Pipes, Fittings & Valves Pt. 2

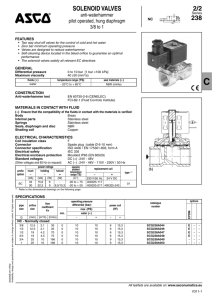

advertisement

PIPES, FITTINGS, AND VALVES Excerpt from “Handbook for Chemical Technicians” by Howard Strauss and Milton Kaufman, McGraw Hill and from the ‘Valve Handbook’ by Philip Skousen, McGraw Hill. Piping systems are constructed from straight-run piping, fittings to change direction and size, and valves to control flow rate. A large variety of standard pipes and fittings are available. When selecting piping or fittings, one must consider factors such as corrosion, resistance, pressure and temperature that will have to be endured. Connecting Pipes and Fittings: Pipes and fittings are connected by welded, threaded, flared, compressed, sweated (soldered) and glued (solvent welded) joints. In general, welded joints and flanged joints (shown later) are used for large diameter pipe (> 2 in), while threaded joints are used for smaller diameter pipe. Flared, compressed, soldered joints are used for smalldiameter copper and brass tubing. See Figure 1. Piping Iron and steel piping comes in a number of ‘schedules’, or wall thicknesses, to accommodate various maximum pressures. See Tables 1 to 6. TABLE I Allowable Pressures for Pipes Nut Nut Schedule 10 20 30 40 60 80 100 120 140 160 Figure 1. Pipe Connections PIPES AND FITTINGS (STRAUSS & KAUFMAN) PAGE 17 OF 12 Wrought iron Max Normal allowable design pressure max (lb/in2) (lb/in2) 50 25 100 50 150 75 25Q 125 350 200 450 250 600 300 700 350 800 400 900 450 Steel Max allowable pressure (lb/in2) 75 150 200 300 450 600 700 900 1,000 1,200 Normal design max (lb/in2) 50 75 100 150 250 300 350 450 500 600 TABLE II Dimensions of Wrought-Iron or Steel Pipe Diameters Size (in) External (in) Internal (in) Circumference Thickness (in) External (in) Internal, (in) Transverse areas External (in2) Internal (in2) Length of pipe/ft Metal (in2) External Surface (ft) Internal Surface (ft) Length of pipe holding 1 ft3 (ft) Wt./ft plain ends (lb) Wt. of water/ft (lb) SCHEDULE 40 (ST –STANDARD WALL) 1/8 1/4 3/8 1/2 3/4 0.405 0.540 0.675 0.840 1.050 0.269 0.364 0.493 0.622 0.824 0.068 0.088 0.091 0.109 0.113 1.272 1.696 2.121 2.639 3.299 0.845 1.144 1.549 1.954 2.589 0.129 0.229 0.358 0.554 0.866 0.057 0.104 0.191 0.304 0.533 0.072 0.125 0.167 0.250 0.333 9.431 7.073 5.658 4.547 3.637 14.199 10.493 7.747 6.141 4.635 2533.775 1383.789 754.360 473.906 270.034 0.244 0.424 0.567 0.850 1.130 0.025 0.045 0.083 0.132 0.231 1 1¼ 1½ 2 2½ 1.315 1.660 1.900 2.375 2.875 1.049 1.380 1.610 2.067 2.469 0.133 0.140 0.145 0.154 0.203 4.131 5.215 5.969 7.461 9.032 3.296 4.335 5.058 6.494 7.757 1.358 2.164 2.835 4.430 6.492 0.864 1.495 2.036 3.355 4.788 0.494 0.669 0.799 1.075 1.704 2.904 2.301 2.010 1.608 1.328 3.641 2.767 2.372 1.847 1.547 166.618 96.275 70.733 42.913 30.077 1.678 2.272 2.717 3.652 5.793 0.375 0.65 0.88 1.45 2.07 3 3½ 4 4½ 5 3.500 4.000 4.500 5.000 5.563 3.068 3.548 4.026 4.506 5.047 0.216 0.226 0.237 0.247 0.258 10.996 12.566 14.137 15.708 17.477 9.638 11.146 12.648 14.156 15.856 9.621 12.566 15.904 19.635 24.306 7.393 9.886 12.730 15.947 20.006 2.228 2.680 3.174 3.688 4.300 1.091 0.954 0.848 0.763 0.686 1.245 1.076 0.948 0.847 0.756 19.479 14.565 11.312 9.030 7.198 7.575 9.109 10.790 12.5.38 14.617 3.20 4.29 5.50 6.91 8.67 6 7 8 8 9 6.625 7.625 8.625 8.625 9.625 6.065 7.023 8.071 7.981 8.941 0.280 0.301 0.277 0.322 0.342 20.813 23.955 27.096 27.096 30.238 19.054 22.063 25.356 25.073 28.089 34.4 72 45.664 58.426 58.426 72.760 28.891 38.738 51.161 50.027 62.786 