site-hr - Institute of Chemical Engineering

advertisement

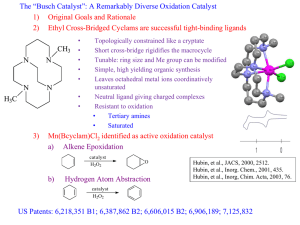

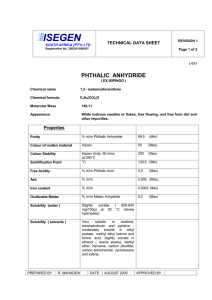

MATERIALS FOR THE ELECTRONIC SITE OF THE INSTITUTE OF CHEMICAL ENGINEERING, BULGARIAN ACADEMY OF SCIENCES, LABORATORY “CHEMICAL REACTORS” In the “Chemical Reactors” Laboratory at the Institute of Chemical Engineering, Bulgarian Academy of Sciences, the research investigations are concentrated in two fields of the chemical engineering leaded by Prof. Asen Ivanov Anastasov, D.Sc. and Prof. Serafim Dimitrov Vlaev, D.Sc. The following problems are developed in the research area “Heterogeneous catalytic and non-catalytic processes and reactors” leaded by Prof. A. I. Anastasov. A. MAIN TOPICS OF INVESTIGATIONS 1. Mathematical simulation of heterogeneous catalytic processes “gas-solid catalysts” carried out in fixed and fluidized bed of the catalyst, as well as noncatalytic processes “gas-liquid”. Here the processes of o-xylene and naphthalene oxidation to phthalic anhydride, oxidation of n-butane and benzene to maleic anhydride, oxidation of anthracene to anthraquinone, oxidation of styrene to styrene oxide and benzaldehyde, etc. are objects of investigations. The research activity involves: a) creation of mathematical models of various catalytic processes carried out in fixed and fluidized catalyst beds and methods for their solution; b) investigation of the behaviour and determination of the deactivation of industrial catalysts during the whole period of their exploitation in industrial reactors; c) creation of new design apparatuses with fixed catalyst bed; d) determination of the kinetics of various catalytic processes realized by different commercial industrial catalysts; e) organization of new technological schemes of operation of fixed bed catalytic reactors. 2. Experimental investigations of heterogeneous catalytic processes “gas-solid catalyst” carried out in fixed catalyst bed. According to the activities shown in 1. and 2. we determine: a) the optimal parameters of the technological regimes in industrial fixed beds composed by different catalysts; b) the optimal constructive parameters of the corresponding industrial reactors. B. MAIN ACHIEVEMENTS In the research direction “Heterogeneous catalytic and non-catalytic processes and reactors” the following more important results are obtained: 1. An optimal strategy for changing the technological regime of the catalytic oxidation of o-xylene to phthalic anhydride depending on the catalyst age of a vanadia-titania catalyst O 4-26 during the whole period of its use is determined. The same is done for a catalyst O 4-28 exploited 36 months under industrial conditions. The change of the technological regimes is conformed to the achievement of maximum phthalic anhydride yield, irrespective of the catalyst age; 2. .A reactor design being new in principle is created. It can be used for carrying out high exothermic or endothermic catalytic processes “gas-solid catalyst”. The theoretical investigations of the new reactor show that the temperature regime in it is practically identical to the theoretical one for every catalytic process. This enables the engineer to increase sharply the yield of the desired product in comparison with the conventional fixed bed reactor. 3. New technological schemes with a dual salt bath and a dual catalyst bed are suggested for the process of o-xylene oxidation to phthalic anhydride. Using them a maximum yield of desired product and practically no content of the main contaminant phthalide can be achieved. 4. The kinetic parameters of the o-xylene oxidation carried out by the high productive catalysts O 4-26 and O 4-28, as well as by a conventional catalyst O 425 calcined under special conditions are determined. 