SIC 2421 - Sawmills and Planing Mills SIC 2426

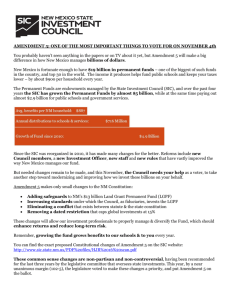

advertisement

SAFETY PROGRAM SAWMILLS AND PLANING MILLS SIC CODE 242 SIC 2421 - SAWMILLS and PLANING MILLS SIC 2426 - HARDWOOD DIMENSION and FLOORING MILLS SIC 2429 - SPECIAL PRODUCT SAWMILLS, NOT ELSEWHERE CLASSIFIED VII.1 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Section 9 The safety rules contained on these pages have been prepared to protect you in your daily work. Employees are to follow these rules, review them often and use good common sense in carrying out assigned duties. ALL PERSONNEL Housekeeping ............................................................................................................................. 3 Personal Protective Equipment .................................................................................................. 4 Lifting Procedures ...................................................................................................................... 4 Ladder and Step Ladder Safety .................................................................................................. 4 ADMINISTRATION PERSONNEL Office Safety ............................................................................................................................... 5 Scaler Safety ............................................................................................................................... 6 SAWMILL and FINISHING/PLANING OPERATIONS PERSONNEL Personal Protective Equipment .................................................................................................. 7 Lockout/Tagout .......................................................................................................................... 7 Truck/Trailer Safety ................................................................................................................... 7 Scaler Safety ............................................................................................................................... 7 Loader and Knuckle Boom Safety ............................................................................................. 7 Lifting Equipment ...................................................................................................................... 8 Lifter/Forklift Safety .................................................................................................................. 8 Put/Take Deck Safety ................................................................................................................. 10 Optimizer and Trimmer Safety .................................................................................................. 10 Sorter Safety ............................................................................................................................... 10 Green Chain/Manual Stackers Safety ........................................................................................ 10 Hand Tool Safety........................................................................................................................ 11 Knives/Sharp Instruments .......................................................................................................... 11 SAWMILL OPERATIONS PERSONNEL Housekeeping ............................................................................................................................. 12 Crane and Hoist Safety............................................................................................................... 12 Front End Loader Safety ............................................................................................................ 12 Ring/Drum Debarker Safety ...................................................................................................... 12 Cut-Up/Decksaw Safety ............................................................................................................. 13 Safety at Primary Breakdown .................................................................................................... 13 Safety at Secondary Breakdown ................................................................................................ 13 Off Bearers ................................................................................................................................. 13 DRYING PERSONNEL Dry Kiln Safety........................................................................................................................... 13 FINISHING/PLANING MILL PERSONNEL Break Down Hoist Safety........................................................................................................... 14 Planer Safety ............................................................................................................................... 14 Bander Safety ............................................................................................................................. 14 Truck/Trailer Safety ................................................................................................................... 14 Personal Protective Equipment .................................................................................................. 14 MAINTENANCE/UTILITY PERSONNEL VII.2 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Personal Protective Equipment .................................................................................................. 15 Housekeeping ............................................................................................................................. 15 Hand Tool/Power Tool Safety ................................................................................................... 15 Tool Boxes/Chest/Cabinets ........................................................................................................ 19 Knives/Sharp Instruments .......................................................................................................... 19 Portable Welding Equipment ..................................................................................................... 19 Compressed Gas Cylinders ........................................................................................................ 20 Welding/Cutting/Brazing ........................................................................................................... 21 Grinders ...................................................................................................................................... 21 Electrical Safety.......................................................................................................................... 22 Batteries ...................................................................................................................................... 22 Confined Space Safety ............................................................................................................... 22 SPECIALTY WOOD SHOP PERSONNEL Personal Protective Equipment .................................................................................................. 23 Housekeeping ............................................................................................................................. 23 Hand Tool/Power Tool Safety ................................................................................................... 24 Tool Boxes/Chest/Cabinets ........................................................................................................ 27 Knives/Chisels/Sharp Instruments ............................................................................................. 28 Grinder/Abrasive Wheels ........................................................................................................... 28 Drill Press Safety ........................................................................................................................ 28 Wood Lathe Safety ..................................................................................................................... 29 Wood Shaper/Overarm Router Safety ....................................................................................... 29 Sander Safety .............................................................................................................................. 29 Miter Saw Safety ........................................................................................................................ 