5.581 6.926 7.265 8.399 9.974 0.576 0.500 0.442 0.442 0.396 0.629 0.543 0.473 0.478 0.427 4.984 3.717 2.815 2.878 2.294 18.974 23.544 24.696 28.554 33.907 12.51 16.80 22.18 21.70 27.20 10 10 10 11 12 10.750 10.750 10.750 11.750 12.750 10.192 10.136 10.020 11.000 12.090 0.279 0.307 0.365 0.375 0.330 33.772 33.772 33.772 36.914 40.055 32.019 31.843 31.479 34.558 37.982 90.763 90.763 90.76:3 108.434 127.676 81.585 80.091 78.855 95.033 114.800 9.178 10.072 11.908 13.401 12.876 0.355 0.355 0.355 0.325 0.299 0.374 0.376 0.381 0.347 0.315 1.765 1.785 1.826 1.515 1.254 31.201 34.240 40.483 45.557 43.773 35.37 34.95 34.20 41.20 49.70 12 12.750 12.000 0.375 40.055 37.699 127.676 113.097 14.579 0.299 0.318 1.273 49.562 49.00 PIPES AND FITTINGS (STRAUSS & KAUFMAN) PAGE 18 OF 12 TABLE II (Cont’d) Dimensions of Wrought-Iron or Steel Pipe Diameters Size (in) External (in) Internal (in) Circumference Thickness (in) External (in) Internal, (in) Transverse areas External (in2) Internal (in2) Length of pipe/ft Metal (in2) External Surface (ft) Internal Surface (ft) Length of pipe holding 1 ft3 (ft) Wt./ft plain ends (lb) Wt. of water/ft (lb) SCHEDULE 80 (XS –EXTRA STRONG WALL) 1/8 1/4 3/8 1/2 3/4 0.405 0.540 0.675 0.840 1.050 0.215 0.302 0.423 0.546 0.742 0.095 0.1l9 0.126 0.147 0.154 1.272 1.696 2.121 2.639 3.299 0.676 0.949 1.329 1.715 2.331 0.129 0.229 0.358 0.554 0.866 0.036 0.072 0.141 0.234 0.433 0.093 0.157 0.217 0.320 0.433 9.431 7.073 5.658 4.547 3.637 17.766 12.648 9.030 6.995 5.147 3966.392 2010.290 1024.689 615.017 333.0l6 0.314 0.535 0.738 1.087 1.473 0.016 0.031 0.061 0.102 0.188 1 1¼ 1½ 2 2½ 1.315 1.660 1.900 2.375 2.875 0.957 1.278 1.500 1.939 2.323 0.179 0.191 0.200 0.218 0.276 4.131 5.215 5.969 7.461 9.032 3.007 4.015 4.712 6.092 7.298 1.358 2.164 2.835 4.430 6.492 0.719 1.283 1.767 2.953 4.238 0.639 0.881 1.068 1.477 2.254 2.904 2.301 2.010 1.608 1.328 3.991 2.988 2.546 1.969 1.644 200.193 112.256 81.487 48.766 33.976 2.171 2.996 3.631 5.022 7.661 0.312 0.56 0.77 1.28 1.87 3 3½ 4 4½ 5 3.500 4.000 4.500 5.000 5.503 2.900 3.364 3.820 4.290 4.813 0.300 0.318 0.337 0.355 0.375 10.996 12.566 14.137 15.708 17.477 9.111 10.568 12.020 13.477 15.120 9.621 12.566 15.904 19.635 24.306 6.605 8.888 11.497 14.455 18.194 3.016 3.678 4.407 5.180 6.112 1.091 0.954 0.848 0.763 0.686 1.317 1.135 0.998 0.890 0.793 21.801 16.202 12.525 9.962 7.915 10.252 12.505 14.983 17.611 20.778 2 .86 3.84 4.98 6.27 7.88 6 7 8 9 10 6.625 7.625 8.625 9.625 10.750 5.761 6.625 7.625 8.625 9.750 0.432 0.500 0.500 0.500 0.500 20.813 23.955 27.096 30.238 33.772 18.099 20.813 23.955 27.096 30.631 34.472 45.664 58.426 72.760 90.763 26.067 34.4 72 45.663 58.426 74.662 8.405 11.192 12.763 14.334 16.101 0.576 0.500 0.442 0.396 0.355 0.663 0.576 0.500 0.442 0.391 5.524 4.177 3.154 2.464 1.929 28.573 38.048 43.388 48.728 54.735 1l.29 14.95 19.78 25.30 32.35 11 12 l1.750 l2.750 10.750 11.750 0.500 0.500 36.914 40.055 33.772 36.914 108.434 127.676 90.763 108.434 17.671 19.242 0.325 0.209 0.355 0.325 1.587 1.328 60.076 65.415 39.40 46.92 PIPES AND FITTINGS (STRAUSS & KAUFMAN) PAGE 19 OF 12 TABLE II (Cont’d) Dimensions of Wrought-Iron or Steel Pipe Diameters Size (in) External (in) Internal (in) Circumference Thickness (in) External (in) Internal, (in) Transverse areas External (in2) Internal (in2) Length of pipe/ft Metal (in2) External Surface (ft) Internal Surface (ft) Length of pipe holding 1 ft3 (ft) Wt./ft plain ends (lb) Wt. of water/ft (lb) SCHEDULE 160 (XX –DOUBLE EXTRA STRONG WALL) 1/2 3/4 1 1¼ 