5. The optimal constructive parameters of a fixed bed composed by a high active catalyst O 4-25 for o-xylene oxidation are specified. It is found out that this catalyst can substitute successfully the expensive high productive catalysts O 4-26 and O 4-28. Hence, significant savings of funds can be realized. 6. Samples of V2O5-ZrO2 catalysts having various content of V2O5 and being of high thermal stability are synthesized. They can be successfully used in the process of o-xylene oxidation. 7. A preliminary project of an industrial installation for oxidation of anthracene to anthraquinone in a fixed catalyst bed is developed. A design engineering of all apparatuses in the installation is accomplished. The development can be directly used to create a detailed design of the installation. 8. The parametric sensitivity of the process of styrene oxidation carried out in an industrial bubble column is specified. C. INDUSTRIAL CONTACTS The scientific direction “Heterogeneous catalytic and non-catalytic processes and reactors” has close co-operation with the Chemical plants “ORGAHIM” – Rousse, Bulgaria. In Bulgaria, phthalic anhydride is produced in these plants only. Many developments realized in the Institute of Chemical Engineering are submitted to the Management of the ORGAHIM plants and are successfully used the industrial practice. D. SELECTED PAPERS 1. Anastasov А. I., The behaviour of a low-productive non-pretreated V2O5-TiO2 (anatase) catalyst for oxidation of o-xylene to phthalic anhydride, Chemical Engineering Journal, 109, 57-66 (2005). 2. Anastasov A. I., Deactivation of an industrial V2O5-TiO2 catalyst for oxidation of oxylene into phthalic anhydride, Chemical Engineering and Processing, 42, # 6, 449-460 (2003). 3. Anastasov A. I., An investigation of the kinetic parameters of the o-xylene oxidation process carried out in a fixed bed of high-productive vanadia-titania catalyst, Chemical Engineering Science, 58, # 1, 89-98 (2003). 4. Anastasov A. I., A study of the influence of the operating parameters on the temperature of the hot spot in a fixed bed reactor", Chemical Engineering Journal, 86, 287-297 (2002). 5. Anastasov A. I., V. A. Nikolov, A catalyst deposited over the external surface of the reactor tubes - a new solution for carrying out heterogeneous catalytic processes, Canadian Journal of Chemical Engineering, 80, # 1, 79-87 (2002). 6. Anastasov A., V. Nikolov, Optimal policies of operation of a fixed-bed reactor for oxidation of o-xylene into phthalic anhydride, Industrial & Engineering Chemistry Research, 37, # 8, 3424-3433 (1998). 7. Tasheva B., A. Anastasov, Successive approximations method for the analysis of gas-liquid reactions in a bubble column, Computers & Chemical Engineering, 17, # 7, 653-661 (1993). 8. Nikolov V., A. Anastasov, Pretreatment of a vanadia-titania catalyst for partial oxidation of o-xylene under industrial conditions, Industrial & Engineering Chemistry Research, 31, # 1, 80-88 (1992). 9. Nikolov V. A., A. I. Anastasov, Influence of the inlet temperature on the performance of a fixed bed reactor for oxidation of o-xylene into phthalic anhydride, Chemical Engineering Science, 47, # 5, 1291-1298 (1992). 10. Nikolov V., A. Anastasov, D. Klissurski, Achievements in the production of phthalic anhydride obtained by vapour phase oxidation of o-xylene in a fixed bed, La Chimica & L Industria (Italy), 72, 111-114 (1990). 11. Nikolov V., D. Klissurski, A. Anastasov, Phthalic anhydride from o-xylene; Catalysis, science and engineering, Catalysis Reviews-Science and Engineering, 33, # 3/4, 319-374 (1991). 