Technology & Engineering Division - Office of Institutional Research

advertisement

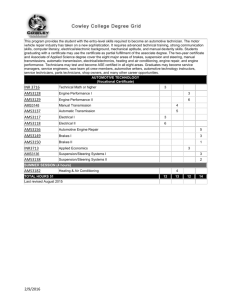

Technology & Engineering Division Automotive Technology I. Program Description A. Program Description and History Fullerton College Automotive Technology has been producing skilled automotive technicians since the first graduating class of 1958. Former students are working all over the world from Orange County to Saudi Arabia. Many have become managers, shop owners, or automobile corporation employees. Fullerton College Automotive Technology started instruction in 1956 with one instructor and four students using part of the Machine Tool building. The new (current) building was designed for two instructors, and was completed in 1960. Starting in 1967, the department employed four full-time instructors, and has for the most part continuously done so. The program became certified by the National Technician Education Foundation (NATEF), the educational arm of the National Institute for Automotive Service Excellence (ASE) in 1990. We are certified at the highest (Master) level. Recertification is required at five-year intervals. We have just completed our third recertification. The results were very positive; some areas received substantial accolades from the inspection team, and approval was received. All core classes have been developed to ASE/NATEF Standards, and course revisions are prepared to comply with these standards. The program also operated in close affiliation with the State of California Smog Referee Program. The State rents space from the department to provide a referee station for failing or specialized vehicles. This provides an opportunity for students to observe customer relations and emissions diagnostics, and also provides well-paid employment for student trainees. We see this as an important linkage with the automotive industry. All instructors, full-time and adjunct, are ASE certified; all are certified Master Technicians. B. Program Goals The major goal of the Automotive Technology program is to produce entrylevel technicians and service advisors for the automotive service and repair industry. For some students this may be their first major employment; for others this is retraining for a change of occupation due to unemployment or personal preference. The program also provides the opportunity to upgrade those already employed. Program Review 1 The program also provides numerous sections of an introductory class that serves auto-related industries, consumers, and serves as a feeder for advanced classes. This class is also transferable to four-year institutions. In order to provide the above, it is necessary to: 1. Develop and maintain contact with the automotive industry and industry groups such as ASE, Orange County Auto Dealers Association, the Automotive Service Council (AC), and Specialty Equipment Manufacturers Association (SEMA),. This provides the opportunity to maintain and improve our curriculum to accurately reflect the occupational needs of the student and the community. 2. Maintain and improve our classrooms, laboratories, and equipment to conform to industry standards. 3. Staff our program with faculty members who are experienced, certified, and who can provide quality instruction in automotive technology C. Linkage of instructional goals and learning outcomes to program outcomes. As a result of participation in the program, students will have the following areas of skills and knowledge: 1. Understand and apply personal and professional requirements of the automotive workplace, e.g.: Professional appearance, positive attitude, punctuality, problem solving, appropriate behavior, communication and teamwork, honesty, integrity, and ethical behavior, freedom from alcohol and drugs, and continuous learning. 2. Understanding of technology of the automobile, and apply this understanding in diagnosing and repairing the automobile. 3. Ability to use service manuals and computer databases in diagnosing and repairing the automobile. 4. Ability to diagnose problems and make necessary repair recommendations, explain the problem and recommendations to the customer, and summarize diagnosis and repair recommendations in writing. 5. Ability to perform repairs to manufacturer’s standard. D. Program Degrees and Certificates Offered: The requirements for degrees and certificates are listed in the Fullerton College Catalog. Program Review 2 A.S. Degree in Automotive Technology. Vocational Certificates: 1. 2. 3. 4. 5. 6. 7. 8. 