Manlift Operator Training - Elkhorn Construction, Inc.

advertisement

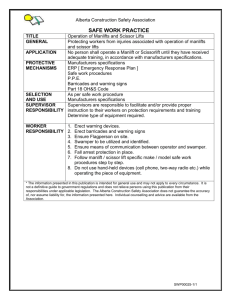

Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 Manlift Operation Manlifts are used to gain access to elevated work areas. OSHA regulations require that employers are to use the safest means of access available for their employee’s protection. This means that if work has to be done in elevated situations, you must determine what methods must be used to gain access to the work and then you must choose from these methods the safer of the methods. The choices are ladders, scaffolding, manlifts and man baskets. OSHA regulations incorporate ANSI Standards by reference and therefore all ANSI Standards that pertain to manlift operation apply. The ANSI Standard that applies to Manlifts is A92.6-1990. Aerial lifts acquired for use on or after January 22, 1073 shall be designed and constructed in conformance with the applicable requirements of the American National Standards for “Vehicle Mounted Elevating and Rotating Work Platforms.” Referenced 1926.453(a)(1), Cal/OSHA T8, and CCR 3638. 1.1. Users of manlifts must comply with all applicable rules and regulations. 1.1.1. These rules are: 1.1.1.1. No aerial platforms shall be placed into service until all malfunctions and problems have been corrected. 1.1.1.2. Manuals, both operating and maintenance, shall be retained with the machine and shall be stored in a weatherproof compartment on the machine. 1.1.1.3. Aerial platforms shall be maintained and inspected to insure proper operation. These inspections shall include: 1.1.1.3.1. Daily Inspection (to be conducted before use each day). 1.1.1.3.2. Operating and emergency controls. 1.1.1.3.3. Safety devices. 1.1.1.3.4. Personal protective devices. 1.1.1.3.5. Air, hydraulic and fuel systems. 1.1.1.3.6. Cables and wiring harness. 1.1.1.3.7. Loose or missing parts. 1.1.1.3.8. Tires and wheels. 1.1.1.3.9. Placards, warnings, control markings & operating manual. 1.1.1.3.10. Outriggers, stabilizers and other structures. 1.1.1.3.11. Guardrail system. 1.1.1.3.12. All items that are specified by the manufacturer. Document No: Revision 1 Page 1 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 1.2. Frequent inspection (every three months or 150 hours or if the aerial platform has been out of service for three months or longer). 1.2.1. 1.2.2. 1.2.3. 1.2.4. 1.2.5. Functions and their controls for smoothness, speed and limit of motion. Lower controls including the provisions for overriding the upper controls. All chain & cable systems for correct operation & for any worn or damaged parts. All emergency and safety devices are functional, including a reverse signal alarm Lubrication of all moving parts, inspection of filter elements, hydraulic, & engine oil & coolant. 1.2.6. Visual inspection of structural components such as pins, fasteners, shafts and locking devices. 1.2.7. Placards, warnings and control markings. 2. Annual Inspection 2.1. All aerial platforms shall have an inspection no later than 13 months from the date of the prior inspection. This inspection shall be done by a person that is qualified as a mechanic on the specific make and model of aerial platform that requires the inspection. 2.2. The inspection shall include all items that are specified by the manufacturer for an annual inspection. 3. Maintenance 3.1. Maintenance and service work will be performed by a qualified maintenance technician 3.2. Any defects that may create an equipment system failure must be corrected prior to placing equipment in service. 3.2.1. A “Do No Operate” tag must be placed in clear view on the main cab access door, Ignition key slot, or steering wheel or operation controls anytime service work can be preformed. 3.3. All manufactures recommendations and safety devices must be used while servicing or repairing equipment. 4. Record retention 4.1. The owner shall retain the following records for at least three years. 4.2. Date that the aerial platform was placed into service. 4.3. Records of all training that are given to personnel concerning the operation of the aerial platform. 4.4. Written records of the frequent and annual inspections that are performed and any deficiencies found and the corrective action taken to repair these deficiencies as well as the name of the person that has conducted the inspection. Document No: Revision 1 Page 2 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 5. Operator Training Requirements 5. All personnel that are required to operate an aerial manlift shall be trained in accordance with the manufacturers operating and maintenance manual. - Only authorized persons shall operate the equipment. Referenced 1926.453(b)(2)(ii). a. All training records shall be retained for at least three years. b. All personnel shall have hands on training on the same model of equipment that they are required to operate or on a model that has the same operating characteristics. c. This training shall be conducted in an area that is free from obstacles. d. “Hands on” training shall be for a sufficient period of time to demonstrate proficiency and knowledge in the actual operation of the aerial platform. e. Before operation it must be verified that the operator has: f. Been instructed by a qualified person in the purpose and function of each control. g. Read and understood the manufacturers operating instructions and safety rules, or been instructed on the contents by a qualified person. h. An understanding of all decals, warnings and instructions that are displayed on the aerial platform. i. Has been informed that the purpose for which the aerial platform is to be used is within the scope of the machine’s capabilities and applications. j. Lift controls shall be tested every day prior to use to determine that such controls are in safe working condition. Tests shall be made at the beginning of each shift during which the equipment is to be used to determine that the brakes and operating systems are in proper working condition. Referenced 1926.453(b)(2)(i). 