WJEC GCSE Design and Technology

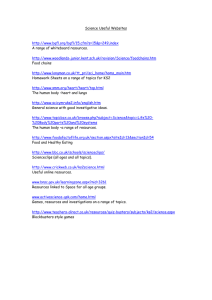

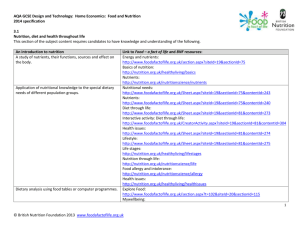

advertisement

WJEC GCSE Design and Technology (Food) 2014 linear specification – English centres only Welsh centres can choose between the Linear and Unitised specifications. The content of the Unitised and Linear specifications are exactly the same. 2 Content This part of the specification is concerned with the process of designing. This will start with an initial problem and conclude with a proposed solution giving due consideration to the issues that can and should influence the outcome. Developing, planning and communicating ideas Link to Food – a fact of life and BNF resources: Candidates should be taught to: (a) develop and use design briefs and detailed specifications; Food product development: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=566 Understand the difference between design brief and design specification. Analyse and clarify a design brief. Identify essential criteria for inclusion in a design specification. Use a specification to help develop a design. Use a design brief and design specification for evaluation. Use existing products as a source of ideas. (b) consider issues that affect their research, designing and Food product development: planning; http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=566 Use different research strategies to find information. Consider the needs and values of a range of users. Appreciate the economic costs involved. Consider issues of sustainability. Consider moral, social, environmental and cultural influences. Take into account relevant safety legislation. Prioritise and summarise research material. Recognise the potential of new technologies. Consider marketing and advertising. (c) be flexible and adaptable in responding to changing circumstances and new opportunities; Food product development: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=566 Recognise that there is a range of possible ways forward when designing and making. (d) generate, develop, model and communicate design proposals; Food product development: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=566 1 Use a variety of graphic techniques to communicate ideas clearly. Use ICT to communicate ideas clearly. Use appropriate modelling techniques to develop proposals. Develop designs in a progressive way. Communicate final design proposals in an appropriate form and level of detail. (e) design for manufacturing in quantity; Consider how products are designed to facilitate manufacturing in quantity. (f) plan work schedules effectively; Produce a realistic schedule of work. Recognise critical points and constraints. (g) match materials and components with tools, equipment and processes, taking account of critical dimensions and tolerances when deciding how to manufacture the product; ICT: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=320 CAD and CAM: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=321 Food product development http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=566 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Food product development http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=566 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Select and justify the materials, components, tools, equipment and processes needed for successful manufacture. Product analysis This part of the specification is about knowing how to analyse a product. This specification provides the opportunity for candidates, through Food to develop a wider understanding of how products are designed and made. Product analysis Link to Food – a fact of life and BNF resources: Candidates should be taught to carry out a detailed analysis of a product addressing the following aspects: (a) the probable specification for the product; Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 (b) the aesthetic appeal of the product; Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 (c) the function and/or purpose of the product; Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 (d) quality issues relating to the product; Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 2 (e) the size data of the product; (f) the safety considerations of the product with reference to the end user; (g) the materials used in the manufacture of the product; (h) the scale of manufacture used to make the product; (i) the commercial processes used to make and assemble the product; (j) safety considerations for making the product; (k) sustainability and environmental issues. Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability Sustainability and legislative issues This part of the specification is about knowing that sustainability and environmental issues, legislation and standards affect and influence designing and manufacturing choices and decisions and use this information in their own designing and making. The specification requires candidates to develop a understanding of sustainability and environmental issues and to be able to use their understanding to guide and assist their decision making during designing in their focus area. Candidates will have to be taught to look at the world we live in and to consider the needs of future generations and will need to consider how, as designers and manufacturers, they can minimise their environmental impact and also to show in their work how we can have a more sustainable future. Sustainability in Design and Technology Link to Food – a fact of life and BNF resources: Candidates should be taught to: (a) recognise why sustainability issues and environmental issues Farming: are important; http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 3 (b) consider sustainability issues and environmental issues when designing and manufacturing; (c) recognise and take account of social, economic and environmental responsibility in designing and making products; (d) understanding and use of SIX R's of sustainability, that is: rethink reuse recycle repair reduce refuse. (e) understand that sustainable designing is more than using recycled or recyclable materials to manufacture their products. It is about the total impact that the process of designing and making has on the environment; (f) carry out a "Life Cycle Analysis" to determine the environmental impact of a product. Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Lifestyle: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=81&contentId=275 Healthy sustainable diets: http://www.nutrition.org.uk/nutritionscience/sustainability 4 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Legislative Issues in Design and Technology This specification requires candidates to develop an understanding of legislative issues and standards as they affect their designing and making in their chosen focus area and to be able to use the understanding they have gained to guide and assist their decision making during designing. Legislative Issues in Design and Technology Link to Food – a fact of life and BNF resources: Candidates should be taught to: (a) know about the work of the British Standards Institution Food processing: (BSI) and how it is related to the Committee for European http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Standardisation (CEN) and the International Standards Organisation (ISO); (b) know how standards are produced, what they are for and Food processing: how products that reach the standards are marked; http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 (c) know about and apply the current Standards applicable to Food packaging and labelling Food products: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=568 Food and labelling facts Packaging of food; http://nutrition.org.uk/nutritionscience/foodfacts Additives; Labelling. Other designers/practitioners This part of the specification is about knowing about and understanding the work of professional designers and/or professional practitioners within the world of Design and Technology. Other designers/practitioners Link to Food – a fact of life and BNF resources: Candidates should be taught to recognise the influence of two Designers/ Practitioners in the world of Design and Technology with respect to: (a) the range of work that each of the Designers/Practitioners have produced over time; (b) how to identify the work of each of the Designers/Practitioners; (c) the innovations and/or new ideas that two Designers/Practitioners have introduced over time; (d) the influence that each of the two Designers/Practitioners has had on the world of Design and Technology. Each Focus Area will specify two Designers/Practitioners for each examination year and the awarding body will review the 5 two Designers/Practitioners each year. Centres will be informed of the details of each of the Designers/Practitioners two years before the examination to be taken. Commercial manufacturing practices In this section candidates should develop an understanding of methods of production used in commercial practice as well as different forms of equipment used. Commercial manufacturing practices Link to Food – a fact of life and BNF resources: Candidates should be taught to (a) understand how products are manufactured in quantity; Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 One-off, batch, repetitive flow, continual flow, mass production. Be aware that different quantities, materials and manufacturing methods are appropriate to each. Identify advantages and disadvantages of the different manufacturing methods. Appreciate the importance of safety and hygiene procedures whilst products are undergoing manufacture Understand JIT and how it is used in the food industry (b) appreciate the use of industrial equipment during the Food processing: production of food products; http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Computerized scales, bench or floor standing mixers, mandolin, depositors, deck/travelling/rotary rack oven, gyro – blast chillers, date stamping, metal detectors, cutters. Have an awareness of an industrial production line in operation noting the use of CAM, the use of sensors / gauges which control the weighing of raw materials, temperature, time, the speed of mixing, flow, depositing etc. Identify advantages of the use of industrial equipment to the manufacturer. Recognize how their own products produced in the school environment would be reproduced in industry. (c) have an understanding of scaling up formulas and the need Food processing: for parameters and tolerances; http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 6 Small scale testing through to large scale production. Importance of accuracy. (d) where relevant, within the school environment simulate food production and assembly lines to produce batches of simple products, for example bakewell tarts; Work in teams. Plan and designate tasks. Produce and work to a specification. Evaluate the process. (e) appreciate the use of data logging during the production of food products. For example to monitor time, temperature, volume of mixtures etc. as part of the control and feedback system process; (f) develop and use different kinds of specifications as used in the food manufacturing industry; Product specification. Manufacturing specification. Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=109 Materials and components In this section candidates are expected to know about the characteristics, properties and availability of a wide variety of food materials and to be aware of technological developments within the food industry. Candidates should be encouraged to apply their knowledge and understanding when designing and making food products. Materials and components Candidates should be taught to (a) know how raw materials/components can be cut, shaped and formed to specific tolerances; Vegetables/fruits cut and prepared to specific sizes/shapes as specification. Vegetables moulded to form tops on pies e.g. piped potato on Shepard’s pie. Pastry mixtures combined to certain consistencies and rolled to specific thicknesses. Yeast mixtures shaped and formed to specified measurements and components e.g. pizza bases. Egg mixtures e.g. meringues shaped using appropriate Link to Food – a fact of life and BNF resources: Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Cooking: http://www.foodafactoflife.org.uk/section.aspx?t=109&siteId=19&sectionId=108 Cook club: http://www.foodafactoflife.org.uk/section.aspx?t=108&siteId=20&sectionId=82 Food life skills: http://www.foodafactoflife.org.uk/section.aspx?t=82&siteId=20&sectionId=80 7 equipment to form decoration/toppings on other components. Dairy products e.g. cream whisked to form certain consistency and shaped by means of piping. (b) know how materials can be combined and processed to create more useful properties, and how these materials are used in industry; Candidates should have a working knowledge of the properties of a wide range of food materials and components. Select materials and components, combining where appropriate, to improve, for example the nutritional content, appearance, texture, taste and aroma of a food product. Identify the five main nutrients including saturated/polyunsaturated fats, non-starch polysaccharide (N.S.P.) Understand their functions and rich food sources. Use methods of nutritional analysis to calculate the nutritive content of a product or portion size. Select food materials in relation to specific nutritional requirement, for example a food product suitable for a diabetic, coeliac or an allergy sufferer or a product enriched with calcium. (c) physical, chemical and composite characteristics; Candidates should be able to explain and justify the selection of food materials used in the making of food products and be aware of food groupings/classification. Cereals – gelatinisation, dextrinisation, bulking, gluten formation Flours -the different types, characteristics of them, suitable uses e.g. strong flour in bread production. Fats/oils the different types, properties such as shortening, lubrication, aeration, plasticity and emulsification. The uses of them in different mixtures like cakes, pastry. Sugars, different types and properties, uses e.g. Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Cooking: http://www.foodafactoflife.org.uk/section.aspx?t=109&siteId=19&sectionId=108 Cook club: http://www.foodafactoflife.org.uk/section.aspx?t=108&siteId=20&sectionId=82 Food life skills: http://www.foodafactoflife.org.uk/section.aspx?t=82&siteId=20&sectionId=80 Explore Food: http://www.foodafactoflife.org.uk/section.aspx?t=80&siteId=20&sectionId=115 Energy and nutrients: http://www.foodafactoflife.org.uk/section.aspx?t=80&siteId=20&sectionId=115 Diet and health: http://www.foodafactoflife.org.uk/section.aspx?t=75&siteId=19&sectionId=81 Healthy eating: http://www.nutrition.org.uk/healthyliving/healthyeating Basics of nutrition: http://www.nutrition.org.uk/healthyliving/basics Nutrients: http://www.nutrition.org.uk/nutritionscience/nutrients Food allergy and intolerances: http://www.nutrition.org.uk/nutritionscience/allergy Functional properties of food: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=83&contentId=306 Interactive activity – The functional properties of food: http://www.foodafactoflife.org.uk/CreatorActivity.aspx?siteId=19&sectionId=83&contentId= 310 Food cards: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=317 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 8 preservation, caramelisation, moisture retention, aeration, crystallisation. Fish/meat/milk/eggs – coagulation, gelatinisation, foam formation and denaturation. Fruit/vegetables - enzymic browning, pectin formation Explain structures in food products, e.g. colloidal