29 Radial Saw Safety ...................................................................................................................... 30 ALL PERSONNEL Housekeeping 1. Do not place materials such as boards, barrels, or trash in walkways and passageways. 2. Do not store or leave items on stairways. 3. Do not block or obstruct stairwells, exits or accesses to safety and emergency equipment such as fire extinguishers or fire alarms. 4. Do not block the walking surfaces of elevated working platforms, such as scaffolds, with tools or materials that are not being used. 5. Return tools to their storage places after using them. 6. Do not use gasoline for cleaning purposes. 7. Use caution signs or cones to barricade slippery areas such as freshly mopped floors. Personal Protective Equipment 1. Do not paint or drill holes into your hard hat. 2. Do not wear hard hats that are dented or cracked. 3. Wear the chemical goggles when using, applying or handling chemical liquids or powders . from containers labeled "Caustic" or "Corrosive." 4. Do not continue to work if your safety glasses become fogged. Stop work and clean the .... glasses until the lenses are clear and defogged. VII.3 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 5. 6. Wear your ear plugs or ear muffs in areas posted "Hearing Protection Required." Do not wear loose clothing or jewelry in the saw mill or planing mill operation areas. Lifting Procedures 1. Plan the move before lifting; ensure that you have an unobstructed pathway. 2. Test the weight of the load before lifting by pushing the load along its resting surface. 3. If the load is too heavy or bulky, use lifting and carrying aids such as hand trucks, dollies, pallet jacks and carts, or get assistance from a co-worker. 4. If assistance is required to perform a lift, coordinate and communicate your movements with those of your co-worker. 5. Position your feet 6 to 12 inches apart with one foot slightly in front of the other. 6. Face the load. 7. Bend at the knees, not at the back. 8. Keep your back straight. 9. Get a firm grip on the object using your hands and fingers. Use handles when they are present. 10. Hold the object as close to your body as possible. 11. While keeping the weight of the load in your legs, stand to an erect position. 12. Perform lifting movements smoothly and gradually; do not jerk the load. 13. If you must change direction while lifting or carrying the load, pivot your feet and turn your entire body. Do not twist at the waist. 14. Set down objects in the same manner as you picked them up, except in reverse. 15. Do not lift an object from the floor to a level above your waist in one motion. Set the load down on a table or bench and then adjust your grip before lifting it higher. 16. Never lift anything if your hands are greasy or wet. 17. Wear protective gloves when lifting objects that have sharp corners or jagged edges. Ladder and Step Ladder Safety 1. Read and follow the manufacturer's instructions label affixed to the ladder if you are unsure how to use the ladder. 2. Do not use ladders that have loose rungs, cracked or split side rails, missing rubber foot pads, or are otherwise visibly damaged. 3. Keep ladder rungs clean and free of grease. Remove buildup of material such as dirt, wood chips, or sawdust. 4. Do not place ladders in a passageway or doorway without posting warning signs or cones that detour pedestrian traffic away from the ladder. Lock the doorway that you are blocking with the ladder and post signs that will detour traffic away from your work. 5. Do not place a ladder at a blind corner or doorway without diverting foot traffic by blocking or roping off the area. 6. Allow only one person on the ladder at a time. 7. Face the ladder when climbing up or down it. 8. Maintain a three-point contact by keeping both hands and one foot or both feet and one hand on the ladder at all times when climbing up or down the ladder. 9. When performing work from a ladder, face the ladder and do not lean backward or sideways from the ladder. 10. Do not stand on lumber, stacks of boards, barrels, chairs or other improvised climbing devices to VII.4 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 11. 12. 13. 14. 15. 16. 17. 18. 19. reach high places. Use a ladder or stepstool. Do not stand on the top two rungs of any ladder. Do not stand on a ladder that wobbles, or that leans to the left or right of center. When using a ladder, extend the top of the ladder at least 3 feet above the edge of the landing. Secure the ladder in place by having another employee hold it. Do not move a rolling ladder while someone is on it. Do not place ladders on barrels, boxes, stacks of lumber or boards, or other unstable bases. Do not carry items in your hands while climbing up or down a ladder. Do not try to "walk" a ladder by rocking it. Climb down the ladder, and then move it. Do not use a ladder as a horizontal platform. ADMINISTRATIVE PERSONNEL Office Safety 1. Do not stand on furniture to reach high places. 2. Do not kick objects out of your pathway; pick them up or push them out of the way. 3. Do not jump from ladders or step stools. 4. Do not block your view by carrying large or bulky items; use a dolly or hand truck or get assistance from a fellow employee. 5. Do not throw matches, cigarettes or other smoking materials into trash baskets. 6. Do not tilt the chair you are sitting in on its back two legs. 7. Use the ladder or step stool to retrieve or store items that are located above your head. Doors 1. Close drawers and doors immediately after using them. 2. Keep doors in hallways fully open or fully closed. 3. Use the handle when closing doors. Files 1. Open only one file cabinet drawer at a time. Close the filing cabinet drawer you are working in before opening another filing drawer in the same cabinet. 2. Put heavy files in the bottom drawers of file cabinets. 3. Use the handle when closing drawers and files. Sharps 1. Store sharp objects, such as pens, pencils, letter openers or scissors in drawers or with the tips pointing down in a container. 2. Carry pencils, scissors and other sharp objects with the tips pointing down. Paper Cutter/Shredder 1. Position hands and fingers on the handle of the paper cutter before pressing down on the blade. 2. Keep the paper cutter handle in the closed or locked position when it is not being used. 3. Do not use paper cutting devices if the finger guard is missing. 4. Do not place your fingers in or near the feed of a paper shredder. VII.5 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Electrical 1. Do not use frayed, cut or cracked electrical cords. 2. Do not plug multiple electrical cords into a single outlet. 3. Do not use extension or power cords that have the ground prong removed or broken off. 4. Use a cord cover or tape the cord down when running electrical cords across aisles, between desks or across entrances or exits. 5. Turn the power switch to "Off" and unplug office machines before adjusting, lubricating or cleaning them. Fans 1. Do not use fans that have excessive vibration, frayed cords or missing guards. 2. Do not place floor type fans in walkways, aisles or doorways. Stairs 1. Use the handrails when ascending or descending stairs or ramps. 2. Do not store or leave items on stairways or walkways. 3. Do not run on stairs or take more than one step at a time. Scaler 1. Do not jump from rail car to rail car. 2. Do not climb onto truck or tractor trailer until driver is out of it. 3. Do not enter areas between tractor trailers for any reason. 4. Do not cross in front of vehicle without establishing direct eye contact with the driver ........ or notifying the driver of your intent to cross. SAWMILL and FINISHING/PLANING MILL OPERATIONS PERSONNEL Personal Protective Equipment • Wear employer approved safety glasses with side shields when working around or within areas where any sawing or finishing operation takes place. Lockout/Tagout 1. Do not remove a lock from equipment unless you placed it there. 2. Attach your own lock or tag when you need to isolate an energy source and/or repair any field machine or equipment (saws, planers, hoists, cranes, etc.) Truck/Trailer Safety Fueling Vehicles 1. Turn the vehicle off before fueling it. 2. Do not smoke while fueling a vehicle. 3. Wash your hands with soap and water if you spill gasoline on your hands. Driving Rules 1. Shut your door and fasten your seat belt before moving the vehicle. VII.6 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 2. 3. 4. 5. 6. 