6. Safe Operation a. The workplace must be inspected before use to determine the following: i. Drop off or holes ii. Bumps and floor obstructions iii. Debris iv. Overhead obstructions and high voltage conductors v. Hazardous locations b. Inadequate surface and support to withstand the loads that will be imposed in all operating configurations Document No: Revision 1 Page 3 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 i. Wind and weather conditions ii. Other possible unsafe conditions c. Fall protection shall be used while operating an aerial platform. i. Self retractable lanyards shall be used while working at any height under 18 feet d. The aerial platform is to be operated on a surface that is in accordance with the manufacturer’s recommendations. Aerial lifts may be “field modified” for uses other than those intended by the manufacturer provided the modification has been certified in writing by the manufacturer or by any equivalent entity. Referenced by 1926.453(1)(2). e. Outriggers, stabilizers, extendible axles or other stability enhancing features shall be used. f. Guardrails and access gates shall be installed and used correctly. g. The load rating that is marked on the platform shall not be exceeded. Booms and basket load limits specified by the manufacturer shall not be exceeded. Referenced 1926.453(b)(2)(vi). h. Aerial platforms shall not be operated where there is not adequate clearance from overhead and side obstructions. a. The minimum safe approach distance (MSAD) to energized power lines and energized equipment must be maintained. As referenced 1926.453© (1)(i). The distances are: • • • • • • • 0 to 300 Volts Avoid Contact 50KV or less 10 Feet Over 5OKVto200KV l5 Feet Over 200 KV to 350 KV 20 Feet Over 350 KV to 500 KV 25 Feet Over 500 KV to 750 KV 35 Feet Over75OKVtol000KV 45 Feet b. Hazardous Locations must be determined prior to operating equipment in those locations. This can be determined by atmosphere checks of suspected areas. c. Personnel shall maintain a firm footing on the platform floor while using aerial platforms. Planks, ladders or any other means of achieving additional height shall not be used. Employees shall always stand firmly on the floor of the basket, and shall not sit or climb on the edge of the basket or use planks, ladders, or other devices for a work position. Referenced 1926.453(b)(2)(iv). Also, approved Fall Protection shall be worn and a lanyard attached to the boom or basket when working from an aerial lift. Document No: Revision 1 Page 4 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 Referenced 1926.453(b)(2)(v). d. Guardrails shall not be stood on to gain more height. e. Flags, roped off areas, flashing lights and barricades shall be used to prevent contact with personnel and moving equipment that are working in the area. f. All problems and malfunctions shall be reported as soon as possible to the supervisor. g. Altering or disabling any interlocks or safety devices is prohibited. h. Care shall be taken to prevent rope, cords and hoses from becoming entangled in the equipment. i. The operator shall ensure that the area surrounding the aerial platform is clear of personnel and equipment while lowering the platform. j. The engine shall be shut down while refueling and fueling shall be done in a well-ventilated area that is free from sparks or other hazards that may cause a fire or explosion. k. Batteries shall be charged in a well-ventilated area. l. The aerial platform shall not be placed against an object in order to steady the platform. m. The aerial platform shall not be used as a crane. n. Travel speed shall be determined by the conditions of the ground surface, congestion, visibility and other factors causing collision or injury to personnel. o. Before and during driving while the platform is elevated, the operator shall: i. Maintain a clear view of the path of travel. ii. Maintain a safe distance from all obstacles, debris, holes, and other hazards to ensure safe elevated travel. iii. Maintain a safe distance from overhead obstructions. p. Stunt driving and horseplay is prohibited. q. Document No: Some means shall be provided to protect against use of the manlift by unauthorized persons. Revision 1 Page 5 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 Written & Performance Test For Manlift Operators’ Employee:____________________________ Date:____________ Time:______ am pm. True or False (Must get a minimum of 12 questions correct) 1. You can safely carry two people as well as 500lbs of material and tools in the basket. 2. With the handrails in place you are not required to wear fall protection. 