Brake forming process - cratel

advertisement

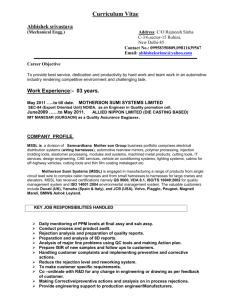

MC 1 Brake Forming Process Unit Process Life Cycle Inventory Dr. Devi Kalla, Dr. Janet Twomey, and Dr. Michael Overcash June 09, 2009 Brake Forming Process Summary ...................................................................................... 2 Methodology of unit process life cycle inventory model (uplci) ........................................ 4 Brake Forming Process Energy Characteristics .................................................................. 5 A. Parameters affecting the Energy required for brake forming ........................................ 7 Brake Forming Energy.................................................................................................... 8 V-die width selection, W ............................................................................................ 8 V-bend force calculation: ............................................................................................ 9 Edge bending force calculation:.................................................................................. 9 Idle Energy .................................................................................................................... 12 Basic Energy ................................................................................................................. 12 B. Method of quantification for mass loss: ....................................................................... 13 Case Study on Brake forming process .............................................................................. 13 Product Details .............................................................................................................. 14 Process Parameters........................................................................................................ 14 Brake forming process .................................................................................................. 14 Time, Power and Energy calculations for V-bend ........................................................ 14 Summary: .......................................................................................................................... 16 References Cited ............................................................................................................... 16 Appendices ........................................................................................................................ 17 Manufacturers Reference Data ..................................................................................... 17 1 Brake Forming Process Summary Brake forming is one of the mechanical metal deformation unit processes in manufacturing to produce shaped workpieces. It is in the manufacturing unit process taxonomy category of mass conserving (MC) whereby the shape of the solid workpiece is altered by plastic deformation while retaining the same mass or composition. Hence this unit process life cycle inventory (uplci) is to establish representative estimates of the energy and mass losses from the brake forming unit process. The brake forming unit process life cycle inventory (uplci) profile is for a high production manufacturing operation, defined as the use of processes that generally have high automation and are at the medium to high throughput production compared to all other machines that perform a similar operation. This is consistent with the life cycle goal of estimating energy use and mass losses representative of efficient product manufacturing. In brake forming a shaped sheet metal is formed along a straight axis by means of a U-shaped, V-shaped, or channel-shaped punch and die set. A sheet metal workpiece is placed on a die and horizontally positioned against stops (backguage). A bend angle is produced by a punch, forcing the workpiece into the die. The metal on the inside portion of the bend is compressed or shrunk, and the metal outside portion is stretched. Generally the material thickness range can be 0.8 mm – 12.5 mm with lengths of the metal sheet along the bend of 15 cm – 10 m (Kalpakjian et al., 2008). The length of the sheet is limited by the size of the press brake. In this process the workpiece is placed over an open die and pressed down into the die by a punch that is actuated