7. Obey all traffic laws and signals at all times. Maintain a three point contact using both hands and one foot or both feet and one hand when climbing into and out of vehicles. Do not jump off of, or onto vehicle. Do not stay in the cab of truck or tractor trailer while the payload is being loaded or unloaded by cranes or loaders. Do not crawl under the raised dump body during inspection of a dump truck. Turn the engine off before leaving vehicle unattended. Scaler Safety 1. Do not walk on piled logs. 2. Do not jump from rail car to railcar. 3. Do not climb onto truck or tractor-trailer until driver is out of it. 4. Do not enter areas between tractor-trailers for any reason. 5. Do not cross in front of vehicle without establishing direct eye contact with the driver or notifying the driver of your intent to cross. Loader and Knuckle Boom Safety 1. Visually survey area around the boom to ensure area is clear of people. 2. Keep area floors free of hydraulic oils and other fluids by using a mop and/or substance approved by your employer to eliminate all identified slip hazards. 3. Visually inspect equipment and floor to ensure safety guards and grates are in place before operating. Lifting Equipment (chains, cables, ropes, slings, etc.) General 1. Do not use chain slings if links are cracked, twisted, stretched or bent. 2. Fabricate all wire in wire rope slings by using thimbles; do not form eyes by using wire clips or knots. 3. Do not shorten slings by using make-shift devices such as knots or bolts. 4. Do not use a kinked chain. 5. Protect slings from the sharp edges of their loads by placing pads over the sharp edges of the items that have been loaded. 6. Do not place your hands between the sling and its load when the sling is being tightened around the load. 7. Wear work gloves when handling rough, sharp-edged or abrasive material such as chains, cables ropes or slings. 8. Do not alter or remove the safety latch on hooks. Do not use a hook that does not have a safety latch, or the safety latch is bent. Lifter/Forklift Safety Rules General 1. Do not use bare forks as a man-lift platform. 2. Steer the forklift wide when making turns. 3. Sound the forklift horn when approaching blind corners, doorways or aisles to alert other operators and pedestrians. VII.7 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Lifting 1. Do not exceed the lift capacity of the forklift. Read the lift capacity plate on the forklift if you are unsure. 2. Follow the manufacturer's guidelines concerning changes in the lift capacity before adding an attachment to a forklift. 3. Lift the load an inch or two to test for stability; if the rear wheels are not in firm contact with the floor, take a lighter load or use a forklift that has a higher lift capacity. 4. Do not raise or lower a load while you are enroute. Wait until you are in the loading area and have stopped before raising or lowering the load. 5. After picking up a load, adjust the forks so that the load is tilted slightly backward for added stability. 6. Raise the forks an additional two inches to avoid hitting or scraping the ramp surface as you approach the ramp. Driving 1. Obey all traffic rules and signs. 2. Drive with the load at a ground clearance height of 4-6 inches at the tips and 2 inches at the heels in order to clear most uneven surfaces and debris. 3. Drive at a walking pace and apply the brakes slowly when driving on slippery surfaces such as icy or wet floors. 4. Do not drive up to anyone standing or working in front of a fixed object such as a wall. 5. Do not exceed a safe working speed of five miles per hour. Slow down in congested areas when driving the forklift. 6. Drive in reverse and use a signal person when your vision is blocked by the load. 7. Look in the direction that you are driving; proceed when you have a clear path. 8. Drive unloaded forklifts in reverse when going up a ramp and forward when going down a ramp. 9. Drive a loaded forklift in a forward gear when going up a ramp. Upon approaching the ramp, raise the forks an additional two inches to avoid hitting or scraping the ramp surface. 10. Do not attempt to turn the forklift around on a ramp. 11. Do not use a gear for the opposite direction of travel as a means to slow down or stop the forklift. 12. Lower the mast completely, turn the engine off and set the parking brake before leaving your forklift. Pre-Use Inspection • Only trained and certified forklift operators may operate the forklift. Do not use the forklift if any of the following conditions exist: 1. The mast has broken or cracked weld-points. 2. The roller tracks are not greased or the chains are not free to travel. 3. The forks are unequally spaced or cracks exist along the blade or at the heels. 4. Hydraulic fluid levels are low. 5. The hydraulic lines and fittings have excessive wear or are crimped. 6. Fluid is leaking from the lift or the tilt cylinders. 7. The hardware on the cylinders is loose. VII.8 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 8. 9. 10. The tires are excessively worn or split, or have missing tire material. Air filled tires are not filled to the operating pressure indicated on the tire. The batteries have cracks or holes, uncapped cells, frayed cables, broken cable insulation, loose connections or clogged vent caps. Starting the Forklift • Apply the foot brake and shift gears to neutral before turning the key. Picking Up a Load 1. "Square up" on the center of the load and approach it straight on with the forks in the travel position. 2. Stop when the tips of your forks are about a foot from the load. 3. Level the forks and slowly drive forward until the load is resting against the backrest of the mast. 4. "Trial Lift" the load by lifting the load approximately two feet (2 ft.) to ensure the load ...... is balanced. Adjust position on load if load is not balanced. 5. Lift the load high enough to clear the lumber, pallets, or whatever is under it. 6. Back up about one foot, then slowly and evenly tilt the mast backwards to stabilize the load. Putting a Load Down 1. "Square up" and stop about one foot from the desired location. 2. Level the forks and drive to the loading spot. 3. Slowly lower the load to the floor. 4. Tilt the forks slightly forward so that you do not hook the load. 5. When the path behind you is clear of obstructions, back straight out until the forks have cleared the pallet. Stacking One Load on Top of Another 1. Stop about one foot away from the loading area and lift the mast high enough to clear the top of the stack. 2. Slowly move forward until the load is squarely over the top of the stack. 3. Level the forks and lower the mast until the load is no longer supported by the forks. 4. Look over both shoulders for obstructions and back straight out if the path is clear. Put-Take Deck Safety • Do not stand under the put-take deck when it is in operation. Optimizer and Trimmer Saw Safety 1. Do not climb on or under the moving conveyor. 2. Do not start the conveyor if someone is on or under it. 3. Do not stand near the outfeed. Remain within the employer established safety zone(s) when working with the optimizer/trimmer saw. 4. Use a safety step when stepping down from the conveyor table. 5. Do not handle lumber on lug chain or even end rollers. 6. Do not feed more than two-thirds (_) of a board at a time. 7. Keep your hands above the lumber at all times as it exits the unscrambler. VII.9 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Sorter Safety 1. Do not walk under suspended lumber. 2. Do not reset sorter until jam or task (pulling board, repairing chain, etc.) is completed. 3. Keep gates closed on upper level of sorter. 4. Do not place your hands near the tipples to move boards. Green Chain/Manual Stackers Safety 1. Do not let hands slide on lumber while pulling carts. 2. Stop loader prior to straightening boards. 3. Do not operate lift arms until stick places are clear. 4. Wear leather gloves, leather aprons and earplugs when working in the area. Hand Tool Safety 1. Use tied off containers to keep tools from falling off of scaffolds and other elevated work platforms. 2. Carry all sharp tools in a sheath or holster. 3. Tag worn, damaged or defective tools "Out of Service" and do not use them. 4. Do not use a tool if its handle has splinters, burrs, cracks, splits or if the head of the tool is loose. 5. Do not use impact tools such as hammers, chisels, punches or steel stakes that have mushroomed heads. 6. When handing a tool to another person, direct sharp points and cutting edges away from yourself and the other person. 