L-1

advertisement

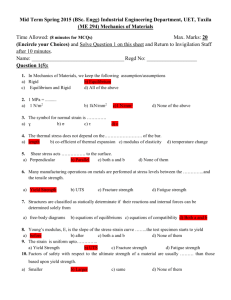

L-1 Elasticity and Plasticity When the shape or size of a body has been altered by the application of a force or a system of forces, there is usually some tendency for the body to recover its original shape or size on the removal of the force. This property of the body by virtue of which it tends to regain its original shape or size on the removal of deforming force is called elasticity. The property of the body by virtue of which it tends to retain the altered size and shape on removal of deforming forces is called plasticity. 1.2 Stress and Strain Stress is a quantity that characterizes the strength of the forces causing the deformation, on a “force per unit area” basis. The deforming force per unite area of the body is called stress. The SI unit of stress is the Pascal (abbreviated Pa, and named for the 17th century French scientist and philosopher Blaise Pascal). One Pascal equals one Newton per square meter.1 Pascal = 1Pa = 1N/m2. Strain is a quantity which describes the resulting deformation. Strain is the fractional deformation produced in a body when it is subjected to a set of deforming forces. Strain being ratio has no units. There are following three types of stress and strain (i) Tensile and compressive stress and strain (ii) Bulk stress and strain (iii) Shear stress and strain 1.2 1.3 Physics for Technologists Tensile and Compressive Stress and Strain Initial state lo F F An object in tension Tensile stress at the cross section is defined as the ratio of the force F to the cross – sectional area A. Tensile stress = F A The tensile strain of the object is equal to the fractional change in length, which is the ratio of the elongation to the original length o . Tensile strain = o o o Tensile strain is stretch per unit length Properties of Matter and Sound 1.3 Initial state lo F F l An object in compression When forces on the ends of a bar are pushes rather than pulls the bar is in compression and the stress is a compressive stress. The compressive strain of an object is defined in the same way as tensile strain, but has the apposite direction. 1.4 Bulk Stress and Strain Initial state F F F F F F An object under bulk stress Pressure plays the role of stress in a volume deformation. The force F per unit area is called the pressure P F A 1.4 Physics for Technologists Bulk stress = P , an increase in pressure. The fractional change in volume that is the ratio of the volume change V to the original volume Vo, is called as bulk strain. Bulk (volume) strain = V V0 Volume strain is the change in volume per unit volume. Shear Stress and Strain h Initial state x F11 F11 An object under shear stress Shear strain is defined as the ratio of the displacement x to the transverse dimension h Shear strain = 1.5 x h Hooke’s Law Hooke’s law states that within the elastic limit, the stress developed is directly proportional to the strain. The constant of proportionality is the elastic modulus ((or modulus of elasticity). Stress = elastic modulus (Hooke’s law) Strain Properties of Matter and Sound 1.5 Plastic range Stress Elastic limit Elastic range 0 Permanent set Strain Stress - Strain diagram If we plot a graph between stress and strain we get a curve as shown in Fig. 1.5 and it is called stress - strain diagram. It is clear from this graph that Hooke’s law holds good only for the straight line portion of the curve 1.6 Elastic Moduli 1.6.1 Three kinds of elastic molduli The coefficient of elasticity or modulus of elasticity indicates how a specimen behaves when subjected to given stress. This has the same units as stress that is Nm-2 or Pa. Table 1.1 Three kinds of elastic moduli Elastic Modulus Definition Nature of strain Tensile stress Young’s modulus (Y) Tensile strain Change of shape and size Bulk stress Bulk modulus (B) Change of size but not shape Bulk strain Shear modulus or Rigidity modulus (S) Shear stress Change of shape but not size Shear strain 1.6 Physics for Technologists Table 1. 