(BASIC -Level 1) Internal Food Safety Training Program

advertisement

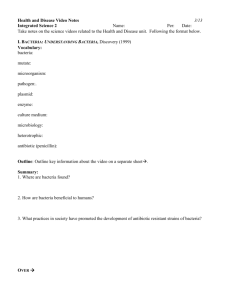

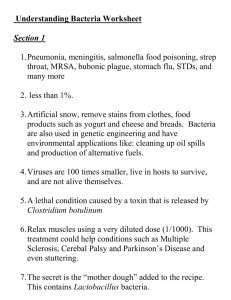

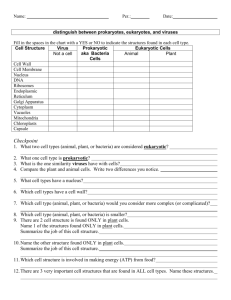

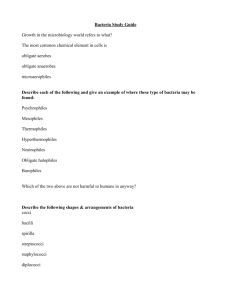

BASIC (LEVEL 1) INTERNAL FOOD SAFETY TRAINING PROGRAM COMPANY XYZ TABLE OF CONTENTS 0 INTRODUCTION 0-2 1 MODULE 1: HAND WASHING 1-3 2 MODULE 2: GLOVE USAGE 2-7 3 MODULE 3: PERSONNEL PRACTICES 3-8 4 MODULE 4: BASIC SANITATION 4-9 5 MODULE 5: ALLERGENS 5-11 6 MODULE 6: TEMPERATURE CONTROL 6-13 7 FOOD SAFETY QUIZ - 2007 7-14 8 ALLERGEN QUIZ - 2007 8-15 9 STATEMENT OF COMPLETION CERTIFICATE OF PARTICIPATION Issued on: Issued by: 17 ERROR! BOOKMARK NOT DEFINED. Version No: 1 Revised: 0 Introduction Welcome to the COMPANY XYZ’s Internal Food Safety Training Course! This 2 hour BASIC FOOD SAFETY course will help you conduct your work in a food safe environment. It is designed to increase your awareness of safe food handling procedures. The purpose of this course is to: 1. Share the importance of safe food handling practices in a processing environment 2. Reduce the possibility of cross contamination during food production 3. Create awareness of food safety issues After completing this course you will: Have a basic understanding of food safety This training manual is yours to keep. You should refer to it if you have any food safety related questions. Otherwise don’t be afraid to ask your QA Manager if you have other questions related to food safety. Issued on: Issued by: Version No: 1 Revised: 1 Module 1: Hand washing 1.1 Learning Outcomes Explain the reasons for hand washing Identify situations when necessary to wash hands List the steps of hand washing List the ten steps of sanitizing hands Demonstrate proper hand washing technique 1.2 Reasons for Hand washing The number of bacteria on your body is greater than the population of Canada! Our hands contain naturally occurring bacteria. They exist on the skin of healthy people. They are always there. However some bacteria can be transferred to your skin. We need to try to keep the number of bacteria in our food as low as possible. Bacteria can not be seen under a microscope. But if we transfer bacteria into an agar plate and keep it warm, the bacteria will reproduce rapidly! First, we touched a plate with dirty fingers. The dirty fingers contained so many bacteria that the areas they touched on the agar plate were masses of colonies! Hand washing is the single most effective way to prevent the spread of infections. Hand washing removes visible dirt from hands and helps loosen and reduce the number of harmful microorganisms (germs). Issued on: Issued by: Version No: 1 Revised: 1.3 When do you need to wash your hands? Wash hands before: Touching any food product! Wash hands after: Eating or snacking. Touching the phone Smoking Touching your ears, nose, or mouth (or any body part) Blowing your nose, coughing, or sneezing. Any kind of cleaning or hand contact with dirty equipment or work surfaces. Taking out the garbage. Handling non-food items Using the washroom. 1.4 Hand washing steps 1. Wet hands with warm potable water 2. Apply soap 3. Rub hands together for at least 40 seconds. Rubs hands using the 6 steps: a. Palm to palm b. Finger webs c. Palm to back d. Palms to knuckles and finger tips e. Thumb f. Wrist and arm sleeves 4. Rinse hands with warm potable water 5. Dry hands with disposable towels 6. Sanitize hands Issued on: Issued by: Version No: 1 Revised: 1.4.1 Rinsed Hand A 20-second water rinse removed large particles of dirt and some bacteria. But millions of bacteria were left! As you can see, JUST rinsing your hands with water is not a very good way to clean them. 1.4.2 Washed Hands for 40 Seconds Washing the hands with soap and water for 40 seconds reduced the number of bacteria. Washing them a full minute is even better! Soap and water will reduce the number of bacteria on your hands. 