EA102 - Lord Grey School

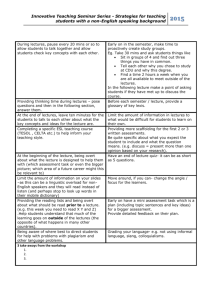

advertisement

Unit/Module Code: Module Title: EA102 PROPERTIES OF MATERIALS Faculty of Engineering and Applied Science 1 Basic information Department responsible for the module Programme Timetable Credit Value Pre-requisites Co-requisites Module Lecturer(s) Contact Formal Contact Hours Private Study Hours Coursework Last Approved Last Revision Referral Policy External Examiner Course Web Site SES All courses in School of Engineering Sciences, ISVR Semester 1 1 Unit (10 CATS points) None None Dr PAS Reed, Lanchester 4045, ext.23763, email: pasr1@soton.ac.uk 24 lectures, 3 laboratory/examples classes and 5 supervisions (28.5 hrs) 71.5 10% September 2002 21/8/2002 As Faculty progression rules Professor Raghu Raghunathan BE, PhD, DSc, CEng, FRAeS, MAIAA, School of Aeronautical Engineering, The Queen's University of Belfast Blackboard, Course code MT161 2 Description 2.1 Aims The aims of this module are to: 2.2 develop a basic understanding of the properties of materials and hence provide a sound rationale for selection and use of materials in engineering. Objectives (planned learning outcomes) Knowledge and understanding Having successfully completed the module, you will be able to demonstrate knowledge and understanding of: the physical origins of properties of materials and their control. the ways in which properties of materials govern their selection in engineering applications. Intellectual skills Having successfully completed the module, you will be able to: demonstrate how defects in atomic structure affect mechanical properties relate the kinetics of a number of apparently different materials processes to the same underlying process (diffusion) explain how strengthening mechanisms occur on the microstructural scale and how this is related to the bulk mechanical properties we require in engineering structures apply the use of phase diagrams to explain the development of microstructure and hence how alloys are designed analyse failure problems and apply the correct fracture mechanics approach show how non-metallic bonding leads to very different properties (e.g. ceramics and polymers) Practical skills [where appropriate] Having successfully completed the module, you will be able to: conduct tensile and fracture toughness tests assess fractography General transferable (key) skills Having successfully completed the module, you will be able to: solve problems (i.e. link appropriate analytical approaches to engineering problems) discuss problem solving approaches in small groups 2.3 Topics Covered Materials in Engineering (1 lecture): Metals, ceramics, polymers and composites. Fundamentals (5 lectures): Atomic structure and interatomic bonding; electrons, atoms and molecules; the Periodic table; bonding and interatomic forces; the structure of crystalline solids; basic structures, unit cells; holes and lattices; imperfections in solids; point, linear, planar and volume defects; diffusion. Mechanical properties (3 lectures): Stress and strain; elasticity; tensile properties; hardness; strengthening mechanisms; recovery, recrystallisation and grain growth. Microstructures and their control (5 lectures) : Phase diagrams; thermal processing; precipitation hardening Failure of metals (3 lectures) : Failure; fracture, brittle and ductile failure; impact and fracture toughness; fatigue; creep. Non metallic materials and their properties (4 lectures): Ceramics and glasses; main classes, properties and uses; polymers; basic structures and bonding; polymerisation; cross linking; thermoplastics and thermosets; composites; main classes, properties and uses. Materials in engineering applications (3 lectures): Case studies. 2.4 Teaching and learning activities Teaching methods include 24 lectures (two 45 minute sessions per week) which develop the themes described in this module. Skeleton notes (orange book) are given out at the start of the course, which means you only have to note down the key points during the lecture, but still have a full set of notes to work from. 2 supervised examples classes (with web-based materials) these are based in computing clusters and last for ~ 2.5-3 hours. You will work through the problems in your green course-book and have access to a detailed web package, incorporating additional material that supplements the lectures, including animations and self-test multiple choice questions (MCQs). An academic supervisor and postgraduate tutor-demonstrators will be on hand throughout the session to discuss the problems set out in your green workbook and to mark and correct your work. You must be signed out by one of these members of staff to confirm you have attended and satisfactorily completed these classes as part of your formal coursework requirement 1 laboratory class on mechanical testing (including MCQ assessment). You will carry out a number of mechanical tests, pool your results and write up the lab as a class in your green course-book during the laboratory session (~ 2.5-3 hours). After a class-room discussion of the results (led by an academic supervisor) there will be a closed notes 15 minute MCQ test, which will be marked in the class and goes towards your formal coursework requirement. This together with the supervised examples classes will define 10% of your overall mark 5 supervisions (small group work in groups of 12-20). There is a set of supervision questions on each of the five main sections of the course in the green coursework book. You should attempt each supervision sheet before the relevant supervision, and the questions and solutions to them will be discussed with the whole class, led by an academic supervisor Learning activities include Web-based self-paced MCQ throughout course Self-study of web-based materials after introduction in supervised examples classes Access to past paper exam question bank 2.5 Methods of assessment (summative assessment) Assessment method Number 2-hour written closed-book 1 examination Coursework: supervised 3 completion of both examples classes and the laboratory class and performance in closed-book MCQ at the end of laboratory session 2.6 % contribution to final mark 90% 10% Feedback and student support during module study (formative assessment) A series of supervision problems are attempted in small groups, and the solutions are discussed with the supervisor. (MCQs) are available electronically from a pool of quizzes on all aspects of the course, and allow you to independently test and retest your own performance. Supervised examples classes using web-based materials (e.g. animations) and problems are worked through with tutors and the students’ working is checked/corrected in their course-book. The formal MCQ at the end of the laboratory is marked at the end of the session giving direct feedback. Past papers and some model answers are available on the web site 2.7 Relationship between the teaching, learning and assessment methods and the planned learning outcomes The laboratory sessions, supervision classes and examples classes are intended to strengthen understanding and application of the lecture material. The examinations test understanding of the underlying concepts and links between the five main subject areas. Examination questions are structured to test problem solving skills and application of knowledge. 3 Resources Specify the resources required to run the module, and means of provision Core Text (include number in library or URL) (inc ISBN) William D. Callister, Materials Science and Engineering, an Introduction, (Sixth edition), Wiley, 2002 ISBN 0-471-32013-7 Background Texts (include number in library or URL) (inc ISBN) Other Library Support required Staff Requirements (including teaching assistants) Supervisors and Lab supervisors: need 5 academic staff (also help with exam marking) Tutor-demonstrators: need 2 Mechanical testing Tutor-demonstrators for each of 14 half-day sessions and 3 examples class tutors (crystallography and phase diagrams) for each of 15 half-day sessions Teaching space, layout and equipment required Physics A or similar sized lecture theatre required (192 students 2001-2002) Laboratory space and equipment required Engineering Materials Laboratories needed for 14 half-day sessions Computer requirements Computing cluster for 48 students needed for 15 half-day sessions Software Requirements Web browser Others