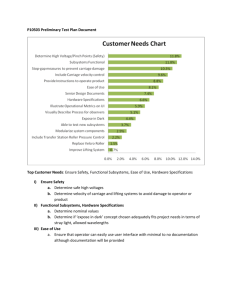

Preliminary Test Plan

advertisement

P10503 Preliminary Test Plan Document Top Customer Needs: Ensure Safety, Functional Subsystems, Carriage Velocity Control, Ease Of Use, Hardware Specifications I) Ensure Safety, Carriage Velocity Control a. Determine safe high voltages b. Determine velocity of carriage and lifting systems to avoid damage to operator or product II) Functional Subsystems, Hardware Specifications a. Determine nominal values b. Determine if ‘expose in dark’ concept chosen adequately fits project needs in terms of stray light, allowed wavelengths III) Ease Of Use a. Ensure that operator can easily use user interface with minimal to no documentation although documentation will be provided Test Plans to meet above Needs: I) Perform Experiment (generally for testing mechanical parts/wiring) Sample of an experiment: EXPERIMENT PERFORMED BY: Jeff Robble PROBLEM: After DAQ hook-up, both paper feed and transfer drum would activate simulataneously. Reason why is what needs to be found out by this experiment. HYPOTESIS: Possibly some wires were crossed or both paper feed/transfer drum hooked up to same relay. OBSERVATIONS: NI DAQ 6602 PFI36 / CTR0 out (pin 5) - paper feed control PFI32 / CTR1 out (pin 9) - transfer drum control When both controls hooked from DAQ to respective relays the following behaviors are observed: 1. Generating continuous pulses [EXPECTED] 2. Generating continuous pulses [EXPECTED] 3. Generating N pulses on PFI36 [NOT EXPECTED] 4. Generating N pulses on PFI32 [NOT EXPECTED] on PFI36 activates paper feed only. on PFI32 activates transfer drum only. activates both paper feed and transfer drum. activates both paper feed and transfer drum. When the transfer drum control is disconnected the following behaviors are observed: 1. Generating [EXPECTED] 2. Generating 3. Generating 4. Generating continuous pulses on PFI36 activates paper feed only. continuous pulses on PFI32 does nothing. [EXPECTED] N pulses on PFI36 activates paper feed only. [EXPECTED] N pulses on PFI32 activates paper feed only. [NOT EXPECTED] When the paper feed control is disconnected the following behaviors are observed: 1. Generating 2. Generating [EXPECTED] 3. Generating 4. Generating EXPLANATION: continuous pulses on PFI36 does nothing. [EXPECTED] continuous pulses on PFI32 activates transfer drum only. N pulses on PFI36 activates transfer drum only. [NOT EXPECTED] N pulses on PFI32 activates transfer drum only. [EXPECTED] Page 3-25 of the NI DAQ 6602 Manual shows a table of counter pairs: CTR0 CTR2 CTR4 CTR6 <-> <-> <-> <-> CTR1 CTR3 CTR5 CTR7 "This pairing allows some counter signals to connect to signals on the other counter." The NI website (http://digital.ni.com/public.nsf/allkb/485201B647950BF886257537006CEB89#case 3) explains: "Generating a finite pulse train and another counter task on the same device in LabVIEW with NI-DAQmx. For any device which uses the STCII chip (CompactDAQ, E and M Series) a finite pulse train generation reserves both counters. When performing a finite pulse train generation, one counter generates the pulse train, and the other counter generates a pulse that acts as a gate for the first counter. If you change the pulse train to generate continuously or only generate one pulse, you can run two counter tasks at the same time without error." In other words, generating finite pulses on CTR0 uses CTR1 as a gate which also generates pulses, and vice-versa. This is why the transfer drum and paper feed are both activated when either is controlled using N pulse generation. As a side note, the 6602 DAQ is only capable of operating two counters at a time (whether for acquiring or generating signals, or both). Thus, if the DAQ is instructed to perform N pulse generation that is all it can do because it uses two counters. SOLUTION: Use non-paired counters