DOC - IADC

advertisement

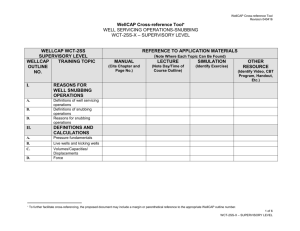

WellCAP Cross-reference Tool Revision 010131 WellCAP Cross-Reference Tool UNDERBALANCED DRILLING WCT-2UBS-X – SUPERVISORY LEVEL WELLCAP WCT-2UBS-X SUPERVISORY LEVEL WELLCAP TRAINING TOPIC OUTLINE NO. I. SIMILARITIES AND CONTRASTS BETWEEN CONVENTIONAL DRILLING AND UNDERBALANCED DRILLING A. B. C. Definitions of conventional and underbalanced drilling Similarities Differences II. UBD OVERVIEW A. B. C. Case studies IADC classifications HS&E III. UBD TECHNIQUES A. B. C. D. E. Air and natural gas drilling Mist drilling Foam drilling Aerated fluid drilling Flow drilling (gas flaring & onsite oil storage) MANUAL (Cite Chapter and Page No.) REFERENCE TO APPLICATION MATERIALS (Note Where Each Topic Can Be Found) LECTURE SIMULATION (Note Day/Time of Course Outline) (Identify Exercise) OTHER RESOURCE (Identify Video, CBT Program, Handout, Etc.) To further facilitate cross-referencing, the proposed document may include a margin or parenthetical reference to the appropriate WellCAP outline number. 1 of 6 WCT-2UBS-X – SUPERVISORY LEVEL WellCAP Cross-reference Tool Revision 010131 WELLCAP WCT-2UBS-X SUPERVISORY LEVEL WELLCAP TRAINING TOPIC OUTLINE NO. F. G. Mud cap drilling Snub drilling H. I. Production drilling (PD) Liquid drilling IV. DOWNHOLE CALCULATIONS FOR UBD TECHNIQUES A. Dynamic (equivalent circulating densityment circulating density) vs. static (hydrostatic) Manual – kill fluid calculations (conventional) Multi-phase flow modeling B. C. V. DETECTING SURFACE CONTROL PROBLEMS A. B. C. Fluid volumes at surface Pressure Determining need for conventional well control Elastomer considerations/flow path D. VI. UBD EQUIPMENT AND RIG UP A. Rotating diverter control head Separation equipment Flare line sizing and hook up B. C. MANUAL (Cite Chapter and Page No.) REFERENCE TO APPLICATION MATERIALS (Note Where Each Topic Can Be Found) LECTURE SIMULATION (Note Day/Time of Course Outline) (Identify Exercise) OTHER RESOURCE (Identify Video, CBT Program, Handout, Etc.) 2 of 6 WCT-2UBS-X – SUPERVISORY LEVEL WellCAP Cross-reference Tool Revision 010131 WELLCAP WCT-2UBS-X SUPERVISORY LEVEL WELLCAP TRAINING TOPIC OUTLINE NO. D. E. Flare line igniters Flame arresters F. G. H. Kill line hook ups Choke manifold hook ups Stripping manifolds/methods Choke considerations Drillstring floats BOP stack configurations Fluid transfer systems and level maintenance Onsite fluid storage systems Emergency well control equipment Standpipe manifold Gas vs liquid injections Compromise on conventional Pit Volume Totalizer (PVT) system Coiled tubing Snubbing Deployment valves I. J. K. L. M. N. O. P. Q. R. S. T. VII. ACCUMULATOR TESTING AND MAINTENANCE A. B. Scheduled maintenance Scheduled testing C. Written testing/maintenance report MANUAL (Cite Chapter and Page No.) REFERENCE TO APPLICATION MATERIALS (Note Where Each Topic Can Be Found) LECTURE SIMULATION (Note Day/Time of Course Outline) (Identify Exercise) OTHER RESOURCE (Identify Video, CBT Program, Handout, Etc.) 3 of 6 WCT-2UBS-X – SUPERVISORY LEVEL WellCAP Cross-reference Tool Revision 010131 WELLCAP WCT-2UBS-X SUPERVISORY LEVEL WELLCAP TRAINING TOPIC OUTLINE NO. D. Special considerations VIII. SURFACE EQUIPMENT TESTING AND MAINTENANCE A. B. Trapped pressure issues Gas vs liquid BOP stack tests IX. BOTTOMHOLE PRESSURE CONTROL A. B. Underbalanced margin Choke control and surface pressure Hydrostatic vs friction dominated flow Surface pressure limitations C. D. X. MAKING TRIPS, COMPLETIONS, LOGGING AND CONNECTIONS A. B. C. D. Tripping in hole Tripping out of hole Making a connection BHA deployment XI. PIPE "LIGHT" CALCULATIONS AND OPERATIONS A. Calculations MANUAL (Cite Chapter and Page No.) REFERENCE TO APPLICATION MATERIALS (Note Where Each Topic Can Be Found) LECTURE SIMULATION (Note Day/Time of Course Outline) (Identify Exercise) OTHER RESOURCE (Identify Video, CBT Program, Handout, Etc.) 4 of 6 WCT-2UBS-X – SUPERVISORY LEVEL WellCAP Cross-reference Tool Revision 010131 WELLCAP WCT-2UBS-X SUPERVISORY LEVEL WELLCAP TRAINING TOPIC OUTLINE NO. B. Operations XII. COMPLICATIONS WHILE DRILLING UNDERBALANCED (SUPERVISORY LEVEL ONLY) A. Excessive surface pressures and high pressure pumping consideration Leak in pressure control equipment Loss of pumping capability Plugged bit Cut out choke or manifold or plugged choke Loss of ability to circulate Bit nozzle washout Casing or cement failure Drill pipe or coil washout B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. Q. MANUAL (Cite Chapter and Page No.) REFERENCE TO APPLICATION MATERIALS (Note Where Each Topic Can Be Found) LECTURE SIMULATION (Note Day/Time of Course Outline) (Identify Exercise) OTHER RESOURCE (Identify Video, CBT Program, Handout, Etc.) Parted drill pipe/coil Open hole loss of circulation Formation influx Leaking float valves Gas leak from BOPs to accumulator Critical escalating problems Injection line leaks Hole cleaning 5 of 6 WCT-2UBS-X – SUPERVISORY LEVEL WellCAP Cross-reference Tool Revision 010131 WELLCAP WCT-2UBS-X SUPERVISORY LEVEL WELLCAP TRAINING TOPIC OUTLINE NO. R. S. Hole stability/collapse Corrosion T. U. V. W. Down hole fire Foam stability Flash points Hydrogen sulfide kick XIII. IADC UBD TOUR REPORT A. Purpose and importance XIV. SITE MANAGEMENT ISSUES A. Safe explosion radius for equipment Crew training B. XV. SIMULATOR TRAINING (SUPERVISORY LEVEL ONLY) A. B. Drilling fluid design Multi-phase flow characteristics Problem detection and response C. MANUAL (Cite Chapter and Page No.) REFERENCE TO APPLICATION MATERIALS (Note Where Each Topic Can Be Found) LECTURE SIMULATION (Note Day/Time of Course Outline) (Identify Exercise) OTHER RESOURCE (Identify Video, CBT Program, Handout, Etc.) 6 of 6 WCT-2UBS-X – SUPERVISORY LEVEL