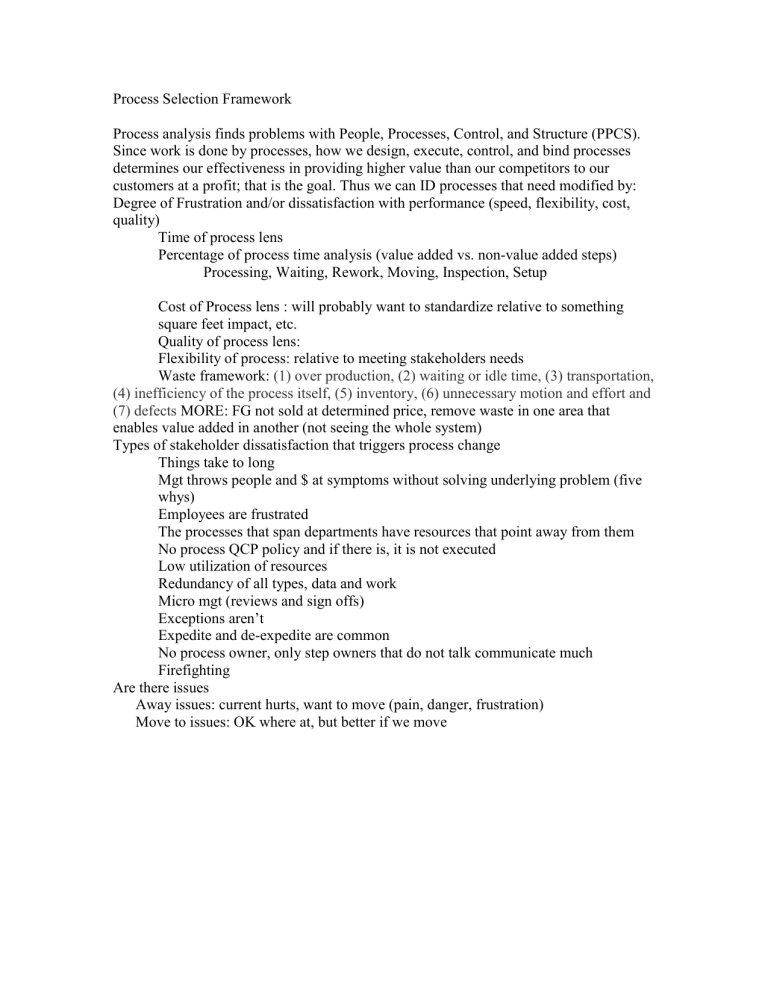

Process Selection Framework

Process Selection Framework

Process analysis finds problems with People, Processes, Control, and Structure (PPCS).

Since work is done by processes, how we design, execute, control, and bind processes determines our effectiveness in providing higher value than our competitors to our customers at a profit; that is the goal. Thus we can ID processes that need modified by:

Degree of Frustration and/or dissatisfaction with performance (speed, flexibility, cost, quality)

Time of process lens

Percentage of process time analysis (value added vs. non-value added steps)

Processing, Waiting, Rework, Moving, Inspection, Setup

Cost of Process lens : will probably want to standardize relative to something square feet impact, etc.

Quality of process lens:

Flexibility of process: relative to meeting stakeholders needs

Waste framework: (1) over production, (2) waiting or idle time, (3) transportation,

(4) inefficiency of the process itself, (5) inventory, (6) unnecessary motion and effort and

(7) defects MORE: FG not sold at determined price, remove waste in one area that enables value added in another (not seeing the whole system)

Types of stakeholder dissatisfaction that triggers process change

Things take to long

Mgt throws people and $ at symptoms without solving underlying problem (five whys)

Employees are frustrated

The processes that span departments have resources that point away from them

No process QCP policy and if there is, it is not executed

Low utilization of resources

Redundancy of all types, data and work

Micro mgt (reviews and sign offs)

Exceptions aren’t

Expedite and de-expedite are common

No process owner, only step owners that do not talk communicate much

Firefighting

Are there issues

Away issues: current hurts, want to move (pain, danger, frustration)

Move to issues: OK where at, but better if we move

![21111 PHYSICS DEPARTMENT PHY 2054 Final Exam [CJ Ch. 25{27]](http://s2.studylib.net/store/data/010449630_1-28444df8a7bd2e426431de9be2571f52-300x300.png)