Pipe Loss Write Up - University of Florida

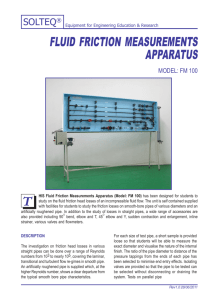

advertisement

University of Florida Department of Mechanical Engineering Pipe Loss Lab EML 4304C Written by: Christian Schneider Date: 10/8/2006 ABSTRACT The purpose of this lab was to measure the pressure drop across a series of PVC pipes and measure the head loss, friction factor and loss coefficient. This was done by pumping water through a system of valves and small pipes and then measuring difference in head pressure using H2O manometers. The flow was measured using a rotometer. The friction factors determined by the calculations were then compared against the theoretical calculations for smooth pipe. It was found that the measured values for the friction coefficient where several hundred percent above the theoretical smooth values. The loss coefficient for the elbow section was calculated to be approximately 0.618. INTRODUCTION / OBJECTIVE The purpose of this lab was to demonstrate the concepts of major and minor losses in hydronic pipe systems. Water with a known density was pumped through a system of varying size pipes and the relative absolute pressures were measured at known increments around the system. These measurements where then used to calculate the subsequent head losses, friction factors and the loss coefficient of the elbow segment. The friction factors of the straight segments of pipe where compared to those of the theoretical smooth pipes. APPARATUS / PROCEDUE The system as given by the instructor consisted of 2 separate hydronic circuits each fed by a common pump source. The measurements included a segment of small diameter pipe, a segment of large diameter pipe, and a segment of small diameter pipe which included a proprietary 90 deg elbow joint. The gauge pressure at each point were measured by piezometers. The volume flow rate of the system was measured using a rotometer positioned before the flow was separated between each circuit of the system. Necessary Constants: The pipe length: 914.4 mm The pipe diameter of the smaller pipe: 13.6 mm. The pipe diameter of the larger pipe: 26.2 mm. H20 Density: 1000 kg /m^3 Viscosity of H20: 0.001 90 elbow (1) Pipe length between (1) and (2) is 914.4mm (2) Main valve V2 V1 26.4 mm straight pipe (914.4mm) (8) (9) (3) (4) 13.6 mm straight pipe (914.4mm) FIGURE 1: Layout of pipe circuits TECHNICAL APPROACH (THEORY / ANALYSIS) The head loss for each segment of piping was calculated by the following formulas where delta H is the difference in the piezometers in mm of H20 and the density is assumed as 1000 kg / m^3 p H * 9.774 hL p The friction factor of the segment was then calculated by using: f p 1 L v2 2 D This would provide the friction factors for both the large diameter and small diameter pipes circuits. To compare the measured values of the friction coefficient to a pipe which was considered smooth the following formula was used to determine the friction coefficient for a smooth pipe. f smooth 0.316 Re 0.25 To determine the loss coefficient of the proprietary elbow the following formula was used. The value of the head loss used in the calculation is the difference between the head loss from the straight segment of small diameter pipe and that of the segment of pipe including the elbow. KL 2 hL v2 RESULTS / DISCUSSION The moody charts for both the small and large diameter segments of pipe can be seen in Figures 2 and 3. As expected the friction factor declines as the flow decreases and the Reynolds number increases. The over all trend of the values follows the theoretical values in overall scope but the measured values seem to be decreasing faster as the Reynolds number increases as opposed to the theoretical values which will reach a azimuth. This is likely caused by the fact that the errors in the measurements tend to increase as the volume flow rate decreases. When the rotometer reaches values below 10 L/s the stability and accuracy of the rotometer come into serious question. The possible error values are not held constant as the equations assume but the error will increase as flow decreases. Aside from