7. When using knives, snips, or other cutting tools, cut in a direction away from your body. 8. Do not carry sharp or pointed hand tools such as screwdrivers, scribes, snips, scrapers, chisels or files in your pocket unless the tool or your pocket is sheathed. 9. Do not perform "make-shift" repairs to tools. 10. Do not carry tools in your hand when you are climbing. Carry tools in tool belts or hoist the tools to the work area using a hand line. 11. Do not throw tools from one location to another, from one employee to another, from ladders, scaffolds, or other elevated platforms. 12. Transport hand tools only in toolboxes or tool belts. Do not carry tools in your clothing. Knives/Sharp Instruments 1. When handling knife blades and other cutting tools, direct sharp points and edges away from you. 2. Cut in the direction away from your body when using knives. 3. Use the knife that has been sharpened; do not use knives that have dull blades. 4. Use knives for the operations for which they are named or made. 5. Do not use knives that have broken or loose handles. 6. Do not use knives as screwdrivers, pry bars, can openers or ice picks. 7. Do not pick up knives by their blades. 8. Carry knives with their tips pointed towards the floor. 9. Do not carry knives, scissors or other sharp tools in your pockets or an apron unless they are first placed in their sheath or holder. 10. Do not attempt to catch a falling knife. 11. Store knives in knife blocks or in sheaths after using them. VII.10 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 12. Do not use honing steels that do not have disc guards. SAWMILL OPERATIONS PERSONNEL Housekeeping 1. Do not place lumber scraps or other trash in walkways and passageways. 2. Using a broom and a dustpan, sweep walkway areas around all sawmill equipment and machinery to avoid any buildup of wood chips or sawdust. 3. Do not block or obstruct stairwells, exits or accesses to safety and emergency equipment such as fire extinguishers or fire alarms. Crane and Hoist Safety 1. Do not use load hooks that are cracked, bent or broken. 2. Passengers are not permitted to ride inside the operator's cab of a truck crane. 3. Keep crane windows clean. Do not use a crane if its windows are broken. 4. Do not exceed the rated load capacity of the crane as specified by the manufacturer. 5. Use the cribbing mats when operating the crane on "soft" ground. 6. Fully extend the outriggers of the crane before attempting a lift. 7. Stay outside the barricades of the posted swing radius of the crane. 8. Do not perform any crane refits or modifications without the manufacturer's approval. 9. Do not leave the crane you are working in unattended if you have a hoisted load suspended in the air. 10. Do not hoist loads over people. 11. Do not drive the crane on the road shoulders. 12. Signalmen must wear the high visibility, fluorescent orange vest. 13. When operating a crane, follow only the signals of the person designated to give you signals. 14. Replace the belts, gears or rotating shaft guards after servicing a crane; do not use the crane if guards are missing from these areas. 15. Wear leather gloves when handling wire ropes. 16. "Trial Lift" the load by lifting the load approximately two feet (2 ft.) to ensure the load is balanced. Adjust grasp on load if load is not balanced. Front End Loader Safety 1. "Trial Lift" the load by lifting the load approximately two feet (2 ft.) to ensure the load is balanced. Adjust grasp on load if load is not balanced. 2. Do not remove lumber from truck or tractor trailers until driver has completely removed himself/herself from the vehicle and areas of operation. Ring/Drum Debarker Safety 1. Lockout/tagout debarker prior to performing any bleeding, repairing or servicing procedures. 2. Wear employer approved ear protection prior to operating debarker. VII.11 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 3. Do not stand on the side of the outfeeder. Cut-Up/Decksaw Safety 1. Do not walk on logs. 2. Do not walk on log deck or canter when the process of handling logs is taking place. 3. Do not stand in front of the saw. 4. Do not run conveyor when the saw is in contact with the log or during the in-cutting process. 5. Lockout/tagout and pin the cut-up/decksaw prior to servicing. 6. Clean floor area surrounding saw blade prior to changing the blade. Safety at Primary Breakdown Scragg Saw • Do not cross through the path of the moving conveyor or path of operation. Head Rig/Head Saw • Stay out of the carriage track. Chipping/Chipper Saw (Chip-n-Saw) 1. Use safety pin and/or blocks when inside chipping saw. 2. Use wire mesh gloves when changing knives on chipping saw. 3. Do not use your hands to clear chipper mouth/infeed. Stop the machine and use a wood push stick to clear a jam. Safety at Secondary Breakdown Chip and Edger Saw 1. Stop the machine prior to clearing any jams. 2. Do not use your hands to clear a jam, use a wood pusher stick or other piece of lumber instead. Resaw and Gang Saw 1. Do not cross through the outfeed area when the feed is in operation. 2. Stop the machine prior to clearing any jams. 3. Do not use your hands to clear a jam. Off Bearers 1. Do not slide your hands on the lumber when piling it. 2. Keep shirts on, drink lots of water, and seek shade during breaks to avoid dehydration ........ and sun burn. DRYING PERSONNEL Dry Kiln Safety 1. Stay out of the path of moving lumber carts. 2. Stand clear of steam traps when blowing down. 3. Do not climb on lumber. VII.12 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 4. Always use a co-worker to aid you when loading and unloading the kiln(s). FINISHING/PLANING MILL PERSONNEL Breakdown Hoist Safety 1. Do not climb on the breakdown hoist when it is in a raised or tilted position. 2. Do not stand under the breakdown hoist. 3. Do not place your hands under the boards coming off of the breakdown hoist. Planer Safety 1. Keep your hands clear of "pineapple" feed rollers. 2. Do not use your hands to clear a jam. Stop feed rollers and then use a pusher stick to clear the jam. Bander Safety 1. Stand to the side of the band around a stack or bundle when installing or removing the band. Do not stand directly in line with the band. 2. Do not carry tin snips in your pocket. 3. Engage safety latch on snips when you finish using them. 4. Store snips in a leather carrying case or sheathed pocket designed for its storage. 5. Do not use snips as a hammer, screwdriver, or pry bar. 6. Keep the blades aligned by tightening the nut and bolt on the snips. 7. Wear safety glasses or safety goggles when using snips to cut metal bands. 8. Wear leather gloves when cutting metal bands. 9. Do not allow bands to accumulate in banding area. Truck/Trailer Safety When Loading and Shipping Chips, Shavings, or Sawdust 1. Do not stay in the cab of truck or tractor trailer while the payload is being loaded or unloaded by cranes or loaders. 2. Do not get inside the truck or trailer. 3. Do not stand on chips, shavings, or sawdust within the truck or trailer. Personal Protective Equipment 1. Wear high-top, heavy leather, steel toed work boots with non-skid soles working with axes, pike poles, pick-a-roons/hook-a-roons, or cant hooks. 2. Wear heavy leather-faced work gloves when using tools such as long arm axes, pike poles, pick-aroons/hook-a-roons, or cant hooks. MAINTENANCE/UTILITY PERSONNEL Personal Protective Equipment 1. Use lifelines, safety harnesses and lanyards when you are working higher than 6 feet off the ground. 2. Safety goggles must be worn while reaming, drilling, welding or cutting steel. VII.13 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 3. 4. 5. 6. 7. 8. 9. 10. 11. Do not drill holes in or paint your hard hat. Do not wear hard hats that are dented or cracked. Wear your safety glasses, goggles or the face shield while operating chippers, grinders, lathes or sanders. Wear the face shield over your goggles or safety glasses during open furnace, hot dipping, metal plating or gas cutting operations. Wear the chemical goggles when using, applying or handling chemical liquids or powders from containers labeled "Caustic" or "Corrosive." Do not continue to work if your safety glasses become fogged. Stop work and clean the glasses until the lenses are clear and defogged. Wear the welding helmet or welding goggles during welding operations. Wear the dielectric gloves when working on electric current. Wear your ear plugs or ear muffs in areas posted "Hearing Protection Required." Housekeeping 1. Do not place materials such as scraps of lumber, trash bends, hand tools or any other material in walkways and passageways. 