair shop in conjunction with priority rules for allocating repaired items to the bases. Up to 1990, there are a little paper related to lead-time reduction in military logistics, but I think that Gulf War is a kind of turning point in this area. After Gulf War, we can see that the papers related to this area increase rapidly. Schrady and Wadsworth (1991), considered the level and seriousness of the interactions between logistics and tactical decisions. They also considered that how a long lead-time can affect the battlefield, since running out of ordnance is an absolute combat stopper. In their paper BGLCSS (Battle group logistics coordinator support system) is introduced. BGLCSS is a program of combat logistics commodities (fuel and ordnance) data, event routines and algorithms designed to support the planning, tracking and prediction of combat logistics states and provide timely and meaningful insight to the commander. To be useful to the tactical commander, the combat logistics support system must be able to predict future logistics states then logically in can also be used to estimate current consumption and states based on activities (steaming, flight operations, strikes, raids, etc.) that have been or are going on. It is asserted that, to a very useful approximation, all consumption can be estimated to provide a running status of the combat logistics posture of each ship. Unit reports, when available, can be used to update the estimates. The support system additionally provides “logistics dead reckoning” during strict emission control or whenever communication with individual units is not possible or desirable. They developed a ship fuel usage estimation and by doing so, they try to estimate an order time for each ship type. Their main aim is that they try to investigate an order point that when the fuel stock level decreases under a certain level. This system is a breakthrough in allowing the fleet commander to aggressively pursue tactical logistics. Tagaras and Cohen (1992) considered the analysis of two-location periodic review inventory systems with non-negligible replenishment lead-times. They used in their system emergency transshipments as a resource action to reduce the occurrence of shortages. A class of partial pooling policies is proposed for the control of transshipments. The cost of performance of this class of policies is shown to be inferior to that of complete pooling. An optimal model and a heuristic algorithm are introduced to compute near-optimal stocking policy solutions. In this paper, they presented a stochastic control model of a two-location system in which pooling can occur. They extended the definition of Tagaras (1989) and is distinguished from that paper by its explicit treatment of the effect of a nonzero replenishment lead-time for each stocking location. Two-location models in which there are zero replenishment lead-times are characterized by complete pooling in that if there is an economic incentive to transship one item, then the maximum amount (minimum of supply and demand) will be sent. Replenishment lead-times have a significant effect on optimal transshipment policies. Kang et al. (1998) described two simulation models for repair processes of aircraft in the navy, and suggested ways to reduce cycle time and improve readiness. As they mentioned in the paper, the goal of naval aviation logistics support is to maintain the highest possible level of readiness, commonly expressed as operational availability, A0=uptime/(uptime+downtime) =MTBM/(MTBM+MDT) Where MTBM is the mean time between maintenance, and MDT is the maintenance downtime, which includes repair time and administrative logistics delay times. Intuitively, operational availability is the fraction of time a weapon system is operational or mission capable. Operational availability can be improved by increasing MTBM or decreasing MDT (i.e. reducing repair time). Cycle time reduction in a military logistics channel (repair depots, intermediate-level maintenance, inventory control points, and supply centers) means that more weapon systems are available at the fleets and fields, and also leads to significant savings in inventory costs. The relationship between inventory levels and repair processes is troublesome in the navy because it crosses physical, organizational and financial barriers. Inventory managers strive to consolidate and minimize stocks of piece parts to free up resources for other priorities. They also seek to get quick turnaround on repairable components in order to minimize pipeline inventory. Concept of reducing costs by increasing worker efficiency and machine utilization leads to a natural conflict in repairables management. Inventory managers want short production runs to minimize pipeline inventory, while depot managers want long production runs to minimize repair costs. They described the use as simulation modeling and other quantitative methods to help to reduce repair cycle times at naval aviation depots. The naval aviation maintenance program divides maintenance into three level; organizational level (O- level), intermediate level (L- level), and depot level (D-level), which are similar to in structure to multi-echelon logistics support systems of commercial firms. To achieve economies of scale in maintenance equipment levels of maintenance are progressively more capable with D-level