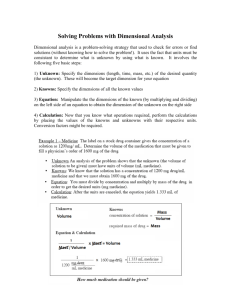

Table 3: Comparison of Competing Power Sources

advertisement

THE DESIGN OF SURFACE TRANSPORT SYSTEMS FOR A MARS POLAR STATION Bob Parkinson & Malcolm Smith Abstract The Mars Polar Expedition will require two sorts of vehicle – a long-range, pressurized Rover for major expeditions, and a short-range, unpressurized Utility Vehicle for EVA operations around the Station and elsewhere. Operating in pairs for safety, the long-range Rover will require a range of about 1600 km to reach the edge of the polar cap and return, carrying two astronauts for up to 24 sols, or four astronauts in an emergency return to Base. Power for the Rover will come from an oxygenmethane turbo-generator power system. The Rover will be delivered in a fully fuelled state to aid in the initial “setting up” operations, and has a delivery mass of 7.1 tonnes plus 1.9 tonnes of support mass. The utility vehicle has an estimated delivered mass of 252 kg. 1. INTRODUCTION To justify the use of human explorers to explore Mars, the astronauts will need to range much further from the landing site than the 7.5 km “walk back” range allowed during the Apollo programme. In the case of the Mars North Polar Station there is a desire to conduct traverses from the pole to the edge of the permanent ice cap. requirements are set by the need to conduct a traverse to the edge of the ice cap and return. An integrated system model has been used to assess trade-offs and produce an initial design of a Mars Polar Rover. 2. REQUIREMENTS 2.1. Mission Definition Initial discussions considered a variety of transportation means across the polar ice cap, including aircraft, airships and “skidoos”. One promising idea – that of “polar kiting”, successfully demonstrated in the Antarctic [1] – turns out to be unsuitable for the Martian environment due to the low density of the Martian atmosphere. In addition, deeper investigation of the environment [2] indicates that skiing in the sense familiar to Antarctic operations may not be possible on Mars due to the high friction factors of the low-temperature ice/dust mix. The ultimate conclusion was that to fulfil the operational requirements of the Polar Station, a long range pressurized Rover serving as a mobile “camper” would be required. In addition, a small, unpressurized “utility vehicle” would be required for EVA operations around the Station itself. The primary requirement for the Polar Rover is to conduct a survey from the Polar Base to the edge of the polar ice cap. Fig. 1 shows three possible routes. The most direct route is about 400 km in length. However, a more interesting route (marked Route C in Fig. 1) to the Chasma Boreale must take a curved route 650 km in length due to the spiral topography of the ice cap. If a 20% allowance is included for off-track travel, a visit to the edge of the ice cap from the pole and return requires about 1560 km. For design purposes this was rounded to 1600 km. Various designs of rover vehicles have been produced both for the Moon and Mars in different contexts [Ref. 3]. Vehicle design is however dependent upon the requirements the environment in which the vehicle must operate. In the case of a Mars Polar Station the environment is significantly different even from elsewhere on Mars, and the mission Maximum travel speed not only depends on terrain roughness and the quality of the vehicle suspension, but also on the local gravity. On the Moon the Lunar Rover managed a top speed of 17 km/hr, but for comfortable extended driving managed about 8 km/hr. Martian gravity is twice that of the Moon, and the polar ice cap is expected to be reasonably The north pole of Mars is also about 3000 m higher than the plain surrounding the polar cap, and the Rover will need to descend this distance on the outward journey and climb it again on the return. smooth, so an average travel speed of about 15 km/hr should be achievable. With 6 hours driving per day (or more accurately per sol) the Rover should be able to achieve 90 km/sol. In addition to having an emergency rescue capability, Rovers will be designed on a “failoperational, fail-safe” basis, and each Rover will be equipped with a winch with which to rescue the twin Rover from soft terrain or “snowdrifts.” During EVAs it is expected that both crewmembers will be outside to support one another. As a consequence it will be necessary to enable the Rover to be controlled externally, either by the EVA party or by a link to the companion vehicle. 