structures, sols, emulsions, gels, suspensions, foams. Devise and apply test procedures to check the appropriateness of the physical property required, e.g. the viscosity of a sauce. (d) sensory characteristics; Candidates should be able to describe how foods are selected in a product because they impart a desired organoleptic quality, including flavour, aroma, mouthfeel and visual qualities (colour, surface texture, shape). (e) to be aware of changes that occur in food materials as a result of various factors; The surroundings (environmental factors) such as heat, cold, light, air cause changes to food, e.g. enzymic browning. The principals behind microbial activity and the various methods used to extend shelf life and prolong quality for example; the application of heat e.g. canning, pasteurisation, UHT, sterilisation. The removal of heat; chilling, freezing, freeze drying. The effect of different processing on nutrient content, physical and sensory properties. The use and function of chemicals such as antioxidants, preservatives, emulsifiers and stabilisers in food products; use of vinegar, sugar, salt in preservation methods; advantages and disadvantages of additives to the manufacture and retailer; use of modified/controlled atmosphere packaging; awareness of ready meals and cook-chill products. (f) to be aware of the importance of healthy eating; Look at the benefits of health eating with respect to food Sensory evaluation: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=83&contentId=308 Interactive activity – The senses and food: http://www.foodafactoflife.org.uk/CreatorActivity.aspx?siteId=19&sectionId=83&contentId= 379 Functional properties of food: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=83&contentId=306 Interactive activities – Functional properties of food: http://www.foodafactoflife.org.uk/CreatorActivity.aspx?siteId=19&sectionId=83&contentId= 310 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Food packaging and labelling: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=568 Food and labelling facts: http://nutrition.org.uk/nutritionscience/foodfacts Energy and nutrients: http://www.foodafactoflife.org.uk/section.aspx?t=109&siteId=19&sectionId=75 9 intake, diet and exercise. The balance of proteins, fats and carbohydrates in a diet. Be aware of the role of sugars, starches, salts and fibres in a healthy diet. Question the role of snack foods in an every day diet. Compare and question a snack food diet against a healthy diet. Healthy eating and current advice i.e. five a day fruit and vegetables. (g) the importance of new technologies to create new materials with specific properties; Be aware of the use of biological processes and the role of additives for different levels of production - the role of enzymes/yeast/micro-organisms in food products e.g. cheese, yoghurt, bread, soya sauce. Consider developments in alternative protein products, meat analogues e.g. TVP, quorn and tofu; modified starches, fat replacers, functional foods e.g. cholesterol lowering spreads, pre and probiotic products; fortified foods e.g. calcium in orange juice, fatty acids in eggs, sweeteners, and gelling agents; encapsulation technology; more useful properties of packaging materials. Have an awareness of the increasing role of nanotechnology in food processing e.g. nanoencapsulated flavour enhancers, nanotubes and nonoparticles as gelation and viscosifying agents, the use of nanocapsule infusions to replace a meat's cholesterol. The use of nanomaterials in foods for increased availability of nutrients and the Diet and health: http://www.foodafactoflife.org.uk/section.aspx?t=75&siteId=19&sectionId=81 Video podcasts – macronutrients: http://www.foodafactoflife.org.uk/VideoActivity.aspx?siteId=20&sectionId=84&contentId=5 07 Video podcasts – Exploring energy: http://www.foodafactoflife.org.uk/VideoActivity.aspx?siteId=20&sectionId=84&contentId=5 13 Healthy eating: http://nutrition.org.uk/healthyliving/healthyeating Basics of nutrition: http://nutrition.org.uk/healthyliving/basics Nutrients: http://nutrition.org.uk/nutritionscience/nutrients An active lifestyle: http://nutrition.org.uk/healthyliving/lifestyle Energy and energy balance: http://nutrition.org.uk/nutritionscience/energy Smart foods: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=368 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Functional foods: http://nutrition.org.uk/nutritionscience/foodfacts/functional-foods Nanotechnology: http://nutrition.org.uk/nutritionscience/nanotechnology 10 possibility of increased health benefits. (h) the function of packaging and the types and properties of packaging material; The purpose of packaging. Select and use appropriate packaging materials for during the designing of their products according to the specification e.g. lightweight, moisture proof, low cost, printable, recyclable, rigid, considering the needs of the consumer, manufacturer and retailer. Understand the variety of materials involved in commercial food packaging: Paper and boards; Plastics; Metals: aluminium ( foil, tins, containers), steel (Tins Etc); Glass. (i) product labelling; Identify key information found on products. (j) how materials are prepared for manufacture and how premanufactured standard components are