1½ 0.840 1.050 1.315 1.600 1.900 0.252 0.434 0.599 0.890 1.100 0.294 0.308 0.358 0.382 0.400 2.639 3.299 4.131 5.215 5.969 0.792 1.363 1.882 2.815 3.456 0.554 0.866 1.358 2.164 2.835 0.050 0.148 0.282 0.630 0.950 0.504 0.718 1.076 1.534 1.885 4.547 3.637 2.904 2.301 2.010 15.157 8.801 6.376 4.263 3.472 2887.164 973.404 510.998 228.379 151.526 1.714 2.440 3.659 5.214 6.408 0.022 0.064 0.122 0.273 0.42 2 2½ 3 3½ 4 2.375 2.875 3.500 4.000 4.500 1.503 1.771 2.300 2.728 3.152 0.436 0.552 0.600 0.636 0.674 7.461 9.032 10.996 12.566 14.137 4.722 5.564 7.226 8.570 9.902 4.430 6.492 9.621 12.566 15.904 1.774 2.464 4.155 5.845 7.803 2.656 4.028 5.466 6.721 8.101 1.608 1.328 1.091 0.954 0.848 2.541 2.156 1. 660 1.400 1.211 81.162 58.457 34.659 24.637 18.454 9.029 13.695 18.583 22.850 27.541 0.77 1.07 1.80 2.53 3.38 4½ 5 6 7 8 5.000 5.563 6.625 7.625 8.625 3.580 4.06:3 4.897 5.875 6.875 0.710 0.750 0.864 0.875 0.875 15.708 17.477 20.813 23.955 27.096 11.247 12.764 15.384 18.457 21.598 19.635 24.306 34.472 45.664 58.426 10.066 12.966 18.835 27.109 37.122 9.569 11.340 15.637 18.555 21.304 0.763 0.686 0.576 0.500 0.442 1.066 0.940 0.780 0.650 0.555 14.306 11.107 7.640 5.312 3.879 32.530 38.552 53.160 63.079 72.424 4.36 5.61 8.16 11.75 16.10 Note that the dimensions of only the 3 most common wall strengths (schedule 40, 80 and 120) are given. “Nominal Pipe Size” (NPS) is the older system and refers to valve and pipe sizes. It is controlled by the American National Standards Institute (ANSI). For pipes up to 12 inches, NPS refers approximately to internal diameter (ID). For pipes larger than 12 inches, NPS values refers approximately to outside diameter (OD). ANSI pressure specifications are given in psi. In many countries outside US and Canada, the pipe size is based on the International System of Units (metric system) established by the International Standards Organization (ISO). In the ISU system, pipe diameters are referred to as ‘Nominal Diameters’ (DN) in units of mm or cm, and pressure ratings are referred to as Nominal Pressure (PN) in units of kPa or bars. For example, an ANSI 1 inch diameter, 150 psi NPS pipe is equivalent to an ISO 25 mm DN, 16 bar PN. PIPES AND FITTINGS (STRAUSS & KAUFMAN) PAGE 20 OF 12 TABLE III Flow Capacities of Iron/Steel Pipe Capacity at velocity of 1 ft/s Nominal size (in) 1/8 1/4 3/8 1/2 3/4 ST (Sch 40) gal/min 0.179 0.323 0.596 0.945 1. 665 lb H2O/h 89.5 162 298 472 833 XS (Sch 80) gal/min 0.113 0.224 0.440 0.730 1.345 2.240 3.99 5.49 9.20 13.20 XX (Sch 160) lb H2O/h gal/min 56.6 112 220 365 673 0.158 0.460 1 1¼ 1½ 2 2½ 2.69 4.57 6.34 10.45 14.92 1,345 2,285 3,170 5,225 7,460 1,120 1,995 2,745 4,600 6,600 3 3½ 4 4½ 5 23.00 30.80 39.6 11,500 15,400 19,800 20.55 27.70 35.80 62.3 31,150 57.7 28,850 6 7 8 8 9 90.0 45,000 81.1 40,550 155.7 152.4 191.0 79,800 78,100 97,900 142 71,200 182 91,100 10 10 10 248.4 245.5 240.2 127,300 125,800 123,100 233 116,500 11 12 12 289.4 290.6 286.5 148,300 178,900 176,400 284 338 141,800 168,900 10,275 13,850 17,900 PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) 0.878 1.97 3.02 5.54 7.70 lb H2O/h 79.2 230 439 983 1,512 2,772 3,852 12.96 18.22 24.34 31.39 40.39 6,480 9,108 12,168 15,696 20,196 58.75 84.60 116 29,376 42,300 57,960 PAGE 21 OF 53 TABLE IV Dimensions of Copper Water Tubing Wall thickness, in. Mean outside diam. Theoretical weight, lb/ft. Nomi- Actual tolerances, in. Type K Type L Type M nal outside Soft size diam., in. Hard drawn Nominal Tolerance Nominal Tolerance Nominal Tolerance Type K Type L Type M annealed 1/8 1/4 3/8 1/2 3/4 0.375 .500 .625 .750 .875 0.002 .0025 .0025 .0025 .003 0.001 .001 .001 .001 .001 0.035 .049 .049 .049 .065 0.004 .004 .004 .004 .0045 0.030 .035 .040 .042 .045 0:0035 ….. .0035 0.025 .0035 .028 .0035 ….. .004 .032 ….. 