2.3. Environment Fig. 1: Possible routes to the edge of the Martian North Polar Cap Allowance must also be made for stops and EVAs to deploy scientific instruments and permit local exploration. With pre- and postEVA activities, EVAs will occupy most of the day (sol) in which they occur. An EVA has been scheduled for every fourth sol of the mission, with no travel on that day. As a consequence, the complete traverse to the edge of the polar cap and return will take 23.8 sol with six EVAs. There is adequate margin built into this model, with the possibility of driving further on particular days with good driving conditions, or some travel during EVA days. 2.2. Safety Safety is a prime concern for any extended mission distant from the permanent base. In the event of a Rover breakdown it must be possible to recover the crew back to the Polar Station either by external support or by design of the expedition. It is proposed that any expedition consists of two Rovers, each with a nominal crew of two but with life support capable of supporting four people on an emergency return to the pole. While it takes ~ 12 sols on the outbound leg to reach the maximum distance, eliminating stops for EVAs and driving 8 hours/sol on the return reduces the return home time to 6.7 sols. For a nominal mission some 47.6 man-sols of consumables are required. The worst-case emergency raises this requirement by only 3.8 man-sols to 51.4 man-sols. The summer polar environment of Mars is relatively benign. Temperatures at the pole can climb to 205 K and the surface is frozen (water) ice with between 10 and 40% of dust [4]. This provides a surface harder than concrete [5] with a friction angle of about 27. There is no significant evidence of cratering, and analogy with Antarctic conditions suggests a surface rippled to a height of a few centimetres. At the edges of the ice cap gradients may be between 10 and 15. The polar winter provides more adverse conditions. Atmospheric condensation deposits 1 - 2 metres of carbon dioxide “snow” onto the surface. The trafficability properties of this CO2 “snow” are not known but possibly lie at the higher end of those encountered in terrestrial snowfields, with a density of ~ 920 kg/m3. Long-range traverses may not be possible in the Martian winter, but the Rover has been designed to be able to drive across the expected “snowfield”. The principal environmental problems the Rover design will face are the low temperatures and the dust in the atmosphere. Ambient temperatures may be less of a problem than first appears - convection is not a major heat transfer mode in the thin Martian atmosphere, but items of the Rover will require continuous thermal control and special measures may be required to prevent wheels “freezing” when the vehicle is immobile [6]. Dust suspended in the atmosphere with particle sizes of a few micrometres may be more of a problem - infiltrating rotating machinery and requiring special precautions for drive and generating equipment. 2.4. Science Payload The science requirements for a long-range traverse will be dealt with in a companion paper [7]. However, some assumptions have to be made of the payloads to be carried on board the Rover. These are listed below in Table 1. RMS Effector Package 6 kg Deployable Surface Experiment 138 kg Packages (5) SEP Storage Rack 14 kg On-Board Analysis Equipment 18 kg Portable Drilling Package 179 kg Table 1: Assumed Science Payload (each vehicle) Deployable packages will be placed at intervals along the traverse and will transmit telemetry back to Mission Control via the communications network. Deployment progressively reduces the mass carried by the Rover, but at the same time the Rover can be expected to acquire samples (principally local drill cores) so the effect on performance has been neglected. 