by the ram portion of a machine called press brake. Press brakes are also used to form metals into complex shapes. An example computer numerical control (CNC) press brake machine is given in Figure MC1.1, while the brake forming mechanism is illustrated in Figure MC1.2. CNC press brakes are standard hydraulic press brakes with a numerical control (NC) back guage fitted to the machine. Main advantage of CNC press brake is the capability to do multiple angle parts without any manual intervention with the backguage or depth penetration of the ram. Reduced setup time and higher production are the result. The illustration in Figure MC1.2 provides a two-dimensional look at a typical press brake setup. The left side of the illustration shows the press brake in the open position and the right side shows it in a closed position, and then the press braked metal workpiece is shown. 2 Figure MC1.1 Computer numerical control (CNC) press brake machine (Photograph from Heller’s Son, Inc, Tarzana, CA, USA.) Figure MC1.2 Process Schematic (Todd et al., 1994) Figure MC1.3 shows an overview of the developed environmental-based factors for brake forming process. When workpiece and tool set (punch and die tools) are input to the process, all activities related to press brake CNC machine and brake forming process are estimated, and then the energy consumption of the press brake, waste generated by the tool set, and the lubricant oil quantity are calculated. Life cycle inventory (LCI) data are evaluated using the resource data. Here the resource data are the press brake machine specifications, lubricant oil specification, die specification and so on. Waste produced is the lubricant oil. The step of quantification aims at finding the actual outputs of brake forming operation, the energy consumed for the whole process, the waste fluid (lubricant oil) incurred and the bending tool usage. 3 Z Y Product X Workpiece and tool set Brake forming Process Press brake Environmental factors Resource Data LCI DATA Tool set Energy Consumption of Press brake Lubricant oil Figure MC1.3 LCI data for brake forming process Methodology of unit process life cycle inventory model (uplci) In order to assess a manufacturing process efficiently in terms of environmental impact, the concept of unit operation is applied. The unit operation consists of the inputs, process, and outputs of an operation. Each unit process is converting material/chemical inputs into a transformed material/chemical output. The unit process diagram of a brake forming process is shown Figure MC1.4. Press Brake, Fixing, Lubricant Oil WorkPiece Tool set Lubricant oil Energy Brake forming Product which is bent Noise Heat Waste Lubricant Waste tool set Figure MC1.4 Input-Output diagram of brake forming process The transformation of input to output in this report generates five lci characteristics, a. Input materials b. Energy required c. Losses of materials d. Major variables relating inputs to outputs e. Generated characteristics of the output product that often enters the next unit process. 4 Brake Forming Process Energy Characteristics In press brake forming, the tooling and setup are relatively simple. Because high production brake forming is a semi-continuous process, the lci is based on a representative operational sequence, in which 1) Work set-up generally occurs once at the start of a batch in production. Before any tooling is installed, the ram must be locked in the “shut height” position. Once the press is locked in a position where the ram can no longer close any tighter, the tooling can slide safely into the press. Set-up is made on the brake forming machine as the first work piece is introduced into the machine. The work piece is positioned, all drawings and instructions are consulted, and the resulting program is loaded. The total set-up time must then be divided by the size of the batch in order to obtain the set-up time per brake formed part. The energy consumed during this set-up period is divided by all the parts processed in that batch and is assumed to be negligible and is discussed in the example below. 2) During loading, the workpiece is fed onto the die and stopped by the preset backgauge. At each punch position a back stop is mounted on the rear of the bed in order for the part to be positioned correctly with respect to the bending tool. This is at the level of Basic energy and is labeled Loading. 