9. Automotive Chassis Specialist Automotive Maintenance Specialist Automotive Management Automotive Service Advisor Automotive Technology Automatic Transmission Specialist Fabrication Specialist Light Repair Specialist Manual Drive Train Specialist E. Program Degrees and Certificate Requirements 1. The Automotive Technology Certificate Program requires the completion of units chosen from required courses. A minimum grade of “C” is required in each course taken. At lease one half of the units towards the certificate must be completed at Fullerton College. (See Attached Golden Rod Form) 2. The Associate in Science Degree Requirements are: (See Spring Class Schedule for requirements.) AUTOMOTIVE TECHNOLOGY Associate in Science Degree Curriculum leads to the Associate in Science Degree and employment in automotive specialties: tune-up and electrical, engine repair, automatic transmissions, brakes and suspensions, power trains, air conditioning, service writing, parts control. Complete 24 or more units from the following list: Units Any Automotive course MACH 116 F Machine Tools 2 TECH 081 F Technical Mathematics I 3 WELD 121AF Introduction to Welding 2 Automatic Transmission Specialist Certificate The Automatic Transmission Specialist Certificate program requires a total of 18 units in required courses. This program will help the student become employed as an automatic transmission specialist. Required Courses (18 units) Units Program Review 3 AUTO 050 F Automotive Specialty Practice 2 AUTO 065 F Automotive Electrical & Electronic Systems 5 AUTO 084 F Automatic Transmission 8 AUTO 086 F Automatic Transmission Fundamentals 3 Automotive Chassis Specialist Certificate The Automotive Chassis Specialist Certificate program requires a total of 14 units of which 14 units are in required courses. Required Courses (14 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 065 F Automotive Electrical & Electronic Systems 4 AUTO 083 F Brake and Suspension Systems Repair 8 Total Units: 14 Automotive Maintenance Specialist Certificate The Automotive Maintenance Specialist Certificate program requires a total of 16 units of which 16 units are in required courses. This program will help the student become employed as an entry level automotive maintenance specialist. Required Courses (17 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 065 F Automotive Electrical & Electronic Systems 4 AUTO 082 F Engine Performance/Driveability 8 AUTO 089 F Automotive Air Conditioning 3 Total Units: 17 Automotive Management Certificate The Automotive Management Certificate program leads to entry-level employment in dealerships, service establishments, or automotive centers. The certificate also assists students who will be starting self-employment in the auto industry. The emphasis is on automotive management rather than automotive repair. The Automotive Management Certificate program requires a total of 50 units of which 45 units are in required courses. An additional 5 units must be chosen from restricted electives listed below. Required Courses (45 units) Units AUTO 055 F Automotive Business Management 5 AUTO 060 F Automotive Powertrains 5 AUTO 065 F Automotive Electrical & Electronic Systems 5 AUTO 081 F Engine Rebuilding and Repair 8 AUTO 082 F Engine Performance and Drivability 8 AUTO 083 F Brake and Suspension Systems Repair 8 AUTO 084 F Automatic Transmissions 8 Program Review 4 AUTO 086 F Automatic Transmission Fundamentals 3 AUTO 089 F Automotive Air Conditioning 4 COUN 141 F Career Exploration 1 Restricted Electives (5 units) Units AUTO 051 F Internship in Automotive 1-4 BUS 151 F Business Mathematics 3 BUS 180 F Small Business Management 3 BUS 266 F Human Relations in Business 3 CIS 100 F Intro to Personal Computers 3 ET 100 F Intro to Environmental Technology 3 MACH 116 F Machine Tools 2 TECH 081 F Technical Mathematics I 3 Total Units: 50 Automotive Service Advisor Certificate The Automotive Service Advisor Certificate program requires a total of 16 units of which 11 units are in required courses. An additional 5 units must be chosen from the restricted units listed below. Required Courses (11 units) Units AUTO 055 F Automotive Business Management 5 BUS 180 F Small Business Management 3 CIS 100 F Intro to Personal Computers 3 Restricted Electives (5 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 131 F Automotive Fundamentals 4 BUS 266 F Human Relations in Business 3 Total Units: 16 Automotive Technology Certificate The Automotive Technology Certificate program requires a total of 32 units of which 28 units are in required courses. An additional 4 units must be chosen from the restricted units listed below. A minimum grade of “C” is required in each course taken. At least half the units toward the certificate must be taken at Fullerton College. Required Courses (28 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 060 F Automotive Powertrains 6 AUTO 065 F Automotive Electrical & Electronic Systems 4 AUTO 070 F Engine Reconditioning 7 AUTO 072 F Automotive Engine Performance 7 Program Review 5 AUTO 073 F Brake Systems Repair 7 AUTO 081 F Engine Rebuilding and Repair 8 AUTO 082 F Engine Performance and Drivability 8 AUTO 083 F Brake and Suspension Systems Repair 8 AUTO 084 F Automatic Transmissions 8 AUTO 086 F Automatic Transmission Fundamentals 3 AUTO 088 F Fuel Systems and Adv. Drivability Diagnosis 5 AUTO 089 F Automotive Air