or use continuous pulse generation on each counter in a pair. Also look into purchasing another counter/timer DAQ card for access to more counters (Jeff: “not necessary at this time”). II) Use built-in i/o system (generally for safety, wiring, and determining nominal values) On user interface, there is the ability to set pre-defined values for controllable variables in the xerographic system such as velocities, bias, etc. These values can be stored in separate input .ini files and the results of running the system under these settings can be saved in output files through the user interface as well. Sample of an input .ini file: [Charging Station Parameters] PC Velocity Across Coronode (mm/s)=110 Coronode Bias (v)=-650 Grid Bias (v)=-650 [Exposure Station Parameters] Expose Time (s)=2 [Developer Station Parameters] PC Velocity Across Developer (mm/s)=110 Toner Bias (v)=-525 [Pre-Transfer Station Parameters] PC Velocity Across Pre-Transfer LEDs (mm/s)=110 [Transfer Station Parameters] PC Velocity Across Transfer Drum (mm/s)=110 Number of Transfer Drum Rotations=3 Transfer Bias (v)=2000 Transfer Drum Velocity (mm/s)=110 Sample of an output .csv (excel) file: (Note: only a small portion of output shown here because it is generally very large. Time (s) PC Velocity (mm/s) 0.1 34.272 0.2 84.481 0.3 110.772 0.4 110.772 0.5 110.772 0.6 110.772 0.7 110.772 0.8 110.772 0.9 110.772 1 110.772 1.1 110.772 1.2 110.772 1.3 110.772 1.4 110.772 1.5 110.772 1.6 110.772 1.7 110.772 1.8 110.772 1.9 110.772 2 110.772 2.1 110.772 2.2 110.772 2.3 110.772 2.4 110.772 2.5 110.772 2.6 110.772 2.7 110.772 2.8 110.772 2.9 110.772 3 110.772 3.1 110.772 3.2 110.772 3.3 110.772 3.4 110.772 3.5 110.772 3.6 0 3.7 0 Proposed Excel Macro Output: 120 PC Velocity (mm/s) 100 80 60 40 20 0 0 0.5 1 1.5 2 Time (sec) 2.5 3 3.5 4 Starting Point Values for General Testing (getting toner on paper) For the purposes of this general experiment, we will be using the ranges of values given in the engineering specs (for the settings that can be controlled): Subsystem Charging Charging Charging Charging Charging Charging Exposure Exposure Exposure Exposure Exposure Exposure Development Development Development Development Development Development Development Development Development Development Pre-Transfer Erase Pre-Transfer Erase Pre-Transfer Erase Pre-Transfer Erase Pre-Transfer Erase Parameter Photoreceptor Velocity Coronode Current Grid Voltage Spacing Stray Light Final Voltage Lamp Intensity Expsore time Spacing Stray Light Charged Voltage Exposed Voltage Bias AC Voltage AC Duty Cycle Mass on roll Sleeve speed Donor speed Stray Light Photoreceptor Velocity Exposed Voltage Developed Mass Lamp Intensity Spacing Charged Voltage Photoreceptor Velocity Erased Voltage Recommended Range Subsystem Output? Units Controllable? mm/s Y 80-120 N μA V mm erg V Y Y Y Y Y 1800 -650 1-2 Minimize -650 N N N N Y erg s mm erg Y Y Y Y 1-2 2 <0.5 Minimize N N N N V Y -650 N V V kV Y Y Y -150 -525 1 Y N N % mg/cm2 mm/s mm/s erg Y Y Y Y Y 50 30 130 130 Minimize N N N N N mm/s Y 100 N V Y -150 N mg/cm2 Y 0.5 Y erg Y 4-5 N mm Y 25 N V Y -650 N mm/s Y 100 N V Y -50 Y Transfer Transfer Transfer Transfer Transfer Transfer Transfer Transfer Transfer Intermediate Roll Bias Photoreceptor Velocity Intermediate Roll Velocity Intermediate Roll Normal Force Developed Mass Transfer Roll Bias Transfer Roll Normal Force Transferred Mass on Interm. Roll Transferred Mass V Y 2000 N mm/s Y 100 N mm/s Y 100 N g/mm Y 700 N mg/cm2 Y 0.5 N V Y -2000 N g/mm Y 700 N mg/cm2 Y 0.45 N mg/cm2 Y 0.45 Y The purpose of performing this experiment is to first see if toner particles get on paper, and then once that is achieved, performing this experiment repeatedly afterwards will be used to determine the nominal value to achieve maximum quality of the image on paper. Focused Needs: Hardware Specifications, Safety, Carriage