2 Approximate elastic moduli Young’s Modulus Bulk Modulus Shear Modulus Y(Pa) B(Pa) S(Pa) Aluminium 7.0x1010 7.5x1010 2.5x1010 Brass 9.0 x1010 6.0 x1010 3.5 x1010 Copper 11 x1010 14 x1010 4.4 x1010 Crown Glass 6.0 x1010 5.0 x1010 2.5 x1010 Iron 21 x1010 16 x1010 7.7 x1010 Lead 1.6 x1010 4.1 x1010 0.6 x1010 Nickel 21 x1010 17 x1010 7.8 x1010 Steel 20 x1010 16 x1010 7.5 x1010 Material 1.6.2 Compressibility The reciprocal of bulk modulus is called compressibility. The unit of compressibility is same as that of reciprocal pressure, Pa-1 1.6.3 Poisson’s ratio Within the elastic limits the ratio of the lateral strain to the longitudinal strain is constant for the material of the body and is known as Poisson’s ratio and is denoted by . Worked Example 1.1: A steel rod 2.0m long has a cross sectional area of 0.30cm 2. The rod is now hung by one end from a support structure and a 550kg milling machine is hung from the rod’s lower end. The Young’s modulus of steel is 20x1010Pa. Determine the stress, the strain and the elongation of the rod. Stress F (550kg) (9.8m / s 2 ) 1.8 10 8 Pa 5 2 A 3.0 10 m Strain Stress 1.8 10 8 Pa 9.0 10 4 o Y 20 1010 Pa Elongation = = (strain) x o = (9.0x10-4) (2.0m) = 0.0018m = 1.8mm Properties of Matter and Sound 1.7 Worked Example 1.2: The bulk modulus of water is 2.1Gpa. Calculate the volume contraction of 100mL of water when subjected to a pressure of 1.5Mpa. Bulk modulus B V P (V / Vo Vo(P) (100mL) (1.5 10 6 Pa) B 2.1 10 9 Pa = 0.071mL Worked Example 1.3: A box – shaped piece of gelatin dessert has a top area of 15cm 2 and a height of 3cm. When a shearing force of 0.50N is applied to the upper surface, the upper surface displaces 4mm relative to the bottom surface. What are the shearing stress, the shearing strain, and the shear modulus for the gelatin? Shear stress tan gential force 0.50 N 333Pa area of face 15 10 4 m 2 Shear strain displacement 0.4cm 0.1333 height 3cm ShearModulus stress strain 1.7 333Pa 2.5kPa 0.133 Twisting Couple on a Cylinder (or Wire) The twisting of a structural member about its longitudinal axis by two equal and opposite torques is expressed through a certain angle. The stress seen in this situation is not tensile or compressive, it is said to be shearing or shear stress. The strain in this case is measured by an angle in unit of radians Let us consider a cylindrical rod of length l and radius r with its upper end fixed. Let a twisting couple-be applied to the lower end of the rod in a plane perpendicular to its length and let the rod twist through an angle θ (radians). While the rod is twisted restoring couple acts in the opposite direction and in the position of equilibrium, the twisting couple is equal and opposite to the restoring couple. To calculate this couple, let us consider the solid cylinder to be made up of a larger number of concentric thin walled cylinders. Let us consider one such hollow cylinder of radius x, and radial thickness dx. When the rod is twisted through an angle θ, the angle through which the rim of the cylinder is sheared is ф. 1.8 Physics for Technologists Fig. 1. 6 Twisting couple on a cylinder i.e. BB’=l ф Also BB’=x θ :. ф = x l (1) From this it is clear that with x, ф varies. ф has the maximum value when x is the greatest. i.e., the strain is maximum on the outermost part of the cylinder and minimum on the innermost. In other words, the shearing stress is not uniform through out the material. If N is the rigidity modulus, N shearing stress F angle of shear Hence F =N ф= Nx (2) Now the face area of the hollow cylinder = 2πxdx :. Total shearing force on this area = 2πxdx. Nx θ / l = 2πN . θ. x2.dx l Therefore, moment of this force about the axis 00’ = 2πN θ x2dx . x l (3) Properties of Matter and Sound 1.9 = 2πN θ x3dx l (4) Total twisting couple of the cylinder can be obtained by integrating this expression between limits x = 0 and x = r. r :. Total twisting couple on the cylinder = 2N l 0 2N l r 0 x 3 dx (5) r 2N x 4 x dx 4 0 3 (6) N r 4 2N r 4 l 4 2l (7) If θ = l radian, we have Twisting couple per unit twist C= πNr4/2 (8) This twisting couple per unit twist of the wire is called the torsional rigidity or modulus of torsion of the cylinder of wire. It is evident form this relation that the couple required is proportional to the fourth power of the radius. Note: Hollow Cylinder For a hollow cylinder of the same length l and of inner radius r1 and outer radius r2, Twisting couple of the cylinder C r2 r1 2N 3 x dx l 2N l (9) r2 x 3 dx (10) r1 r2 2N x 4 l 4 r 1 N 2l (11) (r24 r1 ) If θ = 1 radian, twisting couple per unit twist C= 4 N 4 4 (r2 – r1 ) 2l (12) (13) 1.10 Physics for Technologists Worked Example 1.4: A wire of length 1 meter and diameter 1 mm is fixed at one end and a couple is applied at the other end so that the wire twists by π/2 radians. Calculate the moment of the couple required if rigidity modulus of the material = 2.8 ×1010 N/m2. Rigidity modulus of the material N = 2.8x1010 N/m2 Angle twisted by wire θ = radians 2 Length of the wire l = 1 meter Diameter of the wire d = 1 mm = 1 x 10 -3 meter Radius of the wire r Required couple C d 1 10 3 0.5 10 3 meters 2 2 N r4 2l 3.14 (2.8 1010 ) (0.5 3.14) (0.5 10 3 ) 4 2 1 = 4.3 x10-3 N-m. Worked Example 1.5: A wire of length l m and diameter 1mm is clamped at one of its ends. Calculate the couple required to twist the other end by 90o. Given N = 2.8 × 1010 N/m2. The torque required to twist the free end of a clamped wire of length through θ radian will be N r 4 2l For θ = 90o = π/2 radian , C= 2 Nr 4 4 N= 2.8x10-10 N/m2, l=1m r = 5mm = 0.0005 m :.C 2 2.8 1010 (5 104 )4 4.32×10-3 Nm 4 Properties of Matter and Sound Worked Example 1.6: 1.11 An iron wire of length l m and radius 0.5 mm elongates by 0.32 mm when stretched by a force of 49 N, and twists through 0.4 radian when equal and opposite torques of 3x10-3 N-m are applied at its ends. Calculate elastic constant for iron. Y Stress F / r 2 Fl Strain x/l r2x Force F = 49 N, radius r = 5x10-4 m and elongation x = 32x10-5 m and l = 1m Y 49 1 (5 10 ) (32 10 5 ) 4 2 = 19.5x1010N/m2. Worked Example 1.7: Two solid cylinders of the same material having length and 2 , and radii r and 2r joined coaxially. Under a couple applied between the free ends, the shorter cylinder shows a twist of 30o. Calculate the twist of the longer cylinder. If is the couple, and it produces twist θ in the shorter cylinder and twist θ’ in their longer cylinder. Then Nr 4 2l N (2r ) 4 2(2l ) ' :. θ’ = θ/8 = 30o / 8 = 3.75o. Worked Example 1.8: One end of wire of 4 mm radius and 100 cm in length is twisted through 60o. Calculate the angle of shear on its surface. If θ is the twist at the free end and ф is the angle of shear, then ф = r θ /l As = 1m, r=4x10-3m and θ = 60o :. ф = 4x10-3 x60 = 0.24°. Worked Example 1.9: The restoring couple per unit twist in a solid cylinder of radius 5.0 cm is 10-1 N-m. Find the restoring couple per unit twist in a hollow cylinder of the same material, mass and length but the internal radius is 12cm. The restoring couple per unit twist in a solid cylinder of length of l is given by C = πN r4 / 2l 1.12 Physics for Technologists Here r=0.05m and C=10-1N-m. N 2l C 10 1 r4 (0.05) 4 If r1 and r2 are the internal and external radii of the hollow cylinder of the same length and mass and of same material, then M = π ( r22-r21) = π r2 or r22-r21 = r2 Here r1 = 0.12mm and r = 0.05m r22 = r2 + r12 = (0.05)2 + (0.12)2 = (0.13)2 :. r2 = 0.13m. The restoring couple per unit twist for this hollow cylinder is C N (r 4 2 r 41 ) 2l 10 1 (0.13) 4 (0312) 4 (0.5) 4 = 1.25x10-4 N.m. Exercise Problem1.1 A wire of length 1 metre and diameter 1mm is clamped at one of its ends. Calculate the couple required to twist the other end by 90o. Given the modulus of rigidity is 298GPa. Hint : 90 o Twisting couple = 2 radians Nr 4 4.313×10-3 Nm 2l Exercise Problem 1.2. Given a 2m length and 1mm diameter of a steel wire suspender vertically down keeping the top end fixed. What is the tangential force required to twist the wire at the force end by 1 radian?. Rigidity modulus of the wire = 80 GPa. Hint : Couple required = Nr 4 2 tangential force × diameter Hence, tangential force = couple required diameter = 3.928 N