15710

advertisement

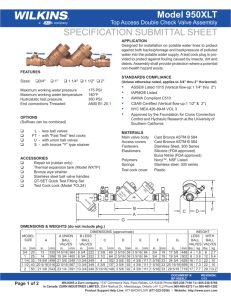

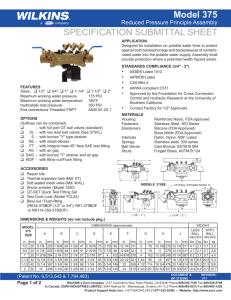

Division 15 Mechanical System 15710 – SPECIALTIES PART 1 - GENERAL 1.01 DESCRIPTION A. 1.02 Provide all labor, materials, equipment, and services necessary to furnish and install miscellaneous materials and equipment for the plumbing systems as indicated or specified. APPROVED MANUFACTURERS A. The following manufacturers are approved for use subject to the detailed requirements of the Construction Documents, and as approved by the Owner during the bidding phase, prior to receipt of bids. 1. Floor Drains, Sinks, and Clean-outs: J.R. Smith, Zurn, Josam, Wade. 2. Fixture Supports: Zurn, J.R. Smith, Wade, Josam. 3. Hose Bibbs: Acorn, J.R. Smith, Woodford. 4. Wall Hydrants, Ground Hydrants: Wade, J.R. Smith, Zurn, Josam, Woodford. 5. Gate and Globe Valves: Milwaukee, Stockham, Hammond. 6. Shock Absorbers: Zurn, Wade, Josam, J.R. Smith. 7. Ball Valves: Apollo, Watts, Hammond. 8. Pipe Hangers: Grinnell, B-Line, Fee & Mason, Elcen, Superior, Michigan. 9. Access Panels: Wade, J.R. Smith, Zurn, Josam. 10. Backflow Preventers: Watts, Febco, Beeco, Conbraco. PART 2 – PRODUCTS 15710-1 Division 15 Mechanical System 2.01 2.02 CLEAN-OUTS A. Interior Concrete and Tile Floors: Wade W-7000, J.R. Smith 4020, Zurn 1400, Josam 56010, with scoriated nickel bronze top. B. Interior Finished Walls: Wade W-8460-R, J.R. Smith 4532, Zurn Z1445-1, Josam 58790-15. C. Exposed Vertical Clean-outs: Wade W-8560-D, J.R. Smith 4510, Zurn Z-1445, Josam 58510. D. Outside Yard Clean-outs: Wade W-8300-MF, J.R. Smith 4253, Zurn Z-1460-15, Josam 58680, with 18” x 18” x 6” deep poured concrete pad at grade. E. Terrazzo Floors: Wade W-7000-US, J.R. Smith 4183, Zurn Z-14255, Josam 56020-12, with nickel bronze top. F. Provide all clean-outs with heavy threaded bronze plugs. DRAINS A. General: Provide cast iron body drains with lacquer finish and inside caulk outlet. Where installed in surfaces having waterproofing membrane, provide drains with non-puncturing flashing clamp device and anchoring flange. See plans for type of grate to be furnished on floor sinks. B. Floor drains. 1. Equipment Rooms and Unfinished Areas: Wade W-1310-TD, J.R. Smith 2220, Zurn Z-551, Josam 32120, with nickel bronze strainer and shallow type bucket strainer. 2. Toilet Rooms and Finished Areas: Wade W-1100-G, J.R. Smith 2010-B, Zurn Z-415, Josam 30000-S, with 6” x 6” square nickel bronze strainer a. Contractor shall coordinate final strainer selection with Owner prior to submittal, and coordinate installation 15710-2 Division 15 Mechanical System with finish floor material. 2.03 2.04 C. Floor Sinks: Wade W-2530, J.R. Smith 3151, Zurn ZN-1801, Josam 49050, 12” x 12” x 8” cast iron floor sink with A.R.E. interior flat bottom strainer, aluminum sediment bucket and nickel bronze grate. D. Roof Drains: Wade W-3000-52-53, J.R. Smith 1010-E.R.C., Zurn Z100-E.R.C., Josam 21000-3, with sump receiver, underdeck clamp, extension sleeves, height as required by thickness of roof construction. FIXTURE SUPPORTS A. General: Provide ¼” bolts or screws, of sufficient length to securely fasten the fixture to the backing wall or closet ring. B. Fixtures set against stud walls shall have their hangers secured to a metal backing plate. Install ¼” thick and 4” wide steel metal backing plates at the time the rough piping is installed. Attach plate to a stud at each end of the plate and to each stud, which it passes. Attach plate by bolting not less than 2½” U-bolts per stud, with bolts through the plate and around the flange of the stud. C. Wall Hung Fixtures: Where indicated, provide Wade supports of appropriate pattern. HOSE BIBBS A. At Building: Woodford 24P-3/4, ¾” lockshield wall faucet with integral flange, lockshield, loose key, vacuum breaker, and ¾” hose end. Exterior units shall have rough brass body. Interior units shall have polished chrome-plated body. B. In Planters: Acorn 8126, ¾” rough brass, bent nose standpipe faucet with lockshield, loose key, vacuum breaker, and ¾” hose end. C. Recessed wall hydrants. 