0:0025 .0025 ….. .003 0.145 .269 .344 .418 .641 0.126 .198 .285 .362 .455 ….. 0.145 .204 ….. .328 1 1¼ 1½ 2 2½ 1.125 1.375 1.625 2.125 2.625 .0035 .004 .0045 .005 .005 .0015 .0015 .002 .002 .002 .065 .065 .072 .083 .095 .0045 .005 .005 .007 .007 .050 .055 .060 .070 .080 .004 .0045 .0045 .006 .006 .035 .1142 .049 .058 .065 .0035 .0035 .004 .006 .006 .839 1.04 1.36 2.06 2.93 .655 .884 1.14 1.75 2.48 .465 .682 .940 1.46 2.03 3 3½ 4 5 6 3.125 3.625 4.125 5.125 6.125 .005 .005 .005 .005 .005 .109 .120 .134 .160 .192 .007 .008 .010 .010 .012 .090 .100 .110 .125 .140 .007 .007 .009 .010 .011 .072 .083 .095 .109 .122 .006 .007 .009 .009 .010 4.00 5.12 6.51 9.67 13.9 3.33 4.29 5.38 7.61 10.2 2.68 3.58 4.66 6.66 8.92 8 10 12 8.125 10.125 12.125 .006 .008 .008 .002 .002 .002 .002 .002 + .002 .004 .002 .006 .002 .006 .271 .338 .405 .016 .018 .020 .200 .250 .280 .014 .016 .018 .170 .212 .254 .014 .015 .016 25.9 40.3 57.8 19.3 30.1 40.4 16.5 25.6 36.7 Adapted from Robert H. Perry and Cecil H. Chilton (eds.), "Chemical Engineers' Handbook," 5th ed., McGraw-Hill Book Company, New York, 1973. TABLE V Dimensions of General-Service Copper Tubing Nominal size 1/8 3/16 1/4 5/16 3/8 1/2 5/8 3/4 Actual outside diam. (in) 0.125 0.188 0.250 0.312 . 0.375 0.500 0.625 0.750 Mean outside diam. tolerances (in) 0.002 0.002 0.002 0.002 0.002 0.002 0.002 0.0025 Wall thickness (in) 0.030 0.030 0.030 0.032 0.032 0.032 0.035 0.035 Wallthickness tolerances (in) 0.003 0.0025 0.0025 0.0025 0.0025 0.0025 0.003 0.003 Nominal wt. (lb/ft) 0.0347 0.575 0.0804 0.109 0.134 0.182 0.251 0.305 Adapted from Robert H. Perry and Cecil H. Chilton (eds.), "Chemical Engineers' Handbook," 5th ed., McGraw-Hill Book Company, New York, 1973. TABLE VI Dimensions of Glass Pipe Inside diam. (in) 1 1.5 2 3 4 6 Outside diam. (in) 1.31 1.84 2.34 3.41 4.50 6.66 Wall thickness (in) 0.156 0.171 0.171 0.202 0.264 0.328 Weight per ft (lb) 0.55 0.87 1.13 1.97 3.41 6.30 Adapted from Robert H. Perry and Cecil H. Chilton (eds.), "Chemical Engineers' Handbook," 5th ed., McGraw-Hill Book Company, New York, 1973. PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 22 OF 53 Common Industrial Valves Valves are mechanical devices designed to start, stop, direct, or regulate flow of a process fluid. Valves come in a variety of sizes. The smallest industrial valves can weigh as little as 1 lb (454 g) and fit comfortably in the human hand, while the largest can weigh up to 10 tons (9070 kg) and extend in height over 24 ft (6.1 m). Industrial valves can be used with pipeline sizes less than 0.5 in to beyond 48 in.. Valves can be used in pressures from full vacuum (-1 atmgage) to over 13,000 psi (885 atm) Valves are manufactured from a number of materials, the most common materials being steel, iron, plastic, brass (alloy of Cu and Zn), bronze (alloy of Cu and Sn), and special alloys. Some common types of industrial valves are shown in Figure 2. The dotted lines show the position of an open valve. Vertical and circular arrows show the motion of the valve stems. Figure 2. Common Industrial Valves PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 23 OF 53 Valve Classification According to Function Valves are categorized into three functions: 1. on-off valves, which block or