3) Punch moving downwards to the metal surface. (Idle Energy) (Handling) 4) Actual bending process occurs, as the press brake is cycled, and the work metal is bent to the desired angle around the nose radius of the punch. The distance by which the punch enters the die determines bend angle and is controlled by a shut height. The to the reset position operator activates the press by pressing a foot pedal (Tip Energy) 5) Punch moving upwards. (Idle Energy) (Handling) 6) Workpieces are taken away or rearranged for another brake forming to be typically sent forward to another manufacturing unit process. (Basic Energy) (Unloading) The machine considered in this study is a hydraulic press brake because the degree of control is greater compared to other press brakes. Hydraulic machinery are machines and tools which use fluid power to do work. In this representative unit process, the life cycle characteristics can be determined on a per single bend basis or on an entire workpiece basis, if here are multiple bends. Since this is a high production process, the start up (at the beginning of a batch or shift) is deemed to be small and not included. In this uplci, there are three typical power levels that will be used, Figure MC1.5. Each power level, kw, is the incremental power not the absolute total power. Thus if electrical measurements are made, the kw during the tip measurement must have the idle and basic power (kw) values subtracted to obtain this tip power (kw). Correspondingly, there are times within the brake forming sequence during which these three power levels are used, Figure MC1.5. The overall time per piece is referred to as cycle time and is generally consistent in a batch. 5 Power Spindle and Coolant motor Startup Idle Energy Tip Energy Basic Energy Pbrake forming Pidle Pbasic tforming Time tidle tbasic Figure MC1.5. Determination of power characteristics and energy requirements of Press brakes. The steps 2), 3), 5), and 6) are estimated as representative manufacturers’ values for use in this unit process lci and energy required for bending material by brake forming, step 4), is measured using break forming force values. High production brake forming involves multiple sub-operations illustrated in Table MC1.1. There are thus many variables which have some influence on the overall energy of the brake forming unit process. The system boundaries are set to include only the use phase of the press brake machine, disregarding input material production, machine production, maintenance and disposal of the machine. Stock decoilers, straighteners, feeders, part handling, and scrap removal systems are known as press brake auxiliary equipments. Moreover, the functioning of the manufacturing machines is isolated, disregarding the influence of the other elements of the manufacturing system, such as material handling systems, feeding robots, etc. Other consumables such as lubricants and coolants are included. 6 Table MC1.1 Machine Units and its functions Energy Consuming Units M1 M2 Hydraulic pump1 (Main Pump with continuous circulation) Hydraulic pump2 Drives Axis Movement servo motors (pedal with instruments) PC computer+control panel1 (screen etc) Control Panel2 Functions Type of Energy Move the pistons connected to the ram basic Clamp the dies basic Move backguage with respect to the table idle Machine operation basic The energy consumption of brake forming is calculated as follows. Etotal = Pbasic * (tbasic ) + Pidle * (tidle) + Pbrakeforming * (tbrakeforming) (1) where power and time are illustrated in Figure MC1.5. A. Parameters affecting the Energy required for brake forming An approximate importance of the many variables in determining the brake forming energy requirements was used to rank parameters from most important to lower importance as follows: 1. Thickness of the material 2. Properties of the material 3. Length of bend line 4. Speed of the punch 5. Bend shape (U, V, channel, modified channel) 6. Springback or energy release (relation of rated hp to actual energy use) 7. bottom force 8. geometry 9. production rate 10. friction at the punch, die, and workpiece interfaces. 