Conditioning 3 AUTO 090 F Emission Control Sys. and Adv. Diagnosis 6 AUTO 091 F Cylinder Head Repair 4 Restricted Electives (4 units) Units MACH 116 F Machine Tools 2 DRAF 070 F Blueprint Reading for the Metal Trades 2 WELD 121AF Introduction to Welding 2 WELD 121BF Fundamentals of Inert Gas Welding 2 Total Units: 32 Emission Control Specialist Certificate The Emission Control Specialist Certificate program requires a total of 16 units of which 16 units are in required courses. This program will help the student become employed as an auto motive emissions testing and repair specialist and provide opportunities to study toward National Institute of Automotive Excellence (ASE) certification and toward the State of California emission control license examination. Required Courses (16 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 082 F Engine Performance and Drivability 8 AUTO 090 F Emission Control Sys. and Adv. Diagnosis 6 Total Units: 16 Engine Performance Specialist Certificate The Engine Performance Specialist Certificate program requires a total of 16 units of which all units are in required courses. This provides preparation for advanced entry level employment as an automotive technician who will specialize in engine performance diagnosis and drivability problem repair, and will also qualify the student to take the National Institute for Automotive Service Excellence (ASE) A6 Electrical and Electronics and A8 Engine Performance examinations. Required Courses (16 units) Units AUTO 065 F Automotive Electrical & Electronic Systems 4 AUTO 082 F Engine Performance and Drivability 8 Program Review 6 AUTO 088 F Fuel Systems and Adv. Drivability Diagnosis 4 Total Units: 16 Fabrication Specialist Certificate The Fabrication Specialist Certificate program requires a total of 17 units of which 17 units are required courses. This certification will be an important first step toward gaining employment in the automotive fabrication area where it is necessary to design and manufacture parts as well as repair them. Required Courses (17 units) Units AUTO 055 F Automotive Business Management 5 AUTO 065 F Automotive Electrical & Electronic Systems 4 DRAF 171 F Fundamentals of Drafting 2 MACH 116 F Machine Tools 2 WELD 121AF Introduction to Welding 2 WELD 121BF Fundamentals of Inert Gas Welding 2 Total Units: 17 Light Repair Specialist Certificate The Light Repair Specialist Certificate program requires a total of 16 units of which 16 are in required courses. Completion of this program will help the graduate find entry level employment as an automotive light repair specialist. Required Courses (16 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 065 F Automotive Electrical & Electronic Systems 4 AUTO 073 F Brake Systems Repair 7 AUTO 089 F Automotive Air Conditioning 3 Total Units: 16 Manual Drive Train Specialist Certificate The Manual Drive Train Specialist program requires a total of 12 units of which all units are in required courses. This program will help provide skills necessary to obtain employment in the area of manual transmission, transaxle, driveline, and axle repair. Students will study the material necessary to take the National Institute for Automotive Service Excellence (ASE) examinations in Manual Drive Train Axle repair and in Auto motive Electricity and Electronics. Required Courses (12 units) Units AUTO 050 F Automotive Specialty Practice 2 AUTO 060 F Automotive Powertrains 6 AUTO 065 F Automotive Electrical & Electronic Systems 4 Program Review 7 Total Units: 12 F. Program Courses Offered 1. Auto 131 Automotive Fundaments 2. Auto 050 Automotive Specialty Practice 3. Auto 051 Internship in Automotive 4. Auto 055 Automotive Business Management 5. Auto 060 Automotive Powertrains 6. Auto 065 Automotive Electrical and Electronic Systems 7. Auto 070 Engine Reconditioning 8. Auto 072 Automotive Engine Performance 9. Auto 073 Brake Systems Repair 10. Auto 081 Engine Rebuilding and Repair 11. Auto 082 Automotive Engine Performance and Drivability 12. Auto 083 Brake and Suspension Systems Repair 13. Auto 084 Automatic Transmissions 14. Auto 086 Automatic Transmission Fundamentals 15. Auto 088 Fuel Systems and Advanced Drivability Diagnosis 16. Auto 089 Automotive Air Condition 17. Auto 090 Emission Control Systems and Advance Diagnosis 18. Auto 091 Cylinder Head Repair 19. Auto 096 Performance Technology G. Program Faculty 1. 2. 3. 4. 5. 