2. Sweep up shavings from around equipment such as drill presses, saws, canters or lumber decks by using a broom and a dust pan. 3. Mop up water around drinking fountains, drink dispensing machines and ice machines. 4. Straighten or remove rugs and mats that do not lie flat on the floor. Hand Tool/Power Tool Safety General 1. Use tied off containers to keep tools from falling off of scaffolds and other elevated work platforms. 2. Carry all sharp tools in a sheath or holster. 3. Tag worn, damaged or defective tools "Out of Service" and do not use them. 4. Do not use a tool if its handle has splinters, burrs, cracks, splits or if the head of the tool is loose. 5. Do not use impact tools such as hammers, chisels, punches or steel stakes that have mushroomed heads. 6. When handing a tool to another person, direct sharp points and cutting edges away from yourself and the other person. 7. When using knives, snips, or other cutting tools, cut in a direction away from your body. 8. Do not carry sharp or pointed hand tools such as screwdrivers, scribes, snips, scrapers, ....... chisels or files in your pocket unless the tool or your pocket is sheathed. 9. Do not perform "make-shift" repairs to tools. 10. Do not carry tools in your hand when you are climbing. Carry tools in tool belts or hoist the tools to the work area using a hand line. 11. Do not throw tools from one location to another, from one employee to another, from ladders, scaffolds, or other elevated platforms. 12. Transport hand tools only in tool boxes or tool belts. Do not carry tools in your clothing. Electrical Powered Tools 1. Do not use power equipment or tools on which you have not been trained. 2. Keep power cords away from the path of drills, saws, vacuum cleaners, floor polishers, mowers, VII.14 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. slicers, knives, grinders, irons and presses. Do not use cords that have splices, exposed wires, or cracked or frayed ends. Do not carry plugged in equipment or tools with your finger on the switch. Do not carry equipment or tools by the cord. Disconnect the tool from the outlet by pulling on the plug, not the cord. Turn the tool off before plugging or unplugging it. Do not leave tools that are "On" unattended. Do not handle or operate electrical tools when your hands are wet or when you are standing on wet floors. Do not operate spark inducing tools such as grinders, drills or saws near containers labeled "Flammable" or in an explosive atmosphere such as a paint spraybooth. Turn off the electrical tool and unplug it from the outlet before attempting repairs or service work. Tag the tool "Out of Service." Do not use extension cords or other three pronged power cords that have a missing prong. Do not remove the ground prong from electrical cords. Do not use an adapter such as a cheater plug that eliminates the ground. Do not plug multiple electrical cords into a single outlet. Do not run extension cords through doorways, through holes in ceilings, walls or floors. Do not drive over, drag, step on or place objects on a cord. Do not stand in water or on wet surfaces when operating power hand tools or portable electrical appliances. Do not use a power hand tool while wearing wet cotton gloves or wet leather gloves. Never operate electrical equipment barefooted. Wear rubber-soled or insulated work boots. Do not operate a power hand tool or portable appliance that has a frayed, worn, cut, improperly spliced or damaged power cord. Do not operate a power hand tool or portable appliance if a prong from the three-pronged power plug is missing or has been removed. Do not operate a power hand tool or portable appliance that has a two-pronged adapter or a two conductor extension cord. Do not operate a power hand tool or portable appliance while holding a part of the metal casing/guard or while holding the extension cord in your hand. Hold all portable power tools by the plastic hand grips or other nonconductive areas designed for gripping purposes. Powder Actuated Tools 1. Wear impact resistant safety goggles or face shields when operating any powder actuated tools. 3. Do not attempt to fasten through a pre-drilled hole unless the powder actuated tool has a hole locator. 4. Keep your head and body behind the powder actuated tool when firing it. 6. Before using powder actuated tools do not alter, bypass, or remove the shield or guard at the muzzle end of the powder actuated tool. 7. Do not load a powder actuated tool until you are ready to fire it. Hydraulic/Pneumatic Tools 1. Do not point a charged compressed air hose at bystanders or use it to clean your clothing. 2. Lock and/or tag tools "Out of Service" to prevent usage of the tool. VII.15 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 3. 4. 5. 6. Do not use tools that have handles with burrs or cracks. Do not use compressors if their belt guards are missing. Replace the belt guards before using the compressor. Turn the power switch of the tool to "Off" and let it come to a complete stop before leaving it unattended. Disconnect the tool from the air line before making any adjustments or repairs to the tool. Files/Rasps 1. Do not use a file as a pry bar, hammer, screwdriver or chisel. 2. When using a file or a rasp, grasp the handle in one hand and the toe of the file in the other. 3. Do not hammer on a file. Chisels 1. 2. 3. 4. Use the chisel that has been sharpened; do not use a chisel that has a dull cutting edge. Do not use chisels that have "mushroomed" striking heads. Hold a chisel by using a tool holder if possible. Clamp small workpieces in the vise and chip towards the stationary jaw when you are working with a chisel. Hammers 1. Use a claw hammer for pulling nails. 2. Do not strike nails or other objects with the "cheek" of the hammer. 3. Do not strike a hardened steel surface, such as a cold chisel, with a claw hammer. 4. Do not strike one hammer against another hammer. 5. Do not use a hammer if your hands are oily, greasy or wet. 6. Do not use a hammer as a wedge or a pry bar, or for pulling large spikes. 7. Use only the sledge type hammer on a striking face wrench. Screwdrivers 1. Always match the size and type of screwdriver blade to fit the head of the screw. 2. Do not hold the workpiece against your body while using a screwdriver. 3. Do not put your fingers near the blade of the screwdriver when tightening a screw. 4. Use a drill, nail, or an awl to make a starting hole for screws. 5. Do not force a screwdriver by using a hammer or pliers on it. 6. Do not use a screwdriver as a punch, chisel, pry bar or nail puller. 7. When you are performing electrical work, use the screwdriver that has the blue handle; this screwdriver is insulated. 8. Do not carry a screwdriver in your pocket. 9. Do not use a screwdriver if your hands are wet, oily or greasy. 10. Do not use a screwdriver to test the charge of a battery. 11. When using the spiral ratchet screwdriver, push down firmly and slowly. Wrenches 1. Do not use wrenches that are bent, cracked or badly chipped or that have loose or broken handles. 2. Do not slip a pipe over a single head wrench handle for increased leverage. VII.16 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 3. 4. 5. 6. 7. 8. Pliers 1. 2. 3. 4. 5. 6. Do not use a shim to make a wrench fit. Use a split box wrench on flare nuts. Do not use a wrench that has broken or battered points. Use a hammer on striking face wrenches. Discard any wrench that has spread, nicked or battered jaws or if the handle is bent. Use box or socket wrenches on hexagon nuts and bolts as a first choice, and open end wrenches as a second choice. Do not use pliers as a wrench or a hammer. Do not attempt to force pliers by using a hammer on them. Do not slip a pipe over the handles of pliers to increase leverage. When you are performing electrical work, use the pliers that have the blue rubber sleeves covering the handle; these pliers are insulated. Do not use pliers that are cracked, broken or sprung. When using the diagonal cutting pliers, shield the loose pieces of cut material from flying into the air by using a cloth or your gloved hand. Vises 1. When clamping a long workpiece in a vise, support the far end of the workpiece by using an adjustable pipe stand, saw horse or box. 2. Position the workpiece in the vise so that the entire face of the jaw supports the workpiece. 3. Do not use a vise that has worn or broken jaw inserts, or has cracks or fractures in the body of the vise. 4. Do not slip a pipe over the handle of a vise to gain extra leverage. Clamps 1. Do not use the C-clamp for hoisting materials. 