1.4.3 After Sanitizing No bacteria grew on the agar plate after the hand was sanitized. The bacteria may or may not have been killed, but the sanitizer stopped their growth. Issued on: Issued by: Version No: 1 Revised: 1.5 Steps to Sanitizing Hands There are 8 steps to rub sanitizer on your hands. 1. Receive sufficient sanitizer to open palms 2. Rub hands together, palm to palm 3. Rub between interlaced fingertips 4. Rub back of each hand with palm of other hand 5. Rub fingertips of each hand in opposite palm 6. Rub each thumb clasped in opposite hand 7. Rub wrist and arm sleeves clasped in opposite hand 8. Continue rubbing until hands are dry Issued on: Issued by: Version No: 1 Revised: 2 Module 2: Glove Usage 2.1 Learning Outcomes Explain the reasons for wearing gloves Describe the magic glove syndrome List when necessary to wear gloves 2.2 Reasons for wearing gloves Although proper hand washing should ALWAYS be the first line of defense in safe food handling, gloves play another pivotal role by providing a barrier between the food and the employee’s hand. Gloves are NOT a substitute for hand washing. As food handlers you MUST NEVER become complacent about hygiene just because you are wearing gloves. Gloves should be treated like a second skin. 2.3 Magic Glove Syndrome The ‘magic glove syndrome’ is when the surface of the glove is dirty and filthy yet the hands are still clean and dry. Food handlers do not feel the filth on their hands and do not stop to wash their hands and change their gloves. Regular hand washing combined with proper glove usage are effective ways to prevent food borne diseases. When should you wash your hands and change gloves? 2.4 When gloves become soiled or torn After four hours of use After handling raw meat Before handling cooked or ready-to-eat foods Any time you need to wash your hands. In this photo, the food handler with a dirty glove touched an agar plate. The dirty glove contained many bacteria, as shown by the large number of colonies left on the agar. Never leave one pair of gloves on for too long! Research shows that wearing disposable gloves over an extended time period can increase the risk of bacterial contamination, by trapping moisture and nutrients for bacteria to survive. Issued on: Issued by: Version No: 1 Revised: 3 Module 3: Personnel Practices 3.1 Learning Outcomes List the company GMPs Explain the consequences of not following the GMPS 3.2 Employee Handbook Please refer to your Employee Handbook (under the headings; Uniform Standards and Good Manufacturing Practices) for this section. Issued on: Issued by: Version No: 1 Revised: 4 Module 4: Basic Sanitation 4.1 Learning Outcomes Explain reasons for proper sanitation Explain the difference between cleaning and sanitizing List the 4 sanitation steps Explain the ‘clean as you go’ The objective of cleaning and sanitizing food contact surfaces is to remove food (nutrients) which bacteria need to grow, and to kill those bacteria which are present. It is important that the clean, sanitized equipment and surfaces drain dry and are stored dry so as to prevent bacteria growth. Necessary equipment (brushes, etc.) must also be clean and stored in a clean, sanitary manner. Sanitation is a dynamic and ongoing function and cannot be sporadic or something that can be turned on once a day, once a week, etc. No longer is sanitation seen as a part of the process; rather it's become a manufacturing philosophy -- one that should permeate every part of production. 4.2 Cleaning vs. Sanitizing 4.2.1 Cleaning "Cleaning" is the physical removal of soil and food matter from a surface. This involves water, mechanical action and temperature. Detergents are used to assist in the process. Cleaning does not by itself, consistently reduce contamination to safe levels. 