used; Differentiate between primary processing e.g. milling of flour and secondary processing e.g. the production of bread and composite processing e.g. lasagne production. Be aware of the processing of cereals including pasta, rice, extruded products, fruit, vegetables, milk based products, meat, fish, eggs and consider the advantages and disadvantages of the selected process. Food packaging and labelling: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=568 Food packaging and labelling http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=568 Farming: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=92&contentId=569 Food and labelling facts: http://nutrition.org.uk/nutritionscience/foodfacts Food and farming: http://www.foodafactoflife.org.uk/section.aspx?t=81&siteId=19&sectionId=92 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 The use and availability of pre-manufactured standard components. Consider the advantages and disadvantages to the manufacturer and the consumer of using items such as: 11 Frozen pastry and prepared pastry cases. Pizza bases. Decoration products such as icing, marzipan. Soups. Pie fillings. (k) a variety of finishing processes, and why they are important for aesthetic and functional reasons; Select and justify appropriate applied finishes to enhance the appearance of food products e.g. glazing, marinating, decorative techniques including use of colour. Draw comparisons between finish on manufactured products and self finishing e.g. consistency, quality, thickness etc. (l) that to achieve the optimum use of materials and components, they need to take into account the relationships between material, form and intended manufacturing processes; Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Food cards: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=317 Food manufacturing: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Candidates should be able to explain the use of different processes and combination/proportion of food materials in a range of product areas: Breads. Pastries. Cakes. Biscuits. Sauces. Cold desserts. Soups. Pasta. Salads and dressings. Tools, equipment and making In this section candidates are expected to develop their awareness of basic tools and equipment pieces, as well as develop their confidence in using them. Candidates are expected to experience making a wide range of products that allow them to apply their developing skills and previous relevant knowledge. Tools, equipment and making Link to Food – a fact of life and BNF resources: 12 Candidates should be taught to Observe safety procedures in the working environment. Appreciate and apply relevant aspects of the Health and Safety at Work Act 1978. Appreciate and apply relevant aspects of Food Safety Act 1990. Understand the importance of safe and hygienic practices in the preparation, cooking, transportation and storage of foodstuffs. Identify main types of micro-organisms and reasons for food poisoning. Select and use the correct materials, hand tools and equipment for a wide range of practical tasks. Know how to set up, use and adjust mechanical, hand and electrical equipment safely. Know how to carry out appropriate risk assessments. (a) candidates should experience tools, equipment and ingredients; Weighing and measuring items – spring balance/digital scales and measuring jugs. Preparation pieces e.g. vegetable peelers and knives, graters, mixing bowls and spoons for combining ingredients. Making items – rolling pins, cutters, electric whisks/hand whisks, blenders both stand alone and hand held. Use equipment items safely; hob, grill, oven, microwave, woks, food processors and pasta machines. Food hygiene and safety: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=83&contentId=307 Interactive activity – Food hygiene: http://www.foodafactoflife.org.uk/CreatorActivity.aspx?siteId=19&sectionId=83&contentId= 311 Cooking: http://www.foodafactoflife.org.uk/section.aspx?t=85&siteId=19&sectionId=108 Cook club: http://www.foodafactoflife.org.uk/section.aspx?siteId=20&sectionId=82 Food life skills: http://www.foodafactoflife.org.uk/section.aspx?t=82&siteId=20&sectionId=80 Cooking: http://www.foodafactoflife.org.uk/section.aspx?t=85&siteId=19&sectionId=108 Cook club: http://www.foodafactoflife.org.uk/section.aspx?siteId=20&sectionId=82 Food life skills: http://www.foodafactoflife.org.uk/section.aspx?t=82&siteId=20&sectionId=80 Through the application of practical skills and processes candidates should be taught about the making of: Bread – combining ingredients and suitable variations, kneading, shaping, proving and baking. Pastries: Shortcrust using the rubbing method. Rough puff and or flaky using rolling and folding to make layers. Choux using saucepan method. 