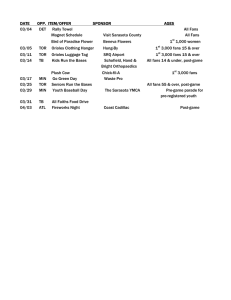

compr & fans, hoods & fans, pts

advertisement

8414 air or vacuum pumps, compressors & fans, hoods & fans, parts

841410

841420

841430

841440

841451

841459

841460

841480

841490

Vacuum Pumps

Hand or Foot Operated Air Pumps

Compressors of a Kind Used in Refrigerating Equipment

Air Compressors Mounted On a Wheeled Chassis for Towing

Table, Floor, Wall, Window, Ceiling or Roof Fans

Other Fans

Hoods Having a Maximum Horizontal Side Not Exceeding 120cm

Other Air Pumps and Air or Gas Compressors; Other Hoods

Parts of Air or Vacuum Pumps, Air or Other Gas Compressors, Fans & Hoods

Indian Standards

IS 9225 : 1979 Specification for Bicycle Air Pumps

IS 6849 : Part

1 : 1999

Positive Displacement Vacuum Pumps - Measurement of

Performance Characteristics - Part 1 : Measurement of Volume

Rate of Flow (Pumping Speed)

IS 6849 : Part

2 : 1993

Positive displacement vacuum pumps - Measurement of

performance characterstics Part 2 Measurement of ultimate

pressure

IS 6849 : Part

3 : 1976

Methods of measurement of the performance characteristics of

positive-displacement vacuum pumps Part 3 Water vapour

pumping capacity

IS 8243 : Part

1 : 1999

Vapour Vacuum Pumps - Measurement of Performance

Characteristics - Part 1 : Measurement of Volume Rate of Flow

(Pumping Speed)

IS 8243 : Part

2 : 1993

Vapour vacuum pumps - Methods of measurement of

performance characteristics Part 2 Measurement of critical

backing pressure

IS 5111 : 1993 Testing of refrigerant compressors

IS 5456 : 1985

Code of Practice for Testing of Positive Displacement Type Air

Compressors and Exhausters

IS 5727 : 1981 Glossary of Terms Relating to Compressors and Exhausters

IS 6206 : 1985

Guide for Selection, Installation and Maintenance of Air

Compressor Plants with Operating Pressures up to 10 bars

IS 6430 : 1985 Mobile air compressor for construction purposes

IS 9242 : 1986 Rated pressure of air compressors

IS 10431 :

Measurement of air flow of compressors and exhausters by

1994

nozzles

IS 10962 :

1984

Technical supply conditions for reciprocating air compressor

above 60 kW

IS 11012 :

1984

Technical supply conditions for reciprocating air compressors

above 25 kW up to and including 60 kW

IS 11119 :

1984

Technical supply conditions for sliding vane rotary air

compressors

IS 11421 :

1985

Techniques of pulsation for suppression for reciprocating

compressors

IS 11465 :

1985

Technical supply conditions for reciprocating air compressors for

power upto 25 kW for general purpose and industrial applications

IS 11563 :

1986

Technical supply conditions for dynamic compressors

IS 11780 :

1986

Code for selection and testing of rotary screw air compressors (oil

flooded)

IS 13124 :

1993

Reciprocating gas compressors - Technical supply conditions

IS 302 : Part 2

Safety of Household and Similar Electrical Appliances - Part : 2

: Sec 80 :

Particular Requirements - Section : 80 Fans

2003

IS 374 : 1979 Electric ceiling type fans and regulators

IS 555 : 1979 Specification for Electric Table Type Fans Regulators

IS 1169 : 1967 Electric pedestal type fans and regulators

IS 1709 : 1984 Specification for Capacitors for Electric Fan Motors

IS 1837 : 1966 Specification for fanlight pivots

IS 1885 : Part

Electrotechnical vocabulary: Part 55 Electric fans

55 : 1981

IS 2312 : 1967 Propeller type ac ventilating fans

IS 2997 : 1964 Air circulator type electric fans and regulators

IS 3588 : 1987 Specification for Electric Axial Flow Fans

IS 6680 : 1992 Railway carriage fans

IS 8354 : 1977 Code of practice for packaging of electric fans

IS 12155 :

1987

General and safety requirements for fans and regulators for

household and similar purposes

Standards

UL 1450-2006, Standard for Safety for

Motor-Operated Air Compressors,

Vacuum Pumps, and Painting Equipment

1. Revision to paragraph 13.1.12 to ensure that

an attachment plug is suitably rated based on

the actual measured input current, rather than

the rated value. A related revision to the Input

Test, 45.1, is also being proposed. 2.