12. Nikolov V., A. Anastasov, D. Elenkov, G. Ganev, N. Dimitrov, Oxidation of oxylene into phthalic anhydride in a reactor with two fixed beds of vanadium-titania catalyst, Chemical Engineering & Processing, 25, 127 - 131 (1989). 13. Nikolov V., A. Anastasov, A study of coolant temperature in an industrial reactor for o-xylene oxidation, A. I. Ch. E. Journal, 35, No 3, 511 - 513 (1989). 14. Nikolov V., A. Anastasov, D. Elenkov, G. Ganev, N. Dimitrov, A new approach to the oxidation of o-xylene into phthalic anhydride in a fixed bed of a vanadiumtitanium catalyst, Chemical Engineering & Processing, 24, 157-162 (1988). 15. Anastasov A., D. Elenkov, V. Nikolov, A model study of a conventional fixed bed tubular reactor with a catalyst layer on the inside tube wall, Chemical Engineering & Processing, 23, # 4, 203-211 (1988). The research activity of the scientific direction “Heterogeneous moving bed reactors” leaded by Prof. S. D. Vlaev is as follows: ACHIEVEMENTS Of the Chemical Reaction Engineering Laboratory in BAS Research group in heterogeneous moving bed operations Thanks to the activity of the research group in ‘Heterogeneous moving bed reactors’, namely, Prof. Serafim D. VLAEV, DSc and his co-workers : (http://www.pse.ice.bas.bg:8080/Professor/S.Vlaev.htm) Dr. M. Valeva, M. Martinov, D. Georgiev, M. Tsenova, and P. Staykov, In response to the program activities of the Bulgarian Academy of Sciences Institute of Chemical Engineering, in the recent 10 years the Laboratory of Chemical Reaction Engineering has achieved the significant results, as follows: (1) Expertise and studies in fundamental and applied science The Laboratory has competed at international calls by elaboration of (more than 10) project proposals in European framework programs FP4, FP5, FP6, FP7 and SEEERA.NET; additionally, bilateral international program projects RILA (2) and national competitive sessions with the local National Science Foundation (a total of 5 projects), the major projects The major expertise of the group is in mixing and aeration. Expertise MIXING AND CHEMICAL AND BIOCHEMICAL REACTORS Subdivisions: Modeling of stirred chemical and biochemical reactors Chem. Eng. Sci. 2001 Trans. Inst. Chem. Engrs. 2002, 2004 Analysis and modelling of bubble column reactors Chem.Eng. Sci. 2000, Can. J. Chem. Eng. 2003 Mechanical stability of immobilised preparations and biocatalyst carriers Biotechnol. Bioeng.(Wiley)1992 Chemical Eng. Processing (Elsevier) 1996 Mixing in non-Newtonian media (incl. gas and solid particles) Chem. Eng. Res.Des. (Hemisphere Publ.) 1995, 1998, 2000. Recents Progress en Genie des Procedes Vol.11:Mixing IX Multiphase Systems, Lavoisier Technique et Documentation, Paris, 1997 Canadian J. Chem. Eng. Special Issues on Mixing (1998, 2002, 2003) Trans. IChemE Part C (2004), Chem. Eng. Science, 2006. Previous areas Rheology and oxygen transfer in stirred cultivation media, Chem. Eng. J. (Elsevier) 1990, J. Chem.Eng. (Japan CEng Society) 1994 World Journal of Microbiology&Biotechnol.(UNESCO) 1992 Rotating disc reactor for reaction processes in slurries, Book of NATO ASI Series:Mass Transfer with Chemical Reaction Vol.2 (Martinus& Nijhof Publishers) 1983 We have participated in numerous international projects. PROJECTS WITH EUROPEAN COMMISSION Supervised by Prof. S.D. VLAEV at BAS (Bulgarian Academy of Sciences) A total of 4 projects: 1. Project BIO-PATH (ERB.CIPA.CT92.4010) “Bioproducts from Agricultural Raw Materials: Research and Technological Development towards High Value Added Market Outlets” Project term 1994/1996 BAS Grant 15 000 Principle result: Methods for utilization of fiber waste 2. Project CIPA.CT94.0179 “Gas-Liquid Reactor Design and