2. Do not use the C-clamp as a permanent fastening device. Drills 1. Do not use dull, cracked or bent drill bits. 2. Physically check the security of the drill bit or cutting tool within the chuck prior to operation. 3. Keep your hands away from rotating parts. Tool Boxes/Chests/Cabinets 1. Use the handle when opening and closing a drawer or door of a tool box, chest, or cabinet. 2. Tape over or file off sharp edges on toolboxes, chests or cabinets. 3. Do not stand on toolboxes, chests or cabinets to gain extra height. 4. Lock the wheels on large tool boxes, chests or cabinets to prevent them from rolling. 5. Push large chests, cabinets and tool boxes; do not pull them. 6. Do not open more than one drawer of a tool box at a time. 7. Close and lock all drawers and doors before moving the tool chest to a new location. 8. Do not use a tool box or chest as a workbench. VII.17 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 9. Do not move a tool box, chest or cabinet if it has loose tools or parts on the top. Knives/Sharp Instruments 1. When handling knife blades and other cutting tools, direct sharp points and edges away from you. 2. Cut in the direction away from your body when using knives. 3. Use the knife that has been sharpened; do not use knives that have dull blades. 4. Use knives for the operations for which they are named or made. 5. Do not use knives that have broken or loose handles. 6. Do not use knives as screwdrivers, pry bars, or can openers. 7. Do not pick up knives or snips by their blades. 8. Carry all sharp instruments, such as knives or pike poles with their tips pointed towards the floor. 9. Do not carry knives, scissors, snips, or other sharp tools in your pockets or an apron unless they are first placed in their sheath or holder. 10. Do not attempt to catch a falling knife or blade. 11. Store knives in knife blocks or in sheaths after using them. Portable Welding Equipment 1. Do not use personal or employee-owned power tools and portable appliances while at work. 2. Do not perform welding tasks while wearing wet cotton gloves or wet leather gloves. 3. Use the insulated work gloves when using welding equipment. 4. Do not use the welding apparatus if the power cord is cut, frayed, split or otherwise visibly damaged or modified. 5. When replacing power plugs and cords of the welding apparatus, always check to ensure that the ground wire is connected and the notches on the power plug prongs are not worn off, allowing the plug to be inserted backward. Compressed Gas Cylinders Storage and Handling 1. Do not handle oxygen cylinders if your gloves are greasy or oily. 2. Store all compressed gas cylinders in the upright position. 3. Place valve protection caps on compressed gas cylinders that are in storage or are not being used. 4. Do not lift compressed gas cylinders by the valve protection cap. 5. Do not store compressed gas cylinders in areas where they can come in contact with chemicals labeled "Corrosive." 6. Hoist compressed gas cylinders on the cradle, slingboard, pallet or compressed gas cylinder basket. 7. Do not place compressed gas cylinders against electrical panels or live electrical cords where the cylinder can become part of the circuit. Use of Compressed Gas Cylinders 1. Do not use dented, cracked or other visibly damaged cylinders. 2. Use only an open ended or adjustable wrench when connecting or disconnecting regulators and fittings. 3. Do not transport cylinders without first removing the regulators and replacing the valve protection caps. 4. Close the cylinder valve when work is finished, when the cylinder is empty or at any time the VII.18 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 5. 6. 7. 8. 9. 10. 11. cylinder is moved. Do not store oxygen cylinders near fuel gas cylinders such as propane or acetylene, or near combustible material such as oil or grease. Stand to the side of the regulator when opening the valve. If a cylinder is leaking around a valve or a fuse plug, move it to an outside area away from where work is performed, and tag it to indicate the defect. Do not hoist or transport cylinders by means of magnets or choker slings. Do not use compressed gas to clean yourself, equipment or your work area. Do not remove the valve wrench from acetylene cylinders while the cylinder is being used. Open cylinder valves slowly. Open the valves fully when the compressed gas cylinder is being used, in order to eliminate possible leakage around the cylinder valve stem. Welding/Cutting/Brazing General 1. Obey all signs posted in the welding area. 2. Do not leave oily rags, paper or other combustible materials in the welding, cutting or brazing area. 3. Use the red hose for gas fuel and the green hose for oxygen. 4. Do not use worn or cracked hoses. 5. Do not use oil, grease or other lubricants on the regulator. 6. "Blow Out" hoses before attaching the torch. 7. "Blow Out" the cylinder valve before attaching or reattaching a hose to the cylinder. 8. Do not use a cigarette lighter to ignite torches; use friction lighters only. 9. Do not wear contact lenses when you are welding. 10. When welding, wear welding gloves, a long sleeve shirt, long pants, a welding apron and the welding helmet that has filter plates and lenses. 11. Do not change electrodes using your bare hands; use the dry rubber gloves. 12. "Bleed" oxygen and fuel lines at the end of the work shift. 13. Use the welding cart that has a safety chain or cable when transporting cylinders used for welding. Oxyacetylene Welding 1. Do not use oxygen cylinders in areas where oils or any combustible liquids such as diesel fuel or motor fuel are present. 2. Turn the valve on the torch clockwise to turn off the gas before putting down the welding or cutting torch. 3. Never allow pressure to remain in the hoses over night: a. Turn the valve knobs located at the base of the torch handle, clockwise, to close the valves. b. Turn the valve knobs on the oxygen and acetylene cylinders, clockwise, to close the valves on these cylinders. c. Reduce the pressure on the regulator diaphragms by pulling back on the T-handles, out from the regulator, until the T-handles turn easily; do not completely back the T-handles out from the regulator. d. Turn the valve knobs at the base of the torch, counterclockwise, to open the valves; leave the valves open for only two seconds, then turn the valve knobs clockwise to close the VII.19 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 4. valves again. If you do not observe a drop in pressure on the regulator gages, repeat steps a.-b. If the cylinder has been transported in a horizontal position, do not use it until it has been stored upright for two hours. Grinders 1. Do not use grinding wheels that have chips, cracks or grooves. 2. Do not use the grinding wheel if it wobbles. Tag it "Out of Service." 3. Do not try to stop the wheel using your hand, even if you are wearing gloves. To prevent your gloves from getting caught by the grinding wheel, hold the work-piece by using vice grip pliers, clamps, or a jig. 4. Adjust the tongue guard so that it is no more than 1/8 inch from the grinding wheel. Electrical Safety 1. Do not use frayed, cut or cracked electrical cords. 2. Do not plug multiple electrical cords into a single outlet. 3. Do not use extension or power cords that have the ground prong removed or broken off. 4. Use a cord cover or tape the cord down when running electrical cords across aisles, between desks or across entrances or exits. 5. Turn the power switch to "Off" and unplug office machines before adjusting, lubricating or cleaning them. Batteries 1. Do not lay tools or metal parts on top of a battery. 2. Turn the fan motor selector switch to the "On" position before operating the battery charger. Turn the power switch of the battery charger to "Off" prior to connecting the cables to the battery posts. 3. Position the fork truck so that the battery is aligned with the rollers or the hoist used for moving it and engage the fork truck brake before removing the battery and placing it onto the charging rack. 4. Set the brakes on the lift truck prior to connecting the charging cables to the battery on the lift truck. 5. Do not smoke in the battery charging areas. Confined Space Safety Boiler Entry 1. Secure all doors in the open position while an entrant is inside the boiler. 2. Do not enter boiler without notifying the boiler operator and receiving authorization from your supervisor. 3. Lockout/tagout all fans and motors at the energy source disconnects prior to entering the boiler. 