CL-05-01_Grit_Blasting_

advertisement

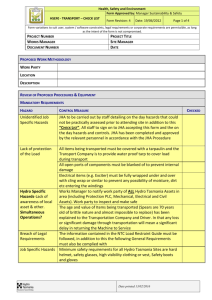

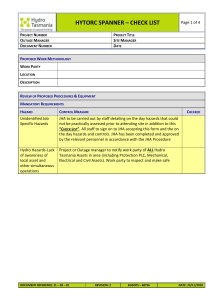

GRIT BLASTING & PAINTING – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 1 of 3 PROJECT TITLE SITE MANAGER DATE PROPOSED WORK METHODOLOGY WORK PARTY LOCATION DESCRIPTION REVIEW OF PROPOSED PROCEDURES & EQUIPMENT MANDATORY REQUIREMENTS HAZARD CONTROL MEASURE CHECKED Unidentified Job Specific Hazards JHA to be carried out by staff detailing on the day hazards that could not be practically assessed prior to attending site in addition to this “CHECK LIST”. All staff to sign on to JHA accepting this form and the on the day hazards and controls. JHA has been completed and approved by the relevant personnel in accordance with the JHA Procedure Hydro Hazards-Lack of awareness of local asset and other simultaneous operations Works Manager to notify work party of ALL Hydro Tasmania Assets in area (including Protection PLC, Mechanical, Electrical and Civil Assets). Work party to inspect and make safe GENERAL REQUIREMENTS HAZARD Abrasive blasting equipment Abrasive blasting materials Surface coatings / paints CONTROL MEASURE N/A CHECKED Nozzle must have automatic shut off fitted Hose whip restraints fitted Earthed for static electricity No siliceous or toxic dust exposures Containment of dusts and over blasts Procedure for lead based paint removal Clean up required after completion Washing / showering facilities required Disposal methods for all waste materials Secure temporary flammable material storage Prevention and containment of spills Hazardous substances risk assessment Material data sheets available and understood Containment of paint overspray Mechanical ventilation in enclosed areas Spray booth used for movable items DOCUMENT REFERENCE: CL – 05 – 01 REVISION: 4 HYDRO-285-64 DATE: 19/06/2012 GRIT BLASTING & PAINTING – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 2 of 3 PROJECT TITLE SITE MANAGER DATE GENERAL REQUIREMENTS HAZARD CONTROL MEASURE N/A Solvents and thinners Fire and explosion Secure temporary flammable material storage Unauthorised access Restrict access to blasting / spray painters only Falls from heights CHECKED No ignition sources near spray painting No ignition sources near flammable store(s) Appropriate fire fighting equipment on hand Blasting / painting area to be securely barriered and delineated Provision of fixed access / scaffolding Elevated work platform or similar Safety harness and lanyard Lack of coordination Works Manager to supervise or delegate responsibility Works Manager to notify Production Manager of date and time of blast(s) Works Manager to notify Generation Operations of date and time of blast(s) Contractor to have direct communication with Works Manager DOCUMENT REFERENCE: CL – 05 – 01 REVISION: 4 HYDRO-285-64 DATE: 19/06/2012 GRIT BLASTING & PAINTING – CHECK LIST PROJECT NUMBER WORKS MANAGER DOCUMENT NUMBER Page 3 of 3 PROJECT TITLE SITE MANAGER DATE SITE REGISTRATION (Note: Applies to all Work Parties and personnel working on site) REQUIREMENT CHECKED Permit To Work issued Visitors register sheet or emergency board being used. Site Map issued (showing emergency assembly areas and fire equipment) Hydro Tasmania Level 2 O H & S Induction complete Hydro Tasmania Level 3 Site induction complete S ADDITIONAL PERSONAL PROTECTIVE EQUIPMENT (COMPLIANT WITH AUSTRALIAN STANDARDS) REQUIREMENT CHECKED REQUIREMENT CHECKED REQUIREMENT CHECKED CERTIFICATION I have personally checked and verified all items on all pages of this check list Works Manager Name Signature Date I acknowledge and agree that all items are detailed on all pages of this check list. I agree to ensure that all employees and sub-contractors engaged in this work will fully comply with all control measures indicated Manager of Work Party Name Signature Date DAILY REVIEW IF THERE IS A SIGNFICANT CHANGE IN WORK AND OR CONDITIONS A NEW CHECK LIST IS REQUIRED DATE AND TIME DOCUMENT REFERENCE: CL – 05 – 01 REVIEWED / COMMENT REVISION: 4 NEW CHECK LIST REQUIRED HYDRO-285-64 DATE: 19/06/2012