2.5. Communications Away from the fixed Polar Station the Rover will be unable to use line-of-sight communications. In the polar region it will also be unable to see any network of aerosynchronous communications satellites above the Martian equator. Since continuous or near-continuous communications between the Rover and the Base and/or Earth are required, the options are for the Rover to deploy a series of repeaters along its journey, or to use a Molniya-type relay satellite in an inclined, elliptical orbit [8]. Surface relays would have to be numerous – a 100 m high mast would only have a range of 26 km – and so a satellite solution is preferred. The Rover will also need to serve as a communications relay for EVA activities and also for Rover-to-Rover communications. 3. POWER OPTIONS 3.1. Housekeeping Power Demands Besides providing power for mobility, the Rover will need to provide housekeeping power for such functions as life support and communications. Housekeeping power is a constant factor, but demands change as different activities are carried out. Table 2 lists the modes have been assessed in an initial housekeeping power budget: The vehicle static, crew active The vehicle moving The vehicle static, crew asleep The vehicle static, crew performing an EVA Static Mobile Sleeping Expected total 232 107 190 duration Life Support 1811 1811 1811 Crew 520 146 32 Accommodations Avionics & 212 251 166 Communications Thermal 30 30 24 Miscellaneous 111 275 0 Switching & 72 67 54 control Total 2766 2581 2087 Table 2: Housekeeping Power Requirements The biggest variation in housekeeping power comes during EVAs, when not only are internal systems shut down, but the absence of the crew themselves removes additional thermal input. Adding a balancing heat input of 1.2 kW during these periods actually reduce the overall mass of the system. 3.2. Power Sources A surface vehicle typically requires about 0.1 w-hr/kg/km travelled [9]. With an all-up mass of ~7.5 tonnes, this implies a total energy requirement of about 1200 kW-hr. Housekeeping power will add about 2300 kWhr to this. Hydrogen-oxygen fuel cells would give the highest energy per unit mass of fuel, but (liquid) hydrogen demands storage at very low temperatures (~20 K) and has a low density. In addition, fuel cells are relatively heavy in terms of mass per kW generated. Gas turbine engines are much lighter for similar power output. At the Martian pole, with carbon dioxide and water (ice) available in abundance, manufacture of methane and liquid oxygen is relatively simple using the exothermic Sabatier reaction: CO2 + 4H2 CH4 + 2H2O The hydrogen is generated electrolysis: 2H2O 2H2 + O2 by water While both methane and oxygen need storing at cryogenic temperatures, they can both be stored at a common temperature (~100 K), and used to drive a turbine-generator system to provide electricity. EVA 42 hr 611 105 w w 198 w 1200 529 71 w w w 2713 w Allen and Zubrin [10] have suggested that it is not much more difficult to manufacture ethylene to provide an even higher density and more readily storable hydrocarbon. Zubrin [11] has also suggested that a carbon monoxide/oxygen propellant combination, with the carbon monoxide generated by a reverse water gas reaction or electrolytic means [12], might be more suited to production on Mars, and ESA have sponsored work on developing a fuel cell for this combination [13]. A comparison was therefore made of the total system mass of oxygenhydrogen fuel cells with methane-oxygen, ethylene-oxygen and carbon monoxide-oxygen turbo-generator systems. The results are shown in Table 3. (Note that these results are for the final computed mobility power requirements, not the approximation in the first paragraph above.) O2 / H2 1.26 CH4 / O2 1.05 C2H4 / O2 0.91 CO/ O2 0.68 Electrical output Reactants* 1758 2055 2342 3117 Storage 860 132 146 217 tanks Generating 293 32 32 32 equipt. Total Mass 2911 2219 2520 3366 Figures include allowance for mass loss due to CO2 venting Table 3: Comparison of Competing Power Sources While H2/O2 has the highest output per kilogram of propellants, the associated mass of generating equipment and storage tanks more than offsets the gain in propellant mass over methane-oxygen. At the other extreme, while CO/O2 takes less power to generate from local resources (the Martian atmosphere), the resultant power density leads to a significantly larger total mass, and hence a larger Rover. Table 3 suggests that, due to the difference in the mass of the associated equipment, a dual CH4/O2 turbo-generator system is the preferred power source. 