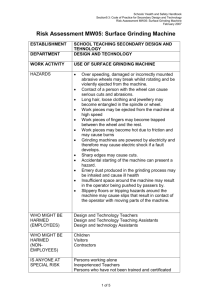

TECHNICAL SPECIFICATION OF “TOOL & CUTTER GRINDER”

advertisement

PROCESS AND PRODUCT DEVELOPMENT CENTRE FOUNDRY NAGAR, AGRA TENDER DOCUMENT FOR SET OF MACHINE TOOLS TENDER COST: Rs. 3000.00 LAST DATE OF SUBMISSION: DATE OF OPENING: VENUE: EMD: Rs. 50,000.00 10.11.2010 12.11.2010 AT 3: 00 P.M P.P.D.C., AGRA (TENDERS TO SUBMIT THIS DOCUMENT DULY FILLED IN & AUTHENTICATED) TECHNICAL SPECIFICATION OF “CYLINDRICAL GRINDING MACHINE” QTY : 01 No. PPDC Requirement 1. Max Grinding length 2. Max height of centres 3. Max swing over bed 4. Max grinding dia 5. Table feed range 6. Max table swivel 7. Hyd. Power motor 8. Workhead swivel either side 9. Work Spindle speed 10. Work spindle speeds range 11. Work head motor 12. Taper in work spindle 13. Taper in tail spindle 14. To & fro swivel of wheel head at base 15. Traverse movement of wheel head max 16. Size of grinding wheel 17. Min. dia of worm out wheel 18. RPM of grinding wheel 19. Wheel head motor 20. Min & max. dia of internal Supplier offer 600 mm 130 mm 259 mm 100 mm 0.5/1-5m/min 7+3 =10 1.1 kw 900 towards wheel head & 300 away from wheel head 4 65, 140, 205, 300 rpm 0.37 kw MT-3 MT-3 600 towards wheel head & 450 towards tail stock 125 mm 354x40x127 mm 205 mm 1750/2000 2.2 kw 12 to 40 mm Deviation if any grinding wheel 21. Min & max. dia of hole for grinding 22. Motor for internal attachment 23 coolant pump motor 24 Gross weight with packing 25. Standard equipment 26. Optional equipments 18 to 50 mm 0.75 kw 0.07 kw 2400 kg. Approx. Coolant pump fitted on tank, one, dressing tool holder, grinding wheel fitted on grease gun, oil can, dead centers, key spanners, wheel flange fitted on Internal grinding attachment, 4 jaw chuck 6”, 3 point steady rest, 2 point steady rest, radius truing device, balancing stand, balancing mandrel spare wheel flange. TECHNICAL SPECIFICATION OF “SHAPING MACHINE” PPDC Requirement 1. Capacity 2. Length of ram stroke 3. Length of ram 4. Length of width ram bearing 5. Max & min. distance from table of ram 6. Working surface of table 7. Max table travel horizontal 8. Max table travel-vertical 9. Angular movement of table on either sides 10. Max. vertical travel of tool slide 11. Max swivel of tool head 12. Dia of clutch pulley 13. Range of ram speeds 14. Stroke per minute 15. Dia of motor pulley 16. Range of table feed per stroke of ram 17. Range of tool head feed 18. Automatic Tool head feed & tool lifting 19. Power supply 20. Speed RPM 21. Main switch starter (Push button type 22. Weight (approx) 23. Standard Accessories (Hydraulic Qty: 1 no.) Supplier offer 18” 457 mm 960 mm 700 x 270 mm 360x75 mm 457x305 mm 488 mm 330 mm 60 L 60 R 152 mm 60 L 60 R 311 mm 4 16,32,64,96 70 0.220 Hand feed On order 2 HP (1.5 KW) 1440 rpm 3.5 amp. 1000 kgs. Automatic lubrication pump, swiveling vice, crank handle, motor pulley. Deviation if any 24. Extra Accessories 1. Key way cutting attachment 2. Automatic tool lifting device 3. Automatic feed to the tool slide 4. Rapid feed system with control panel 5. Allen key set 6. V- Belts 7. Screw driver 8. Electric motor & starter with fitting & wirings. 9. Spanner set 10. Oil can 11. Tool box. TECHNICAL SPECIFICATION OF “SLOTTING MACHINE” PPDC Requirement Working stroke Length of ram Vertical adjustment of ram Centre of cutting tools to col. Working surface of table Longitudinal traverse of table Bore of base Cross traverse of table Table top to ram No. of speeds Range of speeds Motor recommended RPM of motor Approx weight Gross weight with packing Standard Accessories Extra accessories Supplier offer 200 mm 560 mm 150 mm 250 mm 280 mm 250 mm 38 mm 250 mm 330 mm 2 60 – 150 mm 1.5 HP 1440 800 kgs. 950 kgs Tool holder spanner, motor pulley, V-belt guard, friction clutch, lub. pump True chuck, true chuck plate,V-belt, motor, starter QTY : 01 No. Deviation if any TECHNICAL SPECIFICATION OF “TOOL & CUTTER GRINDER” PPDC Requirement Table dimension Admit bet. Centers Longitudinal Traverse Cross Traverse Swing over table Table swivel both side Motor Head swivel clock wise/Anti clock wise Grinding head rpm T-slot width Motor power 3 phase 440 V Approximate net weight Standard equipment Optional Equipment Supplier offer 500 x 114 300 mm 250 mm 160 mm 300 mm 450 450 /450 2800 rpm 13 mm ½ HP 450 kg. Universal work head, half & full centers, universal tool rest, lathe tool grinding attachment, reamer & End mill grinding attachment. Indexing head motorized, drill point grinding attachment, radius grinding attachment, tap grinding attachment, hob grinding attachment, radius wheel turning attachment, universal vice3 way 4”, tilting table 5”x7”,milling machine vice 3”, coolant pump accessory with tank. QTY : 01 No. Deviation if any GENERAL TERMS & CONDITIONS 1. The sealed quotations superscripting tender with number, name of the item and due date should be addressed to the “The Principal Director, Process and Product Development Centre, Foundry Nagar, Agra-282 006. 