being the most capable. The depot repair cycle begins when an unserviceable depot-level repairable is turned in to the O or the I-level maintenance, and it ends when the item is recorded on the inventory control point records as being ready for issue. Depot repair cycle time includes shipping and processing time, accumulation time, repair time, time awaiting parts and delivery time. They used simulation and different scenarios for obtaining the effects of the cycle time reduction to the readiness, maintenance and supply processes. One of their results is that spare levels and repair cycle time must be considered together when attempting to improve material readiness. Their models are important to military systems because they treat all of the significant components in a weapon system together, in order to achieve the singular objective of maximizing operational availability. Alfredson and Verrijdt (1999) considered a two-echelon inventory system for service parts. To obtain high service levels at a low cost, they allowed not only for normal supply of parts but also for emergency supply options in terms of lateral transshipments and direct deliveries. Simulation shows that their model produces accurate estimates and the performance of the inventory system is insensitive to the lead-time distribution. Their modeling assumptions include exponentially distributed shipment times for normal replenishments. In practice these shipment times are close to deterministic since they consist of transportation times between inventory locations. In order to test the sensitivity of the numerical results with respect to the assumption of exponentially distributed lead-times, they also simulated the system with deterministic lead-times and lognormal distributed lead-times. Analyses of their simulation results show that the service performance of the system is almost identical for exponential, deterministic and lognormal shipment times. Apparently the lead-tike distribution does not affect the service performance. Gue (2003) developed a multi-period facility location and material flow model and showed how to configure the land-based distribution system over time to support a given battle plan with minimum inventory. In model, he considered a sea-based containing combat and support units. Each combat unit is required to reach a particular set of objectives on land; and support units can be positioned to provide supplies as needed. Combat units consume food, water, ammunition, and fuel during each time period. Quantities may vary depending on the intensity of conflict or other concerns. Supply units are free to deploy, move and to build up and deplete inventories as necessary to meet demand. The problem is to determine the locations of supply units for each time period and the shipments of each commodity between units to reduce the lead-time of replenishments. He formulated this problem as a mixed integer program. As a result, he obtained followings: the best distribution system depends on: a) The location of the sea base b) Inventory held by combat units c) Available transportation assets d) Timing of troop movements I think the most important development occurred in 1998 in a study-conducted by RAND Arroyo Center. A new concept “Velocity Management” (VM) initiative entered to the military terminology. Through the VM, the Army has been working to adopt best business practices to make its logistics processes faster, better and cheaper. The goal of VM is to improve the Army’s ability to keep equipment ready while reducing total support costs and enhancing mobility. In this study their aim is that making the Army logistics work better and cost less. For decades, the availability of Army logistics fell progressively behind best commercial practices. Army mechanics would wait on average a month for spare parts from distant supply depots in order to repair a “down” weapon system. Through the institutionalization of velocity management – a simple yet powerful process improvement methodology – Army customers nationwide and around the world now routinely the quick and dependable level of service they have come to expect from a highperforming commercial supply chain. In this study, supply cycle times have been reduced to a quarter of their baseline performance times, while distribution costs and process variability have also been reduced. Reducing in order and ship times is very important in military logistics. As a result of the VM initiative, today Army can boast of remarkable achievement, accelerated logistics processes capable of supporting Army forces of the future anytime, anywhere. In past, the Army logistics system was based on massive stockpiles if supplies and weapon systems, most of them propositioned: “just-in-case”. The system became increasingly less effective and unaffordable. The massive stockpiles and complicated supply chains were slow to move and unresponsive when facing volatile surge requirements. Worse, the supply system had become unreliable to soldiers forced to endure lengthy and variable delays or even lost packages. In this new strategy, military responsiveness is paramount. The ability to respond rapidly to crises, before they escalate to major contingencies, requires a different “force-protection” Army. Cycle times is cut by eliminating non-value-adding activities and continuously improving value-adding