1. Wall Hydrant: Woodford B74, Wade W-8635-89, J.R. Smith 5709, Zurn Z-1330. Josam 71020, ¾” anti-siphon wall hydrant with nickel brass box, integral backflow preventer, and key 15710-3 Division 15 Mechanical System lock. 2. 2.05 SHOCK ABSORBERS A. 2.06 Wade W-5, W-10, W-20, W-50, W-75, or W-100; J.R. Smith 5005, 5010, 5020, 5030, 5040, 5050, or 5060; Zurn Z-1700 series, #100 through #600; Josam 1485-1 through 1485-6; shocktrol size as scheduled on the drawings. Provide access panels as required for removal. TRAP PRIMER A. 2.07 Non-Freeze Wall Hydrant: Woodford B65, Wade W-8625, J.R. Smith 5509, Zurn Z-1300, Josam 71000, ¾” anti-siphon, non-freeze wall hydrant with nickel brass box, integral backflow preventer, and key lock. Wade 2400, J.R. Smith 2699, Zurn Z-1022, Josam 88250, ½” automatic trap primer with solder unions. Provide access panels with locking covers as required for removal. Furnish and install trap primers on all toilet area floor drains, and as required by local plumbing code. Install automatic trap primers on cold water supply at nearest fixture, and run drain to trap seal being protected. See the Contract Drawings for location and manufacturer of trap primers that cannot be installed as indicated above. VALVES A. B. Gate valves. 1. Hammond IB648, 150# solder joint, for all lines up to 2” in diameter. 2. Hammond IB629, bronze trimmed, 150# W.P. screwed joint, for all valves 2” thru 3”. 3. Hammond IR1138, 125# iron body bronze trim, flanged ends, for all valves 4” and larger. Check valves. 15710-4 Division 15 Mechanical System C. D. 1. Hammond IB912, #150 solder joint, for all valves up to 2” in diameter. 2. Hammond IB904, screwed joint, for all valves larger than 2” in diameter. Globe valves. 1. Hammond IB423, 150# solder joint, for all valves up to 2” in diameter. 2. Hammond IB413T, 150# solder all bronze screwed joint, for all valves larger than 2” in diameter. Ball valves. 1. Hammond 8614, three piece, full port, bronze trim, solder joint, for all valves up to 2½” in diameter. 2. Nibco F-510 series, carbon steel body with 316 stainless steel trim and flange joints, for all valves 3” and larger. E. Strainer: “Y” type, 125 psi SWP, gray cast iron, bronze model or stainless steel perforations as recommended by the manufacturer for size and service intended. Provide three-piece, full flow ball valve the same size as the unreduced plug connection (blow off connection) on all “Y” strainers. On plug connections 1¼” and larger, the valve shall be piped directly to the nearest floor sink. Provide one-piece, full flow ball valve the same size as the unreduced plug connection (blow off connection) on all “Y” strainers where the unreduced plug connection is 1” or smaller. Plug connection 1” and smaller shall be provided with a hose end. F. Flexible piping connectors shall be either of the following, installed in accordance with manufacturer’s recommendations. 1. Stainless steel braided bronze connection with copper tube ends. 2. Stainless steel braid and carbon steel fittings, flanged for 3” and larger, threaded male nipples for 2½” and smaller. 