13 Cakes: Rubbing in method. All in one method. Creaming method. Whisking. Melting. Decoration techniques, piping, butter icing, glace icing, run outs, feathering. Biscuits: Rubbing in method. Creaming method. Sandwiching/layering. Accuracy when cutting shapes. Decoration techniques. Sauces and methods of thickening:Roux sauce. All in one. Blended. Puree. Reduction. Desserts: including the use of gelatine, foams, creamed, rubbed in and whisked mixtures. Fruit and or vegetable based products stir fry, soups, sauces, salads. Cereal based dishes risotto, pasta based dishes, ravioli, lasagne. (b) use a range of industrial applications when working with familiar materials and processes; Reflect, where possible, industrial manufacturing processes for example combining of ingredients and kneading yeast dough’s using mixers. Combining ingredients for cake making (rubbing in method) using food processors, for creaming method using hand held electric whisks and mixers. Use processes and techniques that save time and repetition and provide accuracy e.g. food processors. (c) manufacture single products and products in quantity, Cooking: http://www.foodafactoflife.org.uk/section.aspx?t=85&siteId=19&sectionId=108 Cook club: http://www.foodafactoflife.org.uk/section.aspx?siteId=20&sectionId=82 Food life skills: http://www.foodafactoflife.org.uk/section.aspx?t=82&siteId=20&sectionId=80 Food manufacturing: 14 applying quality assurance techniques; Develop and use a manufacturing specification which takes into account food materials, methods to be used, and details of processing and machinery types. Develop and use a manufacturing plan which identifies a logical, staged order of work. and the number of operations needed to make the product. Manipulate foods in appropriate amounts considering ratio / proportion to achieve the desired outcome in relation to: nutritional content, volume, palatability, appearance, texture, strength, shelf life, economic factors. Apply safety and hygiene procedures to different types of food production. Correct storage of raw materials. Accurate weighing and measuring. Quality checks to ensure correct viscosity/consistency of raw dough/mixtures. Accurate timing and temperatures. The use of visual checks to measure products portion size, degree of browning, overall appearance and amount of rising. The use of different sensory tests to measure products against their specification. Also check for suitability and improvements/modifications. Explain safety checks required during food production and storage. Make use of the HACCP method. Provide a detailed, objective evaluation of the final outcome. http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=109&contentId=567 Food hygiene and safety: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=83&contentId=307 Interactive activity – Food hygiene: http://www.foodafactoflife.org.uk/CreatorActivity.aspx?siteId=19&sectionId=83&contentId= 311 Cooking: http://www.foodafactoflife.org.uk/section.aspx?t=85&siteId=19&sectionId=108 Cook club: http://www.foodafactoflife.org.uk/section.aspx?siteId=20&sectionId=82 Food life skills: http://www.foodafactoflife.org.uk/section.aspx?t=82&siteId=20&sectionId=80 ICT/CAD/CAM Food technology candidates are expected to use computer systems with appropriate software and hardware to support their designing and manufacturing. They need to be able to use ICT systems to assist research for problem solving, to process text and to analyse and present data. ICT/CAD/CAM Candidates should be taught to Use appropriate software to create documents; word, Link to Food – a fact of life and BNF resources: CAD and CAM: 15 publisher, power point etc Check spelling and grammar when using software. Use appropriate software to create spreadsheets to calculate costing, portion size and ratio of ingredients. Construct star profiles/diagrams to indicate the sensory characteristics of a product. Store versions of work/recipes for later use in development, refinement and /or modification. To edit/ research information to aid the design process. Accessing data from a variety of sources on the internet. Cutting and pasting information from the internet. As a means of communication between people and outlets within the school environment and industry. The advantages of EPOS (Electronic points sale in supermarkets) Understand the importance of the barcode and how supermarkets are able to monitor products and collect detailed information about sales of food, stock rotation and ordering. Be aware of how ICT is used in the wider aspects of the food industry. Use CD-ROM / food industry web sites to show simulation of mass production of food products. Find out how the making of food products would differ if made by school or bench top production compared to industrial manufacture. Access any simulation software related to food technology. (a) be aware of the use of CAD; Candidates must be fully aware of the use of CAD during the designing and manufacture of food products, using either single item production, batch or volume production. They must be taught to: Understand how CAD is used in industry and can be used in food technology lessons to: Design the physical appearance of a product. http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=321 Sensory evaluation http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=329 http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=19&sectionId=83&contentId=308 Interactive activity – Sensory evaluation: http://www.foodafactoflife.org.uk/CreatorActivity.aspx?siteId=19&sectionId=83&contentId= 379 Using the website as a whole could be used for these points ICT: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=320 CAD and CAM: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=321 