the difference in trends between the measured and theoretical friction factors the measured were significantly higher than the theoretical. The trends can be explained as an error in the measurement at low flows, but the general bias error of the measurements must stem from some systematic error within the measurements them selves. This error could have come from many sources but the likely error lie with the measurement of the pressure difference in the piezometers. When we were performing the experiment we were having errors within the measurements which sometimes included the downstream pressure to be higher than the upstream pressure. Some of these errors were eliminated by the removal of air bubbles within the system but other large problems with the system still existed. I believe that if the experimental setup were to be thoroughly checked before the beginning of the experiment and all measurement devices properly calibrated then the experimental results would like much closer to the theoretical values. From the displayed values the straight pipes can not be viewed as smooth as their friction factors vary from about 175% to over 300% difference. The exact values can be seen in table 1. Flow Rate (L/s) % Diff of f (small) %Diff of f (large) 14 312 177 12 300 189 11 309 196 10 309 201 8 316 159 6 333 221 4 251 155 Table 1: % difference between measured and smooth pipe friction factors The loss coefficient for the proprietary 90 elbow was found to be approximately 0.618. This value is an average of the loss coefficient for the flow rates which were measured. The range of these values was determined to be 0.315. Flow Rate Loss Coefficent (K) Average Range: 14 12 11 10 8 6 4 0.68995 0.709342 0.601629 0.404197 0.660023 0.547266 0.719207 0.618802 0.31501 CONCLUSION The results of this experiment showed the general form and process for determining the friction factor of a straight pipe and the loss coefficient of an elbow section. The values of the determined friction coefficient where much higher than expected. The friction factors followed the projected reality in that they decreased as the flow was decreased and the Reynolds number was increased. The lab could be greatly improved by obtaining a more precise set of measuring devices. The errors show a constant bias to a greatly increased pressure drop between the measuring points. This could be eliminated by using a digital measuring system for both the flow measurements and the pressure measurements. Also the system needs to be checked for mineral or other solid mater build ups within the piping system. APPENDIX Darcy Friction Factor (f) Small Pipe Moody Chart 0.16008 0.14008 0.12008 0.10008 0.08008 0.06008 0.04008 0.02008 0.00008 5000 Measured Smooth Poly. (Measured) Poly. (Smooth) 10000 15000 20000 Reynolds # (Re) FIGURE 2: Moody chart of small pipe segment Moody Chart Large Pipe Darcy Friction Factor (f) 0.14 0.12 Measured Values 0.1 Smooth Flow 0.08 0.06 Poly. (Measured Values) 0.04 Poly. (Smooth Flow) 0.02 0 3000 5000 7000 Reynolds # (Re) FIGURE 3: Moody chart for large pipe segment 9000 Pipe Loss Reading Accuracies Q± Length of Pipe ± Diameter ± 3.6 5 1 Constants: Density: Viscosity (l/m) mm mm 1000 0.001 ± 0.02 Uncertainty Del p Small Pipe (3 and 4) Length Diameter Area: 0.9144 0.0136 0.0001453 ± ± m^2 Flow Rate Corrected Flow High Level Low Level Delta H Head loss Flow Rate (m^3/s) Velocity 14 12.2906 800 45 755 7.398547 0.0002048 1.4101137 12 10.6464 680 110 570 5.585658 0.0001774 1.2214729 11 9.8243 637 130 507 4.9682958 0.0001637 1.1271525 10 9.0022 590 155 435 4.262739 0.00015 1.0328321 8 7.358 506 195 311 3.0476134 0.0001226 0.8441912 6 5.7138 435 227 208 2.0382752 9.523E-05 0.6555504 4 4.0696 355 262 93 0.9113442 6.783E-05 0.4669096 Friction Factor Reynolds Number Smooth Uncertainty V Uncertainty del P % Difference of f 0.1106804 19177.547 0.0268528 0.0705057 0.1479709 312.17536 0.1113626 16612.031 0.0278344 0.0610736 0.1117132 300.09025 0.1163255 15329.274 0.0283992 0.0563576 0.0993659 309.6077 0.1188672 14046.516 0.0290265 0.0516416 0.0852548 309.51242 0.127207 11481.001 0.0305276 0.0422096 