4.2.2 Sanitizing "Sanitizing" is the reduction of the number of contaminating microorganisms, such as bacteria and viruses, on tableware, flatware, equipment, and any food-contact surface to “safe” levels. The disease-producing organisms may not be destroyed. Sanitizers are less effective when food particles or dirt are present on equipment surfaces. Always “clean” before sanitizing. Issued on: Issued by: Version No: 1 Revised: 4.3 Sanitation Steps The correct order of events for cleaning/ sanitizing of food product contact surfaces are: 1. Pre-Clean & Rinse: Dry pick up of soil and debris. It is important to remove as much food soil as possible before washing to keep the wash water as clean as possible and allow the detergent to do its work. 2. Wash Apply detergent 3. Rinse Use hot potable water to remove detergent and soil 4. Sanitize Immerse equipment and items in sanitizer for at least 30 seconds. 4.4 Clean-As-You-Go COMPANY XYZ promotes a CLEAN-AS-YOU-GO policy, meaning that workspace should always be kept neat and sanitary while working. All supplies must be returned to their original places when you are done using them! Issued on: Issued by: Version No: 1 Revised: 5 Module 5: Allergens 5.1 Learning Outcomes List the big 9 allergens Identify 4 allergenic ingredients used at COMPANY XYZ Explain how allergen cross-contact can occur Explain reasons for controlling allergens List procedures in place to prevent cross-contamination Employee awareness and training are the best defenses against unintentional allergen residues being added to products, and so it is important that personnel are trained and dedicated to allergen control. COMPANY XYZ’s Allergen Control Plan will only be successful when YOU do your part. 5.2 The BIG 9 Allergens Ninety percent of food allergic reactions are caused by nine common foods and their byproducts. 1. Peanuts 2. Tree Nuts 3. Milk / Dairy 4. Egg/Egg Products 5. Fish/Shellfish 6. Wheat Products 7. Sesame seeds 8. Sulphites 9. Soy products COMPANY XYZ has eliminated the processing of any peanut products at this plant. 5.3 Keep food allergens separate from non-allergenic ingredients During receiving and storage keep food allergens separate from non-allergenic ingredients. Ensure that during receipt the allergenic ingredient is clearly identified with the designated number and/or sticker. The allergenic ingredient should then be stored in the designated allergenic section of the warehouse, cooler or freezer. Issued on: Issued by: Version No: 1 Revised: 5.4 Production During production there can be opportunities for cross-contact of food allergens. Ensure that you are using separate utensils for allergenic ingredients. At COMPANY XYZ we use a color coding system to separate utensils and/or tools for allergenic ingredients. 5.5 Clean thoroughly As mentioned in the Sanitation Module proper sanitation plays a very important role in preventing cross-contamination. Thoroughly clean equipment and visually inspect hard to reach areas for signs of residues. 5.6 Employee Hygiene You have a responsibility to prevent allergen cross-contact. You remain the best defense on our production floor. Keep in mind the following; Ensure that your hands are cleaned and sanitized after coming in contact with an allergen. Wear proper attire (colored apron, sleeve guards) when handling specific allergens. Your attire must be removed before handling a non-allergenic product. Issued on: Issued by: Version No: 1 Revised: 6 Module 6: Temperature Control 6.1 Learning Outcomes Explain the Temperature “Danger Zone” Describe how to properly check food temperatures. 6.2 Temperature “Danger Zone” Bacteria thrive in temperatures between 5°C and 60°C. When the food temperature is between this temperature range, (aka. THE DANGER ZONE) bacteria will multiply fast and grow rapidly. Bacteria can produce toxins and potentially cause our customers to become sick. At times during production we cannot immediately chill foods. Foods may sit in the Danger Zone for no more than 2 hours! Ensure that hot foods are chilled to at least 4°C within 4 hours. Do not assume that reheating the food will kill the bacteria because the toxins that they produce cannot be destroyed. 