Thin-walled open sections

advertisement

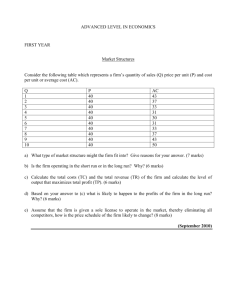

s SCHOOL OF COMPUTING, ENGINEERING AND MATHEMATICS SEMESTER 2 EXAMINATIONS 2011/2012 MATERIALS ENGINEERING ME334 DR. E.M. SAZHINA Time allowed: TWO hours Answer: Any FOUR questions out of SIX Each question carries 25 marks Items permitted: Any approved calculator Items supplied: Formulae sheet (attached: pages 9 - 11) Marks for part of the questions are indicated in brackets ( ) May/June 2012 Page 1 of 11 Question 1 A steel vessel is under cyclic loading of high internal pressure. A fluctuating tensile stress varies in a cyclic manner from zero to 290 MPa. The vessel is made of steel alloy with a value of yield stress equal to 360 MPa. The results of fatigue testing for the steel alloy, with a zero static component, are shown below in Figure Q1: S-N curve Stress amplitude (MPa) 450 400 350 300 250 200 150 100 2 3 4 5 6 7 8 9 Log N Figure Q1 (a) Describe the setup of the rotating-bending beam experiment for fatigue testing, and the concept of an S - N plot. (5 marks) (b) Explain the influence of corrosion on the fatigue limit for a ferrous specimen. (5 marks) (c) Estimate the fatigue limit of the pressurised vessel using the Soderberg criterion for cyclic stress with a non-zero static component. (5 marks) (d) Describe the concept of auto-frettage, and its benefits for increasing fatigue life of a pressurised vessel. (10 marks) ME334 (2011/2012) Page 2 of 11 Question 2 A pressurised vessel is designed as a cylinder under internal pressure of 50 MPa with inner radius R1 = 250 mm and outer radius R2 = 330 mm. The external pressure is normal atmospheric. The yield stress (elastic limit) of the material is 300 MPa. 500 mm 660 mm Figure Q2 (a) Calculate the factor of safety at the critical point under the thick-walled cylinder approximation. Briefly explain your selection of the critical point location under Tresca failure theory. (10 marks) (b) The pressure vessel is redesigned as a cylinder of the same dimensions under internal pressure of 50 MPa, whilst an external pressure of 20 MPa is applied by shrinking a compound cylinder onto it. The inner radius is R1 = 250 mm and the outer radius R2 = 330 mm. Calculate the factor of safety at the critical point under Tresca failure theory. (10 marks) (c) Explain the benefits of the compound-cylinder technique for enhancing the safety of the working cylinder. (5 marks) ME334 (2011/2012) Page 3 of 11 Question 3 Stress analysis at a point in the exhaust pipe of a micro-light aircraft gave the following system of stresses: s x = 28 MPa s y =150 MPa s z = 62 MPa xy yz zx 0 (a) Describe the concept of octahedral planes and stresses and calculate the octahedral normal and shear stresses for this stress system. (5 marks) (b) Explain the derivation of the von Mises failure theory using the concept of ‘octahedral shear stress’ and calculate the factor of safety by von Mises failure criteria. Take the yield stress to be equal to 240 MPa. (10 marks) (c) Describe the concepts of creep and creep testing and how the Larson-Miller method is used for predicting the long-term creep behaviour from data obtained over relatively short periods of time. Calculate the time to rupture (in days) for steel at a temperature of 1000 K if the Larson-Miller parameter is equal to 23 x 103 under applied stress. Take C = 20. (10 marks) ME334 (2011/2012) Page 4 of 11 Question 4 (a) A torque T = 75 Nm is applied to a thin-walled steel tube having a rectangular cross-section 12 mm by 72 mm. The tube is of constant wall thickness of 4 mm as shown in Figure Q4a. All dimensions are given relative to the median line in the wall of the tube. Explain the concept of shear flow and calculate the shear stress in the tube wall. 12 mm 72 mm Figure Q4a: Cross-section of a thin-walled tube under torsion (5 marks) (b) Sketch Mohr’s circle of stress for an element in the tube wall assuming a pure shear state of stress. Calculate the factor of safety by Tresca failure theory assuming that the yield stress for the tube material is equal to 180 MPa. (10 marks) (c) A torque T = 75 Nm is applied to a solid bar having a rectangular cross-section as shown in Figure