3.3. Mobility Analysis Fuel requirements for the Rover are a significant part of the total mass of the vehicle, with a substantial contribution coming from mobility requirements. Estimating mobility power requirements is therefore important in sizing the Rover system. Following the example of Wallace & Rao [14] methods proposed by Bekker [15] have been used to get an initial estimate, even if these will need to be replaced by more accurate methods for further design. The following mobility requirements need to be taken into consideration: Level travel across hard ice/dust surfaces (the principal long-range mode) Descent of up to 3000 m down slopes of 10 - 15 on hard ice/dust Ascent of up to 3000 m up slopes of 10 15 on hard ice/dust A capability to move across CO2 “snow” surfaces with two wheels inoperative Travel across North Polar Erg permafrost surfaces, characterized by the “crusty-tocloddy” material identified by Arvidson et.al. [16] Wheel and tyre dimensions are sized by the kW-needs to travel over soft, CO2 “snow” surface hr/kg without getting buried. In this case a vehicle kg with six wheels of 1.25 m diameter and 0.35 m kg tyre width was used, giving a maximum sinkage of 0.156 m with the assumed load kg carrying properties. kg Resistance to travel comes from the following sources: Rolling resistance, due to energy losses due to flexure of the wheel and calculated from empirical data from terrestrial tyres [17] Bulldozing resistance due to accumulation of surface material in front of the wheel Compaction resistance of the surface material Resistance due to grades. In the case of downhill grades it is assumed that regenerative braking will be applied, recovering 80% of the available energy. The capability of the drive system is defined in terms of “drawbar pull” – measuring the difference between the tractive force applied and the resistance to travel. The power requirement is the product of resistance and speed of travel. For high resistance modes such as the maximum uphill grade or travel in CO2 “snow” reducing the travel speed reduces the power required. Total mobility energy requirements are calculated by assigning travel durations to each mode. The results of the mobility analysis are shown in Table 4. Total resistance Drawbar pull Travel speed Travel duration Total drive power Hard ice 1.2 U/hill Grades 6.0 D/hill Grade - 3.6 CO2 Snow 8.5 Permafrost 2.2 17.4 12.6 22.1 4.1 28.8 4.2 2.7 4.2 2.0 4.2 88.2 2.6 1.2 4.0 10.7 6.0 22.7 -10.1 13.3 10.7 Table 4: Results of Mobility Analysis For short durations, excess power (e.g. to extract the vehicle from a “snowdrift”) can be supplied from the batteries (see § 3.5), but a long duration continuous ascent will require higher powers than provided by a single turbogenerator and which would drain the batteries. The options for an extended climb are to use both turbo-generators or, as a fall back position, to halve the rate of travel. Each wheel of the Rover will be driven independently by an electric motor with an output torque of about 14 N-m driving through a harmonic drive reduction gearbox with a ratio of about 100:1. Independent suspension is provided for each wheel in the form of a MacPherson strut – or rather the Chapman version, since the steering function can be carried out through differential driving of each wheel. temperature. Maximum (rocket) performance occurs at an O/F ratio of about 3.25, but this would reduce the overall density of the propellant mixture and was not considered worthwhile. The basic stochiometric k combustion flame will need to be “watered N down” using recycled steam to give a turbine k Nentry temperature ~ 1700 K. A schematic of mthe power system is outlined (without showing /s the parallel redundancy) in Fig.2. h r k W 3.5. Energy Storage An auxiliary energy storage capability (secondary battery) is included in the overall power system. Battery sizing must fulfil the following conditions: Provide energy storage for peak demands over the nominal generating capacity of the turbo-generators Provide additional energy for long continuous ascents Provide energy storage for regenerative braking on extended descents Provide independent power for start-up and for up to four hours operation without support from the power trailer. 