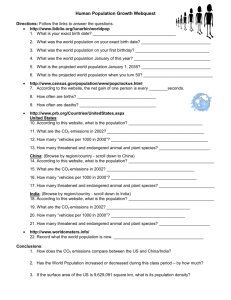

Corporate Leaders

advertisement