Total Lecture Hours: 7 Hours X 4 Days (28 hours)

advertisement

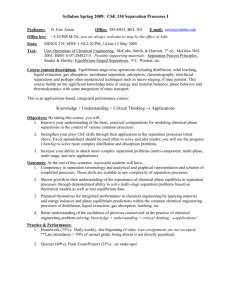

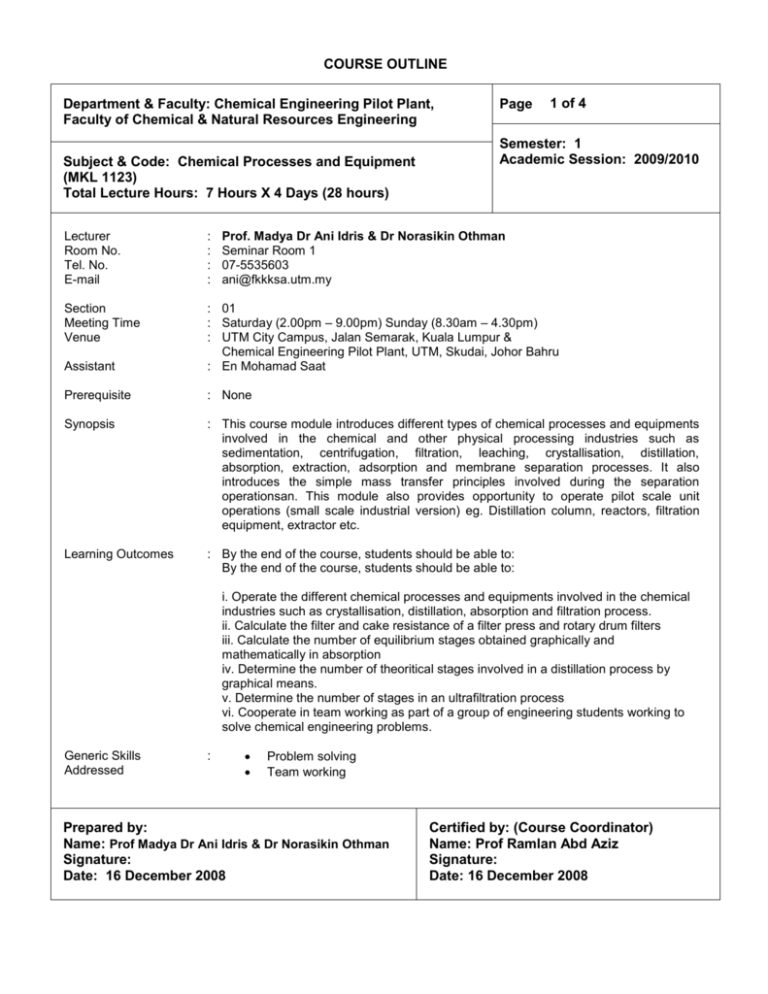

COURSE OUTLINE Department & Faculty: Chemical Engineering Pilot Plant, Faculty of Chemical & Natural Resources Engineering Subject & Code: Chemical Processes and Equipment (MKL 1123) Total Lecture Hours: 7 Hours X 4 Days (28 hours) Page 1 of 4 Semester: 1 Academic Session: 2009/2010 Prof. Madya Dr Ani Idris & Dr Norasikin Othman Seminar Room 1 07-5535603 ani@fkkksa.utm.my Lecturer Room No. Tel. No. E-mail : : : : Section Meeting Time Venue Assistant : 01 : Saturday (2.00pm – 9.00pm) Sunday (8.30am – 4.30pm) : UTM City Campus, Jalan Semarak, Kuala Lumpur & Chemical Engineering Pilot Plant, UTM, Skudai, Johor Bahru : En Mohamad Saat Prerequisite : None Synopsis : This course module introduces different types of chemical processes and equipments involved in the chemical and other physical processing industries such as sedimentation, centrifugation, filtration, leaching, crystallisation, distillation, absorption, extraction, adsorption and membrane separation processes. It also introduces the simple mass transfer principles involved during the separation operationsan. This module also provides opportunity to operate pilot scale unit operations (small scale industrial version) eg. Distillation column, reactors, filtration equipment, extractor etc. Learning Outcomes : By the end of the course, students should be able to: By the end of the course, students should be able to: i. Operate the different chemical processes and equipments involved in the chemical industries such as crystallisation, distillation, absorption and filtration process. ii. Calculate the filter and cake resistance of a filter press and rotary drum filters iii. Calculate the number of equilibrium stages obtained graphically and mathematically in absorption iv. Determine the number of theoritical stages involved in a distillation process by graphical means. v. Determine the number of stages in an ultrafiltration process vi. Cooperate in team working as part of a group of engineering students working to solve chemical engineering problems. Generic Skills Addressed : Problem solving Team working Prepared by: Name: Prof Madya Dr Ani Idris & Dr Norasikin Othman Signature: Date: 16 December 2008 Certified by: (Course Coordinator) Name: Prof Ramlan Abd Aziz Signature: Date: 16 December 2008 COURSE OUTLINE Department & Faculty: Chemical Engineering Pilot Plant, Faculty of Chemical & Natural Resources Engineering Page Semester: 1 Academic Session: 2009/2010 Subject & Code: Chemical Processes and Equipment (MKL 1123) Total Lecture Hours: 7 Hours X 4 Days (28 hours) Day 2 1 of 4 Topic Learning Outcomes 1 Solid – Liquid Separation Solid – Liquid Sedimentation Solid – Liquid Separation - Filtration Liquid – Liquid Separation - Leaching Liquid – Liquid Separation - Crystallization Gas/Vapour-Liquid Separation-Distillation It is expected that the students will be able to: To differentiate the nature of chemical processes, concept of chemical reaction and separation processes involved Calculate the filter and cake resistance of a filter press and rotary drum filters 2 Gas/Vapour – Liquid Separation – Absorption Distillation/Absorption/Extraction Liquid-Liquid Extraction Operations Gas-Solid Separation – Adsorption Gas- Solid Separation – Gas Cleaning It is expected that the students will be able to: Calculate the number of equilibrium stages obtained graphically and mathematically in absorption Determine the number of theoritical stages involved in a distillation process by graphical means. 