3.4. Power System Design The Rover power system consists of two parallel turbo-generators driven by methane-oxygen combustion, with auxiliary battery energy storage. The power system (excluding the batteries) and propellant storage tanks are housed in an articulated “power trailer”. Water in the exhaust will be condensed out and supplied to the Rover life support system. Uncondensed CO2 will be vented to the Martian atmosphere. Using dual redundant turbo-generators (together with having two vehicles supporting one another on an expedition) means that the expedition is not dependent upon maintenance during the mission [Ref. 18], avoiding the need for including it within the pressurized envelope of the Rover. At a stochiometric mixture ratio (O/F = 4), the combustion temperature of methane and oxygen (3053 K) is too high as a turbine entry Fig.2: Schematic of power generation system The last of these cases sizes the battery at 22 kW-hr. Since implementation design is still some distance in the future, lithium-polymer batteries have been assumed [19] rather than the current lithium-ion cells that might have been assumed. However, this is not a critical technology area. The design includes the battery within the main Rover inventory rather than as part of the power trailer, so that the two components can be separated for specific operations at the home Station. 3.6. Support Requirements Using CH4/O2 propellants, the Rover will require a support system at the Polar Station to generate and refuel it. As indicated in §3.2, this will be generated from the atmosphere and polar ice using a Sabatier reactor and water electrolysis, together with a plant for liquefying and storing the propellants. An compartment. The volume estimates are not inconsistent with Mars Society experience [Ref. 22] although those tests were not done with long-term occupancy as a major consideration. initial estimate has been made of the size of this support plant. The size and power requirements are approximately inversely proportional to the time required to generate a full fuel load for the Rover. For a 40-sol recharging time (i.e. taking 80 sols to completely refuel a two-vehicle expedition) the support equipment has a mass of about 1.9 tonnes and uses 14.5 kW of power. Fig. 3: Layout of Pressurized section of Rover In the design shown there is room for life support equipment (and in particular water and air tanks) below the floor, and accessible storage beneath the bunks. The airlock is offset to one side of the rear bulkhead, which allows for an external platform with an isogrid floor to clean off suits after an EVA. 4.2. Environmental Systems 4. LIFE SUPPORT SYSTEMS 4.1. Volume Requirements The volume requirements for short to medium duration missions in space are reasonably well established [20,21]. Because the volume requirement increases with mission duration, it the internal volume is set by the nominal crew living in the Rover for 24 sol rather than the emergency carriage of 4 for a significantly shorter return to base. However, these requirements are for zero gravity enclosures, and the presence of the Martian gravity provides an emphasis on floor area as well. Fig. 3 shows a possible layout for the Rover. The zero gravity requirement suggests a volume of 22.6 m3, but with a diameter of 2.75 m (set by the need to provide adequate headroom) the plan area is insufficient to accommodate sleeping bunks, hygiene, food accommodations and storage and recharging provisions for EVA suits. As a consequence it was necessary to add 0.3 m to the length of the cylindrical section of the pressurized The initial assumption for environmental life support was to recover the CO2 from the atmosphere and reduce it back to provide breathable oxygen via a Sabatier reactor and water electrolysis system. However, this oxygen production process is essentially that used for producing propellant for the Rover. If there is no forward contamination constraint, the recovered CO2 can be vented into the Martian atmosphere, and oxygen supplied directly as liquid oxygen without requiring further energy input. The system still requires CO2 recovery, but eliminating the Sabatier reactor (a mass of 304 kg) reduces the overall mass of the Rover by 465 kg. Removing the water electrolysis unit (mass 161 kg) and replacing it with a liquid oxygen dewar reduces the mass of the Rover by a further 951 kg by eliminating the 1200 watt