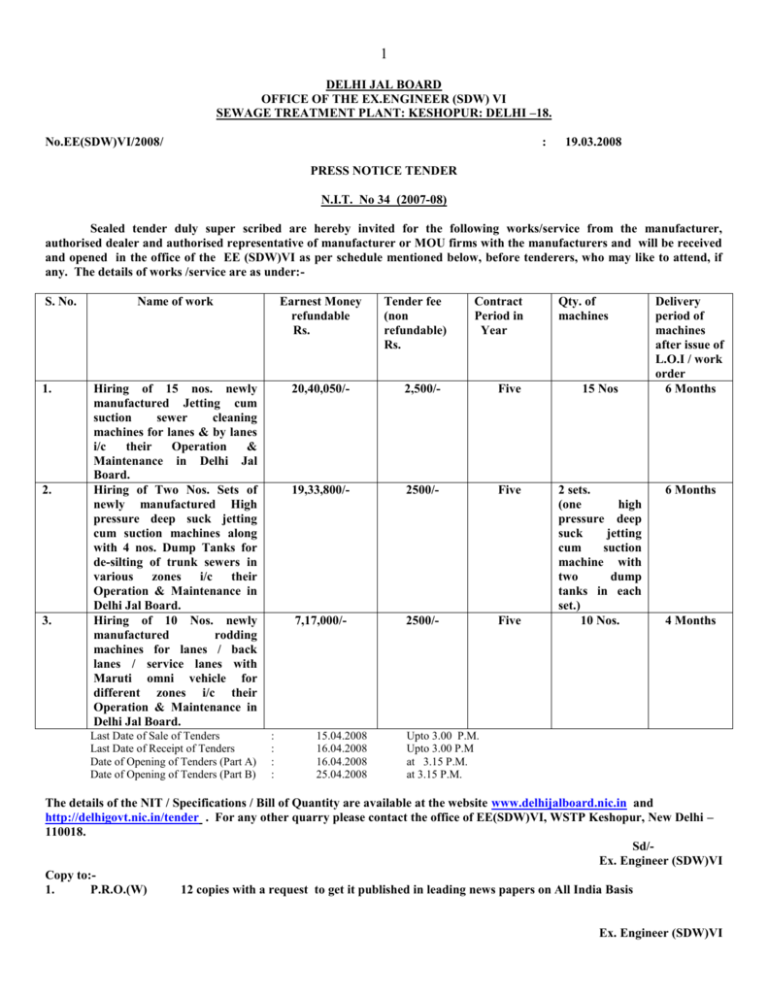

DELHI JAL BOARD

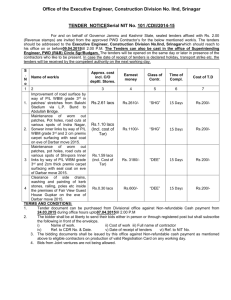

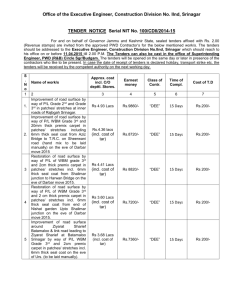

advertisement