Selection for Complex-Rheology Fluids in the Fine Chemicals, Bioprocessing and Pharmaceutrical Industries” Project term 1995/1998 30 000 BAS Grant 35 000 Principle result: Simulation procedure for stirred reactor design 3. Project IC15.CT98.0502 “Evaluation of a new energy saving mixer impeller for the process industries” Project term 1998/2001 BAS Grant: 58 000 Principle result: A new-energy-saving mixing impeller 4. Project BLACKSEASUSTECH (IC.A1.CT2001.60002) “International Workshop on Chemical Engineering Methods for Sustainable Use of Energy and Raw Materials” Project term 2001/2002 BAS Grant: 7 000 Principle result: Building partnerships for joint research. RECENT UNIVERSITY PROJECTS 2001/2004 Convention of bilateral research collaboration with Laboratory ProBioGEM POLYTECH’LILLE, Université des Sciences et Technologies de Lille : Studies on mixing and aeration in fermentation. 2008/2010 Convention of bilateral research collaboration with Laboratory ‘Biologie et Chimie Marine’ at University Bretagne Sud: Studies on the fibre bed bioreactor . (2) Elaboration of prognoses, programs and projects for development We have consulted and disseminated currently the recent European priorities in the area of reaction engineering related to mixing and aeration moving bed equipment. (3) Arrangement and supervision of post graduate educational programs At present, three doctoral programs are being carried out by the group. RECENT SUPERVISED DOCTORAL STUDIES In France University Bretagne Sud, Lab of Marine Chemistry and Biology 2008/2010 Research doctoral project: Analyses of the fixed fibrous bed bioreactor fluid dynamics and mass transfer In France University of Science and Technology of Lille Lab ProBioGem 2006/2008 Research doctoral subject: Application of CFD in bioreactor analysis In Bulgarian Academy of Sciences Institute of Chemical Engineering: 2006/2008 Research doctoral subject: Mixing impellers design modification for energy-saving (4)The group publishes scientific papers and dissiminates the research results During the recent years, numerous papers and conference presentations have been published. These publications have been cited by researchers in international journals more than hundred times. Papers by 20.03.2008 (following the year 2001) D.Georgiev, S.D.Vlaev, Fluid Flow Properties of Slotted Flat- and Hollow-blade Impellers, Chem. Biochem.Eng. Quarterly 22 (No. 2) (2008) S.D.Vlaev, D.Georgiev, I.Nikov, M.Elqotbi, The CFD approach for shear analysis of mixing reactor: verification an dexamples of use, J. Eng. Sci. Technol. 2 (2007) 177-187 S.. Vlaev I. Nikov M. Martinov Shear and skin friction on particles in power-law fluids agitated by flat-blade and fluid foil impellers, Chem.Eng.Science, 61 (2006) 5455-5467. D.Georgiev, S.D.Vlaev, Flow field characteristics of modified inclined-blade mixing impellers, Journal of the University of Chemical Technology and Metallurgy, 41(1), 2006, 45-50. D.Georgiev, S.D.Vlaev Flow field variation by minor modification of impeller blades, in: Proc. 12th Eur.Conf. on Mixing, (Editors: F.Magelli, G.Baldi, A.Brucato) Bologna, Italy, 27-30 June 2006, pp 41-48. O. Faltsi, S.D. Vlaev, D. Sofialidis, J. Kirpitsas, Novel Areas and Future Trends of Computational Fluid Dynamics Software Applications in Chemical Engineering, Chemical Industry & Chemical Engineering Quarterly (CI&CEQ 12 (4) 213-219 (2006)) M. Elqotbi, L. Montastruc, S.D. Vlaev, I. Nikov CFD simulation of gluconic acid production in a stirred gas-liquid fermenter, in: Proc. 12th Eur.Conf. on Mixing, (Editors: F.Magelli, G.Baldi, A.Brucato) Bologna, Italy, 27-30 June 2006, pp 583590. I. Nikov, S.D. Vlaev, M. Martinov, Effectiveness of power law mixing in stirred reactrors utilizing new fluid-foil blades., Bulg. Chem..Commun. 