power requirement associated with this unit. Drinking water is loaded aboard the Rover at the start of the mission, but all remaining water requirements use the condensate from the turbo-generator power system. The Rover is equipped with a toilet but no shower – the crew will have to be content with sponge baths for the duration of their mission. Food is stored in a freezer and heated in a microwave oven. 4.3. Consumables Table 5 shows the estimated consumables required for a 24-sol mission. A 5-day contingency provision is made for emergencies, with the oxygen kept as bottled gas rather than liquid. The “other inorganic material” in Table 5 includes 35 kg of lithium hydroxide canisters for use during the EVAs, plus a limited amount of spares and consumables for the crew accommodations. Emergency (bottled) oxygen 26 kg Liquid oxygen 138 kg Nitrogen 16 kg Potable water 74 kg Dry food 40 kg Packaging 19 kg Other inorganic material 82 kg Total 560 kg Table 5: Consumables for 24-sol mission 4.4. Thermal Control Thermal control of the habitation volume is complicated by the variation of internal heat generation with activity. The external surface temperature changes from 205 K in the summer to less than 148 K in the winter, but this is of secondary importance because the principle mode of heat loss from the outer surface of the vehicle is radiation – convection to the thin Martian atmosphere is typically less than 5% of the total. There is a substantial heat loss through the 0.75 m2 of window. The remainder of the cabin is insulated with 5 cm of Rohacell-50 foam insulation, providing a balanced heat loss (i.e. constant internal temperature) during the minimum EVA mode. An active heat rejection system (thermal loop) is then added to control temperatures during activity modes with higher internal heat generation. Some balance can be achieved by using electrical heaters to compensate for the lower internal activity levels during EVAs, but an additional 400-watt active heat rejection is required to balance all modes. An internal water-cooling loop is also useful to cool local hot spots such as avionic equipment. 1.26 m2 of external radiator area will be required for active heat rejection, using a heat pipe system that will not freeze up at Mars polar temperatures when not in use. 5. VEHICLE CONFIGURATION The pressurized Rover is a six-wheeled vehicle in two sections – a four wheeled tractor section carrying the pressurized habitation unit and an articulated trailer that carries the propellant and power generating equipment. The front of the tractor section carries a strong beam on which are mounted the remote manipulator arm, a winch, and an external driving position so that the vehicle can be moved by the crew during EVAs. The overall configuration is shown in Fig. 4. One feature that needs to be incorporated into the design is the need for the Rover to dock with the Station. When attached to the Base the crew will need to have frequent access to the vehicle for the purpose of maintenance and replenishment, and the need to mount an EVA for each access to the vehicle is not acceptable. Fig. 4: Perspective View of Mars Polar Rover Docking on a planetary surface gives some additional problems over docking in zero gravity since the vehicle lacks all the needed degrees of freedom. Two possibilities exist – a front end docking port, or an access point on the roof of the vehicle. The latter option is illustrated in Fig.4, allowing better access to the vehicle and less interference with the frontdriving position. The docking access hatch also provides the second exit route from the pressurized compartment in the event of emergency. The remote manipulator arm is located at the forward corner of the vehicle. It has the possibility of placing equipment up to 3.5 m from the vehicle, and it also has the capability of reaching round to the side of the vehicle to pick up scientific equipment from an unpressurized external rack. A mass breakdown for the pressurized Rover is summarized in Table 6. The mass estimate has been assembled at equipment level, with margins applied dependent upon the degree of confidence ranging from 5% to 20%. With articulation between the tractor and trailer, the Rover is capable of transitioning between slopes of 20º and 10º in opposite senses, has a ground