430_Final_Report_1

advertisement

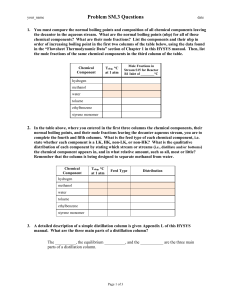

Letter of Transmittal: To: Dr. Henry, Chemical Engineer PhD, PE From: Greg Kirton, Chemical Engineering Student - Team Creative Date: April 21, 2004 This document is an examination of the cost/benefit for the methanol solvent recovery project in which a waste stream is currently being discarded as hazardous waste. This document suggests an alternative approach to discarding the waste stream, by separating the components within the waste stream for savings by using non-hazardous waste disposal as well as an incentive for 99% pure methanol. Technical, & Economic Feasibility: Solvent Recovery Project Greg Kirton Team Creative 4/21/04 ENCH 430 Executive Summary: The purpose of this document is to examine the potential cost benefit from implementing a distillation column to recover valuable solvent while reducing waste disposal costs. There is also an incentive to separate the methanol to 99% purity, and receive a $1 credit per gallon. The current waste disposal is disposed of as hazardous waste and the cost is $230,000 per year. Implementing the distillation column to perform the separation, the hazardous waste cost is eliminated, the operational costs for this design are only $13,000 per year and the waste disposal becomes non-hazardous waste which only costs $35,000 per year. The credit from the 99% pure methanol separation yields $62,000 per year, which results in a net revenue of $14,000 per year. The investment for this project is $380,000, and the payback period is 2 years, using the simple payback method. The total cost savings this design produces is $245,000 per year. In 5 years, this project will have resulted in a total savings of $840,000. Introduction: A process produces a waste stream of methanol and water that is normally disposed of as hazardous waste at an expense of $1.15/gallon. The process generates 200,000 gallons per year, resulting in an annual waste disposal cost of $230,000. However, if the methanol could be separated from the water, the plant could receive a reduction in waste disposal costs at a rate of $0.26/gallon. The condition for the reduced costs is the wastewater must contain only 1% methanol. An additional cost benefit is possible; this benefit is $1 credit per gallon of 99% pure methanol. This document will examine the technical and economic feasibility of reducing waste costs and recovering methanol solvent Design: The proposed design incorporates a distillation column to perform the separation as shown in Figure 1. Methanol Condenser Binary Mixture F= 660 lb/hr 27% MeOH 73% H2O D = 260 lb/hr 99% MeOH 1% H2O Distillation Tower Water Reboiler B= 400 lb/hr 1% MeOH 99% H2O Figure 1 – Block Flow Diagram of Distillation Process. The feed entering the distillation column was examined at 27% methanol - 73% water, temperature is 22oC at a flowrate of 660 lb/hr with a vapor fraction of zero in the feed. Using an overall balance along with a species balance, the distillate and bottoms product flowrates can be determined. The equation for the overall balance is as follows: Overall Balance where F – Feed flowrate B – Bottoms flowrate D – Distillate flowrate F=B+D (1) Species Balance XfF=XbB=XdD (2) Where Xf – feed composition Xb – bottoms composition Xd – distillate composition Using equations (1) & (2) the overall balance around the column is complete. First the reflux ratio must be determined. The reflux ratio was calculated using a VLE model for the binary system of methanol and water. This thermodynamic data can be found in Perry’s Handbook for Chemical Engineers. Figure 2 shows the x-y diagram for methanol-water at 14.7 psi. Methanol-Water 1.0 0.9 Min Reflux = Xdistillate/Yintercept -1 Xdistillate = 0.99 0.8 Reflux Ratio Used = 1.25*Min Reflux 0.7 Yintercept = 0.52 0.6 y (mole fraction) 0.5 0.4 0.3 0.2 Program prepared by: Dr. J. R. Cunningham Mr. M. B. McGann 0.1 0.