allow flow (fully closed or fully open) but are not used for throttling (regulating) flow 2. non-return valves, which allow flow in only one direction 3. throttling valves, which regulate flow at any point between fully open and fully closed. On-Off Valves Gate valves and pressure relief valves are exclusively used for on-off control. Plug valves and ball valves are most often used as on-off valves but can be used for throttling service. On-off valves are used where the flow must be diverted around an area in which maintenance is being performed. Safety regulations also require on-off valves to immediately shut off a system when an emergency situation occurs. Pressure relief valves are self-actuated valves that open only when a preset pressure is exceeded. Pressure relief valves are discussed in more detail in the document ‘PIPES, FITTINGS AND VALVES by Schmidt. Non-Return Valves Non-return valves allow fluid flow in only the desired direction. Preventing back flow is particularly important with corrosive or dirty fluids that could otherwise damage equipment or spoil product quality. All check valves are non-return valves. The swing check valve, lift check valve and the ball check valve are discussed in more detail in the document ‘PIPES, FITTINGS AND VALVES by Schmidt. Check valves are easy to recognize since they have no external handle. They are self-actuating. Throttling Valves Throttling valves allow adjustable flow metering from fully open to fully closed. They are often used to regulate flow, temperature or pressure of a process. Globe valves, butterfly valves, and diaphragm valves are common examples. The angle valve (Fig. 2) is a modified globe valve. Handling Slurries When slurries are being handled, there is a potential for deposition of solids that hinder or prevent valve operation. This is particularly problematic in valves that have high pressure drops (due to abrupt changes in direction of fluid flow). The globe valve is an example of a valve that will become be plugged by slurries. Valves with straight-through flow (low pressure drop) are best for handling slurries. These include ball valves, plug valves, butterfly valves and diaphragm valves. Look at the flow path (indicated by the arrows) in the valves in Fig. 2. PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 24 OF 53 WORKBOOK FOR PIPES, FITTINGS AND VALVES by Strauss STEP 2: Read the excerpt from “Handbook for Chemical Technicians” by Howard J. Strauss and answer the following questions in the spaces provided. 1. A pipeline is to carry water at a pressure of 200 psi. Would schedule 40 steel pipe be suitable for this service? Give reasons for your answer. Refer to Table I 2. A pipeline is to be loaded to a maximum pressure of 500 psi. What schedule of steel pipe should be used for this service? Justify your answer with reasons. 3. When referring to pipe we say 2 in., 2 ½ in., 3 in. etc. and this is called the nominal size. Does nominal size refer to the inside diameter (I.D.) or outside diameter (O.D.) of the pipe? up to 12 “ diameter ……………………………………………….. above 12” diameter ………………………………………………… 4. Considering a nominal size of 3 in. pipe, complete the following table for wrought-iron or steel pipe. Refer to Table II. Schedule O.D. (in) I.D. (in) Thickness (in) Internal Transverse Area (in2) Length (ft) Containing 1 ft3 volume Weight of H2O (lb) per length (ft) 40 80 160 What do you note about the dimensions of a 3 in. pipe? PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 25 