clearance of 0.55 m and can cope with individual blocks of 0.42 m height. The turning circle will have a radius of about 5 m. Crew & EMUs Science Payload Crew Accom. Life Support Basic Mass (kg) 327 328 220 819 Margin 5% 8% 20% 20% System Mass (kg) 344 354 264 982 Avionics 140 16% 162 Power (tractor 161 5% 169 Harness 75 20% 90 Mechanisms, 241 17% 282 wheels etc. Structure incl. 1065 20% 1275 suspension Thermal 192 13% 216 systems Consumables 395 Tractor 4664 (loaded) Power Trailer 674 17% 790 (dry) Propellants & 2125 Residuals Trailer (wet) 2915 Fully Loaded 7451 Delivered Mass 7130 Table 6: Mass Breakdown for Pressurized Rover 6. CONCLUSIONS An initial design concept has shown that it is possible to provide a pressurized Rover capable of supporting a traverse of the Martian North Pole from a base at the pole to the edge of the permanent ice cap. The mission would consist of two identical Rovers carrying a total of four astronauts, and would take an estimated 24 sol to complete, including stops for EVAs. The mission would take place during the polar summer, and is made possible by the fact that the permanent ice cap presents a hard surface relatively free of mobility difficulties. The total mass requirement that must be delivered to Mars, including support equipment for refuelling, amounts to 16.1 tonnes. References 1 P. Woodhead “Misadventures in a White Desert”. Sceptre Books, London 2003. ISBN 0-340-82810-2 Bob Parkinson “The Environment of the North Polar Cap of Mars” JBIS Special Issue[Reference to come] 2 J.J.Zakrajsek et.al., “Exploration Rover Concepts and Development Challenges”, NASA TM-213555 (March 2005), Delivered as AIAA Paper 2005-2525 at 1st Space Exploration Conference, Orlando, Florida, Jan.30 – Feb.1, 2005 3 A.W.Nolin “Mapping the Martian polar ice caps: Applications of terrestrial optical remote sensing methods.” J.Geophys.Res., 103, pp. 25851 – 25864 (1998) 4 B.A.Ivanov “Martian Upper Crust Strength Estimates”, Institutes for Dynamics of Geospheres, Russian Ascademy of Science, www.geokhi.ru/~planetology/theses/31_ivanov_n_a.pdf 5 6 C.S.Cockell “Field Innovations in Support of Martian Polar Expeditions”, JBIS, 57, pp. 92-98 (2004) 7 S.Baxter JBIS Special Issue [Reference to come] 8 J.Pahl “Communications and Navigation Services” JBIS Special Issue [Reference to come] W.J.Larsen & L.K.Pranka (Eds), “Human Spaceflight: Mission Analysis and Design”, Chapter 14: R.Arno, “Planetary Surface Vehicles” (McGraw Hill, New York, 2000) 9 W.J.Larsen & L.K.Pranka (Eds), “Human Spaceflight: Mission Analysis and Design”, Chapter 15: C.C.Allen & R.Zubrin, “In-situ Resources” (McGraw Hill, New York, 2000) 10 R.Zubrin “Methods for Achieving Long-Range Mobility on Mars” 28th AIAA/SAE/ASME/ASEE Joint Propulsion Conference, Nashville TN, July 6-8 1992 http://Zubrin.marsstuff.com/docs/mobility.pdf 11 D.M.Deffenbaugh, M.A.Miller & S.T.Green “Mars In Situ Oxygen Production, 1809065” Southwest Research Institute IR&D http://www.sri.edu/3pubs/IRD1999/18906599.htm 12 “Development of a CO/O2 fuel cell system for power generation on Mars” http://www.esa.int/esaMI/Aurora/SEMUS6A5QCE_2.html 13 B.E.Wallace & N.S.Rao, “Engineering Elements for Transportation on the Lunar Surface”, Appl.Mech.Rev., 46, p.301 (1993) 14 15 M.G.Bekker “Introduction to Terrain-Vehicle Systems” (Univ. Michigan Press, 1970) R.E.Arvidson et.al., “Physical Properties and Localization Investigations associated with the 2003 Mars Exploration Rovers”, J.Geophys.Res., 108 (E12), p. 8070 (2003) 16 A.A.Popov, D.J.Cole, D.Cebon & C.B.Winkler, “Laboratory Measurement of Rolling Resistance in Truck Tyres under Dynamic Vertical Load”, Cambridge Vehicle Dynamics Consortium, University of Cambridge (Nov. 27, 2002) http://www.cvdc.org/recent papers/PopovColeCebonWinkler.pdf 17 C.S.Cockell “The Trans-Mars Expedition – a Long-Distance, Long-Duration, Scientific EVA.” JBIS, 55, pp.291-306 (2002) 18 19 Sanyo, “Next Generation Lithium Power”, http://www.Sanyo.com/batteries/lithpol.cfm “Man-Systems Integration Standards”, NASA-STD-3000, NASA Johnson Space Center, Houston, TX 20 Silvia Bayon, “Model for the Habitation Module of the Transfer Vehicle,” Working Document for the ESA Aurora Study Team, 12 Sept., 2003 21 G.A.Mann et.al. “Comparative Field Tests of Pressurised Rover Prototypes”, JBIS, 57, pp 135-143 (2004) 22