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 x (mole fraction) Figure 2 – VLE Model for Methanol-Water @ 14.7 psi 0.9 1.0 The reflux ratio used for this column was 1.1; this value was based off the operating reflux ratio given in Perry’s Handbook as typically being 1.1-1.5 times the min reflux ratio. In order to determine the column diameter, there are four additional flowrates that are unknown that can be solved for using equations found in the McCabe-Smith text in the Distillation chapter. The variables are shown in Figure 3. The equations required to solve for these variables are as follows: L = D x Rdmin V=L+D L’ = L + (1 – f) x F NOTE: f is the fraction of vapor in the feed V’ = V – f x F Condenser Distillate- 660 lb/hr MeOH - Water 99% - 01% V L Feed - 660 lb/hr MeOH - Water 27% - 73% Reflux Distillation Tower V' L' Reboiler Bottoms- 660 lb/hr MeOH - Water 01% - 99% Figure 3 – Block flow diagram of process identifying the L, V, L’, and V’ variables. Once all of the stream flowrates have been identified, the next step performed was to select the diameter of the column based on the allowable vapor velocity @ 9” tray spacing, and the vapor volume flowrate, VVF. Vapor Volume Flow where: R = gas constant VVF = V’RT/P (3) T = temperature P = pressure The column diameter was calculated to be 0.8 ft2 and was sized to1 ft2. Using a VLE program that models the McCabe-Thiele method for stepping off stages, the number of trays needed to separate the methanol and water at 99% methanol distillate product purity, and 99% water bottoms product purity was determined to be 20 trays. The number of trays is based on the composition of the feed, distillate, and bottoms product, as well as reflux ratio and efficiency. Next, a more detailed process flow diagram is listed and is accompanied by a stream summary table which lists the total flowrate for each stream as well as component flowrate, temperature, and pressure.. Dr Henry comments: this drawing is not clear enough to read easily Figure 4 shows the process flow diagram. This diagram includes all necessary components required in the process; each component is given a unique ID number to identify the unit/component within the report. Table 1 provides technical data to accompany the process flow diagram. This stream summary table includes stream information such as temperature, overall flowrate, component flowrate, pressure, and vapor fraction. Basis 30 lbmol/hr stream 101 Stream # 101 102 111 Temp (o C) 20 22 64.3 Pressure (psi) 14.7 14.7 14.7 Vapor Fraction 0 0 1 Molar Flow (lbmol/hr) 30 30 17 Component Mole Flow (lbmol/hr) MeOH 8.10 8.10 16.83 Water 21.90 21.90 0.17 30 30 17 112 60 14.7 0 17 113 60 14.7 0 9 114 60 14.7 0 8 121 100 14.7 1 42 122 95 14.7 20 123 100 14.7 1 20 124 100 14.7 1 20 125 100 14.7 1 20 126 95 14.7 0 22 16.83 0.17 17 8.91 0.09 9 7.92 0.08 8 0.42 41.58 42 0.20 19.80 20 0.20 19.80 20 0.20 19.80 20 0.20 19.80 20 0.22 21.78 22 Table 1 – Stream Summary Table for Distillation Process. Dr Henry comments: tables are not permitted to go beyond the normal margins The heat duties for the condenser, reboiler, feed, distillate product, and bottoms product heat exchanger were calculated using equation (3): Heat Duty Q=mCpT where Q – heat available m – mass flowrate Cp – heat capacity of the fluid T – Temperature change of the fluid The heat duties for each heat exchanger are shown in Table 2. (3) HX Condenser Reboiler Feed Heater Distillate Cooler Bottoms Cooler Stream # 111 123 102 114 125 Condition Hot Hot Cold Hot Hot o Flowrate (lb/hr) Flowrate (kg/hr) Cp (kJ/kg C) Tin (oC) Tout (oC) Qav ailable (kW) 550 247 2.6 65 50 3 760 343 4.18 92 100 -3 660 296 3.96 22 65 -14 260 116 2.6 65 27 3 400 181 4.18 80 27 11 Heat Available = 0 Table 2 – Summary of Heat Duties required for Distillation Process. Using the Q values found in Table 2 as the heat available, the area of each heat exchanger was sized using equation (4) Heat Transfer Area Q=UAT (4) where Q – heat available U – overall heat transfer coefficient – NOTE: Use 500 (BTU/ft2 hr oF) for U when using methanol and water as heat transfer fluids Dr Henry comments: give reference A – heat transfer area T – temperature change of the exchange fluid Exchanger # E-111 E-121 E-112 E-122 E-101 Exchangers Condenser Reboiler Distillate Cooler Bottoms Cooler Feed Heater Type of Exchanger Spiral Tube Multiple Pipe Double Pipe Double Pipe Double Pipe Area (square feet) 22 29 4 1 10 Table 3 – Heat Transfer Area Necessary to Meet Required Heat Duty Also included in this design is a storage tank that will hold the methanol that is separated from the feed to yield a $1 credit per gallon. The volume of this tank is 8000 gallon, which will hold one week’s supply of methanol at the production rate of 260 lb/hr. This tank shall be emptied weekly, but if a problem arises and the tank cannot be emptied within a week, there is 18% freeboard to allow for greater flexibility in the fill/empty cycle. This design required the use of three pumps, a distillate pump, a feed pump, and a bottoms product pump. The pumps used in this design were sized based on the fluid density, pressure drop and flowrate demand in which the pump must meet. The pumps required less than 1kW power, but were each specified at 1kW. Economic Analysis: Table 4 lists the individual costs for each heat exchanger needed within the design. The condenser was the largest heat exchanger cost by far, due to the type of heat exchanger used. The condenser is a spiral tube heat exchanger, the reboiler is a multipipe heat exchanger, and the feed, distillate, and bottoms product heat exchangers were all double pipe. HX Costs ($1000's) Feed Heater $12 Condenser $60 Reboiler $21 Distillate Cooler Bottoms Cooler $12 $12 Table 4 – Heat Exchanger Costs Table 5 lists the total capital cost for each component required in this design. Distillation Tower Heat Exchangers Storage Tank Pumps $70,000 $120,000 $110,000 $80,000 Total $380,000 Table 5 – Total Capital Investment for Solvent Recovery Project. Dr Henry comments: this total capital investment doesn’t use the Lang Factor to cover installation, etc. Don’t forget that. The operating costs for this design are the utilities: electricity required by the pumps, the cooling water and steam required for the heat exchangers, and the cost of disposing non-hazardous waste. The annual non-hazardous waste disposal costs $35,000, and the annual utilities costs are $13,000. Dr Henry comments: please itemize the utility costs in a table The total amount of methanol credits produced per year is $62,000, thus generating net annual revenue of $14,000. The total annual cost savings of this design is $245,000, due to the elimination of the hazardous waste disposal cost of $230,000 per year. Payback Period $1,000 $840,000 $800 Revenue ($1000'S) $600 $400 $200 $0 -$200 -$400 -$600 Year 0 Year 1 Year 2 Year 3 Year 4 Year 5 Figure 5 - Cash flow diagram for process examined for 5 years. Figure 5 shows the cash flow diagram for this process, with the initial capital investment shown in Year 0. Based on the total annual savings this design yields, this project will become profitable in Year 2 using the simple payback method under the assumption of no interest. The value of this project at the end of Year 5 is shown to yield $840,000. Conclusions: Under the conditions stated in the introduction regarding the $1 credit per gallon of 99% pure methanol produced, as well as a reduction in waste disposal costs from $1.15 per gallon, to only $0.26 per gallon, this design can become profitable. Given the initial investment is only $380,000, the total annual savings of $245,000 which results in the payback period occurring in Year 2, I conclude this design to be feasible to implement.