37 (2),(2005) 126-129. I. Nikov, S.D. Vlaev, M. Martinov, On the measurement of average shear rate in STR with flat and hydrofoil impellers, Compt. rend. Acad. bulg. sci. 57 (2004) 77-82. S.D. Vlaev, P. Staykov, R. Popov, Pressure distribution at impeller blades of some radial flow impellers in saccharose and xanthan gum solutions, Food and Bioproduct Processing, Trans. Inst. Chem.Engrs, 2004, 82, 13-20 Hristov, H., R. Mann, V. Lossev, S.D. Vlaev, A simplified CFD for 3-D analysis of fluid mixing, mass transfer and bioreaction in a fermenter, Food and Bioproduct Processing Trans. Inst. Chem.Engrs 2004, 82(1) 21-34. S.D. Vlaev and M. Fialova Bubble Column Bioreactors:Comparison with Stirred Fermenters Based on Local Gas Holdup Distributrion, Can. J. Chem. Eng. 81 (3-4), 2003, pp. 535-542. S.D. Vlaev, P. Staykov, S. Kraitschev Numerical Analysis of the Drag-Reducing Performance of Blade Shape in Strirred Power Law Fluids, Proc. 11th European Conference on Mixing, (Bamberg, Germany, 14/17 Oct. 2003), VDI-GVC, Dusseldorf, 2003, pp. 331-338. S.D. Vlaev, M. Valeva, R. Mann, Some Effects of Rheology on the Spatial Distribution of Gas Hold-up in a Mechanically Agitated Vessel Chem. Eng. J., 87 (2002) 21-30. M. Martinov and S.D. Vlaev, Increasing Gas-Liquid Mass Transfer in Stirred Power Law Fluids by Using a New Energy-Saving Impeller, Chem. Biochem. Eng. Q. 16 (2002) 1-6 S.D. Vlaev, P. Mavros, P. Seichter, R. Mann Operational Characteristics of a New Energy-Saving Impeller for Gas-Liquid Mixing, Can. J. Chem. Eng. 80(3), 653-659) Special Issue on Mixing (2002) Zahradnik, J., Mann, R., Fialova, M., Vlaev, D., Vlaev, S.D., Lossev,V, Seichter,P A N-o-Z analysis of mixing and mass transfer in three industrial bioreactors. Chem. Eng. Sci. 56 (2001). H. Hristov, R. Mann, V. Lossev, S.D. Vlaev, P.Seichter, A 3-D analysis of gas-liquid mixing mass transfer and bioreaction in a stirred bioreactor, Trans. Inst. Chem. Eng. Part C. Food and Bioproduct Processing, 79 (C4), 232241 (2001) Mavros, P., Mann, R., Vlaev, S.D., Bertrand, J., Exp. visualization and CFD simulation of flow patterns induced by a novel energy-saving dual configuration impeller in stirred vessels. Chem. Eng. Proc. Des. 79A, 2001, 857-866. Conferences 2001-2007: S.D. Vlaev was included in the Scientific Committee of the 12th Eur.Conf. on Mixing, Bologna, Italy, 27-30 June 2006, Three papers of the group have been reported at this European Forum, as noted above in the Proceedings. S.D. Vlaev: Chemical Engineering Analysis Prospective Support for Regional Food and Bioproduct Processing Industry – Proc. 1st South East European Congress of Chemical Engineering, 25*28 Sept. 2005 Belgrade, Serbia/Montenegro D. Georgiev, S.D. Vlaev Flow Field Characteristics of Modified Flat-Blade Mixing Impellers” Proc. 1-st South East European Congress of Chemical Engineering, Belgrade, Serbia and Montenegro, September 25-28, 2005 Staykov, P., Fialova, M., Vlaev, S.D. 2005. Computational Flow Modeling Of A Bubble Column Reactor With Emphasis On Gas Holdup Distribution. (Paper ID = 194) 32nd International Conference of Slovak Society of Chemical Engineering, Tatranské Matliare (Slovakia), May 23 / 27, 2005 S.D. Vlaev, M. Fialová1 Modeling of bubble column reactors gas proliferation: previous and present achievements CHISA’2004 Paper presented tat the 16th International Congress of Chemical and Process Engineering, 22/26 August 2004, Prague, Czech Republic CD-ROM of Full texts, Paper 0809.pdf Vlaev S.D., Fialová M.: Bubble Column Bioreactors: Comparison with Stirred Fermenters Based on Local Gas Hold-up Distribution. Paper