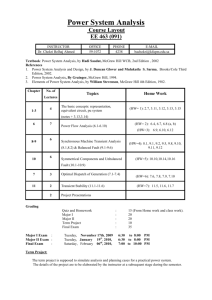

MEEG 304 Design of Machine Elements

advertisement

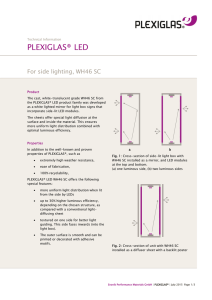

MEEG 304 Machine Design – Elements Spring Semester 2002 2000-2001 Catalog Data: Credit 3 Aspects of machine design: statistical nature, theories of failure and design for strength and design of machine elements. PREREQ: MEEG215. Textbook: Required: R.L. Norton, Machine Design: An Integrated Approach, 2nd edition, Prentice-Hall, 2000. References: J.E. Shigley & C.R. Mischke, Mechanical Engineering Design, 6th edition, McGraw Hill, 2001 - (another common overview text); and U. Hindhede, J.R. Zimmerman, R.B. Hopkins, R.J. Erisman, W.C. Hull, & J.D. Lang, Machine Design Fundamentals: A Practical Approach, John Wiley & Sons, 1983 - (text for 2-year technology program), and Baumeister, Marks' Standard Handbook for Mechanical Engineers, McGraw Hill, (or any basic ME handbook), and W.C. Young, Roarke's Formulas for Stress & Strain, McGraw Hill, - (another useful resource). Coordinator: Dick J. Wilkins, Ph.D., Professor of Mechanical Engineering Goals: The primary objective of this course is to understand how engineering design uses the many principles learned in previous engineering science courses and to begin to learn how these principles are practically applied. The emphasis in this course is on machine design: the design and creation of devices that consist of interrelated components used to modify force and/or motion. Along with traditional "one-answer" homework problems, the students will be presented with design challenges. The type of design addressed in this course is that of detailed design, which is only one part of the entire design process. In detailed design, the general concept, application and basic outline of the required device have already been designed. In this course, one is not trying to invent a new device but rather to define the shape, size and material of a particular machine element such that it will not fail under the expected load and operating conditions. The focus in this course is primarily on the stress-life approach. By the end of the course, each student should be able to: Quantify the statistical meaning of tolerances; For a particular sub-set of machine elements and a given problem: Define failure, Decide on an appropriate failure model, and Design an appropriate machine element using: Allowable load (under the given operating conditions), Required element life, and Manufacturing considerations; Apply those same concepts to more open-ended problems. Prerequisites by topic: 3,4. MEEG 215 Strength of Materials Topics: 1. 2. 3. 4. 5. Introduction of engineering economics and review of design process Statistical nature of properties Static failure review Fatigue failure review Shafts 6. 7. 8. 9. 10. Lubrications and bearings (fluid-film and rolling element) Spur gears Springs Fastening Design process (project) Computer usage: Engineering drawings required for Project 1 Analysis tools required for Project 2 Oral – Written Communication: Written project memos & reports are required. Design: Project 1: Each team (~two students per team) must hand in sketches of an assembly (of at least two pieces per team member) that they will make; each team member must be responsible for a Plexiglas pin (lathe) and Plexiglas plate (mill). Report 1 will include sketches for the components to be fabricated, a list of material required, the steps required to manufacture each component, an estimate of the time required for each manufacturing operation and an estimate of the total production time. Students will manufacture their own pin. However, for the plate parts, drawings will be exchanged and each student will be required to manufacture the team member's part. Report 2 which will include the assembly itself, a drawing package, an explanation/justification of the processes used to produce your parts, the actual times spent on each manufacturing operation and a summary explaining any differences between the drawings and parts as well as any differences between the estimated and actual manufacturing times. Project 2: The class will be broken into teams of three or four and will also be given a set of project problems. Teams must identify their top three projects and projects will be paired with the teams. There will be three milestone events associated with the project. 1st report = define the design problem chosen and list the customers (end users) and their wants; describe the system requirements and indicate the machine elements comprising the system; from the problem definition, derive required load and life for the machine elements in the system; discuss the number of systems to be manufactured as well as any manufacturing and/or assembly issues to be considered in the design. 2 nd report = present a set of engineering specifications for the required solution derived from the customer wants; present at least three solutions and use your engineering specifications to choose the best system; synthesize and design the critical element(s) of your best solution; report will include the following analysis: life (number of cycles) with load for each critical element, strength analysis leading to sizing and/or selection of critical components, engineering drawings, photo-copied web or catalog pages identifying chosen components. Specific consideration should be given to manufacturing and/or assembly requirements, especially in the development of the engineering specifications and the design of the critical elements. 3rd report = synthesize, design and integrate remaining machine elements and present the system solution as a whole; provide the reasoning and analysis justifying the design of each machine element (e.g., for a shaft: present the ultimate & yield strengths and corrected endurance limit plus the critical location and then that location’s max & min of moment, torque and axial loads plus resulting diameter; for a bearing: present axial, radial load, required life, maximum speed and then the chosen bearing and its bore and dynamic load rating; for bushings: give the expected rise in temp; etc.). To receive full credit for this project, the final report must contain some actual concept verification or preliminary prototyping. This can involve tests used to make design decisions through working models of major components or sub-systems. Prepared by: Dick Wilkins Date: 31 January 2002