11. machine energy during standby and idling From this parameter list, only the top 5 were selected for use in this unit process life cycle with the others having lower influence on energy. Energy required for the overall brake forming process is also highly dependent on the time taken for idle and basic operations. 7 Brake Forming Energy Brake forming time (tforming) and power (Pforming) must be determined for the brake forming energy and it is calculated from the more important parameters given above. Brake forming time is used to calculate a part of the energy for this unit process. Figure MC1.6. Schematic of bending mechanics Two general types of bending are used in modern press working. One is V-die bending, which is used extensively in brake die operations as well as in stamping die operations. In V-bending, a distinction can be made between two variations: air bending and bottoming, Figure MC1.7. The second type is edge (wipe) die bending, Figure MC1.9. Figure MC1.7. V-bend types V-die width selection, W V-die openings were determined by operator judgment, usually a range 6 to 12 times the material thickness, with eight times being the optimum width (Eric, 2000). If the bend is not 90, but some angle α, Figure MC1.7, then the depth of the die is different than Figure MC1.8, however in this uplci we will still use the optimum D=8T. Using the optimum width of the die = 8T (half width = 4T), Figure MC1.8, the depth is given by D = 4T/tan (α/2) (α ≠ 180o, α ≠ 0o) 8 For illustration, the depths for several angles are as follows α = 60o D = 6.9T α = 90o D = 4T o α = 120 D = 2.3T o α = 179 D = 0.035T V-bend force calculation: A typical bend operation is shown in Figure MC1.8. The v-die opening width must be at least eight times the thickness of the metal sheet for 90 bends (ASM International, 2006). Because the 90 v-shaped dies are equilateral right triangles, the die depth is determined to be W/2 or 4T. Distance the punch enters the die determines the bend angle and is controlled by the shut height of the machine. Shut height is the vertical distance measured from the ram nose to the bed when the ram is fully closed. Time for bending a V-bend, tforming = D/V (2) The equation to determine bending force is (George et al., 2000): F = S L T2 K/ W (3) Where: F = force, (lbf) S = Ultimate tensile strength, (psi) L = Length of the bend, (in) T = stock thickness, (in) W = die opening width, (in) D = V-die opening depth, (in) V = Punch speed (in/sec) (Based on Machine specification) K = Constant for die opening distance (1.33 for a die opening of 8T) F can be obtained in Newtons by multiplying F in lbf by 4.48 Figure MC1.8. V-Bend Edge bending force calculation: A typical wiping operation is shown in Figure MC1.9. The edge force equation is: F = K S L T2/ W Typical tensile strengths (S) of some materials are given in Table MC.1.2. Where: F = force, (lbf) S = Ultimate tensile strength, (psi) L= Length of the bend, (in) (4) 9 r1 = punch radius, (in) r2 = die radius, (in) T = stock thickness, (in) W = die opening width, (in) (r1 + r2 + T) K = Constant for die opening distance (0.167 for large die and clearances to 0.333 for sharp die radii and high plastic working stress) Figure MC1.9. Edge (Wipe)-Bend Using the bending force calculated in the above, we can estimate the energy required to perform the operation by using the following: Eb = F D (5) Where: Eb = Energy (kJ/bend) F = bending force, (kN) D = die closed depth, (mm) Power required for brake forming P = F*V Where V = Punch speed (mm/sec) (6) 10 Table MC1.2. Typical tensile strengths of some materials (Tschatsch, 2006) Material Lead Tin Aluminum (99.0%) High-tension aluminum alloy Type 4 Duralumin Zinc Copper Brass (70:30) Brass (60:40) Phosphor bronze Bronze Nickel silver Cold rolled iron sheet Steel, 0.1%C Steel, 0.2%C Steel, 0.3%C Steel, 0.4%C Steel, 0.6%C Steel, 0.8%C Steel, 1.0%C Silicon steel sheet Stainless steel sheet Nickel Tensile strength, Psi (Mpa) Soft 3625-5800 (25-40) 5800-7250(40-50) 13,350(92) Hard 246,564(1700) 32,640(225) 69,618(480) 36,990(255) 21,755(150) 31,183-39,885(215-275) 47,140(325) 53,950(372) 58,015-72,518(400-500) 58,015-72,518 (400-500) 50,763-65,266(350-450) 46,412-55,115(320-380) 46,412(320) 58,015(400) 65,266(450) 81,221(560) 104,427(720) 130,534(900) 145,038(1000) 79,770(550) 92,275-101,526(650-700) 63,816-72,518(440-500) 69,618(480) 36,260(250) 43,511-58,015(300-400) 76,870(530) 71,068(490) 72,518-108,778(500-750) 72,518-108,778 (500-750) 