Brenda Coleman - The Manufacturing Alliance of Philadelphia

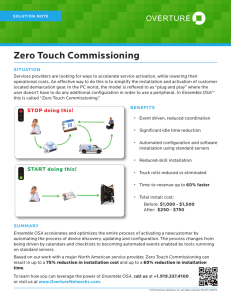

advertisement

4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org Richard C. K.(Inst Eng) Objective To find a company that can benefit from a person with a diversity of engineering, project management, production, construction, installation, and service experience blended with management and personnel skills including P&L responsibility, client liaison, union liaison with a track record of maintaining domestic and international work flow on-schedule and on-budget. Employment History Ray-Guard International Pottstown, PA 9/2009 - Current Chief Engineer • Oversee overall Operations including Engineering, Project Management, Service, Production, Facilities, Maintenance for Manufacturer of Specialized Oncology Vault Radiation Shielded Vault Doors and International Oncology Vault Design-Build Company • Product Design Radiation Shielding Products- Development of Product Manuals and Product Training Programs • Design and Fabrication of custom steel, aluminum, and stainless parts and products; customized tooling, jigs, and fixtures; development of production procedures for listed products. • Manage International IST Team developing installation and service procedures for domestic and international projects, design field solutions on site, develop fabrication procedures for field solutions • Negotiated Business Alliance opening UK operations • Oversee projects from conception stage until close out and commissioning RGI Enterprises A Division of Ray- Guard International • Development of Green Technology System and Product Manufacturing Division • Oversee overall Operations including Engineering, Project Management, Service and Production for green technology integrator utilizing Solar, Solar Thermal, Hydrogen Fuel Cell, and Hydrogen Power GeneratorsManufacturer of Specialized Mobile Applications • Product Design interior/exterior components- power generation, waterless sanitation, water generators, cabinetry, etc. • Design and Fabrication of products made from biodegradable plastic, recycled steel, etc. Atomic International Boyertown, PA 2/2006 - 9/2009 Lead Engineer • Oversaw Engineering, Project Management, Service and Production for Manufacturer of Specialized Oncology Vault Building Materials and International Oncology Vault Builder-Tomotherapy, Cyberknife, Carbon Ion, Particle Therapy, Siemens-Varian- Elekta LINAC, Brachytherapy and Orthotherapy HDR, and Seed Implantation LDR • Product Design Radiation Shielding Products- Neutron Radiation Vault Swing & Slider Doors (up to 35k #), Mechanical Opening Shielding, and Custom Protection Products including supplemental shielding. Development of Product Manuals and Product Training Programs • Design and Fabrication of custom steel, aluminum, and stainless parts and products; customized tooling, jigs, and fixtures; development of production procedures for listed products. • Manage International IST Team developing installation and service procedures for international projects, design field solutions on site, develop fabrication procedures for solutions in field • Oversaw projects from conception stage until close out and commissioning • A total of 33 Projects ranging from $ 250,000 to $14,500,000 completed Apex Fabrication and Design Boyertown, PA 2004 - 2006 CNC Programmer • Oversaw CNC Part Design, Machinery Programming, and Set-up in Pre-Fab Department of 4 personnel • Programming of CNC equipment- Press Brake, BurNY Plasma/Oxy Acetylene Cutting Table, Ironworker (shear and punch), Band Saw, Drill Press and Lathes • Manual operation MiG welder, Chop saw, hand/bench grinders, air compressors, rotating welding stand, and manual press brake 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org • Design of customized tooling, jigs, and fixtures for listed equipment. Provided Operator Training and Maintenance of machines • Manufacturer of Security Gate Systems and Armor Plate Military Products Universal Satellite Pottstown, PA 1996 - 2004 Commercial Division Manager • Managed overall Operations including Engineering, Project Management, Production, Logistics, Installation, Service, Facilities, and Maintenance for a Global Commercial Communications Company manufacturing and installing commercial satellite and RF