4. Do not remove another employee's lock or tag. 5. Reduce temperature of boiler to approximately 85 F prior to entering the boiler. Use a heat probe or similar heat measuring devise to verify the temperature of the boiler prior to entering the boiler. 6. Do not restart the boiler until authorized by your supervisor and a thorough inspection has been made to ensure that the boiler is clear of any personnel. VII.20 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Shavings Bin Entry 1. Lockout/tagout all motors controlling augers prior to entering shavings bin. 2. Do not remove another employee's lock or tag. 3. Do not enter shavings bin without notifying and receiving authorization from your supervisor. 4. If possible, empty shavings bin completely prior to entering. 5. If the shavings bin contains shavings and an entry must be made prior to completely emptying the bin, use a safety rope and harness or any applicable safety equipment necessary for an extraction. Treatment Cylinder Entry 1. Do not enter treatment cylinder without notifying and receiving authorization from your supervisor. 2. Wear your respirator, rubber gloves, long sleeve shirt and hard hat prior to entering the treatment cylinder. 3. Secure all doors in the open position while an entrant is inside the cylinder. Chip Bin Entry 1. Lockout/tagout all motors controlling augers prior to entering a chip bin. 2. Do not remove another employee's lock or tag. 3. Do not enter the chip bin without notifying and receiving authorization from your supervisor. 4. If possible, empty the chip bin completely prior to entering. 5. If the chip bin contains chips and you must enter prior to completely emptying the bin; use a safety rope, body harness, and other applicable safety equipment necessary for your extraction. SPECIALTY WOOD SHOP PERSONNEL Personal Protective Equipment 1. Use lifelines, safety harnesses and lanyards when you are working higher than 6 feet off the ground. 2. Safety goggles must be worn while reaming, drilling, welding or cutting steel. 3. Wear your safety glasses, goggles or the face shield while operating table saws, grinders, lathes, sanders, or any other wood cutting machinery. 5. Wear a face or dust mask during dusty cutting operations. 6. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that could get caught in moving parts. 7. Wear protective hair covering, such as a hair net, hat, or scarf to contain long hair. Note: This rule applies to both males and females. Housekeeping 1. Do not place materials such as scraps of lumber, trash bends, hand tools or any other material in walkways and passageways. 2. Sweep up shavings from around equipment such as drill presses, table saws, or shapers by using a broom and a dustpan. VII.21 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 3. 4. Immediately mop up water around drinking fountains, drink dispensing machines and work floor. Straighten or remove rugs and mats that do not lie flat on the floor. Hand Tool/Power Tool Safety General 1. Carry all sharp tools in a sheath or holster. 2. Tag worn, damaged or defective tools "Out of Service" and do not use them. 3. Do not use a tool if its handle has splinters, burrs, cracks, splits or if the head of the tool is loose. 4. Do not use impact tools such as hammers, chisels, punches or steel stakes that have mushroomed heads. 5. When handing a tool to another person, direct sharp points and cutting edges away from yourself and the other person. 6. When using knives, snips, or other cutting tools, cut in a direction away from your body. 7. Do not carry sharp or pointed hand tools such as screwdrivers, scribes, snips, scrapers, chisels or files in your pocket unless the tool or your pocket is sheathed. 8. Do not perform "make-shift" repairs to tools. 9. Do not carry tools in your hand when you are climbing. Carry tools in tool belts or hoist the tools to the work area using a hand line. 10. Do not throw tools from one location to another, from one employee to another, from ladders, scaffolds, or other elevated platforms. 11. Transport hand tools only in toolboxes or tool belts. Do not carry tools in your clothing. Electrical Powered Tools 1. Do not use power equipment or tools on which you have not been trained. 2. Keep power cords away from the path of drills, saws, vacuum cleaners, floor polishers, mowers, slicers, knives, grinders, irons and presses. 3. Do not use cords that have splices, exposed wires, or cracked or frayed ends. 4. Do not carry plugged in equipment or tools with your finger on the switch. 5. Do not carry equipment or tools by the cord. 6. Disconnect the tool from the outlet by pulling on the plug, not the cord. 7. Turn the tool off before plugging or unplugging it. 8. Do not leave tools that are "On" unattended. 9. Do not handle or operate electrical tools when your hands are wet or when you are standing on wet floors. 10. Do not operate spark-inducing tools such as grinders, drills or saws near containers labeled "Flammable" or in an explosive atmosphere such as a paint spraybooth. 11. Turn off the electrical tool and unplug it from the outlet before attempting repairs or service work. Tag the tool "Out of Service." 12. Do not use extension cords or other three pronged power cords that have a missing prong. 13. Do not remove the ground prong from electrical cords. 14. Do not use an adapter such as a cheater plug that eliminates the ground. 15. Do not plug multiple electrical cords into a single outlet. 16. Do not run extension cords through doorways, through holes in ceilings, walls or floors. 17. Do not drive over, drag, step on or place objects on a cord. 18. Do not stand in water or on wet surfaces when operating power hand tools or portable electrical VII.22 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 19. 20. 21. 22. 23. 24. appliances. Do not use a power hand tool while wearing wet cotton gloves or wet leather gloves. Never operate electrical equipment barefooted. Wear rubber-soled or insulated work boots. Do not operate a power hand tool or portable appliance that has a frayed, worn, cut, improperly spliced or damaged power cord. Do not operate a power hand tool or portable appliance if a prong from the three-pronged power plug is missing or has been removed. Do not operate a power hand tool or portable appliance that has a two-pronged adapter or a twoconductor extension cord. Do not operate a power hand tool or portable appliance while holding a part of the metal casing/guard or while holding the extension cord in your hand. Hold all portable power tools by the plastic handgrips or other nonconductive areas designed for gripping purposes. Powder Actuated Tools 1. Wear impact resistant safety goggles or face shields when operating any powder actuated tools. 2. Do not attempt to fasten through a pre-drilled hole unless the powder-actuated tool has a hole locator. 3. Keep your head and body behind the powder actuated tool when firing it. 4. Before using powder actuated tools do not alter, bypass, or remove the shield or guard at the muzzle end of the powder-actuated tool. 5. Do not load a powder-actuated tool until you are ready to fire it. Hydraulic/Pneumatic Tools 1. Do not point a charged compressed air hose at bystanders or use it to clean your clothing. 2. Lock and/or tag tools "Out of Service" to prevent usage of the tool. 3. Do not use tools that have handles with burrs or cracks. 4. Do not use compressors if their belt guards are missing. Replace the belt guards before using the compressor. 5. Turn the power switch of the tool to "Off" and let it come to a complete stop before leaving it unattended. 6. Disconnect the tool from the air line before making any adjustments or repairs to the tool. Files/Rasps 1. Do not use a file as a pry bar, hammer, screwdriver or chisel. 2. When using a file or a rasp, grasp the handle in one hand and the toe of the file in the other. 3. Do not hammer on a file. Chisels 1. Use the chisel that has been sharpened; do not use a chisel that has a dull cutting edge. 2. Do not use chisels that have "mushroomed" striking heads. 3. Hold a chisel by using a tool holder if possible. 4. Clamp small workpieces in the vise and chip towards the stationary jaw when you are working with a chisel. Hammers VII.23 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 1. 2. 3. 4. 5. 6. 7. Use a claw hammer for pulling nails. Do not strike nails or other objects with the "cheek" of the hammer. Do not strike a hardened steel surface, such as a cold chisel, with a claw hammer. Do not strike one hammer against another hammer. Do not use a hammer if your hands are oily, greasy or wet. Do not use a hammer as a wedge or a pry bar, or for pulling large spikes. Use only the sledge type hammer on a striking face wrench. Screwdrivers 1. Always match the size and type of screwdriver blade to fit the head of the screw. 