72,518-101,526 (550-700) 58,015(400) 72,518(500) 87,023(600) 104,427(720) 130,534(900) 159,542(1100) 188,550(1300) 92,275(650) 82,672-91,374(570-630) Table MC1.3. Recommended minimum bend radius for commercial quality steel sheet, strip and plate (Groover, 2003) Material Soft Hard Aluminium alloys 0 6T Brass, low leaded 0 2T Magnesium 5T 13T Steels: low C, low alloy and HSLA 0.5T 4T Austenitic stainless steels 0.5h 6T Titanium 0.7T 3T Titanium alloys 2.6T 4T 11 Idle Energy Energy-consuming peripheral equipments included in idle power (Pidle) are shown in Table MC1.1. The idle power characterizes the load case when there is relative movement of the tool and the work-piece without changing the shape of the body (e.g. axis movement) - Handling. For brake forming, the handling times are the air time of approach and retraction after forming. The idle time (tidle) is the sum of the handling time (thandling) and the brakeforming time (calculated above as tforming, equation 2), see Figure MC1.5. For brake forming machines, the handling times are the air time of approach and retraction after forming. We can calculate the handling times and energy as follows. Idle energy = [timehandling + timeforming]* Pidle (7) During the brake forming process the punch is considered to be at an offset of at least 6 times the thickness of workpiece. Every time while brake forming the punch comes down from a height of 6 times the thickness of the workpiece and again retraces back to an offset position after completing the process. Approach time is 6T divided the approach speed, which depends on machine specification. While the retraction time may be longer than the brake forming time, this is estimated as the sum of the approach and brake forming times and divided by the return speed, which depends on the machine specification Time for handling is Approach + retraction times = timehandling (8) timehandling= (6T)/Approach speed + (6T+D)/return speed The brake forming time was previously calculated, equation 2 timeidle = thandling + tforming From these calculations the idle energy for a single hole is (9) E (Joule/bend) = (tapproach + tretraction) + tforming]* Pidle (10) The average idle power Pidle of automated CNC press brake machines is between 1,200 and 15,000 watt*. (* This information is from the CNC manufacturing companies, see Appendix 1). Approximately Handling time will vary from 0.1 to 10 min. Basic Energy The basic energy of a press brake is the demand under running conditions in “stand-by mode”. Energy-consuming peripheral equipments included in basic energy are M1, M2 and PC from Table MC1.1. There is no relative movement between the tool and the work-piece, but all components that accomplish the readiness for operation (e.g. machine control unit (MCU), unloaded motors, servo motors, pumps) are still running at no load power consumption. Most of the automated CNC press brake machines are not switched off when not forming and have a constant basic power. The average basic power Pbasic of automated CNC press brake machines is between 800 and 8,000 watt* (* From CNC press brake manufacturing companies the 12 basic power ranges from 1/8th to 1/4th of the maximum machine power, (see Manufacturers Reference Data in Appendix). The largest consumer is the hydraulic power unit. Ostwald, 1986 has shown that the time to load a blank or part into a press and then remove the part is proportional to the perimeter of the rectangle which surrounds the part. This time can be given by tload/unload = 3.8 + 0.11 (L + W) (seconds) Where L, W = rectangular envelope length and width, cm. From Figure MR 1.5, the basic time is given by Tbasic = tload/unload + thandling + tforming where thandling + tforming = tidle as determined in equation 9. (11) With only the following information the unit process life cycle energy for brake forming can be estimated. 