transmission system towers • Oversaw projects from land purchase/lease and project conception until close out and certification • Domestic and International projects- Projects of various size $ 25,000 to $ 12,500,000 Spectrum International Philadelphia-Houston, TX 1984-1996 Field Engineering Manager-Houston TX Facility and Philadelphia Facility 1990-1996 • Managed 6 Installation Engineers, 12 construction project managers both domestic and internationally. Responsibilities included installation drawing set development, field engineering solutions for customized manufacturing machine installation projects, onsiteconstruction supervision (structural, electrical, mechanical, field fabrication and sub-contractor management), Final Quality Control Inspection of Machinery Production Quotient and wrote Installation Project-Schedule Review and managed pilot plants • Developed and Conducted Training Programs Maintenance, Safety and Equipment Operation), QC, Logistics, and upper management liaison for Custom Semiconductor Production Equipment Manufacturer- Reported to VP of Engineering • Oversaw projects from installation drawing set development to close out, training and machinery certification process. Installation Engineer- Philadelphia PA Facility 1986-1990 • Managed 3 installation and construction teams consisting of a ICT Supervisor overseeing approximately 10 personnel installing specialized semiconductor manufacturing equipment and building structures both domestic and internationally • Responsible for manpower scheduling, hiring, OJT, in-house training classes, material requisitions, coordinating Logistics and Storage, effecting weekly-monthly-annual project schedules, development and analysis of construction process, quality control of installation processes, enforcing personnel safety mandates, coordination with other departments and/or sub-contractors; coordinating RFI’s, equipment requisitions, installation drawing set review and designed field solutions for site conditions Production Supervisor- Philadelphia PA Facility 1984-1986 Operation of equipment. Design of customized tooling, jigs, and fixtures for equipment. Setup Maintenance Schedules for equipment Entire tenure- 168 Projects complete ranging from $ 50,000 to $ 35 million ($100 mil today) in 38 states and 47 countries Skills • Technical CCTV, Access Control Systems (Hard wired and Web Based), Road Security Barriers, Vertical/Horizontal Swing Gates, and Sliding Gates, POS, VOD, VOIP, Monitoring Stations, Remote Monitoring Alarm Systems, Equipment Monitoring Systems, Facility Monitoring and Control Systems, Manufacturing Monitoring and Control Systems Satellite--Commercial Satellite SMATV Headend System, Cabling Grid Balancing, signal and satellite meters, Off-Air System Other--PA Systems, Sound Systems; VOIP, T1 Trunk-lines, Character Generators, Telephone Rooms, POS, Bulk Internet; Coaxial, Telephone, and Ethernet cabling network design, installation and maintenance Computer--MS NT, 2000 Server, Dec Vax Server, XP; Server/Client Network design and implementation (LAN-WAN-RemoteWIFI); Exchange, SQL, SAP, DNS, WINS, Proxy, DHCP, SNA, Email, Web, DSL, SMTP, POP3, TCP/IP, IPX/SPX, T-1/T-3 WAN,ICMP, RAS; Network architecture, design, hardware, and implementation; Goldmine, Maximizer; CA software; Lotus Suite, SAS IVLBuilder, Publisher, Front Page,; Accounting/Business Software- QuickBooks, Peachtree, DEC 99, Office Suite 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org • Construction-Manufacturing PLC, Valve Controls, Electrical (up to 440v 3 phase), building of various machinery platforms, site preparation, facility fit-out, and installation of customized equipment; facilities construction-commercial building, plumbing, electrical, structural, environmental and site prep; forklift, heavy machine operation Engineering Software- Proficient AutoCAD, Visio Process Flow, and Familiar with Solidworks, 3-D Architect, Home Builder; Arch Desktop, AutoDesk Inventor Project Management- SW-Prolog, Primavera, MS Project, Logistics Mgr Manufacturing Management – SW: PDM, RBI, SCM, CRM, SPC, KPI, AUTOMATED CONTROLS-PLCSCADA, TMS/WMS, ERP-JITMRP, VISIO PROCESS FLOW Facility/Building Software- FM, PDM, BMS, BEM, BVM, BACS Educational History Urania College-Glasgow, KY 1/79-12/81 • B.S. Industrial Engineering