1.1 section includes - ChubbySmack The Worlds Best Cast-In

advertisement

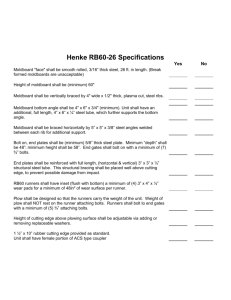

SECTION 03150 CHUBBYSMACK™ CAST IN PLACE ANCHORS SECTION 03150 CHUBBYSMACK™ CAST IN PLACE ANCHORS PART 1 - GENERAL 1.1 SECTION INCLUDES A. Cast in place anchors using ChubbySmack™ products for threaded rods or bolts. 1.2 RELATED WORK 1.3 A. Section 03300 – Cast-In-Place Concrete. B. Section 04200 - Unit Masonry: installed in C. Section 05120 – Structural Steel Framing: Steel members that anchors are to be installed in. D. Section 05310 - Steel Decking: Deck that anchor bolt stands are to be installed in. E. Section 05400 – Cold-Formed Metal Framing: Light gate metal framing to be fastened using anchors specified in this section. F. Section 05500 - Metal Fabrications: Miscellaneous steel members that anchors are to be installed in. G. Section 06100 – Rough Carpentry – Wood supported by fastenings or providing support or anchorage. Masonry that anchors are to be REFERENCES A. AISC - American Institute of Steel Construction B. AISI 12L14 – Carbon Steel Bar C. ASTM A36 – Carbon Structural Steel D. ASTM A193-B7 – Alloy Steel and Stainless Steel Bolting Materials for High Temperature Service E. ASTM A194 - Carbon and Alloy Steel Nuts for Bolts for HighPressure or High-Temperature Service, or Both F. ASTM A307 – Carbon Steel Bolts and Studs, 60 000 PSI Tensile Strength G. ASTM A311 - Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject to Mechanical Property Requirements 03150 - 1 SECTION 03150 CHUBBYSMACK™ CAST IN PLACE ANCHORS 1.4 1.5 1.6 H. ASTM A449 – Standard Specification for Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/105/90 ksi Minimum Tensile Strength, General Use. I. ASTM A563 - Standard Specification for Carbon and Alloy Steel Nuts J. 2005 NDS – National Design Specification 2005 SUBMITTALS A. Product and Design Data: Provide submittal data on all materials within 30 days after award of contract. Do not fabricate or install until shop drawings have been approved by the Structural Engineer. Include descriptive bulletins, report approvals, data sheets, catalog cuts, diagrams, complete installation drawings, and other additional information as required. B. Shop Drawings: Provide minimum 20 days prior to starting fabrication or installation work. Do not fabricate or install until approved by the Structural Engineer. Include complete component sizes and installation information as required. C. Acceptance: The acceptance of a manufacturer's name or product by the Structural Engineer does not relieve the Contractor of the responsibility for providing materials and equipment which comply in all details with the requirements of the contract documents. DEFINITIONS AND ABBREVIATIONS A. The word "provide", as used in these specifications, means "furnish and install". B. The word "Contractor", as used in these specifications, means the Seismic Holdown System Installation Subcontractor or Wood Framing Subcontractor. C. The word "approved", as used in these specifications, means approval of the Structural Engineer of Record. DELIVERY, STORAGE, AND HANDLING A. Deliver products to job site in manufacturers or distributor’s packaging, undamaged, complete with installation instructions. B. Protect and handle materials in accordance with manufacturer’s recommendations to prevent damage or deterioration. 03150 - 2 SECTION 03150 CHUBBYSMACK™ CAST IN PLACE ANCHORS PART 2 – PRODUCTS 2.1 MANUFACTUERS A. 2.2 EARTHBOUND CORPORATION, MONROE, WA. 360-863-0722; Fax: 360-863-0722; Email: techsupport@holdown.com; Web: www.chubbysmack.com MATERIALS A. B. Cast in Place Concrete Anchors - General: Select type and size to achieve required loading capacity using information provided by manufacturer. 1. If required type is not indicated, select type appropriate to conditions and item being fastened. 2. If required loading capacity is not indicated on the drawings, determine required loading capacity in accordance with accepted engineering principles and as required by applicable code. 3. For structural applications, provide engineering design by a professional engineer licensed in the State in which the project is located. 4. Use recommended and appropriate safety factors and load reduction factors. 5. For non-structural applications, space anchors as required to support the material being anchored without sagging or deformation. 6. Confirm application requirements for cracked and uncracked concrete substrates. Cast in Place Anchor Products: The cast in place anchor product shall be ChubbySmack™ anchors and associated components manufactured by Earthbound Corporation, Monroe, Washington (Phone: 360-863-0722). Substitutions for ChubbySmack™ products shall be pre-approved in writing by the Structural Engineer of Record. 1. Bolt Stand: The Smack-Chair™ or Smack-Flat™ injection molded plastic bolt stands. The bolt stands shall be prethreaded to accept UNC threaded rods or bolts. The bolt standsa shall be color coded in accordance to threaded rod or bolt diameter. The Smack-Chair™ shall be tall enough to allow 7/8” aggregate flow underneath threaded rod or bolts. 2. ChubbyNut™ anchor washers or nuts: The ChubbyNuts™ shall be manufactured from AISI 12L14 and be tapped to accept UNC threaded rod or bolts. 03150 - 3 SECTION 03150 CHUBBYSMACK™ CAST IN PLACE ANCHORS 3. C. HeavySet™ anchor washers or nuts: The HeavySet™ anchor shall be manufactured from ASTM A311 and be tapped to accept UNC threaded rod or bolts. Threaded Rod and Nuts: Standard Strength Rod shall be ASTM A36 or A307, UNC thread, 60 ksi ultimate strength (min). High Strength threaded rod shall be ASTM A449 or ASTM A193 B7, UNC thread. Threaded rods shall conform to AISC Table 1-B and designed in accordance to AISC 360 13 th Edition. Supplier shall provide traceable material heat numbers for high strength threaded rod. PART 3 - EXECUTION 3.1. 3.2. 3.3 EXAMINATION A. Do not begin installation until substrates have been properly prepared. B. Concrete and Framing Contractors shall coordinate and verify proper anchor and sill bolt location sizes and layout with seismic system shop drawings and structural plans prior to concrete pour. C. Verify the provided ChubbySmack™ anchor components are at the locations shown in the shop drawings or structural plans. INSTALLATION A. Install the ChubbySmack™ anchor components per approved shop drawing and manufacturer’s instructions. B. Modifications to products or changes in installation procedures should only be made by a qualified designer. The performance of such modified products or an altered installation procedure is the sole responsibility of the designer. C. Apply anchor items neatly, with anchor mounted plumb and level unless otherwise indicated. FIELD QUALITY CONTROL A. Determine that the proper part is being used in the correct location per the shop drawings and has been fabricated by the approved manufacturer by observation of the packaging, color code or field labeling of the product denoting part and manufacturer name. B. Determine that the proper part is being used in the correct location per the shop drawings and has been fabricated by the approved manufacturer by observation of the packaging, color code or field labeling of the product denoting part and manufacturer name. END OF SECTION 03150 - 4