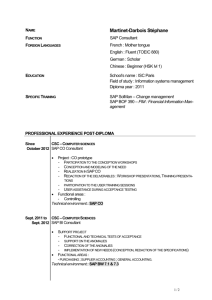

Area Of Expertise in SAP-PP

advertisement

ASHOK KUMAR.V.D Ph: +91 9789839783 (Mobile) Email: vdashoku@yahoo.com SAP Consultant – PP-Module Total Experience – 6+ Years SAP Experience – 1+ Years Professional Experience Profile: Over 6 Years of strong functional experience including various fields like in Production Planning,Quality Assurance,Inventory and Shop Floor Control. Presently working with FOXCONN India Private Ltd since October 2007 as Application Consultant SAP-PP. More than One and Half years Experience as SAPR/3 PP Functional Consultant Post Go live Support and end user training. I have sound knowledge in Discrete Industry, of Master Data, Planning Strategies, MRP, Shop floor control & standard SOP. Vast Experience and implementation of TPM,5S,QC and Kaizen Activities. Wide exposure in productivity improvement and cost reduction studies through Setup time reduction, Cycle time improvement, Multi-manning. Core Team Member for shop floor production planning system. Strengths Quick learner, Belief in hard work, Result oriented, Dynamic, Optimistic, Dedicated Easily trainable, Confident, Highly competitive, Effective both as a lone worker and a Corporate team member. Technical Skills o ERP PACKAGE : SAP R/3 (Enterprise version 6.0) o Technical Package : Auto CAD –2000, Pro-E-2001. EDUCATION QUALIFICATION Post Graguate Diplamo in Plastics Engineering – CIPET-Hyderabad,2004. – Dr.Sivanthi Adithanar College Of Bachelor of Engineering (Mechanical) Engineering, India, 2001.(M.S University) 1 SAP Skill Set in Functional Modules SAP EXPERIENCE: Organization : Foxconn India Private Limited Product : Mobile Phone Enclosures Designation : Application Consultant (SAP – PP) Duration : Sep.2007 – Till Date Foxconn Technology Group is the foremost provider of joint-design, joint-development, manufacturing, assembly and after-sales services to global Computer, Communication and Consumer-electronics ("3C") leaders. Aided by its legendary execution, uncompromising customer devotion and its award-winning proprietary business model, ECMMS, Foxconn Group is not only the largest, but also the fastest growing multinationals manufacturing services provider (including CEM, EMS, ODM and CMMS) In the world. Job Responsibilities Important Responsible for ticket raising and solving the first level Issues . Roles and Responsibilities Prepared the Complete AS-IS Process for Production Planning for Mobile Phone Division. Prepared the master data i.e. MATERIAL MASTER, BOM, WORKCENTRE & ROUTING, for Plastics component Division. Preparation of Business Process Master List, To-Be documents , Gap analysis. Co-ordination with technical team for object development. System Configuration. BDC uploading for material master, BOM & routing. Full Interaction with consultants of implementation partner for developing & customizing the SAP package for Arihant group. Defining the planning strategy. Converting planned order to production orders/purchase requisitions. Posting of goods issue, order confirmation & goods receipt. Rework, scrap & rejection scenarios in production. Day to day job monitoring & scheduling of production order. Post Go-Live support. 2 Area Of Expertise in SAP-PP Creation of Basic master data. Demand Management. Material Requirement Planning (MRP). Production Order Management. Shop Floor Control (SFC). PP Workflow Approval Process. Repetitive Manufacturing. Discrete Manufacturing. Non SAP Experience – Domain Experience (1) Company : Needle Industries India Private Limited (PONY) -Nilgiris Duration : Aug 2006 –Sept 2007 Designation : Assistant Engineer Reporting To : Manager Needle Industries Products is one of the Leading Packaging products (forEXPORT) Manufacturing industries in Nilgiris.The company designs, manufacture and markets Systems. We are a fully devoted company to quality assurance and control Company. Responsibilities Production planner Process planning, optimization Capacity and Material planning in a multivariate production setup Design and modification of parts for Product structures and systems Lean Manufacturing Team Leader Consultant to various Maintenance Divisions for various Repair schemes Process Planner For Production Department Managing and leading 15 technicians and 120 operators in a state of the art production environment End user of ERP application IFS for day to day manufacturing activities such as 1. Work Order Management 2. Job ticket entry to confirm production 3. Material Specification confirmation 4. Part detail Drawing for different projects 3 (2) Company : English Tools & Castings Limited -Coimbatore Duration : June 2004 –July 2006 Designation : Junior Engineer Reporting To : Chief Manager English Tools & Castings Ltd is the leading mfg company which is in the felid of Manufacturing Automobile Components for PRICOL & Ashok Lay Land from Plastics Injection Molding & Aluminum die castings process. (Certified as ISO 9001 company). Responsibilities Develop the Hard Tools & Supply the product as per the customer need. Preparation & Optimization of plant layout. Solving Customer Complaints using problem solving techniques. Monitoring Projects with respect to budgeted cost, demand forecasts, time over runs to ensure timely execution of production. Reviewing shift wise utilization, yield, efficiency and raw material reconciliation. Ensuring high Quality of all components made and making improvements for achieving better quality. Supervising overall production operation, manpower & material planning and production schedule Vendor Product Evaluation & Development. (3) Company : Rain Bird Pipe Products-Coimbatore Duration : June 2001 –June 2003 Designation : Production Technician Reporting To : Manager Rain Bird Products is one of the Leading Automotive (for PRICOL)/ Water Management Systems & Manufacturing industries in coimbatore.The company designs, manufacture and Markets water Management systems. We are a fully devoted company to quality assurance And control and being certified as ISO 9001 Company. 4 Responsibilities New Tool optimization & assembly line optimization. New process / product evaluation & trained the operators in assembly line. Managing Production related tasks including planning, control, and trouble shooting in the shop floor. Ensuring smooth operations including shift management to maintain productivity Setting up production targets and achieving the planned production targets. Monitoring shop floor control systems. Identify Key business issues, with strong target orientation to interact with higher levels of management / engineering departments. Vendor / Sub–contractor development. Career History Taking Pilot run at various stages of New Product Development. Implement 5S and Kaizen activities. Cost reduction by streamlining the manufacturing process Through time study and standardization of work. Implementation and maintenance of kanban systems. Handled Just in time and maintain “ HEIJUNKA”(leveled production) Productivity improvement. Reduce cycle time. Other Relevant Information Father’s Name : A.Vijayaramapandi Date of Birth : 06.06.1980 Gender : Male Nationality : Indian. Marital Status : Unmarried. Passport No. : F1190477 Pan card No : AXWPK3284D Willing to relocate : Yes Language Proficiency : English, Tamil,Telugu Permanent Address : 737,Edayar Street, Coimbatore-641001-India. Yours Sincerely, ( ASHOK KUMAR.V.D ) 5