2. Late tenders are liable to be rejected. 3. Tenders should be submitted in sealed bids in two separate envelopes. PART-I (a) Tender cost Rs.3,000.00 D/D in favouring “Principal Director, PPDC, Agra” (b) EMD through DD/Bank Guarantee for Rs.50,000.00 in favouring “Principal Director, PPDC, Agra” (c) Containing documents of proof in support of eligible tenderer and customer mailing address. (d) Machine printed technical leaflet. (e) Technical offer of machine. PART-II Containing commercial and price bids. These two covers should be sealed individually indicating bid details viz. Technical/Part-I or Commercial bid/Part-II and both should be put in another sealed cover superscribed with tender no. date and name of the item. The price bids (Part-II) of the parties shall be opened only after opening Part-I bid and found meeting the technical requirements as detailed. 4. Tenders should clearly indicate the minimum time required for effecting supply; the date of delivery should be strictly adhered to. Time is the essence of the contract and the centre reserves the right to levy liquidated damages @ ½% of the order value for each week of delay or part thereof subject to a maximum of 5%. The centre may at its option recover all the damages, losses and expenses resulting out of such breach of contract. Tenders should be valid for a minimum period of 90 days from the date of closing. 5. The centre reserves the right to cancel or accept or reject or postpone the procurement either fully or partly without assigning any reason thereof. 6. The centre shall issue FORM’C’ to avail concessional tax & Road Permit only. 7. The centre reserves the right to increase or decrease the quantity at the time of placing firm order. 8. The supplier shall also enclose detailed specifications for the equipment, if any with the technical bid separately. The centre reserves the right to reject the material if found substandard and not as per specification and supplier must make arrangements to replace the same with correct material at the premises of the centre, in case of rejections, immediately within a period of 15 days. The party shall bear for all costs and expenses involved in such an event. 9. The offers quoted shall be for free delivery of stores at the premises of the centre. For outstation parties, the supplies must be made on door delivery basis at the premises of the centre, freight paid. All goods liable to be damaged or deteriorated in transit must be insured, which shall be arranged by the suppliers at their own cost. 10. Payment terms : Advance payment terms are not acceptable. Payment shall be made 80% against inspection/ dispatch and balance on receipt of machine, commissioning and training at PPDC, Agra. 11. Mere participation in the tender and offering of lowest rates does not confer any right on any party for placing order on them. 12. All the disputes arising out of the contract shall be subject to Agra (UP) India Jurisdiction only. 13. Parties are required to affect supplies, commission and install the machinery/equipment/items at any place in the centre’s premises designated by the centre and extend/maintain warranty/guaranty at such places. Guarantee/Warranty commences from the date of completion of installation/commissioning and training. 14. All the matters concerned to and not covered herein above, the decision of Principal Director, PPDC, Agra shall be final and binding on the parties. 15. Commissioning/erection charges, if any should be specifically quoted separately with details of labour charges. 16. The equipment offered shall be strictly conforming to specification or better and for complete unit correct accuracies and standard. 17. PPDC, Agra will have the option to pre-inspect the machine/equipment at supplier’s work by their representative or by third party agency appointed. 18. The final inspection will however be carried out at work at PPDC, Agra. 19. Training for two persons after commissioning / installation of machine. 20. Supplier must enclose in technical bid their offer list of customer (with their full address and their purchase reference no.) to whom they have made similar supplies in the past five years. The date of supply should also be indicated. 21. The supplier should also mention the nearest service centre of the equipment/machines for servicing/repairing after commissioning. 22. The equipment should be complete in all respect. (OFFICE SEAL) (SIGNATURE OF AUTHORIZED PERSON) NAME : DESIGNATION :