Velocity Control Testing the Quality of Enclosure Design: This type of experiment will require two runs: one with our enclosure on and lights on with controllable values as close to nominal as we can get at that time, and one with the lights turned off (to ensure optimal lighting sightings). We will then use the ESVMs to determine the voltage after each of the first two stations and see if there is either a statistically significant difference between the two and/or patterns among the resulting readings in order to quantitatively measure the image quality both with the enclosure and with the lights off. Other metrics that can be used to gauge image quality are the mass of resulting toner on paper and line width of the image on paper. Focused Needs: Functional Subsystems, Hardware Specifications Determining Safety Limits of High Voltage Settings/Controls & Velocity of Carriage: Given the engineering specs to guide our preliminary voltage and velocity settings, we will further test the limits concerning safety issues by finding out the highest value(s) for each control that an operator would ever need to set. Then starting from safer/lower values and building up iteratively we would basically stress test the system to determine how high a voltage or how high a velocity a user should be able to set which would then translate to hard-coded restrictions in the LabView component of the project. Focused Needs: Hardware Specifications, Ensure Safety, Carriage Velocity Control Determining Optimal Photoreceptor Charge: By varying coronode current (uA) and grid voltage (-V) through power supply controls either on hardware side or through LabView once we integrate the system with the new DAQ, we can attempt to narrow down values for the optimal photoreceptor charge/voltage after it passes over the coronode that lends itself the best towards maximum image quality. We will use the ESVM placed at the end of the charge station in order to measure the resulting voltage. As per our preliminary engineering specs, we will begin testing with current set to 1800 uA and grid voltage at -650V and assess from there. Focused Needs: Hardware Specifications Optimizing Outputs of Photoreceptor Discharge: By varying the time the photoreceptor carriage passes over the exposure station (seconds) and intensity of exposure lamps (ergs), we can attempt to narrow down values for the optimal photoreceptor discharge/exposed voltage for our system. The ESVM placed after the exposure station will be used to measure the resulting voltage. Our initial setting for exposure time of the photoreceptor is two seconds and 1-2 ergs for lamp intensity and we will iterate from there towards optimal exposure time. Focused Needs: Hardware Specifications Optimizing Photoreceptor Erase Voltage: (***Contingent on obtaining another ESVM) If we are able to get another ESVM to place after the pre-charge station, we will be able to start optimizing the photoreceptor erase voltage (-V) through varying the relevant controls which are pretransfer lamp intensity (ergs) and distance between the lamp and the photoreceptor (mm). The initial values for this testing will be 4-5 ergs for the lamp intensity and 25mm for the distance between the lamp and the photoreceptor when it passes over it. Focused Needs: Hardware Specifications Usability Testing: The interface should be useable by anyone of various different backgrounds and educational levels and interests. As such, usability tests should be performed iteratively on our LabView interface by having different people that don’t have any direct xerography experience to use a functioning version of the project. Afterwards they will be surveyed and asked what they found difficult or what they liked. This feedback will feed into future iterations of our front end and possibly back end of LabView. Focused Needs: Ease of Use