3. Level ground surfaces are required to operate a Manlift. 4. When traveling in a Manlift avoid all bumps, holes and drop-offs. 5. There are no warning charts and placards/stickers placed on the Manlift. This is because it is really simple and safe to operate any Manlift. 6. It is ok to overload a Manlift basket if you only do so by no more than 50 lbs. 7. You are not required to perform and document a Daily Inspection on a Manlift. 8. Anyone can operate a Manlift if they study and understand the Operators Manual because it contains information the Operator needs to operate the Manlift safely. 9. Because of how they are built it is impossible to overturn a Manlift. 10. Common hazards on the construction site include, pedestrians, overhead power lines wind, and uneven grade and changing surface conditions. 11. When a task can be reached by standing on the lowest handrail, using a ladder or a five gallon bucket is ok as long as you are using fall protection. 12. Manlifts are usually not electrically insulated; the operator should always be fully aware of and avoid sources of electrical shock. 13. When you are working alone and must stretch to reach an item it is best to find a way to block open the dead man switch to keep the Manlift functional. 14. The dead man pedal is designed to protect the occupants of the basket from unintentional movement. 15. It is ok for a fellow worker to work on the Manlift while you are elevated as long as the brakes are set. Document No: Revision 1 Page 6 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 Manlift Operator’s Written Test Key True or False (Must get a minimum of 12 questions correct) 1. You can safely carry two people as well as 500lbs of material and tools in the basket. 2. With the handrails in place you are not required to wear fall protection. 3. Level ground surfaces are required to operate a Manlift. 4. When traveling in a Manlift avoid all bumps, holes and drop-offs. 5. There are no warning charts and placards/stickers placed on the Manlift. This is because it is really simple and safe to operate any Manlift. 6. It is ok to overload a Manlift basket if you only do so by no more than 50 lbs. 7. You are not required to perform and document a Daily Inspection on a Manlift. 8. Anyone can operate a Manlift if they study and understand the Operators Manual because it contains information the Operator needs to operate the Manlift safely. 9. Because of how they are built it is impossible to overturn a Manlift. 10. Common hazards on the construction site include pedestrians, overhead power lines wind, and uneven grade and changing surface conditions. 11. When a task can be reached by standing on the lowest handrail, using a ladder or a five gallon bucket is ok as long as you are using fall protection. 12. Manlifts are usually not electrically insulated; the operator should always be fully aware of and avoid sources of electrical shock. 13. When you are working alone and must stretch to reach an item it is best to find a way to block open the dead man switch to keep the Manlift functional. 14. The dead man pedal is designed to protect the occupants of the basket from unintentional movement. It is ok for a fellow worker to work on the Manlift while you are elevated as long as the brakes are set. Document No: Revision 1 Page 7 of 8 Elkhorn Construction, Inc Title: Manlift Operator Safety Training and Policy Safety Manual Review Date 12-15-2008 Manlift Operator’s Performance Checklist 1. Completed training and written testing. 2. Operator has the Physical capabilities. 3. The knowledge and understanding of the specific Manlift Operation’s Manual. 4. Perform and Document a Daily Inspection on the Daily Inspection Report (3E-0095). 5. The knowledge of the equipment capabilities and capacity. 6. The ability to read and understand gauges. 7. The ability to recognize mechanical discrepancies and problems of the Manlift. 8. The knowledge of Safe Operating Practices and Elkhorn’s Procedures (3E- 0000). 9. The knowledge of electrical service conductors, safety requirements. 10. Hands-on demonstration of ability to perform all functions of the Manlift. 11. Shows familiarity with the Manlift controls and refueling procedures. 12. Gave proper signals and or communication when turning. 13. Slowed down at intersections. 14. Sounded horn at intersections. 15. Obeyed signs. 16. Kept a clear view of direction of travel. 17. Turned corners correctly — was aware of rear end swing. 18. Yielded to pedestrians and or fellow workers. 19. Drove under control and within proper traffic lanes. 20. Approached work area elevation property. 21. Lifted platform property. 22. Maneuvered property. 23. Traveled with platform at proper height. 24. Lowered boom smoothly/slowly. 25. Stops smoothly/completely. 26. Checked bridge-plates/ramps. 27. Did drive backward when required. 28. Did check load weights. 29. Did place platform on the floor when parked, controls neutralized, brake on set, power off. 30. Followed proper instructions for maintenance — checked both at beginning and end. Pass Fail Evaluator_____________________________________ Employee Name: ___________________________________________ Date:_______________ Additional Comments/Limitations:_________________________________________________ __________________________________________________________________ Document No: Revision 1 Page 8 of 8