3 Membrane Separation Processes Cross flow Microfiltration Ultra filtration Reverse Osmosis Pervaporation Practical Experiment (1) It is expected that the students will be able to: 4 - Hands – on approach to Pilot Plant Operations* Distillation Column Reactors Extractors Solid-liquid Separators Utility support ( * - Participants will be exposed to real-life process operation utilizing semi-industrial scale equipment at the Chemical Engineering Pilot Plant, UTM Skudai, Johor) Determine the number of stages in an ultrafiltration process. It is expected that the students will be able to: To practice hands on how to operate a pilot plant manually and cooperate in team working as part of a group of engineering students working to solve chemical engineering problems. COURSE OUTLINE Department & Faculty: Chemical Engineering Pilot Plant, Faculty of Chemical & Natural Resources Engineering Subject & Code: Chemical Processes and Equipment (MKL 1123) Total Lecture Hours: 7 Hours X 4 Days (28 hours) Teaching Methodology Page 3 1 of 4 Semester: 1 Academic Session: 2009/2010 : Lectures, Case Studies, Practical Experiment References : 1. Holland, Charles D (Donald) Fundamentals of chemical reaction engineering/ PrenticeHall. Edition: 2nd ed. Date: 1989 2. Recent trends in chemical reaction engineering/ New Delhi, Ind : Wiley Eastern, 1987 3. Svarovsky, Ladislav (1985). Solid-liquid separation processes and technology. Elsevier Sci. Pub 4. Eilbeck, W J (1987). Chemical processes in waste water treatment. Ellis Horwood 5. King, Ralph W (1990). Safety in the process industries. Butterworth-Heinneman Assessment : Post Module Assignment (50%) Technical Report (30%) Quiz (10%) Presentations (10%) Department & Faculty: Chemical Engineering Dept, FKKKSA Subject & Code: Chemical Processes and Equipment (MKL1122) Total Lecture Hours: 7 Hours x 4 Days No 1 2. 3. 4. 5. 6. Course Outcome Ability to operate the differences of unit operation involved in the chemical industries Ability to calculate the filter and cake resistance of a filter press and rotary drum filters Ability to calculate the number of equilibrium stages obtained graphically and mathematically in absorption University Criteria/PO mapping Bloom’s Taxonomy Page 4 of 4 Semester: 1 Academic Session: 2007/2008 Active Verb Technical Skill/ PO1,PO2 Cognitive Operate Technical Skill/ PO1, PO2 Cognitive Calculate Technical Skill/ PO1, PO2 Cognitive Calculate Cognitive Ability to compare the number of theoritical stages involved in a distillation process by graphical means using McCabe Thiele method or short-cut design Technical Skill/ PO1, PO2 Ability to determine the number of stages in an ultrafiltration process Technical Skill/ PO1, PO2 Ability to cooperate in team working as part of a group of engineering students working to solve chemical engineering problems Team Working/ PO5 Level Assessment KPI Practical Experiment 0.65 Assignment, 0.65 Application (L3) Assignment 0.65 Compare Evaluation (L6) Assignment 0.65 Cognitive Determine Analysis (L4) Assignment 0.65 Affective Cooperate Responding (L2) Practical Experiment 0.65 Application (L3) Application (L3) Subject & Code: Chemical Processes and Equipment (MKL1122) Total Lecture Hours: 3 x 14 weeks STUDENT LEARNING TIME Teaching and Learning Activities Student Learning Time (hours) 1. Lecture 2. Laboratory 14 14 3. Independent Study - self learning - information search - library search - reading - group discussion 22 4. Assignment (6x) - self learning - group discussion 20 5. Lab report 10 Total 80 TEACHING METHODOLOGY Lecture and Discussion, Active Learning, Independent Study, Group Assignment, Practical Experiment. Prepared by: Prof Madya Dr Ani Idris & Dr Norasikin Othman Name: Signature: Date: Certified by: Prof Ramlan Abd Aziz Name: Signature: Date: