Class 4

advertisement

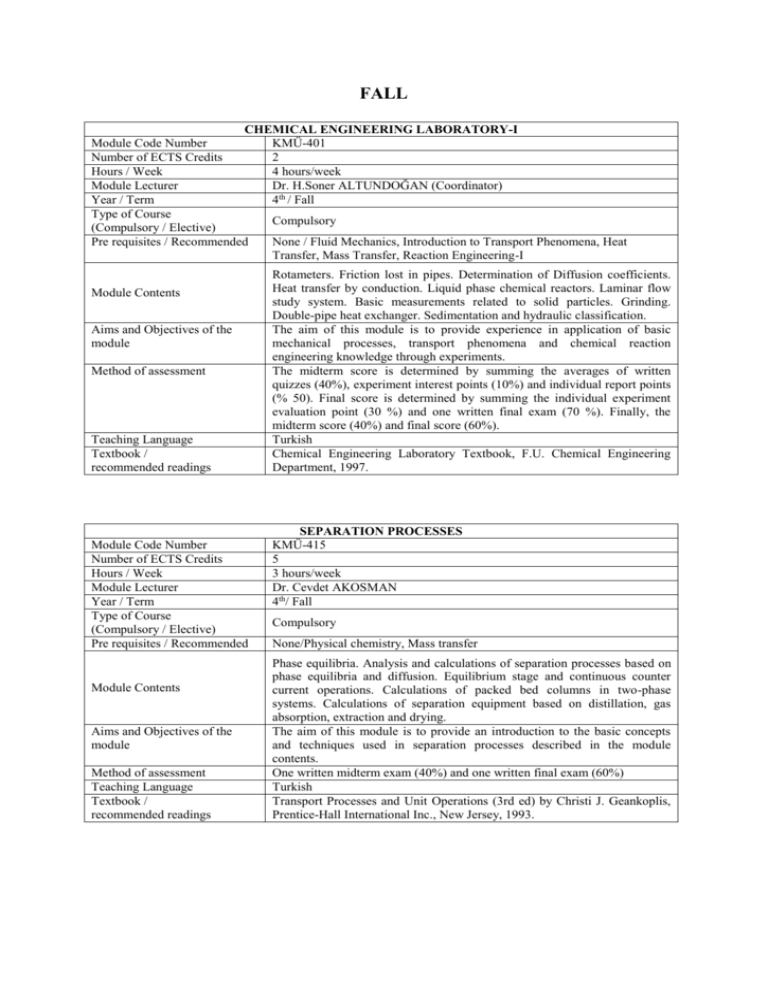

FALL CHEMICAL ENGINEERING LABORATORY-I Module Code Number KMÜ-401 Number of ECTS Credits 2 Hours / Week 4 hours/week Module Lecturer Dr. H.Soner ALTUNDOĞAN (Coordinator) Year / Term 4th / Fall Type of Course Compulsory (Compulsory / Elective) Pre requisites / Recommended None / Fluid Mechanics, Introduction to Transport Phenomena, Heat Transfer, Mass Transfer, Reaction Engineering-I Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Rotameters. Friction lost in pipes. Determination of Diffusion coefficients. Heat transfer by conduction. Liquid phase chemical reactors. Laminar flow study system. Basic measurements related to solid particles. Grinding. Double-pipe heat exchanger. Sedimentation and hydraulic classification. The aim of this module is to provide experience in application of basic mechanical processes, transport phenomena and chemical reaction engineering knowledge through experiments. The midterm score is determined by summing the averages of written quizzes (40%), experiment interest points (10%) and individual report points (% 50). Final score is determined by summing the individual experiment evaluation point (30 %) and one written final exam (70 %). Finally, the midterm score (40%) and final score (60%). Turkish Chemical Engineering Laboratory Textbook, F.U. Chemical Engineering Department, 1997. SEPARATION PROCESSES KMÜ-415 5 3 hours/week Dr. Cevdet AKOSMAN 4th/ Fall Compulsory None/Physical chemistry, Mass transfer Phase equilibria. Analysis and calculations of separation processes based on phase equilibria and diffusion. Equilibrium stage and continuous counter current operations. Calculations of packed bed columns in two-phase systems. Calculations of separation equipment based on distillation, gas absorption, extraction and drying. The aim of this module is to provide an introduction to the basic concepts and techniques used in separation processes described in the module contents. One written midterm exam (40%) and one written final exam (60%) Turkish Transport Processes and Unit Operations (3rd ed) by Christi J. Geankoplis, Prentice-Hall International Inc., New Jersey, 1993. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings REACTION ENGINEERING-II KMÜ-421 5 3 hours/week Dr. Dursun ÖZER 4th / Fall Compulsory None /Reaction Engineering-I, Thermodynamics-II Design and analysis of non-isothermal, recycle, autocatalytic and multiple reactors. Choosing the right kind of the reactor for multiple reactions. The kinetics of non-catalytic fluid-particle reactions and design of fluid-particle reactors. Non-ideal reactors. The aim of this module is to train students to analyse and design nonisothermal reactor with multiple reactions and design of non-ideal reactors. One written midterm exam (40%) and one written final exam (60%) Turkish 1. Fogler, H. S., Elements of Chemical Reaction Engineering, 2nd ed., Prentice-Hall International Inc., New Jersey, 1992. 2. Smith, J. M., Chemical Engineering Kinetics, 3rd ed., McGraw-Hill International Inc., Singapore, 1981. CHEMICAL ENGINEERING DESIGN-I KMÜ-423 5 5 hours/week Dr. Fikret TÜMEN 4th / Fall Compulsory None / Stoichiometry-I, Stoichiometry-II, Basic Computer Science, Economics, Fluid Mechanics, Heat Transfer, Mass Transfer, Reaction Engineering-I, Reaction Engineering-II Analysis of industrial processes point of view of economy, environment and occupational health. Plant location selection. Principles of equipment and plant layout. Optimisation and decision in equipment and process design. Design principles and applications in typical processes. Feasibility studies. Using of computer software in engineering design. The aim of this module is to provide knowledge and skills to understand and design a chemical process and to provide experience in using process simulators (ChemCAD) for chemical plant design. The midterm score is determined by summing the written exam (80%) and ChemCAD application exam (20%). Final score is determined by one written exam. Finally, midterm score (40%) and final score (60%) build the success degree. The students can take make-up exam to enhance the midterm score. Turkish 1. Aksöz, H.İ., Fabrika Organizasyonu ve Yönetimi, I. Kısım, Ege Üniv. Basımevi, Ege Üniv. Müh. Fak. Yayınları No. 12 , Bornova, İzmir, 1987. 2. George E. Dieter, Engineering Design- A Materials and Processing Approach, Second Ed., McGraw Hill, 1991. 3. Max S. Peters, Klaus D. Timmerhaus, Plant Design and Economics for Chemical Engineers, Fourth Ed., McGraw Hill, 1991. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings PROCESS CONTROL KMÜ-425 5 3 hours/week Dr. Gülbeyi Dursun 4th / Fall Compulsory None/ Introduction to control systems. Differential equations and linear systems. The Laplace transforms. Transfer functions. Block diagrams. Transfer functions of systems. Transient response of simple control systems. Control system design by frequency response. The aim of this course is to provide a method of analysis used in the control area to look at a simple control system design problem. One written midterm exam (40%) and one written final exam (60%) Turkish 1.Coughanowr, D. R. and Koppel, L. B., Process Systems Analysis and Control, McGraw-Hill Inc., Singapore, 1965 ORGANIC CHEMICAL TECHNOLOGIES KMÜ-433 5 3 hours/week Dr. H.Soner ALTUNDOĞAN 7th / Fall Compulsory None / Organic Chemistry Sugar technology. Paper technology, cellulose and its derivatives, synthetic fibre. Leather technology. Fat and oil technology. Soap and detergent technology. Petrochemical technology. The aim of this module is to provide basic knowledge on significant organic chemical technologies. One written midterm exam (40%) and one written final exam (60%). The students can take make-up exam to enhance the midterm score. The homework and the presentation are also added directly to the midterm exam score. Turkish Organic Chemical Technologies Lecture Notes Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings INTRODUCTION TO BIOTECHNOLOGY KMÜ-427 3 2 hours/week Dr. Dursun ÖZER 4th / Fall Elective None / Definition of biotechnology. Development of biotechnology. Industrial micro-organisms. Preparing culture medium. Cell growth phases. Microbial kinetics. Sterilisation methods. Bioreactors. Downstream processing. Waste water treatment. Enzymes. The aim of this module is to an introduction to the basic concepts and techniques used in biotechnology described in the module contents. One written midterm exam (40%) and one written final exam (60%) Turkish 1. Lee,M.J., Biochemical Engineering, Prentice Hall ,New Jersey, 1992. 2. Telefoncu, A., Biyoteknoloji, Ege Üni. Basımevi, 1995. INTRODUCTION TO EXTRACTIVE METALLURGY Module Code Number KMÜ-431 Number of ECTS Credits 3 Hours / Week 2hours/week Module Lecturer Dr Melek YILGIN Year / Term 4th / Fall Type of Course Elective (Compulsory / Elective) Pre requisites / Recommended None / Preparing ore (crushing, grinding, classifying). Concentrating ore (gravity Module Contents method, flotation, magnetic method). Roasting, sintering, reduction, refining, metallurgical sludges. Aims and Objectives of the The aim of this module is to provide an introduction to the basis of three module alternative approaches to metal extraction and refining: pyro-metallurgy, hydrometallurgy and electrometallurgy in Extractive Metallurgy described in the module contents. Method of assessment One written midterm exam (40%) and one written final exam (60%) Teaching Language Turkish Textbook / Erdal, I., Ekstraktif Metalurji,Ankara,1976; Bor,F.Y., Ekstraktif Metalurji recommended readings Prensipleri Kısım II,İstanbul Teknik Üniversite Matbaası, Gümüşsuyu,1989; Önal,G., Ateşok,G.,Cevher Hazırlasma El Kitabı, İstanbul,1994. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings INTRODUCTION TO COAL TECHNOLOGY KMÜ-437 3 2 hours/week Dr. Dursun PEHLİVAN 4th / Fall Elective None / Organic Chemistry Energy Concept, Kinds, Conversion, Sources. Main Fuels. Origin and Formation of Coal. Diagenesis and Metamorphism. Maturation of Coal and Coal Series. Physical Composition of Coal. Important Industry-Related Properties of Coal. Chemical Properties of Coal. Coal Mining, Storing and Preparation. Coking and Gasification of Coal. The aim of this course is to provide students a simple way of understanding the energy options of the modern society, with main emphasis on the coal as an important energy source, coal forming processes, coal properties and, the scientific and engineering principles of coal technology. One written midterm (40%) and one final exam (60%) Turkish 1.N. Berkowitz, An Introduction to Coal Technology, New York, Academic Press, 1979. 2.J.H. Harker, J.R. Backhurst, Fuel and Energy, London, Academic Press, 1981 3.Internet sources MECHANICAL SEPARATION PROCESSES KMÜ-411 3 2 hours/week Dr. İnci TÜRKTOĞRUL 4rth/ Fall Elective None / The principles of mechanical separation processes. The systems, which have solid particle and its properties. Classification. Solid-fluid separation processes: Filtration. Solid-gas separation processes: Electrofilters, cyclones. The aim of this module is to provide an introduction to the basic concepts and techniques used mechanical separation processes described in the module contents. One written midterm exam (40%) and one written final exam (60%) Turkish Geankoplis, C. J., Transport Processes and Unit Operations, 3rd ed., Prentice-Hall International Inc., New Jersey, 1993. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings INTRODUCTION TO ENZYME KINETICS KMÜ-429 3 2 hours/week Dr. Dursun ÖZER 4th / Fall Elective None / Introduction to enzymes. Production and purification of enzymes. Enzymes immobilization. Kinetics of unreactant enzymes. Simple and mixed type inhibition systems. Design of enzymes reactors with simple kinetics. The aim of this module is to provide an introduction to the basic concepts in enzymes and knowledge for design of enzymes reactors. One written midterm exam (40%) and one written final exam (60%) Turkish 1. Segel, I. H. Enzyme Kinetics, John Wiley & Sons, USA, 1975. 2. Telefoncu, A. (Editör), Enzimoloji, Kuşadası, 1997. COMBUSTION AND FUEL TECHNOLOGY KMÜ-435 3 2 hours/week Dr. Fethi KAMIŞLI 4th / Fall Elective None / Stoichiometry-I, Stoichiometry-II Fuels used industry. Properties and industrial analyse of coal. Liquid and gaseous fuels. Combustion stoichiometry, exhaust composition, relationship between exhaust oxygen and mixture. Determination of stoichiometric and excess oxygen. Control of combustion efficiency. Determination of factors affected on combustion efficiency. Theory of chain reactions. Determination of thermal efficiency. The lowest and highest thermal values of reactions. Theoretical and adiabatic flame temperature. Industrial combustion systems. The aim of this module is to provide an introduction to the basic concepts and techniques used in combustion and fuel technology described in the module contents. One written midterm exam (40%) and one written final exam (60%) Turkish 1. Elementary Principle of Chemical Processes by Felder R. M. and Rousseau R. W. Wiley, 2002. 2. Stokiometri by Yalçın H. ve Gürü, M., Palme Yayıncılık, Ankara/Türkiye, 2000. 3. Sınai Stokiometri by Çataltaş İ., Inkılap ve Aka Yayınevi, İstanbul /Türkiye, 1982. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings INTERNSHIP-II (INDUSTRIAL) 2 25 days/term 3rd/ Spring Compulsory None Carry out practical training (25 days) in an industrial setting or a research institute. Apply the knowledge acquired in earlier coursework to a real-life situation under supervision of qualified personnel. The aim of this module is to provide a real-life experience in the application of knowledge acquired in earlier coursework, and the identification, formulation and solution of engineering problems. One written report (70%) and one final exam (oral presentation) (30%) Turkish - SPRING CHEMICAL ENGINEERING LABORATORY-II Module Code Number KMÜ-402 Number of ECTS Credits 4 Hours / Week 6 hours/week Module Lecturer Dr. H.Soner ALTUNDOĞAN (Coordinator) Year / Term 4th / Spring Type of Course Compulsory (Compulsory / Elective) Pre requisites / Recommended None / Fluid Mechanics, Introduction to Transport Phenomena, Heat Transfer, Mass Transfer, Process Control, Reaction Engineering-I, Reaction Engineering-II Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Heat transfer by natural and forced convection. Cross flow heat exchanger. Cooling tower. Gas absorption. Tray dryer. Distillation. Liquid-liquid extraction. Plug flow reactor. Dynamic behaviour of manometers. Process controlling and control systems. The aim of this module is to provide experience in application of transport phenomena, chemical reaction engineering and process control knowledge through experiments. The midterm score is determined by summing the averages of written quizzes (40%), experiment interest points (10%) and individual report points (% 50). Final score is determined by summing the individual experiment evaluation point (30 %) and one written final exam (70 %).Finally, the midterm score (40%) and final score (60%). Turkish Chemical Engineering Laboratory Textbook, F.U. Chemical Engineering Department, 1997. MATHEMATICAL MODELING KMÜ 404 5 4 hours/week Dr. Dursun PEHLİVAN 4th/ Spring Compulsory None / Fluid Mechanics, Heat Transfer, Mass Transfer, Reaction Engineering, Numerical Methods Modelling and Simulation, Analysis of Chemical Processes, Equations, Math-Cad Applications, Numerical Solutions of Algebraic Equations, of Arbitrary Function Derivation, Interpolation, Extrapolation, Numerical Solutions of Differential Equations, Numerical Integration Methods, Modelling of Dynamical Fluid Flow Systems, Modelling of Dynamical Chemical Reaction Systems, Modelling of Heat Transfer Systems, Modelling of Simultaneous Heat and Mass Transfer Systems, Modelling of Higher-Order Systems. The aim of this module is to provide students the ability to define and analyse chemical process systems, the methods for thorough understanding of the systems and, the ability to write all governing equations and solve them simultaneously by using computer routines. One homework a week (40% of the arithmetic mean of the marks given for homework), and one written final exam (60%) Turkish 1.D. Pehlivan, S. Altundoğan, M. Tanyıldızı, Mathematical Modelling, Course notes, Fırat University, 1999. 2.R.G.E. Franks, Modelling and Simulation in Chemical Engineering 1981. 3.H.S.Mickley, T.K.Sherwood, and C.E.Reed, Applied Mathematics In Chemical Engineering. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings GRADUATION PROJECT KMÜ-408 5 4 hours/week All Lecturers in the Department 4th/ Spring Compulsory All modules in 1st and 2nd years/All previous compulsory modules A project requiring experimental and/or theoretical studies on a specific subject related to Chemical engineering that will contrite to the professional development of students supervised by the departmental staffs. The aim of this module is to provide students an opportunity to apply the knowledge and skills acquired in previous coursework to solve a specific problem and/or acquire in-depth knowledge on a specific topic. One written report (40%) and one final exam (oral presentation) (60%) Turkish - CHEMICAL ENGINEERING DESIGN-II KMÜ-424 5 5 hours/week Dr. Fikret TÜMEN 4th / Spring Compulsory None / Chemical Engineering Design-I, Stoichiometry-I, Stoichiometry-II, Basic Computer Science, Economics, Fluid Mechanics, Heat Transfer, Mass Transfer, Reaction Engineering-I, Reaction Engineering-II Alternative processes and process selection in some industrial processes. Equipment materials selection. Preparation of process flow sheet. Calculation and sizing of equipments in typical processes. Economical evaluation of processes and cost analysis. Design report preparation. Making a project work given and oral presentation. The aim of this module is to provide knowledge and skills to understand and design a chemical process and to provide experience in using process simulators (ChemCAD) for chemical plant design. The midterm score is determined by summing the written exam (50%) project I (ChemCAD) (20%) and project II (30%) . Finally, midterm score (40%) and final score (60%) build the success degree. The students can take make-up exam to enhance the midterm score. Turkish 1.Turton, R., Bailey, R.C., Waiting, W.B., Shaeiwitz, J.A., Analysis, Synthesis and Design of Chemical Process, Prentice-Hall, 1998. 2.Vilbrandt, F.C., Dryden, C.E., Chemical Engineering Plant Design, McGraw-Hill, 3.Max S. Peters, Klaus D. Timmerhaus, Plant Design and Economics for Chemical Engineers, Fourth Ed., McGraw Hill, 1991. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings EXTRACTIVE METALLURY KMÜ-432 3 2 hours/week Dr. H.Soner ALTUNDOĞAN 4th / Spring Elective None / Introduction to Extractive Metallurgy Iron metallurgy, carbonaceous steel production. Production of alloyed steel making materials (chromium, nickel, manganese, cobalt, silicon) Copper Production. Lead production. Zinc production. Production of light metals (aluminium, magnesium). Hydrometallurgical production methods. The aim of this module is to provide basic and advanced knowledge in the extractive metallurgy. One written midterm exam (40%) and one written final exam (60%). The students can take make-up exam to enhance the midterm score. The homework and the presentation are also added directly to the midterm exam score. Turkish 1. Işık, E., Kimya Mühendisliği Ekstraktif Metalurjisi, Ankara D.M.M.A., Ankara, 1976. 2. Diğer Yardımcı Kaynaklar: 3. Tulgar, H. E. (W.H. Dennis’den Çeviri), Demirden Gayri Metaller Metalurjisi (2. cilt) , İTÜ Kimya-Metalurji Fak. Ofset Atölyesi, İstanbul, 1987. PETROCHEMICAL TECHNOLOGY KMÜ436 3 2 hours/week Dr Melek YILGIN 4th /Spring Elective None / The definition of the industry, the basic sources and the main products. The important chemicals production such as PVC, polystyrene, synthetic rubber. The aim of this module is to provide an introduction to chemicals and derivates that are obtained from the processing of crude oil and natural gas in petrochemical technology described in the module contents. One written midterm exam (40%) and one written final exam (60%) Turkish List, H.L., Petrochemical Techonolgy, New Jersew, 1986; Kuleli, Ö., Petrol Arıtım Teknolojisi, Çağlayan Kitabevi, 1981. Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings INTRODUCTION TO FOOD CHEMISTRY KMÜ-440 3 2 hours/week Dr. Filiz KAR 4th / Spring Elective None/Organic Chemistry Basic concepts in food chemistry. Amino acids. Carbohydrates. Lipids. Proteins. Enzymes. Vitamins. Components and properties of fruits. Food additives and ingredients. Last developments in food technology. The aim of this module is to teach the important properties and chemical structures of food components, the importance of the reactions of each food component taking place during food processing. One written midterm exam (40%) and one written final exam (60%) Turkish 1. Arslan, N., Gıda Kimyasına Giriş, Fırat Üniv. Müh. Fak. Kimya Müh. Bölümü, Elazığ, 1999. MEMBRANE SEPARATION PROCESSES KMÜ-412 3 2 hours/week Dr. İnci TÜRK TOĞRUL 4th /Spring Elective None / Classification of membrane separation processes. Properties of membrane separators. Microfiltration, ultrafiltration, osmosis, electrodialysis. Liquid membranes. Gas separation processes. Operating design in membrane separation The aim of this module is to provide an introduction to the basic concepts and techniques used membrane separation processes described in the module contents. One written midterm exam (40%) and one written final exam (60%) Turkish Geankoplis, C. J., Transport Processes and Unit Operations, 3rd ed., Prentice-Hall International Inc., New Jersey, 1993. INTRODUCTION TO HETEROGENEOUS REACTIONS Module Code Number KMÜ-422 Number of ECTS Credits 3 Hours / Week 2 hours/week Module Lecturer Dr. Dursun ÖZER Year / Term 4th / Spring Type of Course Elective (Compulsory / Elective) Pre requisites / Recommended None /Reaction Engineering-I, Reaction Engineering-II Overall reaction rates. Types of heterogeneous reactions. Mechanisms of catalytic reactions. Adsorption and adsorption isotherms. Determination of Module Contents surface area. Void volume and solid density. Pore-volume distribution. Catalyst preparation. And catalyst deactivation. Rate equations for fluidsolid reactions. Aims and Objectives of the The aim of this module is to train students to collect and analyse reaction module rate data to drive reaction rate expressions for heterogeneous reactions and design heterogeneous reactors. Method of assessment One written midterm exam (40%) and one written final exam (60%) Teaching Language Turkish Textbook / 1. Fogler, H. S., Elements of Chemical Reaction Engineering, 2nd ed., recommended readings Prentice-Hall International Inc., New Jersey, 1992. 2. Smith, J. M., Chemical Engineering Kinetics, 3rd ed., McGraw-Hill International Inc., Singapore, 1981 Module Code Number Number of ECTS Credits Hours / Week Module Lecturer Year / Term Type of Course (Compulsory / Elective) Pre requisites / Recommended Module Contents Aims and Objectives of the module Method of assessment Teaching Language Textbook / recommended readings WATER TECHNOLOGY KMÜ-434 3 2 hours/week Dr. H.Soner ALTUNDOĞAN 4th / Spring Elective None / Inorganic Chemical Technologies Properties and occurrence of water in the nature. Characteristics of drinking, washing and industrial waters. The matters in water and phenomena from them. Water treatments and purification. The aim of this module is to provide basic and advanced knowledge on water chemistry and municipal and industrial water treatment. One written midterm exam (40%) and one written final exam (60%). The students can take make-up exam to enhance the midterm score. The homework and the presentation are also added directly to the midterm exam score. Turkish M. Bildik, Water Technology Lecture Notes, F.U. Chemical Engineering Department, 1996.