6.3 Checking Temperatures We need to ensure our coolers and freezers are kept at the right temperature. Our coolers should always be below 4°C and our freezers should be at -18°C. If you notice the thermometer in the coolers and freezers reading a different temperature please alert the QA Manager immediately! When cooking the sauces and soups we need to ensure that they have reached the appropriate temperature. We use a digital thermometer to read the temperature. Ensure the thermometer is cleaned and sanitized before inserting the metal stem into the food. Issued on: Issued by: Version No: 1 Revised: 7 Food Safety Quiz - 2008 Name: ----------------------------------------- Date: ---------------------------- Please answer all questions by selecting either O True or O False. You must correctly answer 6 out of 8 (75%) to Pass. Score: /8 1. The last step of handwashing is to sanitize hands O True O False 2. You only need to wash your hands after your break. O True O False 3. You do NOT need to sanitize your hands BEFORE wearing gloves. O True O False 4. You can wear a nose ring or earring if it is covered. O True O False 5. If you have an open wound on the hand, you must cover the wound with a bandage and glove. O True O False 6. Thawing/Defrosting of frozen ingredients can be done outside of the cooler. O True O False 7. If an ingredient, utensil, product or food-contact packaging has fallen on the floor, then pick it up and reuse it. O True O False 8. All Lot number / Best Before Dates of ingredients must be recorded when working on a recipe. O True O False Issued on: Issued by: Version No: 1 Revised: 8 Allergen Quiz - 2008 Name: ----------------------------------------- Date: ---------------------------- Please answer all questions by selecting either O True or O False. Score: /8 You must correctly answer 6 out of 8 (75%) to Pass. 1. Employee does not have to wear a plastic apron when working with milk, egg and soy products. O True O False 2. Employee must wash their hands after working with milk, egg, fish, wheat and soy products. O True O False 3. Any coloured scoop can be used for transferring an allergenic ingredient. O True O False 4. Allergens can be stored anywhere in the warehouse, cooler and freezer. O True O False 5. Allergenic ingredient can be stored on TOP of a non-allergenic ingredient. O True O False 6. After processing (insert allergenic finished product), an operator must clean the equipment before processing (insert non-allergenic finished product). O True O False 7. Any container can be used for storing an allergenic ingredient. O True O False 8. List an allergenic ingredients (provide ingredient name) in each category: Egg: Milk: Soy: Sulphites: Issued on: Issued by: Version No: 1 Revised: BLANK PAGE Issued on: Issued by: Version No: 1 Revised: 9 Statement of Completion (BASIC -Level 1) Internal Food Safety Training Program I hereby certify that ____________________ ____has completed BASIC (LEVEL 1) INTERNAL FOOD SAFTEY TRAINING PROGRAM and understands the following principles and expectations of COMPANY XYZ’s’s Food Safety Program; 1. Proper Handwashing 2. Proper Glove Usage 3. Employee Handbook: o Uniform Standards o GMPs: Employee Hygiene Work Area Habits / Personal Hygiene Totes / Buckets / Utensils Spices and Spice Room Paperwork Preparing Food (Signatures Required) QA Instructor: -------------------------------------------- Date: ----------------------------------- (Photocopy certificate and file under individual employee folders) I hereby declare that I have been taught and understand the above information. Employee: Issued on: Issued by: ----------------------------------------------------- Version No: 1 Revised: BLANK PAGE Issued on: Issued by: Version No: 1 Revised: