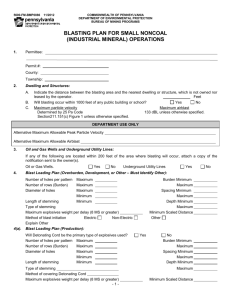

13-7. characteristics of explosives materials.

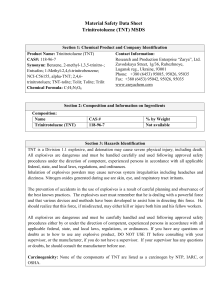

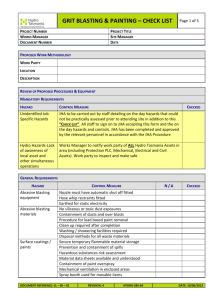

advertisement

CHAPTER THIRTEEN DEMOLITIONS 13-1. CHARACTERISTICS OF EXPLOSIVES. There are two categories of explosives, Low and High. a. Low Explosives are characterized by having a detonating velocity up to 1300 feet per second; producing a pushing or shoving effects. b. High Explosives are characterized by having a detonating velocity between 3,280 - 27,888 feet per second, producing a shattering effect. 13-2. INITIATION SYSTEMS. Demolition systems are primed using a variety of methods. There are two types of initiation systems; electric and non-electric. The latest method uses the Modernized Demolition Initiators (MDI). MDI consists of blasting caps attached to various lengths of time fuse or shock tube. These blasting caps, along with a fuse igniter and detonating cord, can be used to create numerous firing systems. 13-3 NON-ELECTRIC FIRING SYSTEMS. Detonating cord firing systems are probably the most versatile and the easiest to install of all firing systems. a. To employ the non-electric firing system it is important that the length of the time fuse be computed correctly. (1) Determine roll burning rate (average burn rate [ABR]: Tie overhand knot on one end of time fuze (standing end), cut and discard 6 inches of the working end, cut and test-burn 3 feet of time blasting fuze to determine ABR for that specific roll. Do this for every roll. Divide the ABR in total seconds by 3 to find seconds per foot. Burn rates over 45 seconds are considered bad time fuse and should not be used. When test-burning rolls test under similar conditions in which they will be used; i.e., for use on open range let time fuse warm in the sun, for use at night test when temperature is cooler. (2) Determine desired length of time fuze needed: Divide desired burn length (in total seconds) by ABR (seconds per foot). Carry out answer two places past decimal point. Number(s) from the decimal point to the left will become "feet" of time fuze. Using the numbers from the decimal point to the right, multiply by 12. From this answer, the number(s) from the decimal point to the left will become "inches" of time fuze. Using the numbers from the decimal point to the right, multiply by 16. From this answer, numbers from the decimal point to the left will become 1/16 of inches. Disregard the numbers from the decimal point to the right. Stretch out the time fuse flat along a tape measure and cut the exact length. b. Following are the steps used to construct and emplace the non-electric system: (1) Cut the desired length of the time blasting fuze and crimp a non-electric blasting cap to the length of time blasting fuze, ensuring that the crimp is between 1/8 and 1/4 inch from the open end of the basting cap. (2) Double crimp by rotating crimpers 90 degrees and moving 1/8 inch. double crimp increases water resistance. 13-1 A (3) Use cap seal when system is to be used in damp climates or under water. (4) Attach M60 fuse igniter. Rotate coupling base counter-clockwise one or two turns, remove shipping plug, insert time fuse fully, and retighten. Use a condom to waterproof fuse igniter. (5) Two complete time fuse systems taped together at the caps, and along the length of the time fuse, make a dual detonating assembly. Use an 18-inch detonating cord loop at the caps for ease of tying into detonating cord firing system. This system provides dual priming. wells. (6) Insert and secure the blasting cap in the demolition charges with cap If priming adapters are not available, use tape or string. (7) Whenever plastic explosives without cap wells are used, make a hole with a non-sparking instrument large enough to contain the blasting cap. Insert the blasting cap and tie with string or use tape to secure the cap to the charge. (8) M118 or M186 demolition charges may be primed by cutting a notch the size of the blasting cap in the sheet explosive and inserting the blasting cap into the notch. Secure the cap with string, tape, or a strip of sheet explosive. A cap may also be placed between two sheets of the explosive. (9) Dynamite can be primed at the end or the side. End priming is used when a whole case is fired or when the charges require no tamping. Side priming is used when placing the dynamite in a tamped borehole. (10) Det Cord is attached using a prusik knot. (11) A Uli knot or double overhand knot may be used to prime C-4 instead of a blasting cap. c. Non-electric Misfires. During training, a 30-minute waiting period will be observed before investigating a non-electric misfire. Carefully approach misfire, look for smoke, and inspect fuse for evidence of complete burn. If the misfire is above ground, place a new, primed 1-pound charge next to the misfired charge. If the charges is tamped or below ground, dig to within 1 foot of the old charge and place a new, primed 2-pound charge. 13-4 ELECTRICAL FIRING SYSTEMS. An electric firing system is one in which electricity is used to fire the primary initiating element. The electric firing system offers the advantage of giving the fire control over the instant of detonation. The electric 13-2 blasting cap, firing wire, and power source are the components of the electric firing system. a. There are several general rules concerning the use of electrical firing systems: (1) Blasting caps of older or different manufacture, i.e., Atlas, Hercules, DuPont, J1, and J2, will not be mixed in the same circuit. The label, color of the cap, or shape of the shunt may identify blasting caps of the same manufacture. (2) All M6 special electric blasting caps are made according to the same specifications. (3) Only the Western Union "pigtail" splice will be used when making wire connections in all electric firing systems. (4) All blasting caps and firing wire will be checked with the blasting galvanometer/M51 test set prior to laying out the circuit. Once the circuit has been set up, the system will be checked again with blasting circuit test instruments. (5) Blasting cap lead wires and firing wires will be shunted at all times except when the caps are being spliced together or being connected into the firing wire. (6) Always carry the electric power source with you when working with electric firing systems. (7) Never use more blasting caps than the power source rating permits. (8) Calculate and understand the power requirements for series firing circuit. (9) Four forms of external power may cause premature firing of an electric firing system. (a) (b) (c) (d) Induced currents. Lightning. Electric power lines. Static electricity. b. Following are the procedures for an electric misfire: Always ensure that all wires are shunted and that you have the power source with you when checking an electrical misfire. Immediately attempt to re-fire the charge, change power source. If the charge is single primed and is above ground, it may be investigated immediately. If a charge is primed below ground, a 30-minute waiting period must be observed before investigating. Test and visually inspect firing wire (look for breaks), repair or replace, retest, and re-fire. Visually inspect cap lead wires for breaks. Reconnect or replace, retest, and re-fire. If no problem can be detected emplace clearing charges as follows: 13-3 (a) If the misfire is above ground, place a new, primed 1-pound charge next to the old charge. (b) If the charge is below ground or tamped, dig to within 1 foot of the old charge and place a new, primed 2-pound charge. 13-5. MDI. a. MDI Components include: (1) Shock tube. Thin plastic tube of extruded polymer with a layer of special explosive material on the interior surface. Explosive material propagates a detonation wave which moves along the shock tube to a factory crimped and sealed blasting cap. Detonation is normally contained within the plastic tubing. However, burns may occur if the shock tube is held. (a) Advantages of shock tube: The shock tube offers the instantaneous action of electric initiation without the risk of accidental initiation caused by radio transmitters, static electricity, etc. It is Extremely reliable and may be extended using left over pieces from previous operations. (b) Disadvantages for Special Operations Forces is that MDI leaves a very distinct U.S. signature. (2) Blasting caps. Five MDI blasting caps are available which replace the M6 electric and M7 Non-electric blasting cap. Three of these are high-strength caps and two are low-strength. (a) High-strength blasting caps. Can be used to prime all standard military explosives (including detonating cord) or to initiate the shock tube of other MDI blasting caps. 1. M11: Factory crimped to 30-foot length of shock tube. A movable "J" hook is attached for quick and easy attachment to detonating cord. A red flag is attached 1 meter from the blasting cap and a yellow flag 2 meters from the blasting cap. 2. M14: Factory crimped to 7 1/2 foot length of time fuse. May be initiated utilizing fuse igniter or match. Burn-time for total length is approximately five minutes. Yellow bands indicate calibrated one minute time intervals. NOTE: Burn time will increase with altitude and colder temperatures. 3. M15: Two blasting caps factory crimped to a 70 foot length of shock tube. Each blasting cap has delay elements to allow for staged detonations. (b) Low-strength blasting caps. Used as a relay device to transmit a shock tube detonation impulse from an initiator to a high strength blasting cap. NOTE: Low strength blasting caps cannot reliably set off explosives. They should only be used to set off additional shock tubes. 1. M12. Factory crimped to a 500 foot length of shock tube on a cardboard spool. 2. M13. Factory crimped to a 1,000 foot length of shock tube. (3) M81 Fuse igniter. Used to ignite time blasting fuse or to initiate the shock tube of MDI blasting caps. NOTE: The M60 may still be used to ignite time blasting fuse. However, it will not reliably initiate the shock tube. 13-4 13-6 BREECHING CHARGES. Primarily in the destruction of concrete slab, bridges, bridge beams, bridge piers, bridge abutments. Breaching charges should be placed so that there is free reflection surface on the opposite side of the target to facilitate spalling. The k factor is the strength and hardness of the material to be breached. If in doubt of material type assume it to be of the stronger type. For concrete bridge beams, each beam is breached individually. a. Breaching Charge Formula: P = R3KC (for external charge, round breaching radius up to the nearest 1/2 foot) P R K C untamped) = = = = POUNDS OF TNT BREACHING RADIUS CONSTANT FOR MATERIAL FACTOR TAMPING FACTOR (3.6 for on the ground untamped, 1.8 for elevated b. The width of the breach determines the number of charges used: N = W/2R N = NUMBER OF CHARGES W = WIDTH OF PIER, SLAB OR WALL R = BREACHING RADIUS (IN FEET) (IN FEET) 13-7. CHARACTERISTICS OF EXPLOSIVES MATERIALS. CHARACTERISTICS OF US DEMOLITIONS EXPLOSIVES Detonation Velocity Name Ammonia nitrate PETN RDX Trinitrotoluene (TNT) Tetryl Nitroglycerin Black powder Amatol 80/20 Composition A3 Composition B Composition C4 Composition H6 Tetrytol 75/25 Applications Cratering chg. Det. Cord Blasting caps Demo chgs. Blasting caps Comp. Expl. Demo chgs. Comp. Expl. Booster chg. Comp. Expl. Commercial dynamite Time fuse Bursting chg. Booster chg. Bursting chg. Bursting chg. Breaching & Cutting chg. Cratering chg. Demo chgs. Min/Sec Ft/Sec 2,700 8,900 RE Factor 0.42 Fume Toxicity Dangerous Water Resistance Poor 8,300 27,200 1.66 Slight Excellent 8,300 27,400 1.60 Dangerous Excellent 6,900 22,600 1.00 Dangerous Excellent 7,100 23,300 1.25 Dangerous Excellent 7,700 400 4,900 25,200 1,300 15,000 1.50 0.55 1.17 Dangerous Dangerous Dangerous Good Poor Poor 8,100 7,800 26,500 25,600 ----1.35 Dangerous Dangerous Good Excellent 8,400 7,190 26,400 23,600 1.34 1.33 Slight Dangerous Excellent Excellent 7,000 23,000 1.25 Dangerous Excellent 13-5 Pentolite 50/50 Bursting & Booster chgs. 7,450 24,400 ----- Dangerous Excellent M1 dynamite Demo chgs. 5,100 20,000 0.92 Dangerous Fair Detonating cord Priming & Demo chgs. 6,100 to 7,300 20,000 to 24,000 ----- Slight Excellent Cutting chg. 7,300 24,000 1.14 Dangerous Excellent Demo chg. 7,800 25,600 1.17 Dangerous Excellent Dangerous Excellent Sheet explosive M118 & M186 Bangalore torpedo, M1A2 Shaped chgs. M2A3, M2A4 & M3A1 Demo chg. 7,800 25,600 1.17 *TNT equals 1.00 relative effectiveness (RE). CHARACTERISTICS OF BLOCK DEMOLITION CHARGES Unit (lb) Size (in) Detonation Velocity M/Sec Ft/Sec RE Packaging/ Weight³ M112 block² 0.25 0.50 1.00 1.25 1½x3½ 1¾x1¾x3¾ 1¾x1¾x7 1x2x10 6,900 6,900 6,900 8,040 22,600 22,600 22,600 26,400 1.00 1.00 1.00 1.34 192/bx@5# 96/bx@3# 48/bx@53# 30/bx@40# M118 block 2.00 1x3x12 7,300 24,000 1.14 M118 sheet² 0.50 ¼x3x12 7,300 24,000 1.14 M186 roll 25.00 ¼x3x600 7,300 24,000 1.14 2# blocks; 20/bx@42#; 4 sheets/pk 3/bx@80# Explosive TNT¹ Composition H6¹ 43.00 7x20 7,190 23,600 1.33 1/bx@52# M1 dynamite¹ 0.50 1¼x8 6,100 20,000 0.92 100/bx@62# ¹The ¼ block of TNT, composition H6 cratering charge and M1 dynamite are cylindrical in shape & described in terms of diameter and length. ²The volume of M112 is 20 cubic inches & the volume of M118 is 9 cubic inches. ³Packaging weights include packaging material and weight of container. DOMESTIC EXPLOSIVES AMMONIUM NITRATE - Ammonium nitrates is the explosives. It requires a booster charge to of its low sensitivity, ammonium nitrate is (combined with a more sensitive explosive). least sensitive of the military initiate detonation successfully. Because a component of many composite explosives Ammonium nitrate is not suitable for 13-6 cutting or breaching charges because it has a low detonating velocity. Commercial quarrying operations use ammonium nitrate demolitions extensively. Ammonium nitrate should be packed in an airtight container because it is extremely hygroscopic (absorbs humidity). Ammonium nitrate or composite explosives containing ammonium nitrate are not suitable for underwater use unless packed in waterproof containers or detonated immediately after placement. CYCLOTRIMETHLENETRINITRAMINE (RDX)-RDX is also a highly sensitive and very powerful military explosive. It forms the base charge in the M6 electric and M7 nonelectric blasting caps. When RDX is desensitized, it serves as a sub-booster, booster, bursting charge, or demolition charge. RDX is primarily used in composite explosives, such as composition A, B, and C explosives. RDX is available commercially under the name cyclonite. PENTAERYTIIRITE TETRANITRATE (PETN)-PETN is a highly sensitive and very powerful military explosive. Its explosive potential is comparable to RDX and nitroglycerin. Boosters, detonating cord, and some blasting caps contain PETN. It is also used in composite explosives with trinitrotoluene (TNT) or with nitrocellulose. A PETNnitrocellulose composite (M118 sheet explosive) is a demolition charge. The PETN explosive is a good underwater demolition because it is almost insoluble in water. TRINITROTOLUENE-TNT is the most common military explosive. It may be in composite form (such as a booster, a bursting or demolition charge) or in a noncomposite form. Since TNT is a standard explosive, it is used to rate other military explosives. TETRYL-Tetryl is an effective booster charge in its noncomposite form and a bursting or a demolition charge in composite forms. Tetryl is more sensitive and powerful than TNT. However, RDX- and PETN-based explosives, which have increased power and shattering effects, are replacing tetryl and composite explosives containing tetryl. NITROGLYCERIN-Nitroglycerin is one of the most powerful high explosives (HEs). Its explosive potential is comparable to RDX and PETN. Nitroglycerin is the explosive base for commercial dynamites. Nitroglycerin is highly sensitive to shock and is affected by extreme temperatures. Military explosives do not use nitroglycerin because of its sensitivity. Do not use commercial dynamites in combat areas. BLACK POWDER-Black powder is the oldest-known explosive and propellant. It is a composite of potassium or sodium nitrate, charcoal, and sulfur. Time fuses, some igniters, and some detonators contain black powder. AMATOL- Amatol is a mixture of ammonium nitrate and TNT. It is a substitute for TNT in bursting charges. Some older bangalore torpedoes use 80-20 amatol (80% ammonium nitrate and 20% TNT). Because amatol contains ammonium nitrate, it is a hygroscopic compound. Keep any explosives containing amatol in airtight containers. If properly packaged, amatol remains viable for long periods of time, with no change in sensitivity, power, or stability. COMPOSITION A3-Composition A3 is a composite explosive containing 91% RDX and 9% wax. The purpose of the wax is to coat, desensitize, and bind the RDX particles. Composition A3 is the booster charge in some newer shaped charges and bangalore torpedoes. High-explosive plastic (HEP) projectiles may also contain composition A3 as a main charge. COMPOSITION B-Composition B is a composite explosive containing about 60% RDX, 39% TNT, and 1% wax. It is more sensitive than TNT. Because of its shattering power and high detonation rate, composition B is the main charge in shaped charges. COMPOSITION B4-Composition B4 contains 60% RDX, 39.5% TNT, and 0.5% calcium silicate. Composition B4 is the main charge in newer models of bangalore torpedoes and shaped charges. 13-7 COMPOSITION C4 (C4)-C4 is a composite explosive containing 91% RDX and 9% nonexplosive plasticizers. Burster charges are composed of C4. It is effective in temperatures between –70o to +170oF; however, C4 loses its plasticity in colder temperatures. TETRYTOL-Tetrytol is a composite explosive containing 75% tetryl and 25% TNT. It is the explosive component in demolition charges. Different mixtures of tetryl and TNT are required for booster charges. Tetrytol is more powerful than its individual components, is better at shattering than TNT, and is less sensitive than tetryl. PENTOLITE-Pentolite is a mixture of PETN and TNT. Because of its high power and detonating rate, a mixture of 50-50 pentolite (50% PETN and 50% TNT) makes an effective booster charge in certain models of shaped charges. DYNAMITES STANDARD DYNAMITE-Most dynamites, with the notable exception of military dynamite, contains nitroglycerin plus varying combinations of absorbents, oxidizers, antacids, and freezing-point depressants. Dynamites vary greatly in strength and sensitivity depending on, among other factors, the percentage of nitroglycerin they contain. Dynamites are for general blasting and demolitions, including land clearing, cratering and ditching, and quarrying. Military Dynamite-Military dynamites is a composite explosive that contains 75% RDX, 15% TNT, and 10% desensitizers and plasticizers. Military dynamite is not as powerful as commercial dynamite. Military dynamite's equivalent strength is 60 percent of commercial dynamite. Because military dynamite contains no nitroglycerin, it is more stable and safer to store and handle than commercial dynamite. DETONATION CORD DATA Type Class Minimum weight of explosive core per 1,000’ Nominal Diameter, (in) Maximum wt. (lb) of finished cord per 1,000’ Minimum breaking strength, (lb) I I *I I I I I I I II II a b c d e f g h j a b 5 lbs. PETN 6 lbs. PETN 6.4# PETN 