activities in supply processes. The new logistics concept required that soldiers view logistics as processes, rather than individual functions or piles of things. More important, the focus is the customer and how processes ultimately serve customer needs. VM uses the “Define-Measure-Improve” (DMI) methodology to lead continuous improvement efforts. The first step is to define the process. The second step is to measure the process to baseline performance, define metrics and identify performance drivers. The third step is to improve the process by implementing change, establishing goals and repeating the DMI methodology. The order and ship process, a critical part of the Army’s supply chain is intended to deliver supplies responsively and efficiently so weapon systems can be repaired and combat readiness can be maintained. The demand for repair or service parts is characterized by increasingly unpredictable demand (The increasing use of digital and high-tech components in weapon systems has increased the unpredictability of failure modes and repair parts needed. In addition, since these items are generally more expensive, a strategy of buying out the problem with surplus stocks is not affordable.), and there is a paramount need to support rapid deployments and surge requirements. As a result, this supply chain must not be confused with those supporting more predictable manufacturing operations or the movements of regularly ordered commodities, e.g. resupply of bread and milk to a grocery store. More comparable are corporations that must rely upon highly responsive supply chains to survive rapidly changing environments and unpredictable demands. In defining the supply process, it is important to understand how each Army unit requests and receives supplies. To define the end-to-end order and ship process, VM teams “walked the process” visiting and observing activities at the inventory control points, wholesale supply depots and many Army bases. They carefully reviewed all information processing, distribution, and material-handling segments along the supply process. Their observation point is that since high-priority parts tend to be expensive, requiring authorization, the more expensive the item, the higher rank of officer, the clerk, must track down for a signature. Signatures in themselves are also a source of delay, since the requisition can only travel as fast as the sheet of paper the signature is on, rather than at the speed of electrons in this networked world. As a result, the highest-priority items have the most cumbersome authorization process before the requisition can be submitted. Every Army installations and unit does things somewhat differently, even if they have identical missions by doctrine, so process improvements at one location may not address issues elsewhere. Consecutively, the largest boxes moved first, including low-priority but bulky clothing and paper products. Smaller boxes, sometimes including express packages containing expensive and high-priority items, waited for the floor to be cleared. The negative repercussion of variable delivery times on the repair of weapon systems and ultimately on combat readiness is clear. If an operable tank requires ten repair parts, many of them should arrive within a couple weeks. Another couple of parts may take a month to arrive. The mechanic must wait until the tenth and final part arrives, however, probably more than two months later, before repairs can be made. For this reason VM improves Army metrics for order and ship time. To measure the Army’s logistics performance properly, the VM team developed a percentile bar-chart presentation of order and ship times to portray not only times of peak, but also for the tail of the distribution. This chart allows managers and customers to quickly see and understand overall performance and process variability. Longer bars indicate poor performance, and shorter bars indicate improved performance. The VM teams examine the mix of shipment modes from each supply depot in more detail. Small packages are sent by a premium air service such as FedEx, and surface carriers like UPS send larger packages. If the shipment were large enough it might justify an entire truck, otherwise less-than-truckload providers were used. One of the most effective process improvement initiatives is the implementation of scheduled truck deliveries. Scheduled truck deliveries have resulted in a reliable and high-performing distribution system through which high-volume shipments are delivered directly from primary depots to customers. Proper leverage of this system required that stocks be made readily available from primary depots. Improved stock positioning at each installation’s chief depot allowed shipments to be sent by truck in the first place and for fill rates to improve in the second. Customers could also avoid the hassles associated with receiving stocks from multiple sources. These changes benefit the trucking service as well as the soldiers. For the driver, there is less time wasted driving and waiting at unprepared delivery points. For the soldiers, their responsibility to receive shipments is confined to a short period every day, rather than waiting for deliveries, which may or may not arrive. In this study, they consider the improvements in order and ship time (OST) that have led to quick, dependable and accurate delivery of repair parts globally. Reduced OST has led to immediate benefits in repair processes, since less time is spent waiting for parts. Besides greater availability of reparable, it also benefits the Army’s stockage determination processes, since more responsive replenishment reduces the need for massive stockpile held “just-in-case”. Ultimately, better repair processes; faster supply processes and more appropriate inventory management lead to improve mission readiness, improved deployability, and more cost efficient military. 5) Importance of Lead-Time in Military Logistics: In every supply chain, lead-time has different importance. In military logistics, reduction of leadtime is very important especially in wartime. For that reason, every Army unit has different scenarios for both wartime period and peace time period. Reduction of lead-time is related with the budgetary constraints and other constraints (transportation links, communication between units, etc.). Especially in battlefield, the aim of the logistics support units is to send the items to the right place at the right time, because this affects the tactics of the war and the commander’s plans. To be sure about confidence of your plans in battlefield, you must be sure about the logistics support behind your forces. For every item, different lead-times exist. In the last years, the percentage of the high-tech material used in the army units increased. For that reason, it is important that you must be sure about the operational readiness of your weapon system and the other systems in your units. When your critical weapon system failures, you need to be repaired it as quickly as possible, if not you might lose your units and the war. In wartime period scenarios, generally the armies use continuous review policy for their inventories. These reviews change according to these three important points: 1) The importance of the item or the system 2) Lead-time of the item or the system 3) The answer of the question that “Can I use another item or system in place of that failured item or system?” All of the plans, related with the logistics supply are made according to these basic rules (Of course there are other rules but these are the main logic behind the logistics support of military.) We know that the negative repercussion of variable delivery times on the repair of weapon systems and ultimately on combat readiness is clear. Let give an example, if an operable tank requires ten repair parts, many of them should arrive within a couple weeks. Another couple of parts may take a month to arrive. The mechanic must wait until the tenth and final part arrives, however, probably more than two months later, before repairs can be made. The idea behind the reduction of lead-time in this area is very related with the readiness of the units and weapon systems. Since every commander wants his units be ready, the reduction of lead-times and cycle-times are two important topics for him. In the last years, there are lots of applications in this area. Especially, in US Army, many improvements are made after the Gulf War. The new idea is that whole supply chain system is being examined and the officers answer the question of which echelons can be omitted from the supply chain system without giving any harm to the flow of the system. In our Army, the same logic is being used by some of the selected items. In a logistic system, there can be lots of echelons; between these echelons also there are different lead-times. In the Army there are lots of echelons because of the hierarchical construction and for this reason we have different lead-times but these lead-times are very long. In these systems, there are some echelons that cannot be omitted from the flow system of logistic materials but if it can be examined carefully, it can be found that there are some echelons in the system that can be eliminated. So by doing this elimination we can reduce the physical lead-time that emerges from the system for which we are responsible. 6) The Proposed Model and Current Model being used in Turkish Army: Turkish Army has three main forces; Land Forces, Air Forces and Navy. These three forces use the same logistics support system for the greatest amount of the items like food, water, clothes, ammunition, fuel, special mission equipments, etc. These materials are divided into five different classes: Class-1 Materials: Foods, water, etc. Class-2 Materials: Vehicle parts, weapon systems, etc. Class-3 Materials: Fuel, gas, etc. Class-4 Materials: Special mission equipments (These equipments are given to the units in case of a special mission. For example night vision devices are given to units in case of a night mission.) Class-5 Materials: All kinds of ammunitions of the weapon systems. We can separate the policy for these main supply items into two groups; the one used in peace time period and the one used in wartime period. For the basic logistics items, in peacetime, all of the forces use periodic review policy. For each of the item different periodic review policies (Replenishment times) are being used in the Army. Every item has different period to be replenished. (It is similar to the commercial logistics) For example, for food, replenishment is made in the first day of every month. Every unit takes its food stock for a one-month period. Here, I should mention “Ratio”. Ratio is the amount that every unit must keep it in their stock for an emergency period and this amount must be equal to unit’s three-day-needs. This amount is not related with the normal food stock. The concept of ratio is being used in every main logistics items. Ratio can be thought as a safety stock that used in commercial logistics systems but the difference stems from that the military units have two levels of safety stock. Let say s0 and s1 as two levels. The first level is Ratio level and that is s0, the second level is normal safety level and that is s1, so we can say that for a typical unit, they have a (s0+s1) safety level. The period for the fuel stock is three months (this period can change from unit to unit and the importance of the missions, for example combat aircraft fuel stock is different from the system used by land forces). I will try to explain the current system and the proposed system for Army briefly. Firstly, lets look the logistic flow of our present system: A typical distribution of present system : L0 materials taken from outside main depot L1 RA REGIONAL DEPOT L3 L2 DISTRIBUTION CENTERS LT=L0+L1+L2+L3 Figure-1 In the current system there are so many echelons in the logistic flow of the materials and all of the items whether they are very critical or not, they all are following the same way as in the figure-1. We can say that, in this model priorities of the materials are not considered. For that reason lead-times of the materials are very high. (We consider the physical lead-times of the materials) For all kinds of materials, L1, L2, L3 are the same. For example, if your unit needs a very important weapon part and some kind of clothes that are not important at the same time, they will reach to your unit at the same time, so the importance of the materials and operational readiness are ignored in this system. For that reason a new system can be adopted. The proposed model for the Army: L0 materials taken from outside L3 RA REGIONAL DEPOT LT=L0+L3 Figure-2 In the new model, some of the echelons for some of the critical items (not for all kind of materials) are omitted from the flow system without jeopardizing the system. In new logic, materials are classified according to their importance, priorities, etc., and their lead-times can be reduced by this way. The main disadvantage of the new system is that we need a very high requirement for information between the units and the coordination center. Mainly, system is based on the computerization and information flows. The cost of the new system is very high and for that reason it may take some time to cover all of the units in the Army and this system requires more qualified personnel. As a result in the new model, lead-times can be very small and the operational readiness can be very high. In the proposed model, this must not be forgotten that we use a priority approach for reducing the lead-times. Both of the systems have some advantages and disadvantages: Advantages of the current system: 1. Low cost (Transportation and holding), 2. Planned activities, 3. Low technology requirement, 4. Low information requirement. Disadvantages of the current system: 1. Complex flow of materials, 2. Low ratio of operational readiness, 3. High number of echelons, 4. Long lead-times, 5. Long response times, 6. Failures in replenishments. Advantages of the proposed system: 1. Increase in ratio of operational readiness, 2. Reduction of lead-times, 3. Decrease in response times, 4. Right time- Right place replenishment. Disadvantages of the proposed system: 1. High cost, 2. High technology requirement, 3. Requirement for a complex coordination. This proposed model suggests only for a physical lead-time reduction for the military supply chain process. Disadvantages of the proposed model and calculation of the effects of the model can be thought as future works in this area. 7) Future Works: There are some open problems or future directions related with military logistics systems and lead-time reduction in military logistics. The interaction between logistics and tactics will continue to be an issue for the foreseeable future; in fact, in a climate of reduced resources and changing threats, logistics becomes even more important. For a commander to be able to incorporate logistics considerations into his tactical planning, he must have current (and future, if possible) information about his logistics state. This is an area where operational researchers can continue to make significant efforts. There are four areas of growth in commercial logistics that may be relevant to military logistics in the future. Inventory reduction; Stocks in warehouses will be kept at a minimum through continuous resource reduction, supplies kept “on wheels” inventories managed directly by vendors, component parts made to order, and distribution based on one-touch, internet-type information exchange. Increased reliance on technology; The paperless cargo manifest is a good example of how technology can speed cargo delivery for an interrelated supply chain. Cargo can be transported only as quickly as the accompanying bill of lading and other necessary paperwork. In that sense, electronic data interchange offers electronic customs clearance, real time information exchange, and more lead-time for scheduled pickups of cargo. An automated system linking retailers to manufacturers can flag replenishment needs so reorders can be shipped directly from the manufacturers’ distribution centers. Strategic outsourcing; Outsourcing some services to specialized service providers may work well when there is a change in manpower, when logistics providers merge, when operations are consolidated, or when it is desirable to tailor services to the individual needs of customers. If the military is to outsource some of its supply chain management operations, total visibility from order placement to distribution destinations will be essential. The first step determining what part of military logistics operations to outsource may be determined by customer demands. Customer needs should be the number one variable for creating the military supply chain management system and making asset investment decisions. After all, without the customers who create demands, there is no need for a supply chain management system. Over time, accounting for the changing needs of customers and devising a mechanism for the federal agencies that also are logistics users to share that information will lead to the best expenditure of appropriated funds. Joint use of public assets; as trade and transportation become more global and seamless, joint use of infrastructure and equipment-whether they belong to the military of other branches of the government-may serve as cost-cutting measures. Use of commercial rates for frequently traveled routes; Cargo deliveries that use frequently traveled routes cost less and can have shorter delivery times. I believe that the developments in commercial logistics support systems are very important for the future of the military logistics support systems. Every improvement in the commercial logistics should be investigated whether it can be used in the military logistics support system or not. 8) References: 1) CLARK A.J. and SCARF H., “Optimal Policies for a Multi-echelon Inventory Problem”, Management Science, v.6, #4,July 1960, 475-490. 2) COLEMAN J.J. and ABRAMS I.J., “Mathematical Model for Operational Readiness”, Space Technology Laboratories, May 1960, 126-137. 3) DENICOFF M., HABER S.E., VARLEY T.C., “Military Essentiality of Naval Aviation Repair Parts”, Management Science, v13, #8,April 1967,B439-B453. 4) SHERBROOKE C.C., “Metric: A Multi-echelon Technique for Recoverable Item Control”, OR, v.16, #1, Jan.-Feb., 1968, 122-141. 5) GROSS D., SORIANO A., “The Effect of Reducing Lead-time on Inventory Levels-Simulation Analysis”, Management Science, v.18, #2,October 1969, B61-B76. 6) GOODRICH D., WARD G., “Development in Ships and Shipping”, Mathematical and Physical Sciences, v.307, #1499, October 1982, 295-310. 7) LEVIN K.D., FRIEDMAN Y., “Optimal Deployment of Logistic Units in Dynamic Combat Conditions”, European Journal of OR, v.9, 1982, 6-41. 8) SCHRADY D., WADSWORTH D., “Naval Combat Logistics Support System”, J.Opl.Res.Soc., v.42, #11,1992, 941-948. 9) TAGARAS G., COHEN M.A., “Pooling in Two-location Inventory Systems with Non-negligible Replenishment Lead-times”, Management Science, v38, #8,August 1992,1067-1083. 10) GIRARDINI, KENNETH J., et al., “Establishing a Baseline and Reporting Performance for the Order and Ship Processes”, RAND publications, DB-173-A, 1996. 11) HAVLICEK, J. D., “Aerospace Ground Equipment’s Impact on Aircraft Availability and Deployment”, MS Thesis, AFIT/GAL/ENS/97S-4. School of Engineering, Air Force Institute of Technology (AU), Wright-Patterson AFB, OH, September 1997. 12) HACKMAN, D. V., “Analysis of Aircraft Sortie Generation With Concurrent Maintenance and General Service Times”, MS Thesis, AFIT/GOR/ENS/97M-11. School Of Engineering, Air Force Institute of Technology (AU), Wright-Patterson AFB OH, February 1997. 13) KANG K., GUE K.R., EATON D.R., “Cycle Time Reduction for Naval Aviation Depots”, Department of system management Naval postgraduate school, 1998. 14) RAND Co., ”Velocity Management in Military Logistics Systems”, RAND publications, 1998. 15) RAND Co., “How The Army Cut Order and Ship Time”, RAND publications, RB-3006, 1998. 16) EDWARDS, THOMAS J., EDEN R., “Velocity Management and the Revolution in Military Logistics”, RAND publications, RP-752, 1999. 17) O’FEARNA, F. C., “ Reduction of the Aircraft Ground Equipment Footprint of an Air Expeditionary Force”, MS Thesis, AFIT/GOR/ENS/99M-14. School of Engineering, Air Force Institute of Technology (AU), Wright-Patterson AFBOH, March 1999. 18) FRICKER, RONALD D., Jr., ROBBINS M., “Retooling for the Logistics Revolution: Designing Marine Corps Inventories to Support the War Fighter”, RAND publications, MR-1096-USCM, 1999. 19) ALFREDSSON P., VERRIJDT J., “Modeling Emergency Supply Flexibility in a Two-echelon Inventory System”, Management Science, v45, #10,Oct., 1999,1416-1431. 20) O’FEARNA F.C., HILL, J.O. Miller. “A Methodology to Reduce Aerospace Ground Equipment Requirements for an Air Expeditionary Force” Department of Operational Sciences Working Paper WP00-01. Air Force Institute of Technology, January 2000, 21) Director for Strategic Plans and Policy, J5, Strategy Division; “Joint Vision 2020.”Report to Chairman, Joint Chiefs of Staff. US GPO, Washington DC. June 2000. 22) LEIPHART K.L., “Creating a Military Supply Chain Management model”, RAND publications, 2001. 23) GUE K.R., “A Dynamic Distribution Model for Combat logistics”, Computer & Operations Research, v.30, 2003, 367-381.