4.5 Friction Forces

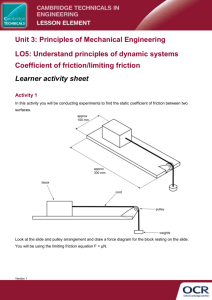

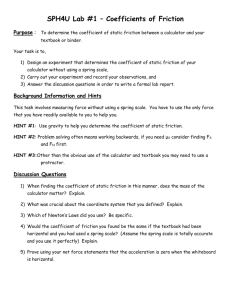

advertisement