MENG 351 Machine Shop Lab: Drawings for Fast

advertisement

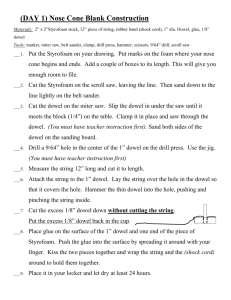

MENG 351 Machine Shop Lab: Drawings for Fast-Return Actuator Wood Shop Lab #1: Reading Chapters: 6 (all), 10.0–10.7, 10.9–10.14.1 This pin-slot mechanism provides a slow and powerful working stroke and a quick return stroke. It is useful in various kinds of machinery, such as a power hack-saw. Suggested Materials: Base plate and Back plate: Pine. The dimensions of these parts are to be set by you. Crankdisk: Walnut Various Dowel pins: Walnut Yoke: Pine, Maple, or Oak Optional Pulley (on backside, for optional motor drive): Pine Parts may be finished with polyurethane if desired. For advanced students, the mechanism may be powered by an electric motor driving another Crankdisk on the backside (initially, make a longer main axle if this is your intent). These plans are from Making Mechanical Marvels in Wood, R. Levy, Sterling, 1991 (out of print). Notes: We will use woodscrews (not dowel pins) to secure Backplate to Baseplate. Dimensions of Backplate and Baseplate are up to you (we have ½” and ¾” pine available). Make the disk axle longer if driving from the back is desired. The ¼” dowel connecting Crankdisk to Backplate is to be glued in the Crankdisk and freely running in the Backplate. Wood dowel diameters are not precise--the “F” drill may not be large enough. Yoke: Below are the basic dimensions of the Yoke, however, I suggest you make it in a simpler way than the book’s plans (see next page for simpler design). Simpler Yoke: Use similar overall dimensions as previous page, but construct in these 4 pieces: Glue the stack together with cyanoacrylate (superglue). Note the 25/64 hole on the left cuts through the joint. Drill the holes while the stack is clamped together, to prevent the drilling operation from disturbing the joint. Trim the corners after construction, as shown on previous page. You may find it simpler to make all the parts 17/64 thick. Note the thickness of the Sideplates is not very critical, while the Spacer thickness is (must allow dowel to slide in the opening). (Not to scale)