Replacement of a reference to UL 1604 with a

reference to ANSI/ISA-12.12.01-2000. 3.

Revisions to clarify paragraph SA10.13.1.5

regarding test specimen preparation

UL 1450-2006, Standard for Safety for

Motor-Operated Air Compressors,

Vacuum Pumps, and Painting Equipment

1. Revision to paragraph 13.1.12 to ensure that

an attachment plug is suitably rated based on

the actual measured input current, rather than

the rated value. A related revision to the Input

Test, 45.1, is also being proposed. 2.

Replacement of a reference to UL 1604 with a

reference to ANSI/ISA-12.12.01-2000. 3.

Revisions to clarify paragraph SA10.13.1.5

regarding test specimen preparation.

ANSI/AMCA 204-2005, Balance Quality and

Vibration Levels for Fans

This standard defines appropriate fan balance

quality and operating vibration levels to

individuals who specify, manufacture, use and

maintain fans.

ANSI/AMCA 230-1999, Laboratory Method

of Testing Air Circulator Fans for Rating

The purpose of this standard is to establish

uniform methods for laboratory testing of fans

and other air circulating devices to determine

performance in terms of airflow rate for rating or

guarantee proposes. This standard may be

used as the basis for testing pedestal fans,

ceiling fans, box fans, table fans, and portable

personnel coolers, or other air circulating

devices when air is used as the test gas.

Blowers, exhausters, compressors, positive

displacement machines, and positive pressure

ventilators are not within the scope of this

standard. The following change has been

made: a the end of Section 7.2, a new

sentence has been added, "In all cases, the

test apparatus shall provide the means of

isolating the load cell from torque loading.”

ASTM D4167-1997, Specification for

Fiber-Reinforced Plastic Fans and

Blowers (08.04)

UL 507-2005 (Report of the Meeting of the

Standards Technical Panel of UL for

Electric Fans dated April 21, 2004),

Electric Fans

This project documents the comments received

on, and substantive changes made to

proposals from the Report of the Meeting of the

Standards Technical Panel of UL for Electric

Fans dated April 21, 2004.

UL 507-2006, Electric Fans

The following items are subject to comment:

1.) Clarification of Impact Testing In The

As-Received Condition, and Testing Other

Than Polymeric Guards.

2.) Definitions and Additional Requirements for

Convenience Receptacles.

3.) Miscellaneous Revisions.

ANSI/ARI 500-1990, Variable Capacity

Positive Displacement Refrigerant

Compressors and Compressor Units for

Air-Conditioning and Heat Pump

Applications

Applies to electric motor driven variable

capacity positive displacement refrigerant

compressors and compressor units; for

air-cooled, evaporatively-cooled, or

water-cooled air conditioning and heat pump

applications. Also, applies to compressors

which are capable of variable capacity that is

obtained by mechanical and/or electrical

means. The rating points in this standard are

based on commonly used refrigerants. This

standard is intended to serve as a guide for use

with other refrigerants.

ANSI/ARI 500-2001, Variable Capacity

Positive Displacement Refrigerant

Compressors and Compressor Units for

Air-Conditioning and Heat Pump

Applications

The purpose of this standard is to establish for

Variable Capacity Positive Displacement

Refrigerant Compressors and Compressor

Units for Air-Conditioning and Heat Pump

Applications: definitions; test requirements;

rating requirements; minimum data

requirements for Published Ratings; marking

and nameplate data; and conformance

conditions.

ANSI/ARI 530-2005, Rating of Sound and

Vibration for Refrigerant Compressors

This standard applies to External-drive,

Hermetic and Semi-Hermetic Refrigerant

Compressors. In the case of External-drive

Refrigerant Compressors, the driving

mechanism shall be excluded from the sound

and vibration measurements. However, for

Semi-Hermetic Refrigerant Compressors where

the driving mechanism is an integral part of the

compressor assembly, it shall be included in

the measurements.

ANSI/ARI 540-1999, Positive Displacement

Refrigerant Compressors and

Compressor Units

Applies to performance data presentation for all

positive displacement refrigerant compressors

and compressor units. This standard was listed

for public review in the 5/8/1998 issue of

Standards Action. It is being resubmitted due

to substantive changes to the text.