at 6th International Conference on Gas-Liquid and Gas-Liquid-Solid Reactor Engineering, Vancouver,B.C., Canada, 17-20 August 2003. [10571] Fialová M., Vlaev S.D.: Local gas Holdup in Viscous Batches in Bubble Column Reactor. (Eng) 30th International Conference of Slovak Society of Chemical Engineering, Proceedings, p. 150, Tatranské Matliare, Slovakia, 26-30 May 2003. [10455] Paper at 11th Eur.Conf. on Mixing, Bamberg (Germany), Oct. 2003 S.D. Vlaev, P. Staykov, Application of RANS modeling for drag-velocity analysis of blade hydrodynamics in stirred tanks Proc. 2003 South-Eastern Europe Fluent Users’ Group Meeting (Istanbul, Turkey, Oct. 16/17, 2003), pp. 9-26. (5) Performing research collaboration with partners in and out of the country The group has numerous partners in the country and abroad. Among them, we have joint research with companies BALKANPHARMA (formerly Antibiotic Co. in Razgrad) and recently BioVet Co. (Peshtera) and national Universities (Technical University in Sofia and Russe Polytechnics College of Biotechnology in Razgrad). The international aspect of our collaboration includes industry and academia. ● Department of Engineering and Analytical Science (formerly chemical Engineering department) of Manchester University University of Science and Technology (Prof. Reg Mann) ● Research Institute of Chemical and Process Engineering (Veszprem, Hungary) (Prof. E. Nagy, Dr. Cs. Sisak) – 20 years ● Institute of Chemical Process Fundamentals at the Czech Academy of Sciences in Prague (Czech Republic) – (Dr. Zahradnik, Dr. Fialova)since more than 20 years ● Polytech’Lille, University of Science and Technology of Lille (Prof. Nikov), France – since 8 years ● University Bretagne Sud, Lorient, France (Prof. Hadjiev)– since 2007 ● Aristotel University in Thessaloniki, Greece (Prof. Mavros) ● Simtec (FLUENT) Company in Greece (Dr. Faltsi) ● Techmix Co. (Brno, Czech Republic) (Dr. Seichter) ● Hannover University (Prof. Schuegerl) ● National Technical University of Athens in Greece (Prof. E. Koukios) ● University of Chemical Engineering (Veszprem, Hungary)- (Prof. Gyula Marton) (6) Membership in international organizations and activities The following memberships in International Bodies have been realized: Delegacy in the European Federation of Chemical Engineering Working Parties: Two working parties have been involved in these activities by the membership of Prof. S.D. Vlaev: European Working Party on Mixing (since 1993) and European Working Party on CAPE (Computer Aided Process Engineering) – since 2007 (see http://www.efce.cz/wpm) (7) Performing activities related to research and application of scientific results The following applied projects have been realized in recent years by orders from academic and industrial partners ● Design and know how of impeller mixing fermenter as physical model for bioreaction studies (22 000 euro) ● Design and testing of a ‘shock-cooling’ system (5000 euro) ● Separation and diffusion units – concept and prototypes of study (2200 euro) ● Starting in 1995, the group has been consulting pharmaceutical companies in BG: Antibiotic Company in Razgrad and since 2004 our experience covered also BioVet Company in Peshtera. LABORATORY STAFF 1. 2. 3. 4. 5. 6. 7. 8. 9. The following scientists and specialists are involved in the Laboratory staff: Prof. Asen Ivanov Anastasov, PhD, D.Sc., Head; Prof. Serafim Dimitrov Vlaev, PhD, D.Sc.; Assoc. Prof. Valentin Asenov Nikolov, PhD, D.Sc.; Assoc. Prof. Vera Vladimirova Mircheva, PhD; Assist. Prof. Minka Dimitrova Valeva, PhD; Assist. Prof. Martin Stefanov Martinov; Assist. Prof. Evgenia Krasimova Vasileva; Eng. Radka Nikolova Popova; Eng. Dragomir Yotov Yotov.