2. Do not hold the workpiece against your body while using a screwdriver. 3. Do not put your fingers near the blade of the screwdriver when tightening a screw. 4. Use a drill, nail, or an awl to make a starting hole for screws. 5. Do not force a screwdriver by using a hammer or pliers on it. 6. Do not use a screwdriver as a punch, chisel, pry bar or nail puller. 7. When you are performing electrical work, use the screwdriver that has the blue handle; this screwdriver is insulated. 8. Do not carry a screwdriver in your pocket. 9. Do not use a screwdriver if your hands are wet, oily or greasy. 10. Do not use a screwdriver to test the charge of a battery. 11. When using the spiral ratchet screwdriver, push down firmly and slowly. Wrenches 1. Do not use wrenches that are bent, cracked or badly chipped or that have loose or broken handles. 2. Do not slip a pipe over a single head wrench handle for increased leverage. 3. Do not use a shim to make a wrench fit. 4. Use a split box wrench on flare nuts. 5. Do not use a wrench that has broken or battered points. 6. Use a hammer on striking face wrenches. 7. Discard any wrench that has spread, nicked or battered jaws or if the handle is bent. 8. Use box or socket wrenches on hexagon nuts and bolts as a first choice, and open end wrenches as a second choice. Pliers 1. 2. 3. 4. 5. 6. Do not use pliers as a wrench or a hammer. Do not attempt to force pliers by using a hammer on them. Do not slip a pipe over the handles of pliers to increase leverage. When you are performing electrical work, use the pliers that have the blue rubber sleeves covering the handle; these pliers are insulated. Do not use pliers that are cracked, broken or sprung. When using the diagonal cutting pliers, shield the loose pieces of cut material from flying into the air by using a cloth or your gloved hand. Vises 1. When clamping a long workpiece in a vise, support the far end of the workpiece by using an VII.24 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 2. 3. 4. adjustable pipe stand, sawhorse or box. Position the workpiece in the vise so that the entire face of the jaw supports the workpiece. Do not use a vise that has worn or broken jaw inserts, or has cracks or fractures in the body of the vise. Do not slip a pipe over the handle of a vise to gain extra leverage. Clamps 1. Do not use the C-clamp for hoisting materials. 2. Do not use the C-clamp as a permanent fastening device. Drills 1. Do not use dull, cracked or bent drill bits. 2. Physically check the security of the drill bit or cutting tool within the chuck prior to operation. 3. Keep your hands away from rotating parts. Router 1. Do not use dull, cracked or bent drill bits. 2. Hand check tool in collet to ensure it is secure. Tool Boxes/Chests/Cabinets 1. Use the handle when opening and closing a drawer or door of a tool box, chest, or cabinet. 2. Tape over or file off sharp edges on toolboxes, chests or cabinets. 3. Do not stand on toolboxes, chests or cabinets to gain extra height. 4. Lock the wheels on large toolboxes, chests or cabinets to prevent them from rolling. 5. Push large chests, cabinets and toolboxes; do not pull them. 6. Do not open more than one drawer of a toolbox at a time. 7. Close and lock all drawers and doors before moving the tool chest to a new location. 8. Do not use a toolbox or chest as a workbench. 9. Do not move a toolbox, chest or cabinet if it has loose tools or parts on the top. Knives/Chisels/Sharp Instruments 1. When handling knife blades and other cutting tools, direct sharp points and edges away from you. 2. Cut in the direction away from your body when using knives. 3. Use knives and chisels that have been sharpened; do not use knives or chisels with dull blades. 4. Use knives, chisels and other sharp cutting tools for the operations by which the tools are named or made. 5. Do not use knives or chisels that have broken or loose handles. 6. Do not use knives as screwdrivers, pry bars, or can openers. 7. Do not pick up knives, chisels or saw blades by their blades. 8. Carry all sharp instruments, such as knives or chisels with their tips pointed towards the floor. 9. Do not carry knives, scissors, chisels, or other sharp tools in your pockets or an apron unless they are first placed in their sheath or holder. 10. Do not attempt to catch a falling knife or blade. 11. Store knives, chisels and other cutting tools in blocks, racks, or sheaths after using them. VII.25 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified Grinder/Abrasive Wheels 1. Do not use grinding or abrasive wheels with chips, cracks or grooves. 2. Do not use the grinding or an abrasive wheel if it wobbles. Tag it "Out of Service." 3. Do not try to stop the wheel using your hand, even if you are wearing gloves. To prevent your gloves from getting caught by the grinding wheel, hold the work-piece by using vice grip pliers, clamps, or a jig. 4. Adjust the tongue guard so that it is no more than 1/8 inch from the grinding wheel. Drill Press Safety 1. Do not use dull, cracked or bent drill bits. 2. Physically check the security of the drill bit or cutting tool within the chuck prior to operation. 3. Adjust the table or depth stop, as required per manufacturers instructions, to avoid drilling into the table. 4. Remove the chuck key from the chuck prior to starting the drill press. 5. Use a clamp or vise to secure small and/or short jobs to the work table. 6. Use a clamp or vise to secure jobs to the work table when using a hole saw or cutting tool larger than 1/2 inch diameter. 7. Do not operate drill press if safety guard is missing. 8. Use safety glasses when operating drills. Wood Lathe Safety 1. Clean/clear lathe bed of all objects, such as wood scraps or tools, prior to operation. 2. Position and adjust tool rest as close to the work piece as possible. 3. Rotate the work piece by hand to verify clearance prior to engaging power. 4. Do not adjust the tool rest while the work piece is turning. 5. Do not loosen the tailstock spindle or tailstock while a work piece is turning. 6. Secure/tighten all clamp handles prior to operating the lathe. 7. Position and lock tailstock center snugly against the work piece when turning between centers. Note: Lubricate tailstock center if it is not a ball bearing center. 8. Remove the tool rest prior to sanding or polishing. 9. Do not jam tool into work piece or take too big a cut when roughing off a job. 10. Do not drive work piece into the drive center when the drive center is in the headstock. Position the drive center into the work piece using a soft mallet prior to installing it into the headstock. Wood Shaper/Overarm Router Safety 1. Make all adjustments with the power off. 2. Do not run the stock between the fence and the cutter. 3. Always feed against the cutter rotation. 4. Adjust the fence endwise so the opening is never more than what is required to clear the cutter. Sander Safety VII.26 SIC 2421 - Sawmills and Planing Mills SIC 2426 - Hardwood Dimension and Flooring Mills SIC 2429 - Special Product Sawmills, Not Elsewhere Classified 1. 2. 3. 4. 5. Feed work piece against rotation of sander. Hold the work firmly to keep the sanding belt or disc from driving the work piece out of your hands. Do not press on the belt of the sander when it is in operation. Maintain 1/16-inch maximum clearance between the table and sanding belt or disc. Stand to side of sander when operating. Miter Saw Safety 1. Do not operate the miter saw with the guard removed. 2. Check the turntable by hand to ensure that it is locked in position prior to operating the saw. 3. Wait until the motor has reached full speed prior to beginning your cut. 4. Do not perform any operation freehand. Use the fence as a backstop. 5. Wait for the blade to stop rotating prior to reaching and retrieving a work piece, a piece of scrap, or anything else that is in or near the point of operation/cutting path of the blade. Radial Saw Safety 1. Do not reach around the blade to the end with an anti-kickback pawl and attempt to hold down or pull the work piece through to complete a cut. 2. Do not force or rush the job. 3. Use a clamp or vise to secure the work piece. 4. Always feed the work piece against the direction of rotation. 5. Engage the locks on the rip and miter prior to moving the saw from one place to another. VII.27