6. Robert Berryhill Robert Gordon David Lopez Victor Miranda John Farley, Shop Manager Three additional Adjunct Faculty H. Program Advisory Committee 1. William Brown, Brown Sun Technical 2. Dallas Hazleton, Retired FC Automotive Instructor 3. Keith Jones, Fullerton College 4. John O’Cain, Air Resources Board 5. Greg Ramirez, Referee 6. Mike Russell, NOCROP, Sonora High School 7. Daniel Waltman, Bureau of Auto Repair 8. Alan Vester, Fairway Ford (Service Manager/Shop Foreman) 9. Fred Vinton, Bureau of Auto Repair 10. Robert (Bob) Wenzlaff, Retired FC Automotive Instructor/Coordinator 11. Charles Zepeda, Auto Instructor; NOCROP, Sunny Hills High School Instructor Program Review 8 II. Program Key Performance Indicators A. (Attached data sheet institutional research to the report) III. Program Outcomes Analysis A. Report on Status of Previous Review Outcomes Analysis Since the last review, we have brought up to full staffing with four-full time instructors. Additional courses and certificates have been added to the program to meet needs of our students and employers. The facility has been improved with the addition of three hoists, three-foot high floor hoists and one additional work station under the roof which was part of the addition. Various equipment items have been added or replaced old equipment. Classrooms have been equipment with PowerPoint/video/DVD projection equipment which is also linked with on-line computer capabilities that greatly facilitates instruction ease and efficiency, new Hunter alignment equipment DPS-400 and rack, boring bar, and Scan tools updated. The NATEF recertification team noted that in order to train students for the current market, some of our diagnostic equipment needs to be replaced with current equipment as used by local shops, typically Windows computer based machines. A very serious need still exists for additional classroom space which will incorporate classrooms dedicated to the subject matter. At present, only one actual classroom exists for eight areas of instruction. Each presentation must have all teaching materials brought in before class, then moved out after the class (while the incoming class is being set up). Additional storage space is needed for instructional equipment and student projects. If three to four additional classrooms were added with supporting instructional equipment, this would allow a comprehensive supply of appropriate teaching materials to facilitate instruction in each classroom, and students learning could be improved. B. Summary of Data – Recommend Evaluation of Data Program Access: The 2008-2009 data provided shows 232 auto majors with a total enrollment of 558 students. FC Auto Tech intends to maintain or improve this enrollment by improving contact with feeder high schools, ROP’s and employers. A Program Review 9 videotape presentation has been made to facilitate presentations and to leave with high school auto teachers and counselors. We believe that program access is greatly facilitated by the relatively large number of courses or classes (listed as 14 courses and 37 total classes in the Health Indicators Sheet). Classrooms are nearly 100% booked during both day and evening hours. Program Resources: Department relies upon funding from lottery, base budget, referee program, and occasional augmentations from instructional equipment money. Program Success: Students typically enter the Auto Tech program to obtain skills for employment. Many leave for employment as soon as they become employable at an entry level. Although there is no hard data on the level of employment, our advisory committee, some of who employ our students, estimates placement at 95%. With high employment demand, few students stay to finish degree or certificate requirements. C. Identification of Trends The automotive industry is becoming increasingly technical. Nearly all functions are electronic or electronically controlled by on-board computers, which are also used in self-diagnostics. Emissions are more closely monitored than in the past, and the necessity to pass emissions on a biannual basis causes a need for precision maintenance and repair. New diagnostic equipment is required to address these issues. The personal computer is taking a larger role in auto repair and in training students for their occupation. Diagnostic equipment is increasingly important. It must be noted, however, that hands-on work, beginning on school-owned lab units, and progressing to customer cars, is the focus of our program, and computer diagnostics serve to help the student technician accomplish this goal. Classroom presentation methods are changing here as elsewhere. As mentioned previously, our classroom is equipped with PowerPoint/video projection. As a follow-up, we expect that some instruction is computer – based with access during class time to CD-ROM based training. D. Immediate Short-Term Plans Program Review 10 Implementing the following suggestions will help to support our curriculum: Budget for new equipment: As identified by the NATEF review team, acquire new diagnostic equipment for the increasingly electronic automobile. Add storage space for better organization of teaching aids and student projects. Investigate and acquire updated classroom presentation materials, both CDROM based and video, as available. Upgrade present student computer work stations and increase the number of computers available for study and researching diagnostic problems, with accompanying software. Acquire additional alignment equipment