1. material of part being bent and Table MC1.2 2. thickness of the material 3. length of the sheet along the bend line 4. angle of the bend (see illustrations page 9) 5. punch speed, using representative manufacturers’ values, see Appendix B. Method of quantification for mass loss: For ordinary press-brake operations such as bending and simple forming, coolant oil is less commonly used. Hydraulic press brakes use fluid power to do work. In this machine, high pressure liquid called hydraulic fluid is transmitted throughout the machine to various hydraulic motors and hydraulic cylinders. In addition to transferring energy, hydraulic fluid needs to lubricate components, suspend contaminants and metal filings for transport to the filter, and to function well to several hundred degrees Fahrenheit. Hydraulic fluid replacement occurs so infrequently that on per bend or per 1,000 bend basis, this mass loss is neglected. Lubricant oil is commonly (but not always) used on the metal surface in contact with the die. Lubricant is applied along the bend line and then is some subsequent processing step, it is removed before a final product is used. In order to link this mass loss directly to brake forming, it is included here. Note the energy or ancillary waste for lubricant removal (solvent degreasing, rag wipe, etc) would be captured in the uplci of those processes and only the lubricant mass is assigned to brake forming. Lubricant applied and removed is estimated (Madavan, Wichita State University, 2009, personal communication) as 5cm width x L (cm) x (2.54/1000) cm thickness x 0.9 g/cm3 = 0.11 g/cm length of bend. Case Study on Brake forming process In this report we analyze the detailed energy consumption calculations in brake forming process. The forming process is performed on BAILEIGH CNC press brake machine (BP – 5060). The machine specifications are listed below: 13 Table MC 1.4. Machine specification Specifications Model Number Max. Bending force, kN Approach Speed, in/sec Bending Speed, in/sec Return Speed, in/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW Total Maximum Power consumption BAILEIGH BP-5060 500 3.15 0.28 2.4 3.7 0.4 0.75 6kW Product Details For this example we are assuming a stainless steel (soft) sheet as the work piece. The work piece is of sheet-metal part of 3mm thick and 20mm bend length is bent to an included angle of α = 1200 and a bend radius of 7.5 mm in a V-die. The objective of the study is to analyze the energy consumption in press brake machine. The die opening is 24 mm. The metal has tensile strength of 675 Mpa. Process Parameters The forming conditions and the process parameters are listed in Table MC1.5. Table MC1.5. Process Parameters for Example Case Process Conditions Sheet thickness (T) 0.12 in Ultimate Tensile strength (UTS) 96,900 psi Die opening (W) 0.94 in Bend angle (A) 120 deg Bend radius (R) 0.30 in Bend Length (L) 0.79 in Die closed depth, D 0.27 in Brake forming process During forming operation the tool is considered to be at an offset of 18mm (6 times the workpiece thickness) above the workpiece. During brake forming the tool comes down from a height of 18mm. It retracts (D+18) mm back to the offset position after completing the forming process. Time, Power and Energy calculations for V-bend The total processing time can be divided into the 3 sub groups of basic, idle, and brake forming time. 14 Brake forming time: The time for bending is determined by tforming = (D)/V (sec) Where V is the bending speed in mm/sec, and D is the die depth in mm. D = depth of close die = 0.28 in (0.12*2.3, see page 9) V = 0.28 in/sec Time to bend will be, tforming = (0.28 in)/0.28 in/sec) = 1 sec/bend Energy required for each bend, E=D*F The force required to bend a 20-mm long sheet of soft stainless steel 3mm thick can be estimated using the following calculation: F = S L T2 K/ W F = 96,900 psi * (0.79) * (0.12)2 * 1.33 = 1,560 lbf = 7,000 N 0.94 Brake forming energy for each bend, E = 7,000 N * 0.0069 m = 0.048 kJ Power required P = F * V = 7,000 * 0.007 = 0.0.049 kW/bend Handling Time: The air time for bending is approach and retract time Approach time = 18/80 = 0.225 sec Retracts time = (18 + D) /60 = 24.9/60 = 0.415 sec Total air time = 0.64 sec Total idle time = tbf + tair = 1 + 0.64 = 1.64 sec Idle power from Appendix 1 can be assumed as = 2.5 kW Idle energy = 2.5 * 1.64 = 4.125 kJ/bend Basic time: Loading and unloading time t = 3.8 + 0.11 (L + W) = 3.8 + 0.11 (2 + 5) = 4.57 sec = tl/u Pbasic = 1.25 kW Ebasic = Pbasic * tbasic Tbasic = tl/u + tidle = 4.57 + 1.64 = 6.2 sec Ebasic = 1.25 * 6.2 = 7.8 kJ/bend Total Energy Etotal = 0.207 + 4.125 + 7.8 = 12 kJ/bend Mass Loss Lubricant loss is 0.011 g/cm length *2 cm length = 0.022 g lubricant loss/bend 15 Summary: This report presented the models, approaches, and measures