15710-5 Division 15 Mechanical System 2.08 THERMOMETERS A. 2.09 4” round mercury filled dial type thermometers, 1% +/- accuracy, industrial universal joint, concealed capillary. Sealed well to be ½” pipe diameter in length. Temperature range 30°F to 240°F. PRESSURE GAUGES A. 4” round, cast case, ½% accuracy. Provide gauge range with operating point in the middle half of scale, and compound range for gauges, subject to sub-atmospheric pressures. 1. Pressure Gauge Cocks: Crane, Whitey, Trerice, 2000# needle valve. PART 3 – EXECUTION 3.01 FLASHING A. 3.02 SLEEVES A. 3.03 Unless otherwise detailed or specified, construct 24 gauge galvanized steel sleeves around pipes passing through masonry and concrete walls, concrete slabs, stems, etc. ESCUTCHEON PLATES A. 3.04 Supply flashings for all vent pipes through roof to be installed with roofing. Flash vents with 4 lb. sheet lead. Extend flashing into roofing at least 10 inches from vent, and turn flashing over and down into vent opening. Install cast brass split ring with set screw at all locations where pipes pass through walls, floors, and/or ceilings. Provide polished chrome plated escutcheons in finished rooms. All others are to be polished brass. PIPE HANGER AND SUPPORTS A. General: Adequately support piping against sagging, pocketing, 15710-6 Division 15 Mechanical System swaying, and displacement. Properly space and apply hangers to achieve the result, and not farther apart than the following. 1. 2. 3. 4. Cast iron pipe. a. All branches in excess of 30” in length, 5 feet on center. b. Pipe exceeding 5 feet in length may be supported at not more than 10 foot intervals. c. Provide supports within 18” of the joints on both sides. Steel pipe. a. ¾” diameter and smaller, 8 foot on center. b. 1¼” thru 2” diameter, 10 foot on center. c. 2½” thru 4” diameter, 12 foot on center. Copper tubing. a. ¾” diameter and smaller, 6 foot on center. b. 1” and 1¼” diameter, 8 foot on center. c. 1½” and 2” diameter, 10 foot on center. d. 2½” thru 4” diameter, 12 foot on center. Plastic piping. a. ¾” diameter and smaller, 3 foot on center. b. 1” and 1¼” diameter, 4 foot on center. c. 1½” and 2” diameter, 5 foot on center. d. 2½” thru 4” diameter, 6 foot on center. 15710-7 Division 15 Mechanical System 3.05 B. Trapeze Hangers: Use approved channel, supported from structure with full threaded rod. Space hangers for smallest pipe in the group from the schedule in Paragraph 3.04.A. Secure piping to the channel. Where piping is insulated, provide pipe clamp around outside of insulation. Do not damage insulation. C. Pipe Supported from Wall: Use hanger supported from F&M, Figure 151, wall bracket. D. Piping, Vertical: Secure with F&M, Figure 238, riser clamp. For steel pipe, use F&M, Figure 378. For copper tube risers, use F&M, Figure 368. E. Single Pipe Hanger: Use F&M, Figure 239 for steel or cast iron pipe, and Figure 365 copper clad clevis hanger for copper pipe, with washers and double nuts on the rod. Support from structure with full threaded rods. F. Install “Stoneman” trisolators to isolate all uninsulated copper piping, or provide copper coated hangers. G. Size all hangers on insulated lines to fit around outside diameter of insulation specified, with allowance for F&M, Figure 81, galvanized sheet metal shield. H. Support ½” thru 12” piping with all-thread rods per the following. 1. ½” thru 2” diameter, 3/8” rod size, minimum. 2. 2½” thru 6” diameter, ½” rod size, minimum. 3. 8” thru 12” diameter, 5/8” rod size, minimum. ACCESS PANELS A. Unless otherwise specified elsewhere, the Contractor shall furnish and install wall type access panels equal to J.R. Smith 4762, stainless steel construction with key lock. End of Section 15710-8