with hoist due to increased alignment demands on newer vehicles. Continue emphasizing the need for staff to engage in ongoing development of their technical knowledge by attending conferences and technical seminar/workshops, and self-study. Increase research of grant funds to help in this capacity, working closely with the Career Technical Education Counselor. E. Long-Term Plans A larger facility will allow us to do a more effective job and also attract manufacturer’s training programs. We have tried to accomplish this in the past, but lack of space always led to the location of their programs at another community college. The remodeling of the existing building will increase capability and capacity through new construction incorporating dedicated classroom/labs with adequate demonstrations space, and needed teaching materials, both demonstration and units and student lab units. These classrooms should have adjacent storage space for teaching aids and space for instructors to develop specialized teaching materials, whether presentation material or specialized laboratory demonstration materials. The facility will need proper heating, ventilation, and air conditioning, as well as an additional classroom. Parking for customer cars, donated vehicles, and vehicles under repair will also need to be increased possibly using three-high stacked storage lifts for vehicles. F. Request for Resources Market the program to appropriate audiences. This activity has been initiated at the Division Level in a very minor way recently. Funding at the campus Program Review 11 level for marketing vocational programs is an important priority. High school campus visitations; Career Day information booth; Professional activities such as the National Hot Rod Association (NHRA); College Career Days. As with other Technology and Engineering Divisions, quality instruction is dependent on current equipment and software. Replacement of equipment continues to be an important priority, as is continuing software annual upgrading for both auto computer lab and diagnostic machine software. Software upgrades consume an increasing larger part of our limited budget every year. Staff upgrading on a continuing basis will be emphasized. Travel funding for attending automotive conferences and technical programs is a high priority. At the present time, due to California State budget constraints, the travel funds are limited or non-existent. Obtaining additional lab units for student practice can sometimes be accomplished through automobile manufacturers. We intend to continue making use of our linkages with the automotive industry. Our recent NATEF recertification will help in this endeavor. Grant funding when it addresses our needs will also be utilized. The greatest need is for a new facility with dedicated classrooms and supporting equipment. State Referee money is still viable at this time and the money is used to purchase needed equipment as the budget will allow, but the State Referee program could be eliminated. Delco Remy has expressed interest in continuing to use our facility to train and update technicians in the industry on electrical components. In return they donate various instructional equipment and new technical material. IV. Strengths, Weaknesses, Opportunities, and Trends A. Strengths 1. All the instructors have extensive industry experience, all are Master Technicians, and have high level degrees. 2. The department receives strong support from the Division Dean and the College Administration. 3. The Automotive Program has equipment that is at or exceeds in most cases industry standards. 4. High enrollment Program Review 12 B. Weakness 1. The facility is small as compared to most of the automotive programs in the State. We are the second smallest. 2. We have no room for growth. 3. We have no major manufacturers support. i.e. Ford, Honda, Toyota, etc. 4. We lack classroom space to make all subject areas dedicated classrooms. i.e. a classroom for Brakes and Suspension, Electrical, Engine Performance, etc. 5. Lack of funding for development of Hybrid vehicles class but with the possibility of a grant or possibly the VTEA funds we may be able to implement this class. C. Trends 1. Automotive industry for decades has had a high demand for highly skilled technicians. 2. There has been a shortage of trained technicians. 3. There has been an interest in performing your own repairs on a vehicle with no real interest in becoming a technician. 4. Strong Retention D. Opportunities 1. The economy has effected an interest in becoming an automotive technician because of high layoffs. 2. The closing of thousands of dealerships throughout the United States has not affected the repair industry. 3. Skilled technicians typically can move from one repair facility to another. 4. To develop Hybrid class. Currently have training and material available. 5. The parts industry is strong and there is a demand for parts personnel. Program Review 13