0.0609523 316.69544 0.1410858 8915.4854 0.03252 0.0327775 0.0407655 333.84291 0.1243511 6349.9702 0.0353993 0.0233455 0.0182269 251.2816 Small Pipe Uncertainty (df/dL)*δL 6.052E-07 (df/dd)*δd 8.138E-06 (df/dρ)*δρ 2.214E-09 (df/dv)*δv 1.107E-05 (df/dΔp)*δΔp 2.214E-06 6.089E-07 8.188E-06 2.227E-09 1.114E-05 2.227E-06 6.361E-07 8.553E-06 2.327E-09 1.163E-05 2.327E-06 6.5E-07 8.74E-06 2.377E-09 1.189E-05 2.377E-06 6.956E-07 9.353E-06 2.544E-09 1.272E-05 2.544E-06 7.715E-07 1.037E-05 2.822E-09 1.411E-05 2.822E-06 6.8E-07 9.143E-06 2.487E-09 1.244E-05 2.487E-06 δf=sum(uncertainties) Root Sum Square 2.203E-05 1.393E-05 2.216E-05 1.401E-05 2.315E-05 1.464E-05 2.366E-05 1.496E-05 2.532E-05 1.601E-05 2.808E-05 1.775E-05 2.475E-05 1.565E-05 Large Pipe Length: Diameter Area: 0.9144 0.0262 0.0005391 ± ± m^2 7 6.5359 221 214 7 0.0685958 5.5 5.30275 174 168 6 0.0587964 4 4.0696 118 115 3 0.0293982 Flow Rate Corrected Flow High Level Low Level Delta H Head loss 13 11.4685 535 515 20 0.195988 11.5 10.23535 444 427 17 0.1665898 0.005 0.001 0.005 0.001 10 9.0022 338 324 14 0.1371916 m m m m 8.5 7.76905 281 270 11 0.1077934 Flow Rate (m^3/s) Velocity 0.0001911 0.3545381 0.0001706 0.3164164 0.00015 0.2782947 0.0001295 0.240173 0.0001089 0.2020513 8.838E-05 0.1639296 6.783E-05 0.1258079 Friction Factor Reynolds Number Smooth Uncertainty V Uncertainty del P % Difference of f 0.0893509 9288.898 0.0321882 0.0177269 0.22937 177.58929 0.0953511 8290.1097 0.0331167 0.0158208 0.204707 187.92442 0.1015109 7291.3213 0.0341968 0.0139147 0.180044 196.84325 0.1070875 6292.5329 0.0354798 0.0120087 0.155381 201.82703 0.0962873 5293.7445 0.0370464 0.0101026 0.130718 159.90994 0.1253808 4294.9561 0.0390344 0.0081965 0.106055 221.20591 0.1064388 3296.1677 0.0417047 0.0062904 0.081392 155.22019 Large Pipe Uncertainty (df/dL)*δL 4.886E-07 (df/dd)*δd 3.41E-06 (df/dρ)*δρ 1.787E-09 (df/dv)*δv 8.935E-06 (df/dΔp)*δΔp 0.0001046 5.214E-07 3.639E-06 1.907E-09 0.0005858 0.0001172 5.551E-07 3.874E-06 2.03E-09 0.0006661 0.0001332 5.856E-07 4.087E-06 2.142E-09 0.0007718 0.0001544 5.265E-07 3.675E-06 1.926E-09 0.0009174 0.0001835 6.856E-07 4.786E-06 2.508E-09 0.0011308 0.0002262 5.82E-07 4.063E-06 2.129E-09 0.0014734 0.0002947 δf=sum(uncertainties) Root Sum Square 0.0007072 0.0005975 0.0008037 0.0006793 0.0009309 0.0007871 0.0011051 0.0009356 0.0013624 0.0011532 0.0017728 0.0015026 0.0001174 0.000105 Elbow Pressure (1 and 2) Length 0.935 Diameter 0.0136 Area 0.0001453 ± ± Flow Rate Corrected Flow High Low Delta H Head loss Volume Flow Rate Velocity 14 12.2906 855 30 825 8.084505 0.0002048 1.4101137 12 10.6464 700 76 624 6.1148256 0.0001774 1.2214729 11 9.8243 640 94 546 5.3504724 0.0001637 1.1271525 10 9.0022 570 113 457 4.4783258 0.00015 1.0328321 8 7.358 470 135 335 3.282799 0.0001226 0.8441912 6 5.7138 370 150 220 2.155868 9.523E-05 0.6555504 4 4.0696 265 164 101 0.9897394 6.783E-05 0.4669096 Friction Factor Reynolds Number Smooth Uncertainty V Uncertainty del P % Difference of f 0.1182776 19177.547 0.0268528 0.0705057 0.245812 340.46726 0.2348613 16612.031 0.0278344 0.0610736 0.212928 743.78167 0.2413359 15329.274 0.0283992 0.0563576 0.196486 749.79696 0.2405755 14046.516 0.0290265 0.0516416 0.180044 728.81272 0.2639719 11481.001 0.0305276 0.0422096 0.14716 764.70017 0.2874783 8915.4854 0.03252 0.0327775 0.114276 784.004 0.2601659 6349.9702 0.0353993 0.0233455 0.081392 634.94733 Elbow Pipe Uncertainty (df/dL)*δL 6.325E-07 (df/dd)*δd 8.697E-06 (df/dρ)*δρ 2.366E-09 (df/dv)*δv 1.183E-05 (df/dΔp)*δΔp 3.596E-06 6.376E-07 8.767E-06 2.385E-09 1.192E-05 4.152E-06 6.552E-07 9.008E-06 2.45E-09 1.225E-05 4.499E-06 6.531E-07 8.98E-06 2.443E-09 1.221E-05 4.91E-06 7.166E-07 9.853E-06 2.68E-09 1.34E-05 6.007E-06 7.804E-07 1.073E-05 2.919E-09 1.459E-05 7.736E-06 7.063E-07 9.711E-06 2.641E-09 1.321E-05 1.086E-05 δf=sum(uncertainties) 2.548E-05 2.642E-05 2.676E-05 2.998E-05 3.384E-05 3.449E-05 2.476E-05 0.005 0.001 m m Root Sum Square 1.513E-05 1.538E-05 1.587E-05 1.595E-05 1.77E-05 1.971E-05 1.968E-05 Loss Coefficient (K) 0.6899526 0.7093418 0.601629 0.4041967 0.660023 0.5472661 0.719207 Average Range: 0.6188023 0.3150103