Codes_inventory_r

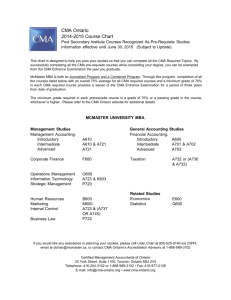

advertisement