ANSI/ASHRAE 23-2005, Methods of

Testing for Rating Positive Displacement

Refrigerant Compressors and

Condensing Units

Adds zeotropic alternative refrigerants,

excludes emerging supercritical refrigerants

like CO2 (which require a new test standard),

provides six test methods for determining

refrigerant mass flow rates, permits the same

test method for the primary and confirming

tests under certain conditions, includes test

methods that properly account for the effects of

liquid refrigerant injection, and adds

compressor-efficiency computations to the test

requirements.

ASME PTC 10-1998 (R2003), Performance

Test Code – Compressors and

Exhausters

To provide test procedures to determine the

thermodynamic performance of axial or

centrifugal compressors or exhausters doing

work on a gas of known or measurable

properties under specified conditions.

ASME B19.1-1995, Safety Standard for Air

Compressor Systems

Addresses all aspects of air compressor

systems, from the entrance to the inlet device,

through the compressor and associated heat

exchangers, dryers, and pulsation suppression

devices, to the point of entry to the distribution

system.

ASME B19.3-1991, Safety Standard for

Compressors for Process Industries

Covers the requirements for safety devices and

protective facilities to prevent compressor

accidents as a result of excessive pressure,

destructive mechanical failures, internal fires or

explosions, and leakage of toxic or flammable

fluids. General safety practices and hazards

unique to compressors are also covered.

ASME B19.3a-1994, Safety Standard for

Compressors for Process Industries

ASME B19.3b-1995, Safety Standard for

Compressors for Process Industries

ANSI NGV4.8/CSA 12.8-2002, Natural Gas

Vehicle Fueling Station Compressor

Guidelines

Details construction and performance

requirements for natural gas compressors for

use in compressed natural gas fueling stations

service. The compressor package should

include but not be limited to all necessary

equipment from inlet connection immediately

upstream from the isolation valve to the

packager - specified discharge connection.

UL 1450-2006, Standard for Safety for

Motor-Operated Air Compressors,

Vacuum Pumps, and Painting Equipment

1. Revision to paragraph 13.1.12 to ensure that

an attachment plug is suitably rated based on

the actual measured input current, rather than

the rated value. A related revision to the Input

Test, 45.1, is also being proposed. 2.

Replacement of a reference to UL 1604 with a

reference to ANSI/ISA-12.12.01-2000. 3.

Revisions to clarify paragraph SA10.13.1.5

regarding test specimen preparation.

International Standards

IEC 60335-2-41 Amd.1 Ed. 3.0 b:2005 Amendment 1 –

Household and similar electrical appliances - Safety - Part 2-41: Particular requirements

for pumps

IEC 60335-2-41 Ed. 3.1 b:2005

Household and similar electrical appliances -Safety - Part 2-41: Particular requirements

for pumps

"Deals with the safety of electric pumps for liquids having a

temperature not exceeding 90 deg C, with a rated voltage of

not more than 250 V for single-phase and 480 V for other

appliances. Examples of appliances within the scope of this

standard are aquarium pumps; pumps for garden ponds;

sludge pumps; submersible pumps; table fountain pumps;

vertical wet pit pumps. Pumps incorporated in appliances are

not covered by this standard unless a specific reference is

made."

IEC 60601-2-24 Ed. 1.0 en:1998

Medical electrical equipment - Part 2-24: Particular

requirements for the safety of infusion pumps and

controllers

"Specifies the requirements for infusion pumps, infusion

controllers, syringe pumps and pumps for ambulatory use.

These devices are intended for use by medical staff and home

patients as prescribed and medically indicated. It is the

responsibility of the manufacturer to ensure that the

requirements of this standard are reliably implemented."

IEC 60335-2-34 Amd.1 Ed. 4.0 en:2004 Amendment 1 - Household and similar electrical

appliances - Safety - Part 2-34: Particular

requirements for motor-compressors

IEC 60335-2-34 Ed. 4.0 en:2002 Household and similar electrical appliances Safety - Part 2-34: Particular requirements for

motor-compressors

"Deals with the safety of sealed (hermetic and semi-hermetic

type) motor-compressors, their protection and control systems,

if any, which are intended for use in equipment for household

and similar purposes. The rated voltage being not more than

250 V for single-phase and 480 V for other

motor-compressors. Some examples of equipment which

contain motor-compressors are refrigerators, food freezers, ice

makers, air-conditioners, electric heat pumps and

dehumidifiers."

IEC 60335-2-89 Amd.1 Ed. 1.0 b:2005 Amendment 1 - Household and similar electrical

appliances - Safety - Part 2-89: Particular

requirements for commercial refrigerating

appliances with an incorporated or remote

refrigerant condensing unit or compressor

IEC 60335-2-89 Ed. 1.1 b:2005 Household and similar electrical appliances Safety - Part 2-89: Particular requirements for

commercial refrigerating appliances with an

incorporated or remote refrigerant condensing unit

or compressor

"Deals with the safety of commercial refrigerators with an

incorporated compressor, or split systmes supplied in two units

for assembly together. Examples are refrigerated display and

storage cabinets, service counters, blast chillers. For domestic

refrigerators see IEC 60335-2-24. For motor compressors, see

IEC 60335-2-34. For commercial vending machines, see IEC

60335-2-75."

IEC 60335-2-80 Amd.1 Ed. 2.0 b:2006 Amendment 1 - Household and similar electrical

appliances - Safety - Part 2-80: Particular

requirements for fans

IEC 60335-2-80 Ed. 2.0 b:2005 Household and similar electrical appliances Safety - Part 2-80: Particular requirements for fans

"Deals with the safety of electric fans, their rated voltage being

not more that 250V for single-phase and 480V for other

appliances,intended for household and similar purposes.

Appliances intended for use in shops, light industry and on

farms, are within the scope of this standard."

IEC 60704-2-7 Ed. 1.0 b:1997 Household and similar electrical appliances - Test

code for the determination of airborne acoustical

noise - Part 2: Particular requirements for fans

"Applies to electrical fans including their accessories and their

component parts for household and similar use, designed for

a.c. or d.c. supply. Motor, impeller and their housing, if any,

form a single unit. Applies to table fans, pedestal fans, ceiling

fans and partition fans"

IEC 60879 Ed. 1.0 b:1986 Performance and construction of electric

circulating fans and regulators

"Applies to fans for household and similar purposes and to

fans for use in ships of electric motor directly driven fans and

their associated regulators intended for use on single-phase

a.c. and d.c. circuits not exceeding 250 V. This publication

supersedes IEC 60174, 60175, 60176, 60307, 60385 and

60385A.

ISO Standards

ISO 14617-9:2002

Graphical symbols for diagrams - Part 9: Pumps,

compressors and fans

ISO 1607-1:1993

Positive-displacement vacuum pumps - Measurement of

performance characteristics - Part 1: Measurement of

volume rate of flow (pumping speed)

ISO 1607-2:1989

Positive-displacement vacuum pumps - Measurement of

performance characteristics - Part 2: Measurement of

ultimate pressure

ISO 1608-1:1993

Vapour vacuum pumps - Measurement of performance

characteristics - Part 1: Measurement of volume rate of

flow (pumping speed)

ISO 1608-2:1989

Vapour vacuum pumps - Measurement of performance

characteristics - Part 2: Measurement of critical backing

pressure

ISO 14617-9:2002

Graphical symbols for diagrams - Part 9: Pumps,

compressors and fans

ISO 12499:1999

Industrial fans - Mechanical safety of fans - Guarding

ISO 13347-1:2004

Industrial fans - Determination of fan sound power levels

under standardized laboratory conditions - Part 1:

General overview

ISO 13347-2:2004

Industrial fans - Determination of fan sound power levels

under standardized laboratory conditions - Part 2:

Reverberant room method

ISO 13347-3:2004

Industrial fans - Determination of fan sound power levels

under standardized laboratory conditions - Part 3:

Enveloping surface methods

ISO 13347-4:2004

Industrial fans - Determination of fan sound power levels

under standardized laboratory conditions - Part 4: Sound

intensity method

ISO 13348:2006

Industrial fans - Tolerances, methods of conversion and

technical data presentation

ISO 13349:1999

Industrial fans - Vocabulary and definitions of categories

ISO 13350:1999

Industrial fans - Performance testing of jet fans

ISO 13351:1996

Industrial fans - Dimensions

ISO 14694:2003

Industrial fans - Specifications for balance quality and

vibration levels

ISO 14695:2003

Industrial fans - Method of measurement of fan vibration

ISO 5801:1997

Industrial fans - Performance testing using standardized

airways

ISO 5802:2001

Industrial fans - Performance testing in situ

ISO 6580:2005

General-purpose industrial fans - Circular flanges Dimensions

ISO 9097:1991

Small craft - Electric fans

Additional Requirements

Air Pumps

US Code – Title 42, Chapter 77 – Energy Conservation

http://fatty.law.cornell.edu/uscode/html/uscode42/usc_sup_01_42_10_77.html

http://fatty.law.cornell.edu/uscode/search/display.html?terms=testing%20and%20labeling

%20requirements%20for%20air%20pumps&url=/uscode/html/uscode42/usc_sup_01_42

_10_77notes.html

US Code 6315

A labelling rule prescribed in accordance with this section shall require the product

discloses by label, the energy efficiency of such article, determined in accordance

with test procedures under section 6314….

http://fatty.law.cornell.edu/uscode/search/display.html?terms=testing%20and%20labeling

%20requirements%20for%20air%20pumps&url=/uscode/html/uscode42/usc_sec_42_00

006315----000-.html

Vacuum Pumps

Test Procedure

ANSI Document#: TIP 0420-12

Title: Guidelines for measurement of vacuum pump air flow

Abstract: This test procedure is described for cone ported, single stage, liquid ring

vacuum pumps because these are most common in the pulp and paper industry. This

design of pump is typically equipped with two top suction flanges and two side or bottom

discharge flanges. Often the suction flanges are manifolded together as are the discharge

flanges. Other designs of single stage liquid ring vacuum pumps exist, such as flat plate

ported, and the test procedure can be adjusted to fit these style pumps.

Normative References: No normative references available

Additional Standards

http://engineering-standards.globalspec.com/engineering-search/engineeringstandards/vacuum_pump

Fans

Federal Requirements

http://www.ftc.gov/bcp/conline/edcams/eande/popups/ceilingfanrule.pdf

Mandatory Test Procedures

Ceiling Fans are subject to the Appliance Labeling Rule of the Federal Trade

Commission, 16 CFR Part 305. The FTC statute requires manufacturers to derive the

energy information on ceiling fan labels from DOE tests, which must be based on the

ENERGY STAR Guidance Manual.

The ENERGY STAR program, administered by EPA and DOE, is a voluntary

government labeling program that identifies high efficiency products.

ENERGY STAR requires participating manufacturers to conduct tests and self certify

those product models that meet the ENERGY STAR guidelines.

Section 137 of EPACT 2005 directs the Department of Energy (‘‘DOE’’) to prescribe test

procedures and energy conservation standards for ceiling fans. According to EPACT

2005, the test procedure for ceiling fans must be based on the ‘‘ENERGY STAR Testing

Facility Guidance Manual: Building a Testing Facility and Performing the Solid State

Test Method {Under this method, testing personnel place the fan above a large diameter

tube in a standard temperature and humidity-controlled room. The air delivered by the fan

passes through the tunnel where velocity sensors mounted on a rotating arm measure the

airflow at various points. ENERGY STAR directs manufacturers to measure efficiency at

each of three fan speeds (low, medium, and high). For example, to meet ENERGY STAR

standards, at low speed, fans must have a minimum airflow of 1,250 CFM and an

efficiency of 155 CFM/Watt and, at high speed, fans must have a minimum airflow of

5,000 CFM and an efficiency of 75 CFM/Watt. ENERGY STAR also requires

manufacturers to label the packages of qualifying products with airflow, fan power,

consumption, and airflow efficiency at three operating speeds.}for ENERGY STAR

Qualified Ceiling Fans, Version 1.1’’ (‘‘ENERGY STAR Guidance Manual’’) published

by the Environmental Protection Agency (EPA). (42 U.S.C. 6293(b)(16)). As per the

Energy Star Requirements, manufacturers must derive airflow and airflow

efficiency measurements using the Solid State Test Method as defined in the

ENERGY STAR Guidance Manual.

Mandatory Labeling Requirements for Ceiling Fans:

Content

Any covered product that is a ceiling fan shall be labeled clearly and conspicuously on

the principal display panel with the following information in order from top to bottom on

the label:

(i) The words ‘‘ENERGY INFORMATION’’ shall appear at the top of the label with the

words ‘‘at High Speed’’ directly underneath;

(ii) The product’s airflow at high speed expressed in cubic feet per minute and

determined pursuant to § 305.5 of this part;

(http://www.ftc.gov/bcp/conline/edcams/eande/popups/ceilingfanrule.pdf)

(iii) The product’s electricity usage at high speed expressed in watts and determined

pursuant to § 305.5 of this part, including the phrase ‘‘excludes lights’’ as indicated in

Ceiling Fan Label Illustration of Appendix L of this part; (as exhibited below).