used to represent the unit process life cycle inventory (uplci) of brake forming operations. The only major environmental characteristics are is the energy consumption of the press brake and lubricant loss. Calculations for product manufacturing are presented, based on knowing only the bend length and the material bent. The life cycle of brake forming is based on a typical high production scenario (on a CNC press brake machine) to reflect industrial manufacturing practices. The energy can be calculated from a basic list of variables, likely to be known for each part to be brake formed 1. material of part being bent and Table MC1.2 2. thickness of the material 3. length of the sheet along the bend line 4. angle of the bend, illustrated on page 9 5. punch speed, using representative manufacturers’ values References Cited 1. Abele, E.; Anderl, R.; and Birkhofer, H. (2005) Environmentally-friendly product development, Springer-Verlag London Limited. 2. ASM International. (2006) Metalworking: Sheet Forming Hand book, Vol. 14B, American Society of material. 3. Clarens, A.; Zimmerman, J.; Keoleian, G.; and Skerlos, S. (2008) Comparison of Life Cycle Emissions and Energy Consumption for Environmentally adapted Metalworking Fluid Systems, Environmental Science Technology, 10.1021/es800791z. 4. Erik Oberg. (2000) Machinery’s Handbook, 26th Edition, Industrial Press. 5. George, F.S; and Ahmad, K. E. (2000) Manufacturing Processes & Materials, 4th Edition, Society of Manufacturing Engineers. 6. Groover, M.P. (2003) Fundamentals of Modern Manufacturing, Prentice Hall. 7. Kalpakjian, S.; and Schmid, S. (2008) Manufacturing Processes for Engineering Materials, 5th Edition, Prentice Hall. 8. Ostwald, P. (1991) Engineering cost estimating, 3rd Edition, Prentice Hall. 9. Piacitelli, W.; Sieber, et. al. (2000) Metalworking fluid exposures in small machine shops: an overview, AIHAJ, 62:356-370. 10. Schuler GmbH. (1998) Metal forming Handbook, 1st Edition, Springer. 11. Todd, R.; Allen, D.; and Alting, L. (1994) Manufacturing processes reference guide, Industrial Press, New York. 12. Tschatsch, Heinz. (2006) Metal forming practice: Processes-machines-tools, Springer. 13. Wlaschitz, P. and W. Hoflinger. (2007) A new measuring method to detect the emissions of metal working fluid mist, Journal for Hazardous Materials, 144:736-741. 16 Appendices Manufacturers Reference Data The methodology that has been followed for collecting technical information on CNC machines has been largely based in the following: The documentation of the CNC press brake and the technical assistance collected from the manufacturing companies through the internet. Several interviews with the service personnel of the different CNC manufacturing companies have been carried out. After collecting the information from the different companies it has been put together in the relevant document that describes the different approaches the different companies have regarding the technical information on the CNC press brake machine. Telephone conversations allowed us to learn more about basic power and idle power. Companies that involved in our telephone conversations are Baileigh, Ronmack, Trumpf and Cincinnati. These companies manufacture different sizes of CNC machines, but this report shows the lower, mid and highest level of sizes. For our case study we picked machine at the mid level. Specifications Model Number Bending force, kN Approach Speed, mm/sec Bending Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW Specifications Model Number Bending force, kN Approach Speed, mm/sec Bending Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW BP-3360 330 80 7 60 2.2 0.4 0.75 RM-2050 600 120 9 100 5.5 1 1 BAILEIGH BP-5060 500 80 7 60 3.7 0.4 0.75 RONMACK RM-3100 1500 120 9 80 11 1 1 BP-9078 900 80 7 60 7.4 0.4 0.75 RM-8000 5000 120 9 80 37 1 1 17 Specifications Model Number Bending force, kN Approach Speed, mm/sec Bending Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW Specifications Model Number Bending force, kN Approach Speed, mm/sec Bending Speed, mm/sec Return Speed, mm/sec Main motor, kW Motor 2, kW 3 Axes motor output(X,Y,Z), kW TB V-50 560 150 12 120 6 1 1 90MX6 500 300 30 200 15 2 1 TRUMPF TB V-130 1440 150 12 120 18 1 1 CINCINNATI 175MX10 1200 275 25 180 20 2 1 TB V-320 3570 150 12 120 35 1 1 350MX12 4000 250 20 150 25 2 1 18