7 lbs. PETN 7 lbs. PETN 12.5# PETN 12.5# PETN 14.5# PETN 6.4# PETN 7 lbs. RDX 8.5 lbs. RDX 0.175 0.216 0.200 0.200 0.235 0.245 0.270 0.235 0.200 0.216 0.255 14 19 18 19 22 26 33 29.5 18 19 22 60 175 175 110 190 75 190 110 150 175 190 III -- All Type III det cord is inert loaded with PVC filler. *This type det cord (Type I, class c) has been agreed upon as “standard” within the American-British-Canadian-Australian Standardization Program. CHARACTERISTICS OF SHAPED DEMOLITION CHARGES Type Explosive Wt. Size (in) 13-8 Packaging and total weight Charge Demo.: Shaped, 15#, M2A3 15 lb. 14-15/16”x7” w/fiberboard standoff Charge Demo.: Shaped, 15#, M2A4 Charge Demo.: Shaped, 40#, M3 Pentolite or Composition B, w/ 50/50 Pentolite booster Composition B, w/composition A3 booster Composition B, w/ 50/50 PentOlite booster 15 lb. 14-15/16”x7” w/fiberboard standoff 15½”x9” less standoff Charge Demo.: Shaped, 40#, M3A1 Composition b, w/ composition A3 booster 40 lb. 40 lb. 15½”x9” less standoff 1. 2/wood box @ 58 lb. 2. 3/wood box @ 65 lb. 3/wood box @ 65 lb. 1 charge/wood box @ 65 lb. 1 charge/wood box @ 65 lb. CHARACTERISTICS OF DYNAMITE Name Principal Use Military dynamite,M1 Straight Dynamite 40% 50% 60% Ammonia 40% Dynamite 50% (commercial) 60% Gelatin 40% Dynamite 50% (commercial) 60% Ammonia-gelatin 40% Dynamite (commercial) 60% D e m o l i t i o n C h a r g e Velocity of detonation (m/secft/sec) RE as Breachi ng chg Intensity of fumes Water resistanc e 6,100m/s-20,000f/s 0.92 Dangerous Good 4,600m/s-15,000f/s 5,500m/s-18,000f/s 5,800m/s-19,000f/s 2,700m/s-8,900f/s 3,400m/s-11,000f/s 3,700m/s-12,000f/s 2,400m/s-7,900f/s 2,700m/s-8,900f/s 4,900m/s-16,000f/s 4,900m/s-16,000f/s 0.65 0.79 0.83 0.41 0.46 0.53 0.42 0.47 0.76 --- Dangerous Good (if fired in 24 hours) Dangerous Poor Slight Slight Good Excellent 5,700m/s-18,700f/s --- 8-8. SAFETY CONSIDERATIONS. a. MDI is not recommended for below ground use, except in quarry operations with water-gel or slurry explosives. Utilize detonating cord when it is necessary to bury primed charges. b. Do not handle misfires downrange until the required 30 minute waiting period for both primary and secondary initiation systems has elapsed and other safety precautions have been accomplished. c. Never yank or pull hard on the shock tube. This may actuate the blasting cap. d. Do not dispose of used shock tubes by burning because of potentially toxic fumes given off from the burning plastic. e. Do not use M1 dynamite with the M15 blasting cap. The M15 delay blasting cap should be used only with water-gel or slurry explosives. 8-9. FIELD EXPEDIANT DEMOLITION. a. GRAPESHOT CHARGE: Consists of a container (an ammo can or Number 10 can), projectiles (nails, bolts, glass, small pieces of scrap metal, or rocks), buffer 13-9 material (soil, leaves, felt, cloth, cardboard, or wood), a charge (C4) & blasting cap/det cord. Explosive's weight equal to one quarter the projectile weight. Place plastic explosive uniformly in bottom of container. Remove all voids or air spaces. Place 2" buffer material directly on top explosives. Place projectiles on top of buffer material. Place a covering over projectiles to prevent them from spilling out when handling the charge. Cover blasting cap w/small quantity C4 if any part exposed. ≈100 feet range. b. PLATTER CHARGE: Use a round, steel platter, if available. However, a square platter also will work. The platter should weigh 2 to 6 pounds. Use a quantity of explosive equal to the platter's weight. Uniformly pack explosive behind platter. Container not necessary, tape acceptable anchoring material. Prime charge exact, rear center. Cover blasting cap w/small quantity C4 if any part blasting cap exposed. Use gutted M6O fuse igniter as an expedient aiming device & aim charge at direct center of target. ≈25 yards range. c. Barbed Wire AP Charge: A roll of barbed wire is charged with one block C-4 or one pound TNT to create a shrapnel producing AP weapon. Shrapnel is produced in a 360o radius, but can be restricted through the use of terrain. 13-10 8-10. BOOBY TRAPS a. Concealed devices used to inflict casualties, booby traps were an integral component of the war waged by Vietcong and People's Army of Vietnam (PAVN) forces in Vietnam. These devices were used to delay and disrupt the mobility of U.S. forces, in fact, the threat was often enough to slow any advance to a snail's pace, divert resources toward guard duty and clearance operations, inflict casualties, and damage equipment. They were a key component in prearranged killing zones. Booby-traps could be covered by snipers to further annoy the enemy or they might be the signal to spring an ambush. The use of booby traps also had a long-lasting psychological impact on Marines and soldiers and helped to further alienate them from civilian populations that could not be distinguished from combatants. The fear of booby-traps and mines were so great those units in the field were under stress the whole time. This created severe mental fatigue on both the commanders at platoon level and the individual soldiers. Many of the materials for the mines and booby traps were of U.S. origin. This included dud bombs, discarded and abandoned ammunition and munitions, and indigenous resources such as bamboo, mud, coconuts, and venomous snakes. They are classified as explosive or non-explosive. b. Non-explosive booby traps. (1) Punji Stake Pit. By far the most common types of booby trap was the single punji stake. Punji stakes were sharpened lengths of bamboo or metal with needle-like tips that had been fire-hardened. Often they were coated with excrement to cause infection. (2) Bamboo Whip. The bamboo whip was encountered on trails and was set off by a tripwire. It comprised a length of bamboo under tension and set with spikes (poisoned in the normal fashion) at chest height. The unfortunate victim would receive severe, it not fatal, wounds to the chest as it whipped across the trail (3) Arrow Trap. The bow trap mountainous areas - though it was not which released a tensioned bow set in arrow was normally tipped with poison was a favorite in the heavily forested limited to these. It too was tripped by a wire a shallow pit. The target area was the leg. The or human excrement. 13-11 c. Explosive Booby Traps. (1) Hand Grenade Traps. (a) Simple Trip Wire. The simplest trap was a trip wire connected to one or two grenades. The grenades were placed in tubes of bamboo or tins to keep the safety lever from releasing when the pin was pulled. The victim tripped the wire, set at whatever height, pulling the grenades from their containers. (b) Gate/Door Trap. Grenades were also set in the ground below gates so that the slightest movement of the gate would detonate it right below the victims' feet. In areas where the vegetation closed above the trail grenades were often set to shower splinters of wood and metal downwards, causing messy wounds which would require urgent casualty evacuation. (2) Toe Poppers. A small variation of this used a 12.7 mm machine gun bullet set in a bamboo tube with its primer resting on a nail or firing pin. The tip of the bullet just protruded from the earth. A foot would press down sufficiently to set it off. The bullet would explode shattering the victim's foot. If he was unfortunate enough to be wearing the reinforced-soled jungle boot then the steel or plastic plate 13-12 turned into shrapnel. The grunts called these 'toe poppers". They were usually set in long grass. (3) Explosive Initiation Devices: Explosive initiation devices can be used to activate electrical or non-electrical detonating systems. (a) Time Delay. A simple mechanical clock can be used in various ways. (b) Tension Release. (c) Pull Release. (d) Pressure Release. 13-13 (e) Pull Pin. 13-14