Q4b. Indicate the location of maximal stress and calculate its value. t = 12 mm b = 72 mm Figure Q4b: Rectangular section of a solid bar under torsion (10 marks) ME334 (2011/2012) Page 5 of 11 Question 5 An aircraft component is made of an alloy with plane strain fracture toughness K Ic = 50 MPa m . A non-destructive test has established that the maximal internal crack half-length is a = 3.0 mm. (a) Explain the concepts of stress intensity factor and the plane strain fracture toughness in Mode I as a material property. (10 marks) (b) Calculate the stress intensity factor under an applied tensile stress of 200 MPa assuming that Y = 1.2. Will the component fracture? (5 marks) (c) A large steel bar under tension is drilled with a transverse circular hole of diameter 20 mm as shown in Figure Q5a. The nominal tensile stress is 30 MPa. Two smaller relief holes are drilled in close proximity to the original hole as shown in Figure Q5b. Calculate the maximal stress in both cases, by assuming that the stress distribution can be approximated by an elliptical hole with a = 20 mm and b = 30 mm following the notations of Figure Q5b. Explain this method of stress relief by using the following expression: a b m o (1 2 ) 2a 2a 2b Fa tig ue lim it 30 MPa Figure Q5a 30 MPa Figure Q5b (10 marks) ME334 (2011/2012) Page 6 of 11 Question 6 (a) The data from a series of Charpy impact tests on ductile cast iron are shown in Figure Q6a. Explain the setup of the Charpy test and estimate the ductile-tobrittle transition temperature from the plot. Figure Q6a (10 marks) (b) A large sheet of glass is under a tensile stress of 6 MPa. It is known that there is a central slit in the middle of the glass sheet as shown in Figure Q6b. Determine the maximum crack length that is possible without fracture. Assume that the modulus of elasticity E is 60 GPa and that the specific surface energy GC = 0.5 Jm-2 for the glass. 2a Figure 6b (5 marks) Question 6 continues on the next page ME334 (2011/2012) Page 7 of 11 Question 6 (continued) (c) A cylindrical vessel has an internal diameter D1 = 180 mm. The outer diameter is D2 = 204 mm as shown in Figure Q6c: D2 = 204 mm D1 = 180 mm Fig. Q6c The internal pressure in the vessel is 3 MPa. The vessel is made of a steel alloy with a yield stress of 210 MPa and a plane strain fracture toughness given by: K Ic = 50 MPa m Calculate the upper limit for tensile stress in the vessel walls for the leak-beforebreak (LBB) condition and compare it with the yield stress. Assume that Y = 1.1 for this geometry. (10 marks) ME334 (2011/2012) Page 8 of 11 ME334 MATERIALS ENGINEERING – LIST OF EQUATIONS All the symbols have their usual meaning Axisymmetric stress systems Stresses in thick-walled cylinders under pressure: H A B r2 L A ; ; r A B r2 The constants A, B are given by P1 R12 P2 R22 A ( R22 R12 ) B P1 P2 R12 R22 2 2 ( R2 R1 ) Thin-walled cylinders under internal pressure: H pR1 t Bending: L y pR1 2t where R1 is the inner radius M E I R I y 2 dA Second moment of area: A For a rectangle about N.A.: For a circle about diameter: bd 3 12 r4 I 4 I Torsion of circular sections: T Ip r ; 0 < r < R where τ is the shear stress produced by torque T, I p is the polar second moment of area Solid circular shaft: Ip Hollow circular shaft: I p ME334 (2011/2012) R4 2 2 R 4 o Ri4 Page 9 of 11 Torsion of non-circular sections Thin-walled closed sections: T 2At Thin-walled open sections: max T k1bt 2 1.5 1.75 2.0 2.5 3.0 4.0 6.0 8.0 10.0 b/t 1.0 k1 0.208 0.231 0.239 0.246 0.258 0.267 0.282 0.299 0.307 0.313 0.333 Fracture mechanics. Griffith’s equation: a 2 EGc 2 Stress intensity factor K Y a Creep Larson-Miller parameter (K-h): P1 T (C log t r ) Fatigue n n n1 n2 3 ... i .. 1 N1 N 2 N 3 Ni Soderberg criteria a N (1 m ) yield Miner’s law Failure theories Factor of safety SF= yield / E ; Tresca failure criterion: E 1 3 where 1 2 3 Von Mises failure criterion: E 0.5 ( 1 2 ) 2 ( 2 3 ) 2 ( 3 1 ) 2 Principal stresses in plane stress (2D case): 1 ,2 x y 2 ME334 (2011/2012) 1 2 ( x y )2 4 xy2 Page 10 of 11 Three-dimensional stress and strain analysis Normal and shear stresses on the octahedral planes oct 1 2 3 3 ME334 (2011/2012) oct 1 3 1 2 2 2 3 2 3 1 2 Page 11 of 11