course outline - Department of Mechanical Engineering

advertisement

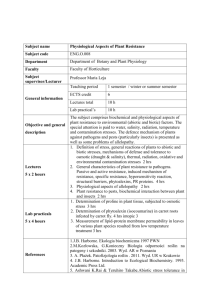

COURSE OUTLINE Fall 2009-2010 COURSE : INSTRUCTOR : Assoc. Prof. Dr. Erbil Akbil Room: ME 200 B Phone: xxx.1045 E-Mail: erbil.akbil@emu.edu.tr ASSISTANT MENG 375 (3, 1) 3 Machine Elements I : XXXXX Room: ME xxx Phone: 630 XXXX E-Mail: XXXX.XXX@emu.edu.tr CLASS SCHEDULE & OFFICE HOURS: Day Period Place/Room Monday 7, 8 ME 111 Wednesday 1, 2 ME 111 Lecture/Tutorial Lecture and/or Tutorial Lecture Office Hours 4th.. Period 4th. Period CATALOG DESCRIPTION MENG 375 Machine Elements I Systematic approach to design; standardization, dimensioning and tolerancing; strength of mechanical elements; theories of failure under static and dynamic loading situations; impact loading; shaft design: screw threads and threaded fasteners; power screws; bolted and riveted joints in shear; keys and couplings. (Prerequisite: MENG 222 Strength of Materials) Required Background: It is expected that the student taking this course have a good background and problem solving skills in: Statics, strength of materials, calculus, and trigonometry. Also knowledge of dynamics, materials, and manufacturing processes would be helpful. Textbook: Mechanical Engineering Design, 8th. Edition, By J.E. Shigley & C.R. Mischke, R.G. Budynas, Mc Graw-Hill, 2004 References: 1. Machine Elements in Mechanical Design, 4th.. Edition, R.L. Mott, Prentice Hall, 2004. 2. Machine Design “An Integrated Approach”, 2nd. Ed., By R.L. Norton, Prentice Hall, 2000. 3. Fundamentals of Machine Elements, By Hamrock-Jacobson-Schimid, McGraw-Hill, 1999. 4. Design of Machine Elements, 7th. Edition, By M.F. Spotts & T.E. Shoup, Prentice Hall, 1998. 1 Course Objectives: 1. To develop an understanding on the fundamentals of the mechanical design process, 2. To develop good and careful problem formulation and solution skills for designing selected machine components and systems. 3. To develop an ability to make proper analysis and assumptions by employing the concepts and theories. 4. To develop an understanding of standards, tolerances and fits. 5. To develop a working knowledge in the use of various standard procedures and catalog information in the identification and selection of engineering materials. 6. To develop an understanding of the importance of safety, reliability, and cost factors in design. 7. To develop an ability to work well as a part of a team. Course Outcomes: The student, after satisfactorily completing this course, will be able to: 1. Apply the design process to engineering problems, including the consideration of different technical alternatives while bearing in mind cost, environmental concerns, safety, and other constraints. 2. Use material properties data for strength, stiffness, and ductility in the analysis and design of machine elements to insure safe operation. 3. Identify loading of machine elements and perform stress and deformation calculations to design safe machine parts. 4. Design machine members subjected to axial tensile and compressive forces, bending moments, and torsion. 5. Design long and intermediate length columns. 6. Properly consider loading, stress concentrations, and fatigue in design calculations. 7. Analyze combined stresses using Mohr's circle. 8. Get familiar with codes and standards in relation to machine elements. 9. Select and specify materials, and understand the importance of tolerances and fits in critical design applications. 10. Appreciate the importance of working in teams. GRADING POLICY - Midterm Exams (2) - Final Examination - Semester Project(s) - Quizzes - Homework & Participation = = = = = 30 %, 34 % 16 % 14 % 6% Minimum Student Material: Assigned Textbook, calculator, a complete set of drafting tools and supplies, binder for handouts and class notes, sufficient amount of A-4 size plain papers, and three pen/pencils of different colors. You must always come to class with your Textbook and calculator. Attendance: Attendance shall be taken regularly. Being present in the classroom is the own responsibility of the student. All homework will be collected in the classroom (not to be submitted to the mailbox or at the office of the instructor or the assistant). All missing work will be scored with a zero. 2 COURSE CONTENTS: Week-1 Introduction to Design: Engineering Design Process; Stress versus Strength, Design Factors & Factor of Safety, Reliability, Numbers and Units (4 hrs.) Week-2 Review of Statics: Static Equilibrium, Constraints/Supports, Shear & Bending Moment Diagrams, and Force Flow Concepts (4 hrs.) Week-3 Mechanical Properties of Materials: Static Strength; Elastic & Plastic Deformations; Hot Working, Cold Working and Heat Treatment; Hardness; Alloyed, Cast, and Non-ferrous Metals; Plastics; Notch Sensitivity; and Corrosion (4 hrs.) Week-4 Stress and Strain: Stress Components, Mohr’s Circle, Elastic Strain, StressStrain Relations, Normal & Shear Stresses, Beam Stresses, (4 hrs) Week-5 Torsion, Stresses in Cylinders, Temperature Effects (4 hrs.) Week-6 Deflection and Stiffness: Spring Rates; Deflections Due to Tension, Compression, and Torsion; Deflection due to Bending; Methods of Finding Deflection; (4 hrs) Week-7 Midterm Exam (Midterm Exam Week) Week-8 Statically Indeterminate Deflection Problems; Curved Members (2 hrs.) Tolerances and Fits. (2 hrs.) Week-9 Compression Members: Short, intermediate, and long columns with central loading; Columns with eccentric loading; Column Design (4 hrs.) Curved Members, Contact Stresses, Week-10 Shock & Impact-: Suddenly applied loading; Deflections and Stresses due to impact loading (4 hrs.) Week-11 Static Failure Criteria: Failure Under Static Loading; Ductile and Brittle Failure Criteria; Effects of Stress Concentration (4 hrs.) Week-12 Failure Due to Variable Loading: Introduction to Fatigue; Strain-Life & StressLife Relationships; Endurance Limit; Fatigue Strength, Endurance-Limit Modifying Factors; Effects of Stress Concentration & Notch Sensitivity (4 hrs.); Week-13 Cumulative Fatigue Damage; Surface Fatigue Stress & Strength; Safe Design & the Design Factor in Fatigue. Fatigue Diagrams; Torsional Fatigue Strength; Combined Loading (4 hrs.) Week-14 Applications Involving Endurance Limit, Endurance Strength and Fluctuating Stresses; General Revisions (4 hrs); Week-15 General Revisions; and Week-16 Final Examination 3 Eastern Mediterranean University Faculty of Engineering Department of Mechanical Engineering Assignment Cover Page Sample Meng375-Machine Elements 1 (Fall 2008-2009) Assignment #: Student, Question Number :……………………… Name :……………………… Surname :……………………… Group :……………………… Grade 2.25 2.25 2.44 2.55 2.77 TOTAL Due date :…………………… Submitted on :…………………… Instructor: ………………….. 4