(iv) The product’s airflow efficiency rating at high speed expressed in cubic feet per

minute per watt and determined pursuant to § 305.5 of this part;

(v) The following statement shall appear on the label for fans fewer than 49 inches in

diameter: ‘‘Compare: 36’’ to 48’’ ceiling fans have airflow efficiencies ranging from

approximately 71 to 86 cubic feet per minute per watt at high speed.’’;

(vi) The following statement shall appear on the label for fans 49 inches or more in

diameter: ‘‘Compare: 49’’ to 60’’ ceiling fans have airflow efficiencies ranging from

approximately 51 to 176 cubic feet per minute per watt at high speed.’’; and

(vii) The following statements shall appear at the bottom of the label as indicated in

Ceiling Fan Label Illustration of Appendix L of this part: ‘‘Money-Saving Tip: Turn off

fan when leaving room.’’

Label Size and Text Font

The label shall be four inches wide and three inches high. The text font shall be Arial or

another equivalent font. The text on the label shall be black with a white background. The

label’s text size and content, and the order of the required disclosures shall be consistent

with Ceiling Fan Label Illustration of Appendix L of this part.

Placement

The ceiling fan label shall be printed on the principal display panel of the product’s

packaging.

Additional Information

No marks or information other than that specified in this part shall appear on this label,

except a model name, number, or similar identifying information.

{Special Requirements for California

In addition to the ENERGY STAR specifications and test method, the State of California

has requirements for ceiling fans. Under the California regulations, each ceiling fan

package must display, in characters no less than 1/4 inch high, the unit’s airflow (in

CFM) and airflow efficiency (in CFM/ Watt) at low, medium, and high speeds. The

requirements only apply to fans with diameters of 50 inches or greater. (Cal. Code Regs.

tit. 20, § 1607(d)(7)). California regulations do not specify the necessary test

procedures.}

Reporting Requirements

Consistent with EPCA (42 U.S.C. 6296), the NPRM contained certain reporting

requirements for ceiling fans consistent with those applicable to other products covered

by the Rule. For example, the statute requires manufacturers to submit annual reports to

the FTC listing energy data for each model under current production (42 U.S.C.

6296(b)(4)).

Consistent with the proposed rule, the Final Rule will require manufacturers to submit:

Information on the energy efficiency of ceiling fans, the model numbers for each

basic model, the total energy consumed, the number of tests performed, and the

capacity (i.e., cubic feet per minute).

The Rule also requires the submission of an annual report for all models under

production on March 1st of each year (beginning in 2009).

In addition, pursuant to section 305.8(c) of the Rule, manufacturers must submit

data for new models prior to their distribution.

The Final Rule contains an additional sentence in 305.8(a)(1) clarifying that

manufacturers must report the diameter of models in inches and efficiency ratings,

electricity consumption, and capacity at high speed.

(Quasi Mandatory)

Energy Star Requirements for Fans

Ceiling Fans

Key Product Criteria

Equipment Specification

Specification defines residential ceiling fan airflow efficiency on a

performance basis: CFM* of airflow per watt of power consumed by the

motor and controls. Efficiency is measured on each of 3 speeds.

At low speed, fans must have a minimum airflow of 1,250 CFM* and an

efficiency of 155 CFM/Watt

Qualifying ceiling fan models must come with a minimum 30-year motor

warranty; one-year component(s) warranty; and 2-year light kits warranty.

At high speed, fans must have a minimum airflow of 5,000 CFM* and an

efficiency of 75 CFM/Watt

Integral or attachable lighting, including separately sold ceiling fan light kits,

must meet certain requirements of the RLF specification.

Testing Requirements for Energy Star Logo:

All manufacturers are required to perform tests on residential ceiling fan models by using

the Solid State Test Method (A test method that specifies the apparatus and testing

protocol for measuring a residential ceiling fan’s airflow and power consumption. The

method utilizes a hot-wire anemometer and requires a temperature controlled room and

computer for recording test data. ) described in the Program Requirements for Residential

Ceiling Fans.

Fan models identical in every respect but housing and blade finish may be represented by

a single representative model for testing purposes. However, separate test data is required

for all models that differ in motor type or size, rotational speed, control type, or blade

weight, number, size, or pitch.

Air Flow Efficiency Requirements for Ceiling Fans:

Labeling Requirements for Energy Star qualified fans:

For more information on the eligibility criteria, please visit:

http://www.energystar.gov/ia/partners/product_specs/eligibility/ceiling_fans_elig.pdf