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=83&siteId=19&sectionId=109 Explore Food: http://www.foodafactoflife.org.uk/section.aspx?t=85&siteId=20&sectionId=115 16 Display the assembly procedure for a product. Produce packaging nets and designs. Calculate the nutritional value of a product using nutritional analysis software. Product and present sensory attribute data. Model the cost or portion size, of a single or batch of products using a spreadsheet. Calculate the expected shelf-life of some products. Be aware of the advantages and disadvantages of CAD. The appropriate use of CAD to produce flow charts. Recognise the limitations of CAD in the school environment compared to industry. The advantages and disadvantages of CAD. The appropriate use of CAD for Flow charts, packaging nets, designs and labelling. The limitations of CAD in the school environment compared to industry. (b) understand how CAM is able to produce food products and packaging; Understand that several manufacturing processes can be carried out at one time aided by a computer. Be aware that one person can supervise many operations during food manufacture. Understand that the manufacturer of food products uses a computer to control a range of production aspects for example: Weighing and measuring. The rate at which an ingredient is added. The amount and time of mixing and combining. Oven temperatures and temperature adjustment. Speed of conveyor belts. The amount of chocolate coating used on a biscuit. Appreciate the use of industrial equipment during the production of food products. Understand how CAM can be used in the school environment e.g. using pre-programmed equipment ICT: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=320 CAD and CAM: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=321 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=83&siteId=19&sectionId=109 17 (microwave oven, bread-maker) to manufacture products. Also include the use of electronic scales when weighing out ingredients for accuracy in weight tolerances. Apply an aspect of CAM used in industry when manufacturing products t the classroom environment, for example, data logging and the use of a temperature problem; record how long it takes for a product to achieve internal heating above the stated danger zone temperature. Systems and processes In this section candidates are expected to understand a systems approach, how it is organised to achieve the expected outcomes. They should be able to apply the concept of a system to the manufacturing of products. They should understand the importance of feedback in controlling systems. Systems and processes Candidates should be taught to (a) understand the concept of input, process and output and the importance of feedback in controlling systems; Be able to identify input, process and output of a system. The use of simple graphical conventions for communicating flowcharts and block diagrams for food systems. Analyse familiar products in terms of their input, process and output for example a food processor: input – select the speed, process – motor turns the gears, output – whisks/blade turns. Recognise that systems can be open-loop or closed-loop and understand the difference between the two. Recognise that systems in a block diagram format can be split into several sub-systems. Understand the importance of feedback. Describe how feedback is incorporated into a system during the manufacturing of products for example; computers monitoring the weight of fillings, or the monitoring of oven temperatures, metal detection of foreign bodies, the rate of production. Have a basic understanding of how a Central Processing Unit (CPU) operates. Link to Food – a fact of life and BNF resources: ICT: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=320 CAD and CAM: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=321 18 Have a basic understanding of how Computer Integrated Manufacture (CIM) operates. Understand the principle of flowcharts and the symbols used e.g. terminator, process and decision. (b) know that systems can be made up of several sub-systems; Appreciate complex situations leading to the system being broken down into a series of smaller sub-systems. They should also be aware of how these differ in relation to products produced within the school environment. Compile and use flow diagrams including the different stages of production in correct sequence, making economical use of energy and labour, connections with subsystems, control points and feedback systems. (c) the use of quality control and quality assurance systems used in food; Understand the process of quality assurance and how control systems are applied to ensure the final product is to the desired standard. Understand the process of quality control and the range of checks applied throughout the process of manufacture for example; visual check, organoleptic check, temperature check, weight check, micro-biological check, metal check, chemical check. ICT: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=320 CAD and CAM: http://www.foodafactoflife.org.uk/Sheet.aspx?siteId=20&sectionId=85&contentId=321 Food processing: http://www.foodafactoflife.org.uk/section.aspx?t=83&siteId=19&sectionId=109 19