OF 53 5. Pipe tables provide much useful information. Complete the following using Table II. a) What is the external diameter of a 1 in. sch. 40 steel pipe? ……………………… b) What is the I.D. of a 2 in. sch. 40 steel pipe? ……………………………………… c) What is the thickness of a 5 in. sch. 40 steel pipe? ………………………………. d) What is the external circumference of a 1 in. sch. 80 steel pipe? …………………….. e) What is the internal circumference of a 2 in. sch. 80 steel pipe? …………………. f) A fluid is flowing in a 3 in. sch. 40 steel pipe. What is the cross-sectional area of flow in this system? …………………………………………………………….. g) The pipe in f) is changed to sch. 80; what is the new cross-sectional area of flow? ………………………………………………………………… h) What is the weight of a 20 ft. section of 5 in. sch. 40 pipe? i) A 3 in. sch. 80 steel pipe is carrying water at 200 psi. What is the weight of water in a 100 ft. section of this pipe? j) A 1 in. sch. 40 steel pipe is being used in a heating unit. It is required to have 16 sq. ft. of external surface on this pipe. What length of pipe should be used? k) A 5 in. sch. 80 steel pipe is carrying a fluid through a plant. If the line is 250 ft. long, what volume of fluid is contained in the pipe? PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 26 OF 53 6. Refer to Table III to answer the following questions. a) Note that the flow capacities are given in gal/min. and lb H2O/h. A 1 in. standard wall (sch. 40) iron pipe with a velocity of 1 ft/s can carry 2.690 gal/min or 1345 lb H2O/h. Are the gallons referred to as Imperial gallons or U.S. gallons? Justify your answer with calculations. b) If the velocity is 2 ft/s, what is the flow capacity of a 1 in. standard iron pipe in lb H2O/h? c) Is there a practical limit to the increase in the velocity and hence the flow capacity of a system? State reasons for your answer. 7. Refer to Table IV. a) How many types of copper water tubing are there? b) What is one difference between these types? 8. Compare Tables IV and V. a) In what respects do general service copper tubing and copper water tubing differ? b) With general-service water tubing, what is the relationship between nominal size and the external diameter? PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 27 OF 53 Answers to questions on Strauss. 1. 2. 3. Schedule 40 steel pipe is designed for 150 psi and handles 300 psi max. Schedule 40 should be suitable by not recommended. Best to use Schedule 60 pipe Schedule 80 pipe handles 600 psi max. Schedule 140 is designed for 500 psi. Use pipe that is designed to handle the working pressures. Avoid problems. Up to 12”, nominal size = ID (for low pressure pipe) For sizes larger than 12:, nominal size = OD. 4. a) b) Fill out the table 3” is nominal not actual ID. ID decreases as schedule (thickness) increases. OD is constant. As thickness increases, internal volume decreases. a) b) c) d) e) f) g) h) i) j) k) 1.315 in. 2.067 in 0.258 in 4.131 in 6.092 in 7.393 in2 6.605 in2 292 lb 286 lb H2O 46.5 ft 31.6 ft3 a) b) c) Volumes are US gal. 2690 lb/h Yes. Frictional resistance increases with fluid velocity and pressure drop increases with flow velocity. Increasing pressure drop will limit velocity. a) b) Three: Type K, Type L, and Type M. They have different wall thickness and weight. a) Copper water tubing: actual OD > nominal size, ID nominal size. General service Copper: actual OD = nominal size, ID < nominal size. nominal size = OD 5. 6. 7. 8. b) PIPES, FITTINGS, VALVES AND PUMPS (STRAUSS & KAUFMAN) PAGE 28 OF 53